End socket forming die and end socket forming method

A technology for forming molds and heads, which is used in household appliances, other household appliances, applications, etc., can solve the problems of uneven thickness of the head and high raw material cost, so as to slow down the local excessive stretching and thinning, and reduce the cost of raw materials. , The effect of uniform thickness of the head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

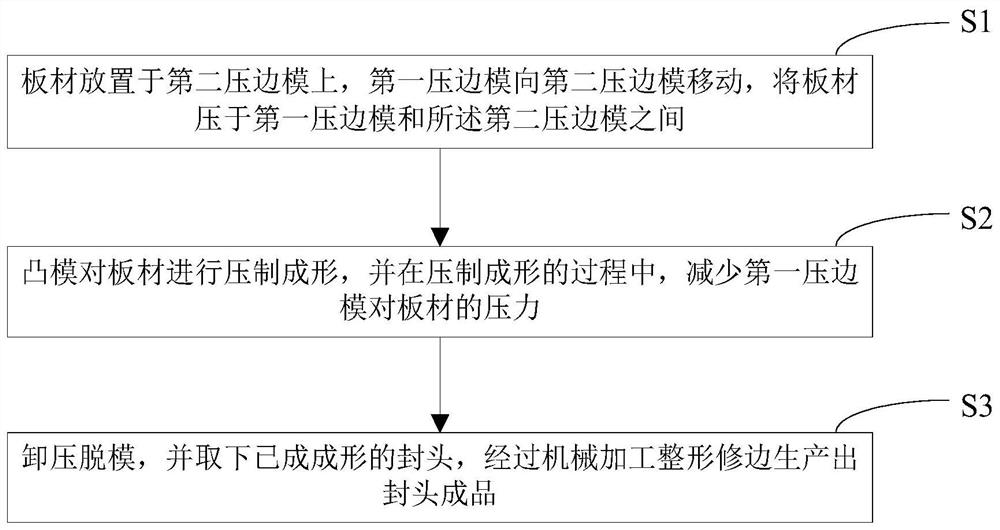

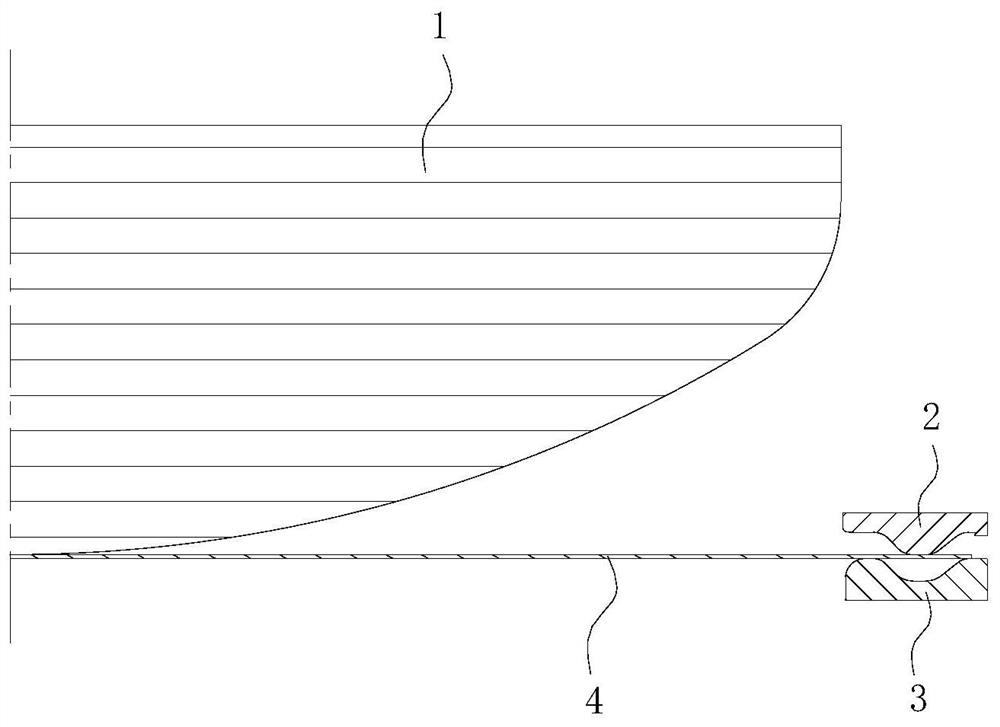

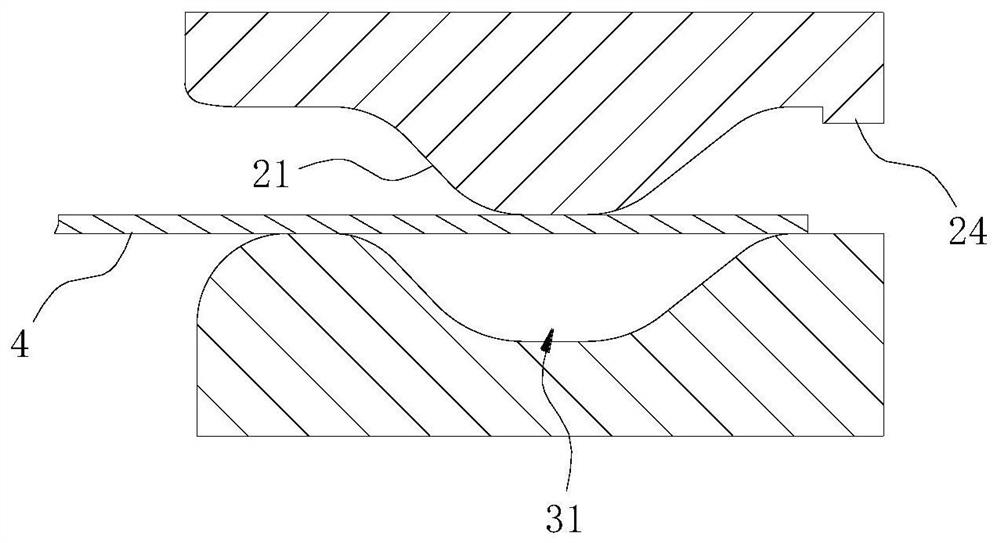

[0061] The diameter of the head product is required to be 2000 mm, the initial pressure of the first blank holder 2 on the plate 4 is 28000 kN, and the four stroke sections of the punch 1 are divided as follows:

[0062] The first stroke section is to continue to move from 0 mm to 100 mm after the punch 1 contacts the plate 4, the second stroke section is to move from the punch 1 to 100 mm to 310 mm, and the third stroke section is to move from the punch 1 to 310 mm to 380 mm, the fourth stroke section is to move from punch 1 to 380 mm to 470 mm.

[0063] Before the start of each stroke section, the pressure reduction of the first blank holder 2 to the plate 4 is adjusted as follows:

[0064] Reduce the pressure to 25500 kN before the start of the first stroke segment;

[0065] Before the start of the second stroke segment, reduce the pressure to 21500 kN;

[0066] Before the start of the third stroke segment, reduce the pressure to 19500 kN;

[0067] The pressure is reduce...

Embodiment 2

[0071] The diameter of the head product is required to be 2500 mm, the initial pressure of the first blank holder on the plate is 28000 kN, and the four stroke sections of the punch 1 are divided as follows:

