Patents

Literature

32results about How to "Improve turning accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

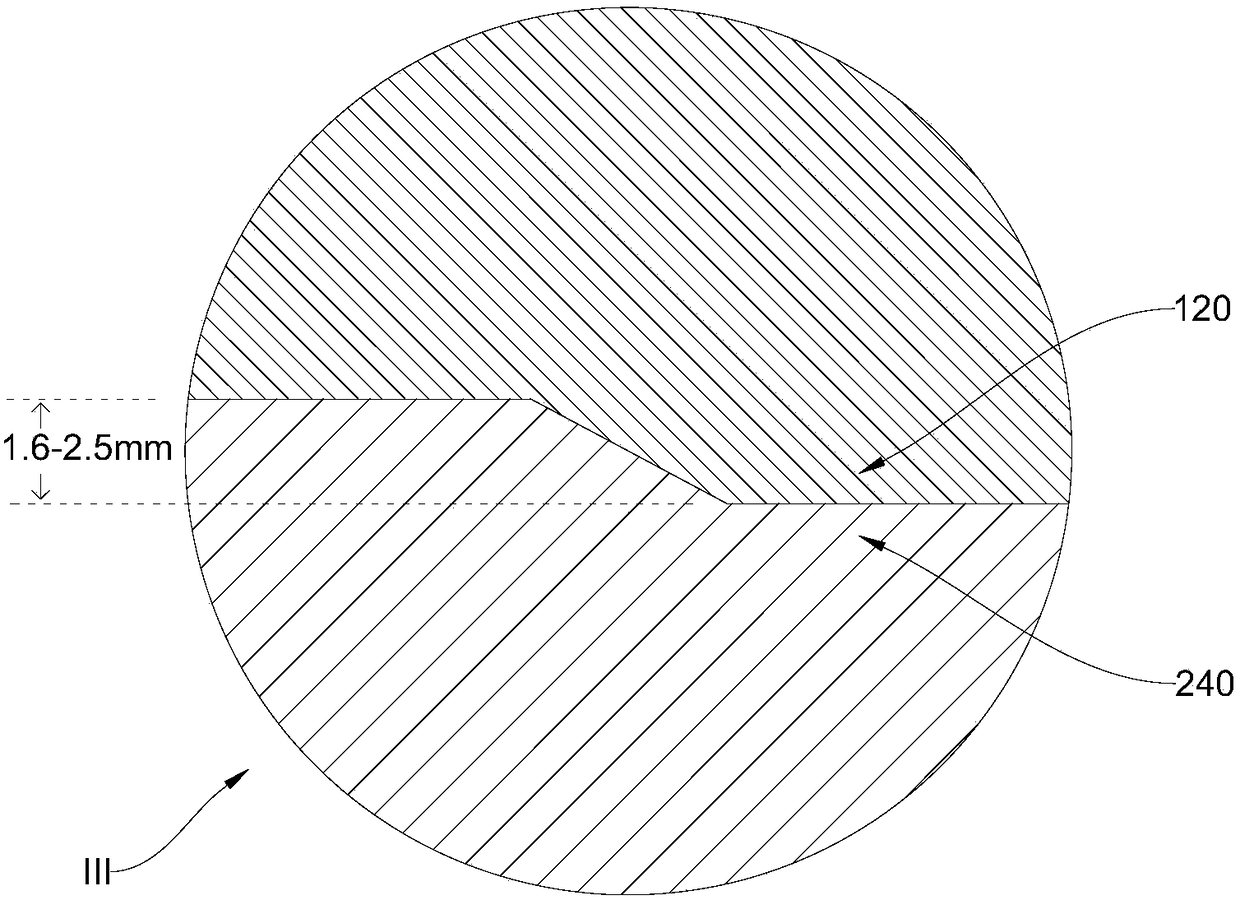

