Multi-strip polishing machine head of printed circuit board

A technology for printed circuit boards and machine heads, which is applied in the field of multiple grinding heads for printed circuit boards. It can solve problems such as skin work injuries, product defects, and easy burrs, and achieve high grinding precision, high grinding efficiency, and labor-saving effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

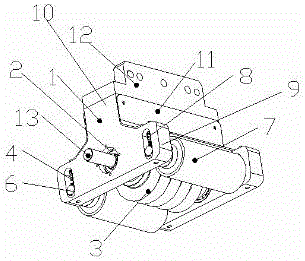

[0016] Such as figure 1 As shown, a plurality of grinding heads for printed circuit boards include a main shaft frame and a main shaft 13. The main shaft frame includes frame plates 1 at left and right ends, and a through hole 2 is provided at the central position of the frame plate. A number of evenly arranged grinding wheels 3 are installed on the main shaft, and the two ends of the main shaft are in clearance fit with the through hole; waist-shaped holes 4 are arranged on both sides of the through hole, and two roller shafts 6 are also included. The roller 7 that rotates with it is installed on it, and the two ends of the roller shaft can move up and down in the said waist hole, and an elastic member 8 is installed between the top of the waist hole and the roller shaft. The elastic member is a spring.

[0017] In one embodiment o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com