[0072] The first stroke segment is to continue to move from 0 mm to 230 mm after the punch 1 contacts the plate 4, the second stroke segment is to move from the punch 1 die 230 mm to 440 mm, and the third stroke segment is to move from the punch 1 to 440 mm to 510 millimeters, the fourth stroke section is to move 510 millimeters to 600 millimeters from punch 1.

[0073] Before the start of each stroke section, the pressure reduction of the first blank holder 2 to the plate 4 is adjusted as follows:

[0074] Reduce the pressure to 26,500 kN before the start of the first stroke;

[0075] Before the start of the second stroke segment, reduce the pressure to 22500 kN;

[0076] Before the start of the third stroke segment, reduce the pressure to 20500 kN;

[0077] The pres...

Embodiment 3

[0081] It is required that the diameter of the head product is 2380 mm, the initial pressure of the first blank holder on the plate is 28000 kN, and the four stroke sections of the punch are divided as follows:

[0082] The first stroke section is to continue to move from 0 mm to 200 mm after the punch 1 contacts the sheet 4, the second stroke section is to move from the punch 1 to 200 mm to 410 mm, and the third stroke section is to move from the punch 1 to 410 mm to 480 mm, the fourth stroke segment is to move from punch 1 to 570 mm from 480 mm.

[0083] Before the start of each stroke section, the pressure reduction of the first blank holder 2 to the plate 4 is adjusted as follows:

[0084] Before the start of the first stroke segment, reduce the pressure to 26000 kN;

[0085] Before the start of the second stroke section, the pressure is reduced to 22000 kN;

[0086] Before the start of the third stroke segment, reduce the pressure to 20000 kN;

[0087] The pressure is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com