Cleaning device for LCM backlight source structural part

A technology for cleaning devices and structural parts, applied in the field of backlight sources, to achieve the effects of smooth sliding, reducing friction, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

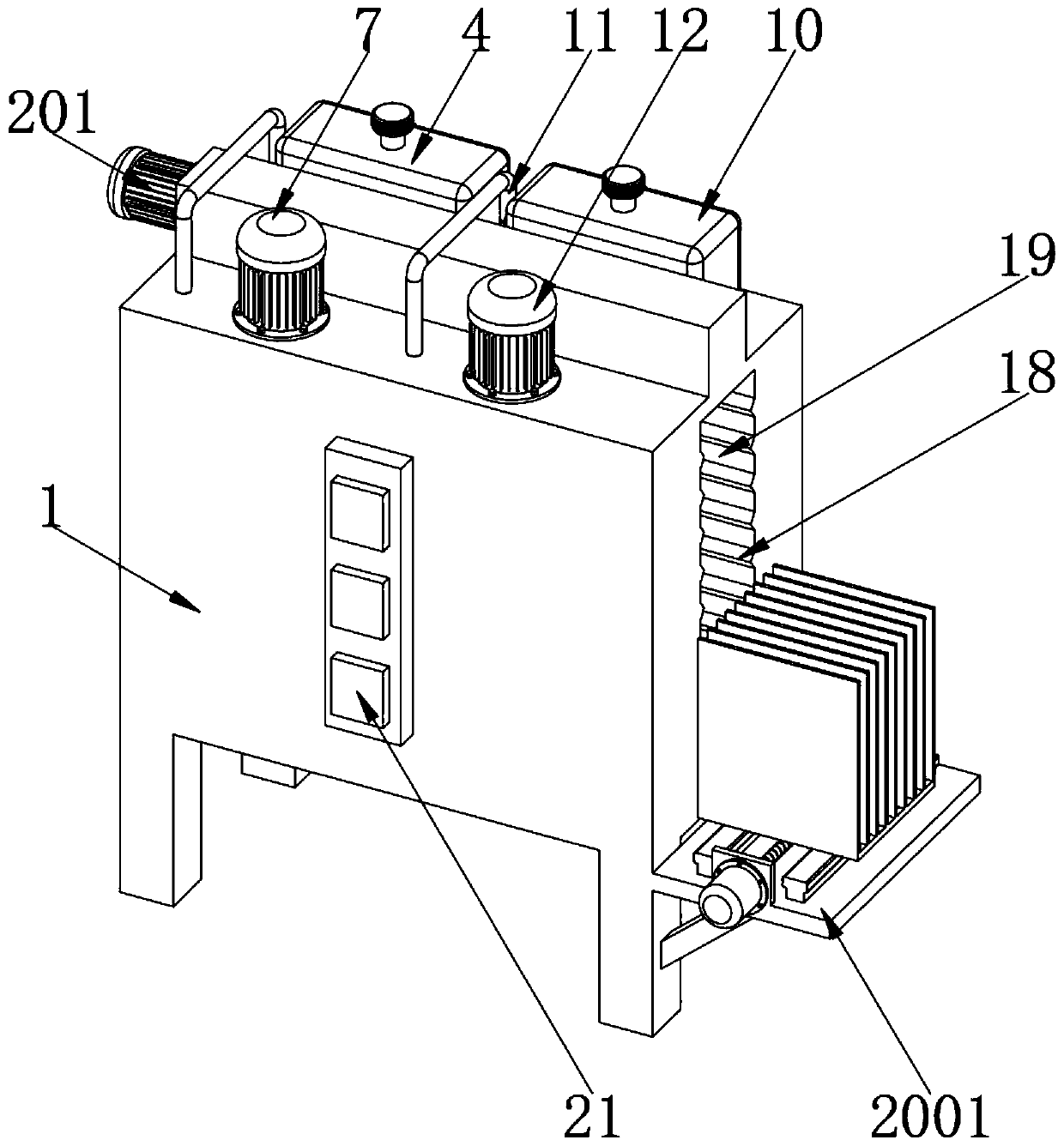

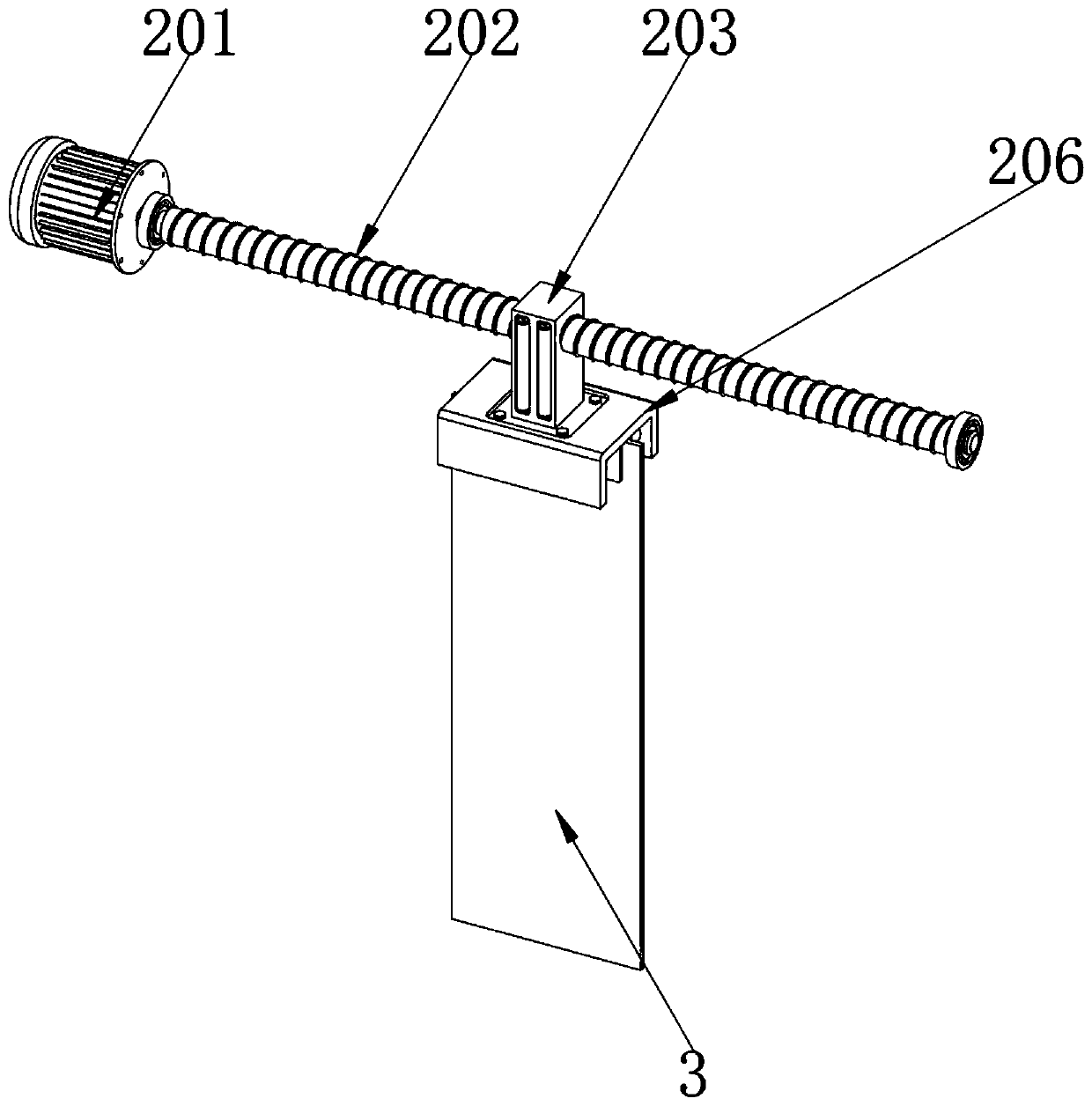

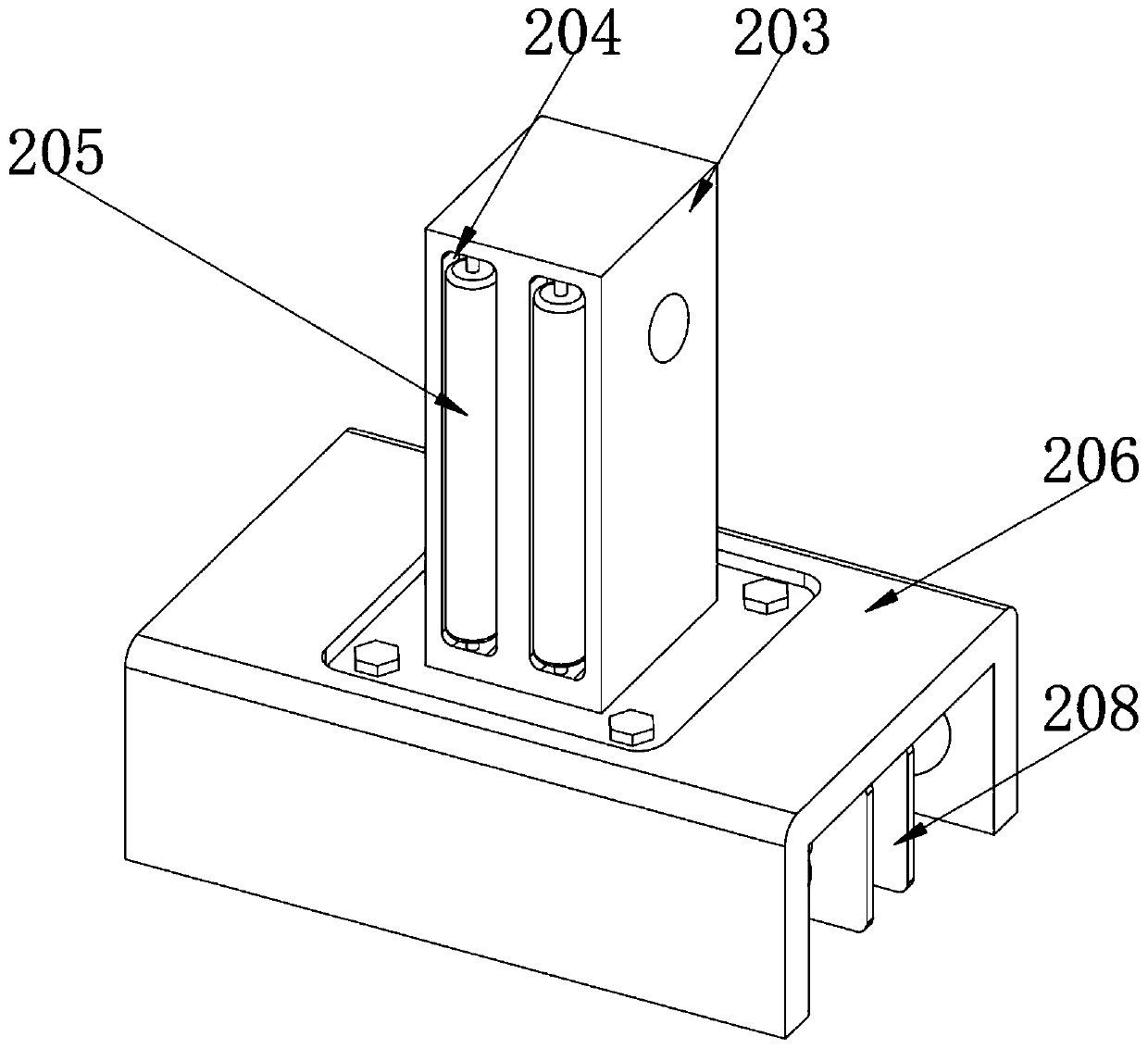

[0035] Example: such as figure 1 As shown, the present invention provides a technical solution for the cleaning device of the LCM backlight structure. The cleaning device includes a cleaning box 1, a transfer and clamping assembly 2, a cleaning roller 3, a wiping roller 13 and a transfer and loading assembly 20;

[0036] A control switch 21 is fixedly installed on one side of the cleaning box 1, and the control switch 21 is electrically connected to the power supply for controlling the power connection of the entire cleaning device. The structural part 3 is clamped under the component 2. The transfer and clamping component 2 is used to transfer and clamp the structural part 3. The cleaning liquid tank 4 is fixedly installed on the top side of the cleaning tank 1, and one end of the cleaning liquid tank 4 is fixedly installed. There is a cleaning liquid pipeline 5, and the cleaning liquid tank 4 and the cleaning liquid pipeline 5 are fixedly connected by threads. The inside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com