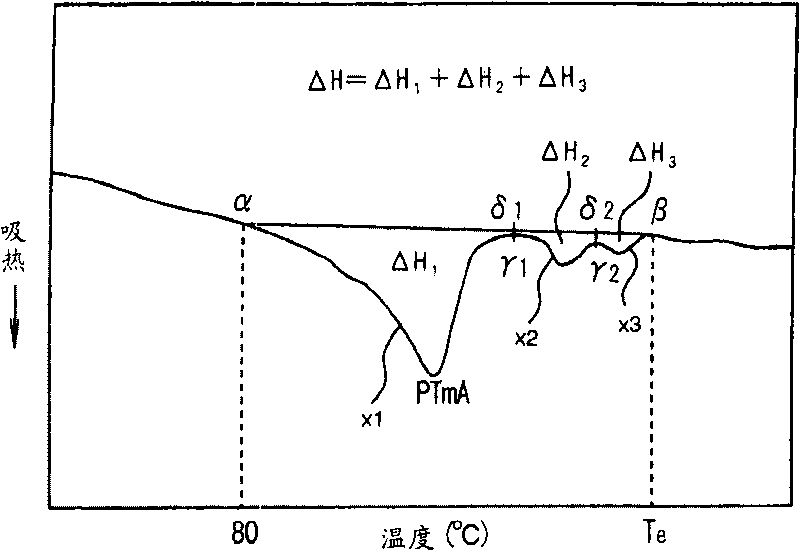

Expanded polypropylene resin beads and foamed molded article thereof

A technology of polypropylene-based resin and expanded particles, which is applied in the field of expanded particle moldings to achieve the effects of reducing clamping pressure, reducing thickness, and reducing energy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

