Auxiliary cooling device for liquid crystal display module production and processing

A liquid crystal display module and auxiliary cooling technology, which is applied to household refrigeration devices, applications, household appliances, etc., to achieve the effects of ensuring normal use, reducing friction, and improving cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

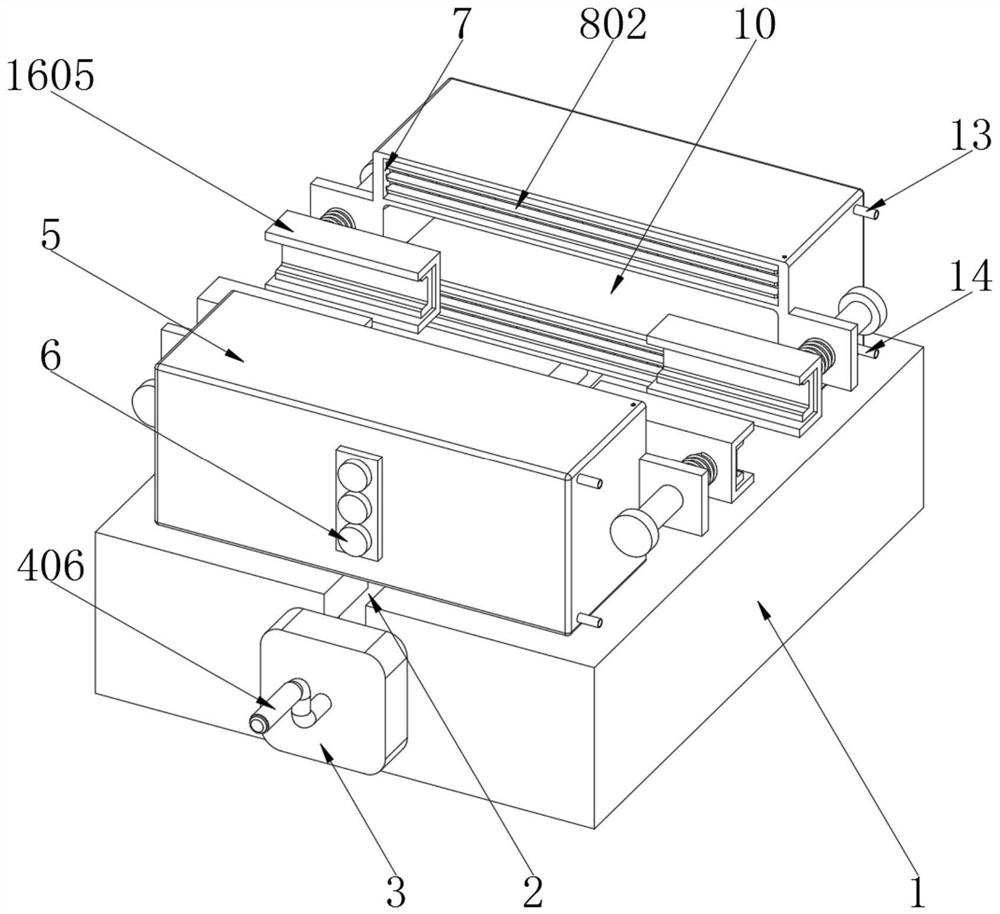

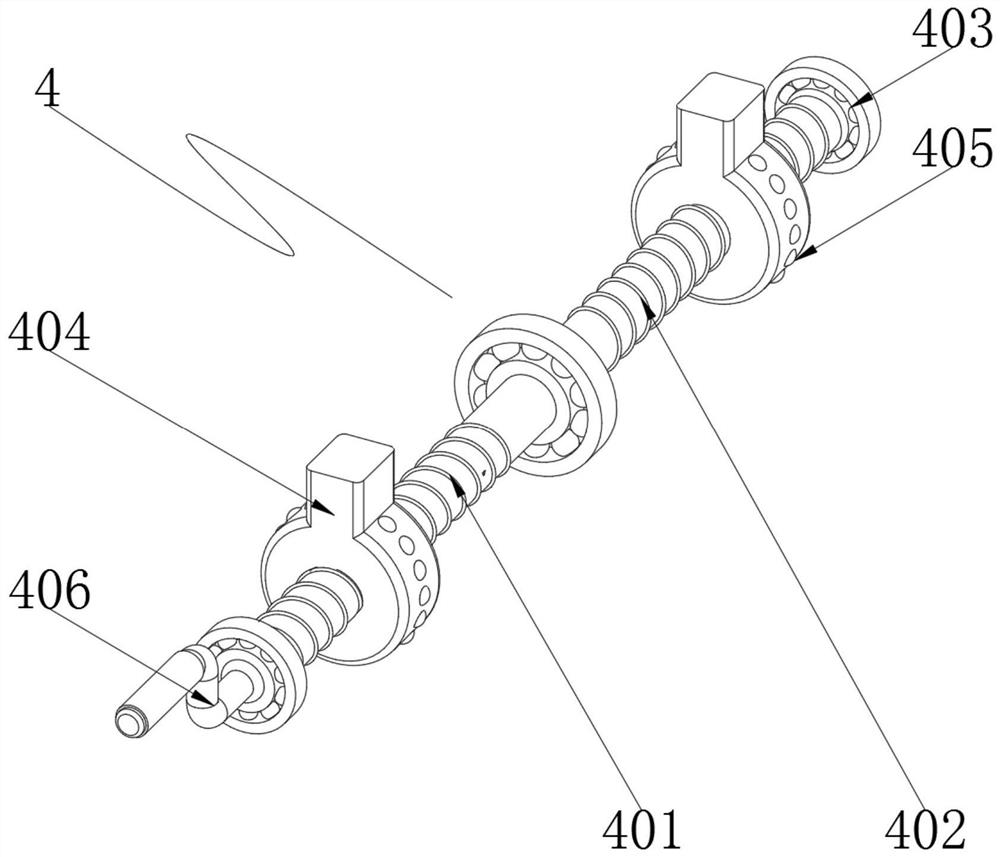

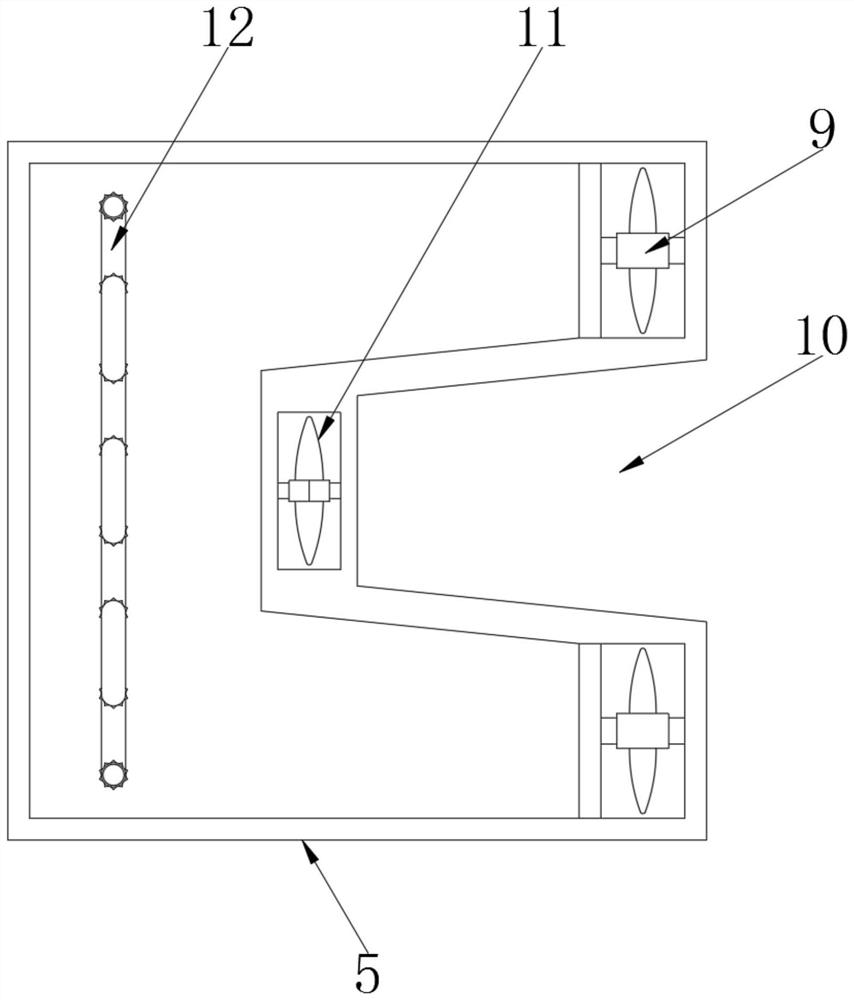

[0037] Example: such as Figure 1-7 As shown, the present invention provides a technical solution for the auxiliary cooling device used in the production and processing of liquid crystal display modules. 8. Cooling the U-shaped pipe 12 and fastening the clamping assembly 16;

[0038] A sliding adjustment slot 2 is opened through the middle of the cooling table 1, and the size of the auxiliary cooling device is adjusted according to the size of the liquid crystal display module to be cooled. A distance adjustment component 4 is installed inside the sliding adjustment slot 2, which is used to adjust the auxiliary cooling device. The size is adjusted, and the two ends of the distance adjustment assembly 4 are fixedly connected between the bearing housing 3 and the cooling table 1. A cooling box 5 is fixedly installed between the two sides above the cooling table 1 and the distance adjustment assembly 4, which is used to generate cold air for processing. Afterwards, the liquid cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com