Floating fixture and method for processing inner and outer rings of single-row tapered roller bearing

A technology of single-row tapered rollers and floating fixtures, which is applied to bearing components, shafts, bearings, chucks, etc., can solve the problems of low product market competitiveness, low production efficiency, and high manufacturing costs, and achieve shortening of the lathing process and reducing Clamping pressure and effect of improving machining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

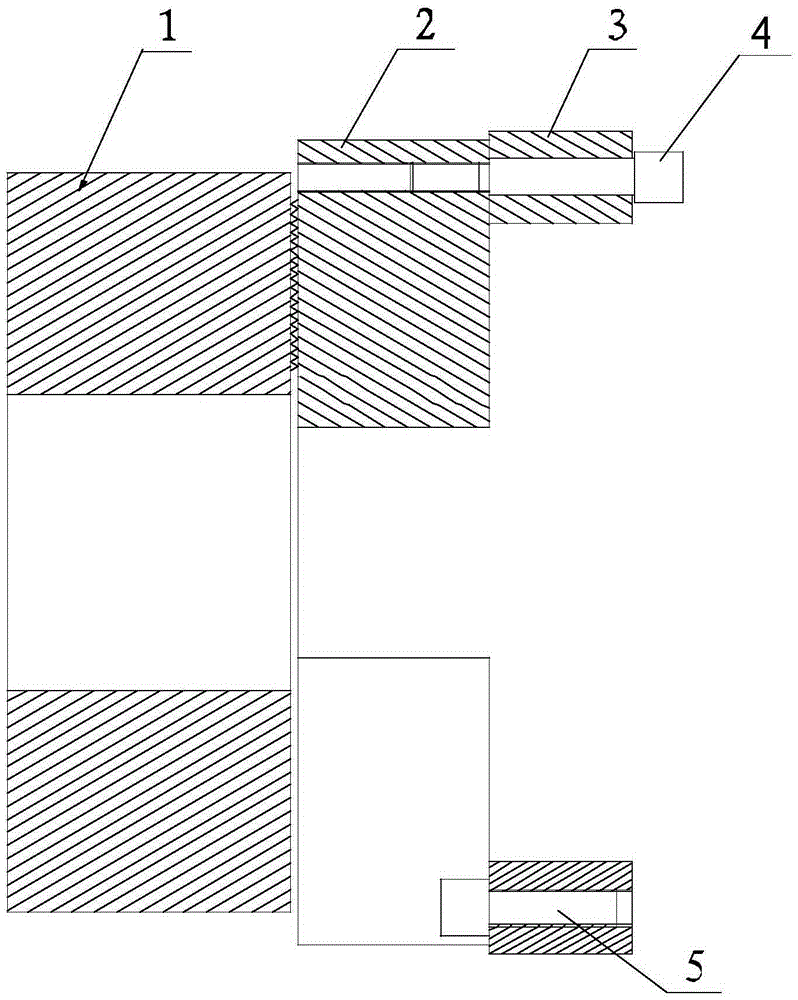

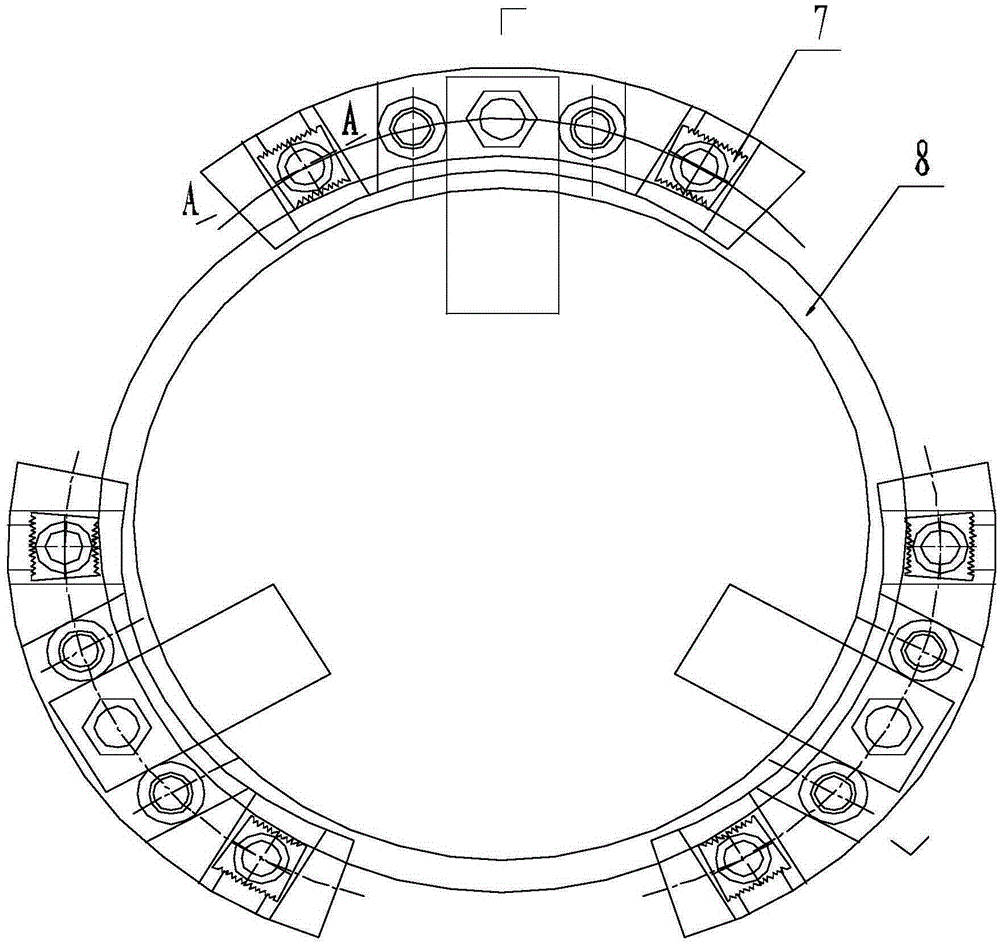

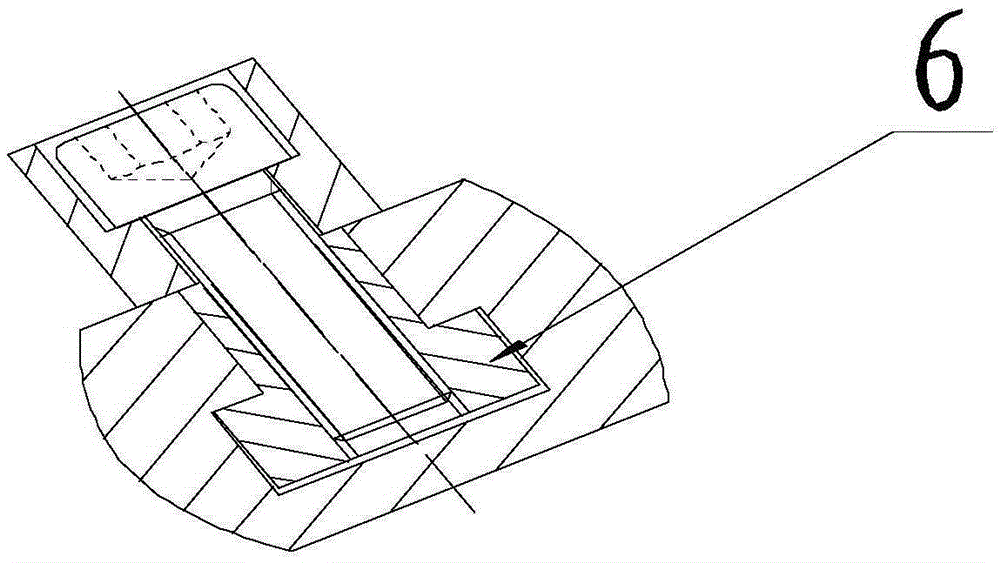

[0033] Such as Figure 1 ~ Figure 4 As shown, a floating fixture for processing the inner and outer rings of a single row tapered roller bearing, including a three-jaw chuck 1, three jaws 2, jaw body 3, floating connecting rod 4 and six jaws 7, the three jaws 2 are connected correspondingly On the three-jaw chuck 1, there are three claw bodies 3, and the three claw bodies 3 are respectively arranged corresponding to the three claws 2, and the claw bodies 3 are correspondingly connected to the three claws 2 through the floating connecting rod 4. The claw body 3 can float in the three claws 2 . There are two limit screws 5 connected between the claw body 3 and the three claws 2 , and the two limit screws 5 are symmetrically arranged on both sides of the floating link 4 . There is a certain gap between the limit screw 5 and the three claws 2, which can play a certain role of floating up and down during the clamping process. Each claw body 3 is connected with two claws 7 through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com