Chemical foaming prepressing high speed injection molding method

An injection molding and chemical foaming technology, which is applied in the field of chemical foaming pre-compression injection molding of thick-walled plastic foam parts, can solve the problems of high requirements for auxiliary machine parts and high equipment requirements, so as to reduce the consumption of raw materials and the production of products. Reliable performance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

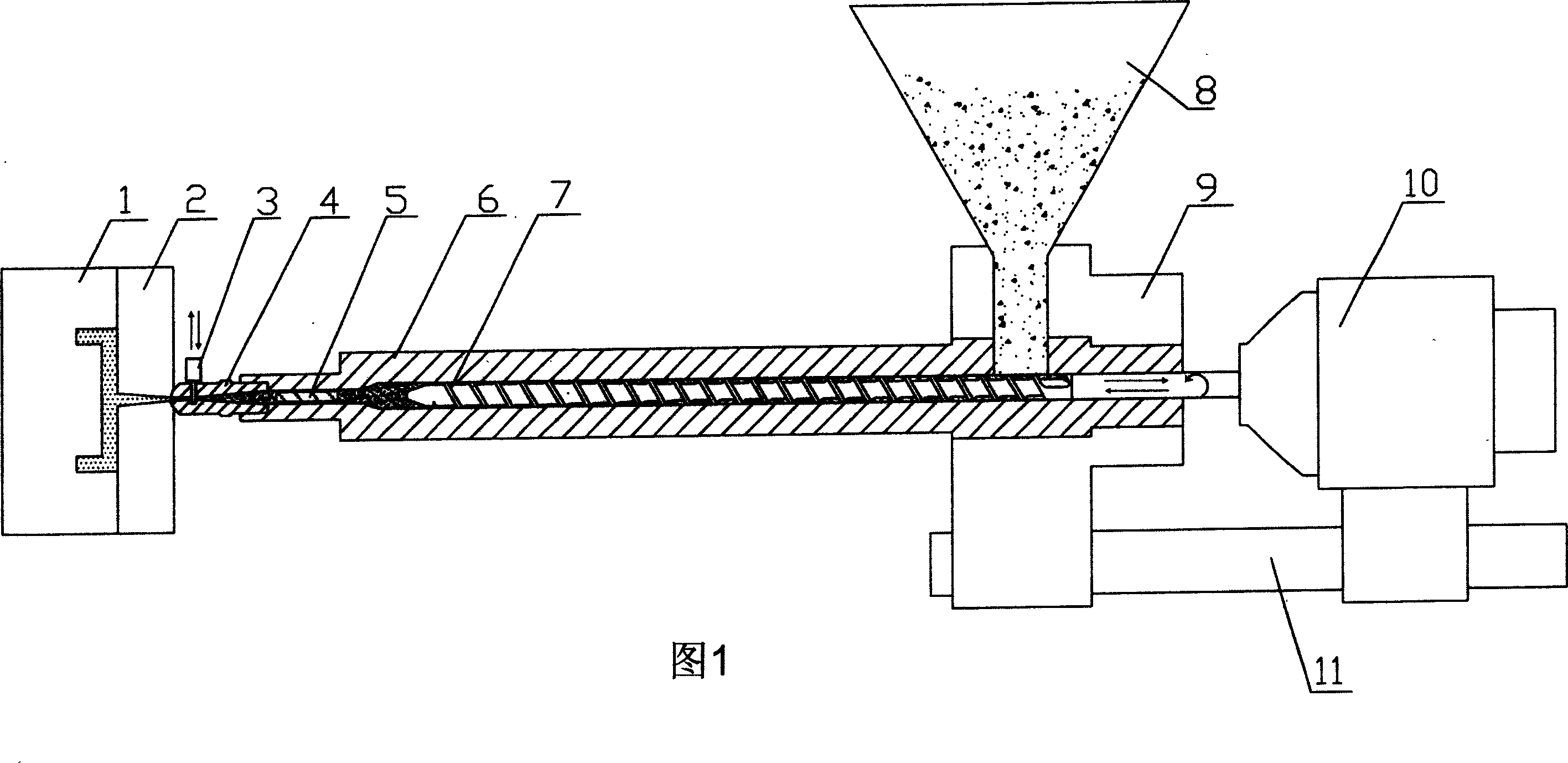

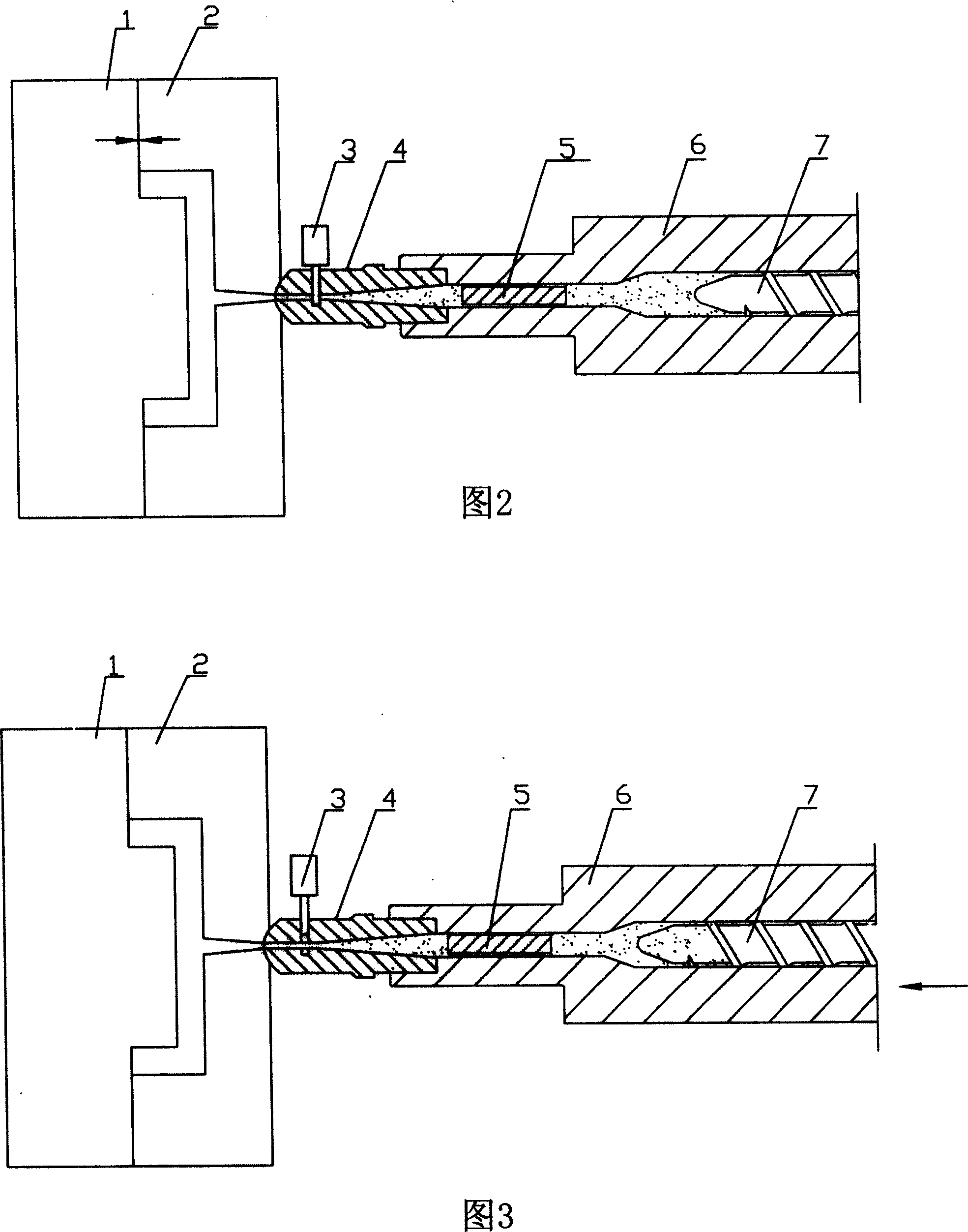

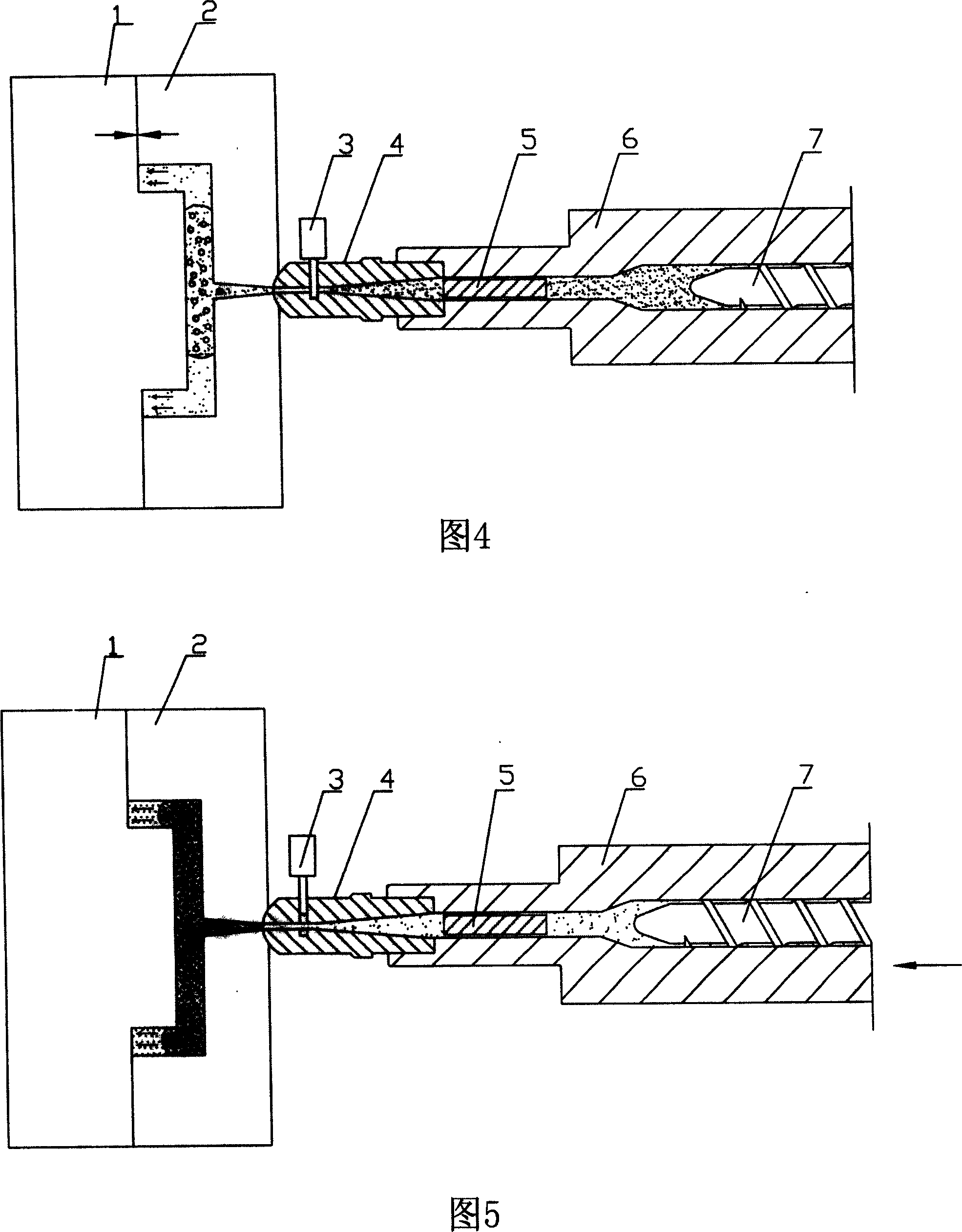

[0032] The related equipment structure of the present invention mainly includes the following parts (or devices): movable mold 1, fixed mold 2, sealing device 3, nozzle 4, mixer 5, barrel 6, plasticizing screw 7, hopper 8, barrel Support base 9, screw drive device 10, moving guide rod 11, plastic parts 12.

[0033] In the chemical foaming pre-compression high-speed injection molding method of the present invention, when the mold is clamped, the 4 holes of the nozzle are sealed to prevent the molten material from flowing into the mold cavity; The material is compressed under the push of the plasticizing screw 6, and the melt pressure increases to 1500-2000kg / cm2; then the automatic sealing nozzle 3 is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com