Flow restrictor

A flow restriction, restrictor technology, used in chemical instruments and methods, mechanical equipment, dissolution, etc., to solve problems such as easy damage to components, incorrect reinstallation, operator exposure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

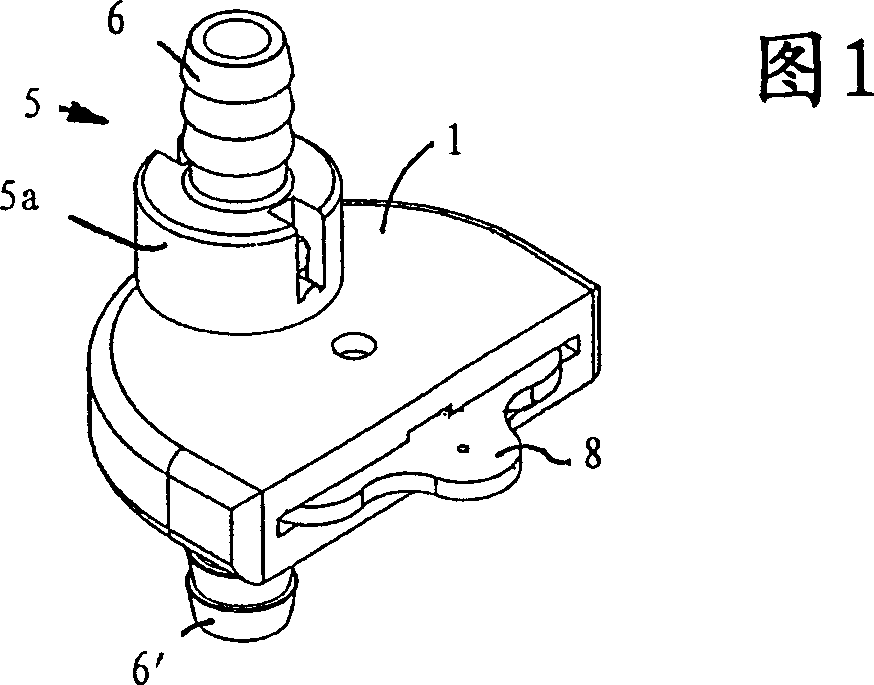

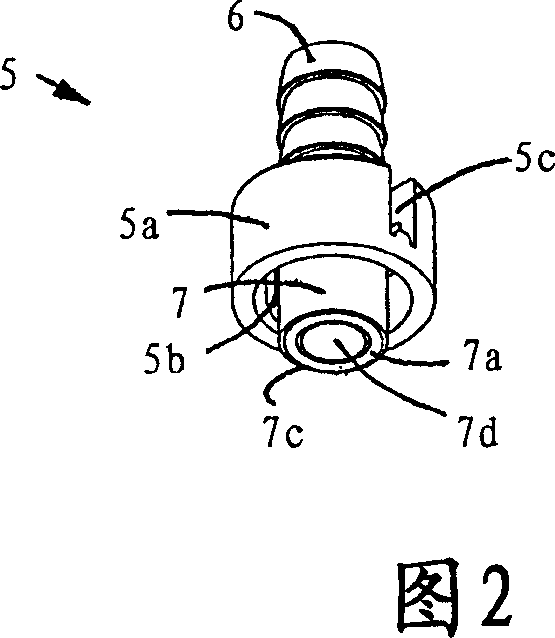

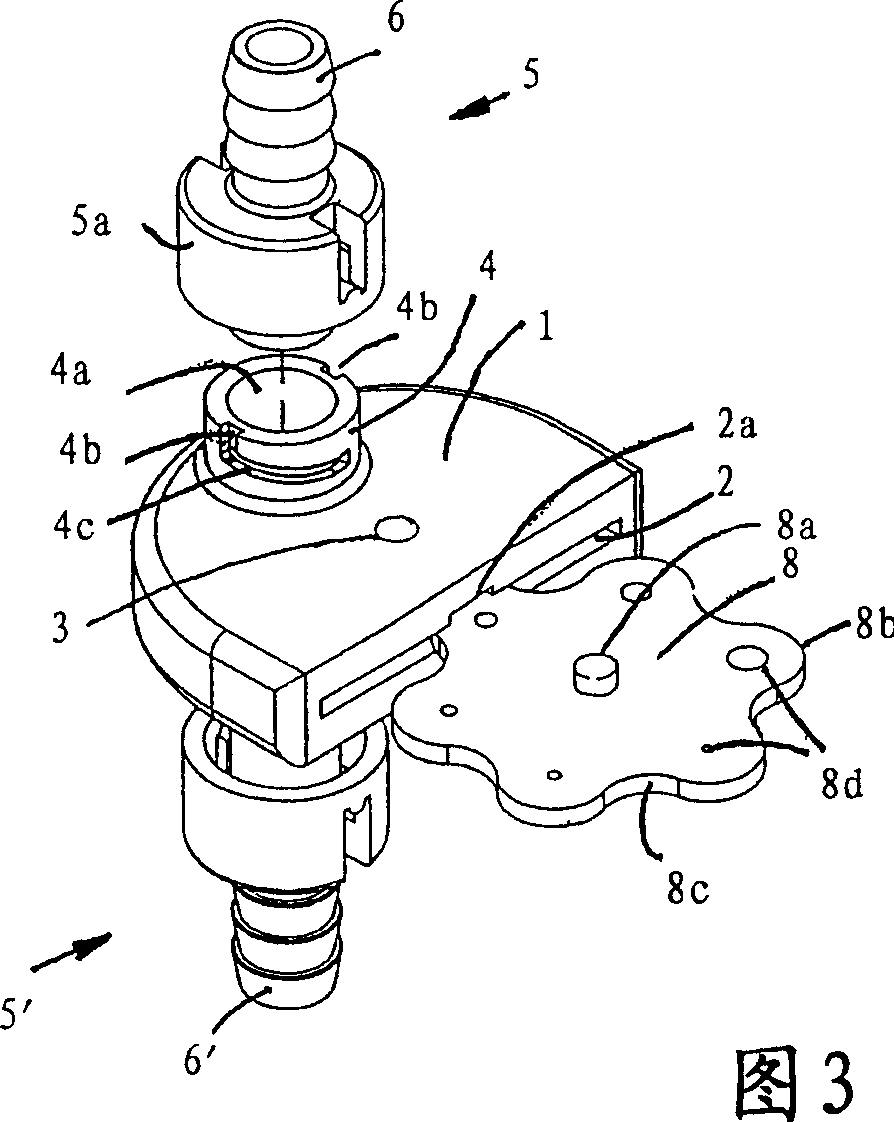

[0021] Figures 1 to 3 show a liquid flow restrictor embodying the present invention in the form of a housing 1 in which the orifices 4a of the housing connector 4 are located on both sides of the housing (only one is visible). The respective ends 7 of the one-to-one identical flow conduits 5, 5' pass through the orifice 4a when the housing 1 and the flow conduit 5 are assembled. Each flow conduit 5, 5' has a central axial tube providing a flow path 7b and an integral fitting 6, 6' for connecting a flow restrictor in the supply line of a device such as an injector provided. Around the central tube is an integrally formed sleeve portion 5a. The axes of the two orifices 4a are aligned with each other, and the orifices 4a extend from outside the casing 1, through the casing wall, to the cavity 2 inside the casing 1.

[0022] The cavity 2 of the housing has a substantially flat shape and an orifice leading to one side of the housing, as can be seen in FIGS. 1 and 2 . The cavity 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com