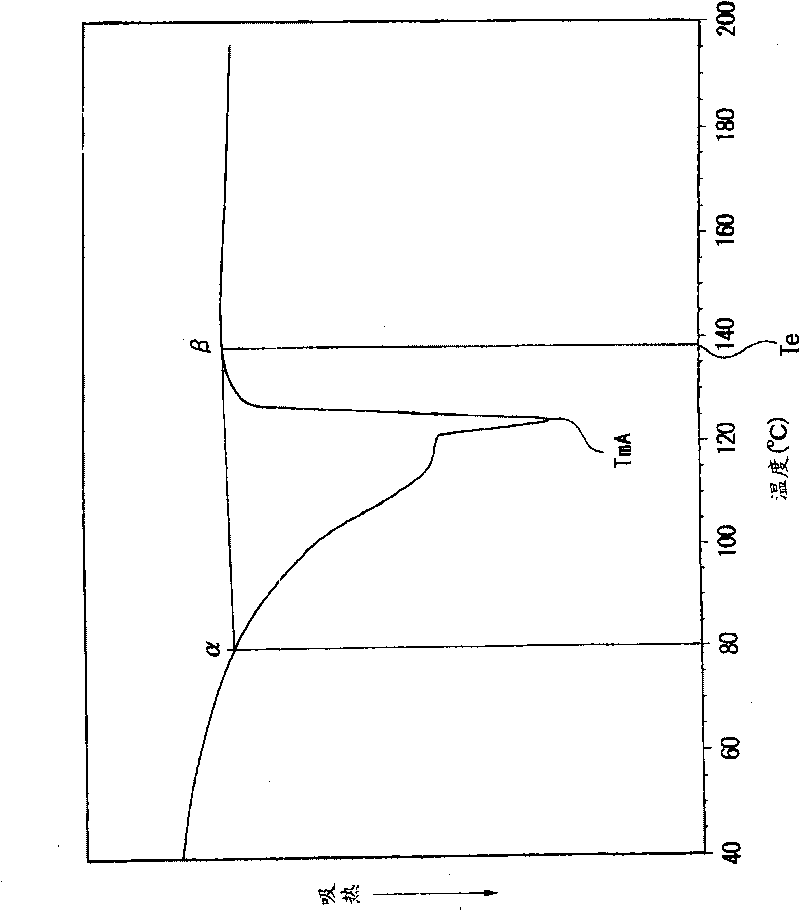

Method used

Image

Examples

Embodiment

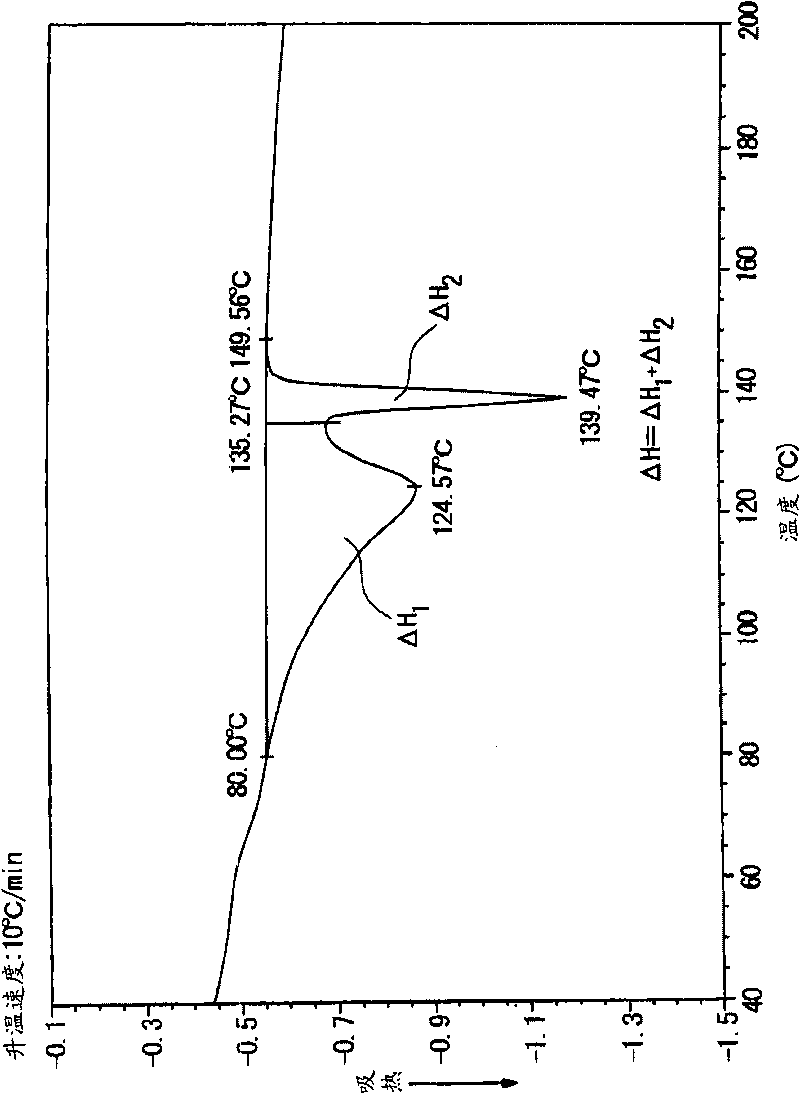

[0066] The present invention will be described in more detail below by way of examples. However, the present invention is not limited to these examples. Evaluation methods and the like in Examples are described below. In addition, the DSC apparatus used in the Example of this invention, and a comparative example is the product of Tei-Ei-Instrument-Japan Co., Ltd., and a brand name: DSC Q1000.

[0067] (1) Evaluation method (1-1) The melting point of the base resin (i) base resin adopts "[1] For the expanded polypropylene-based resin particles as the first aspect, (2) the polypropylene-based resin (a ), (2-3) Polypropylene-based resin including mixed resin (a), (ii) Measurement method of melting point" by the method described in the item. (1-2) For the measurement of the resin melting point of expanded particles (i) expanded particles "[1] For the expanded polypropylene resin particles as the first aspect, (1) expanded polypropylene resin particles ( b), (1-1) The method of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com