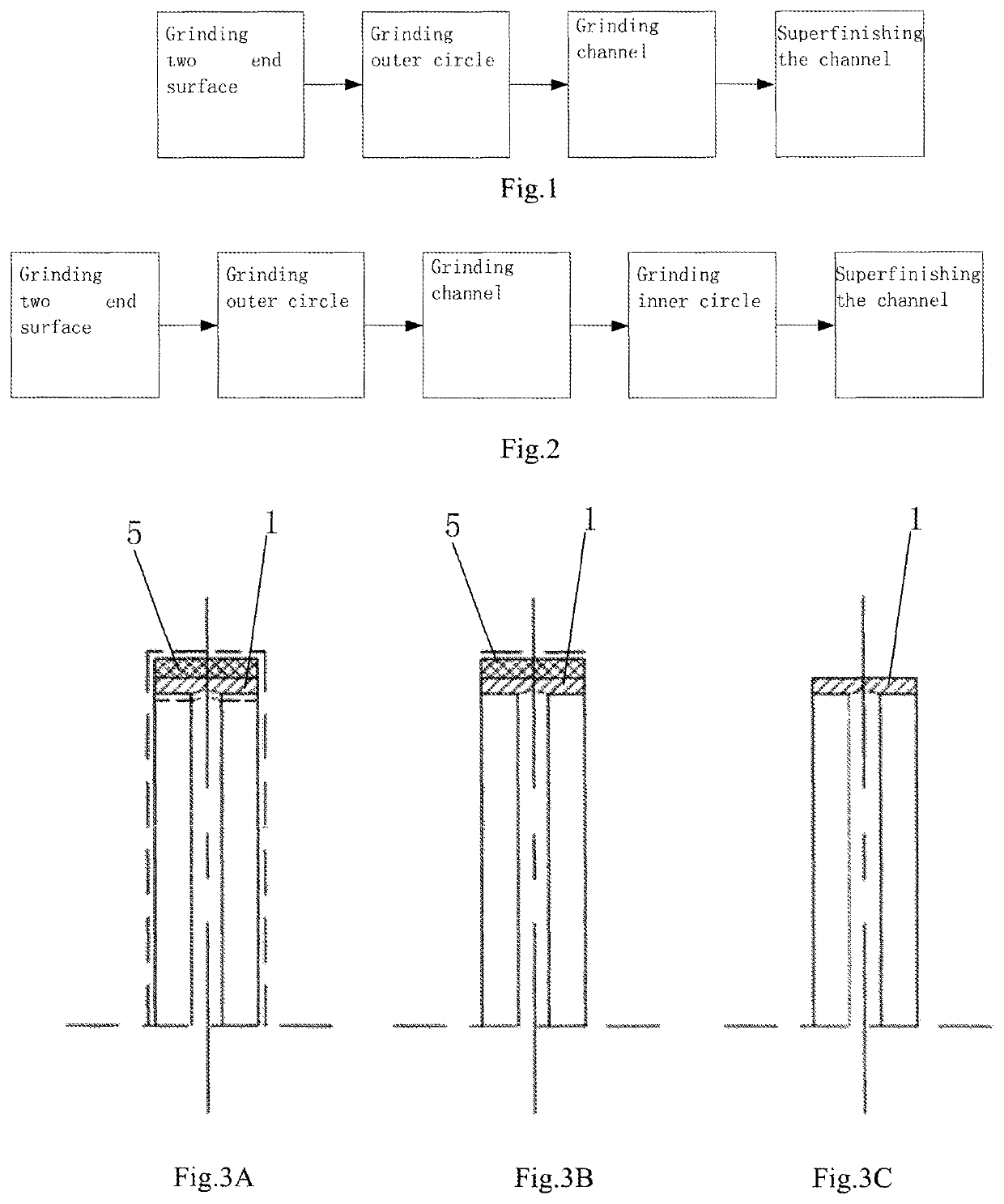

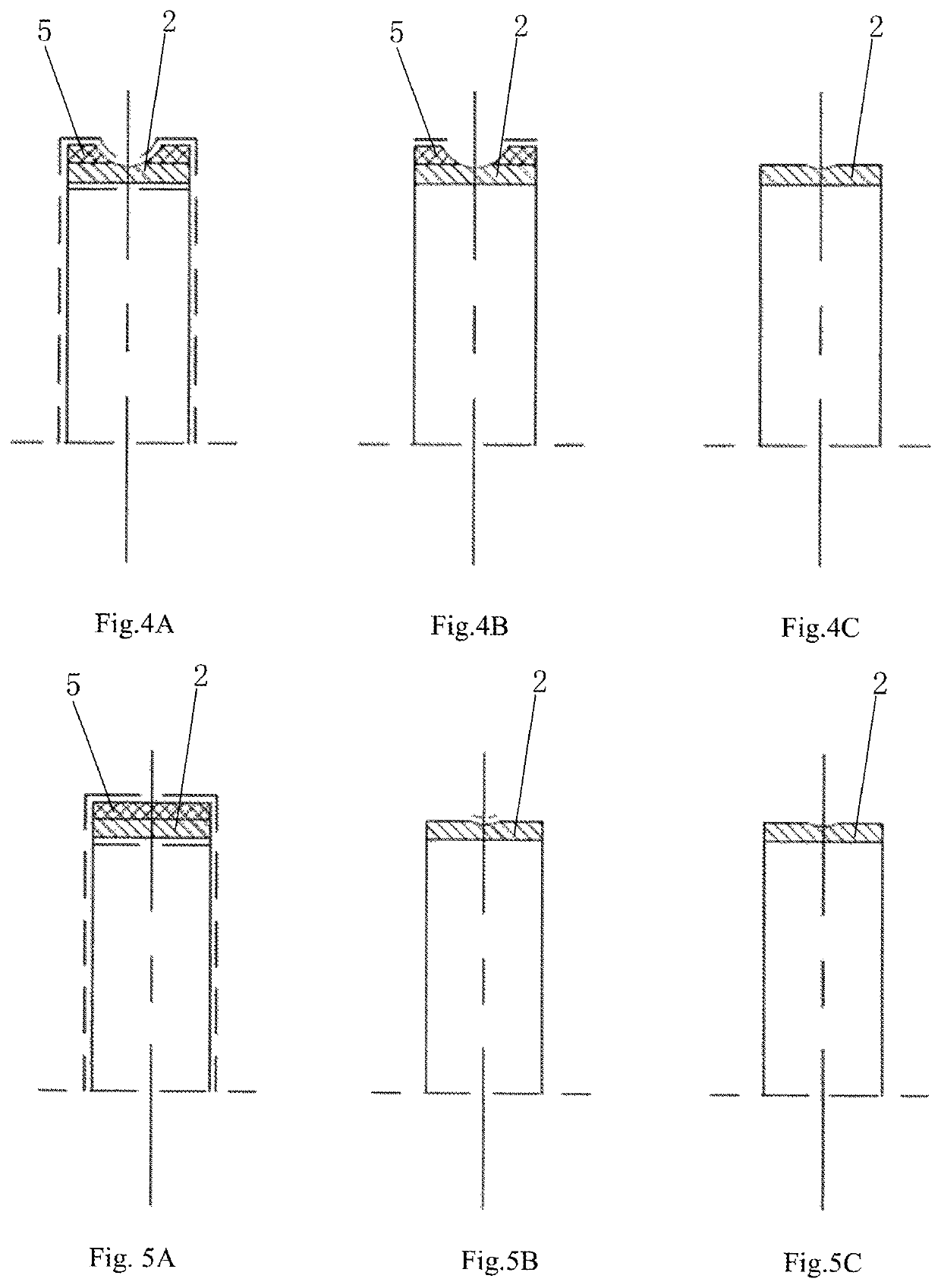

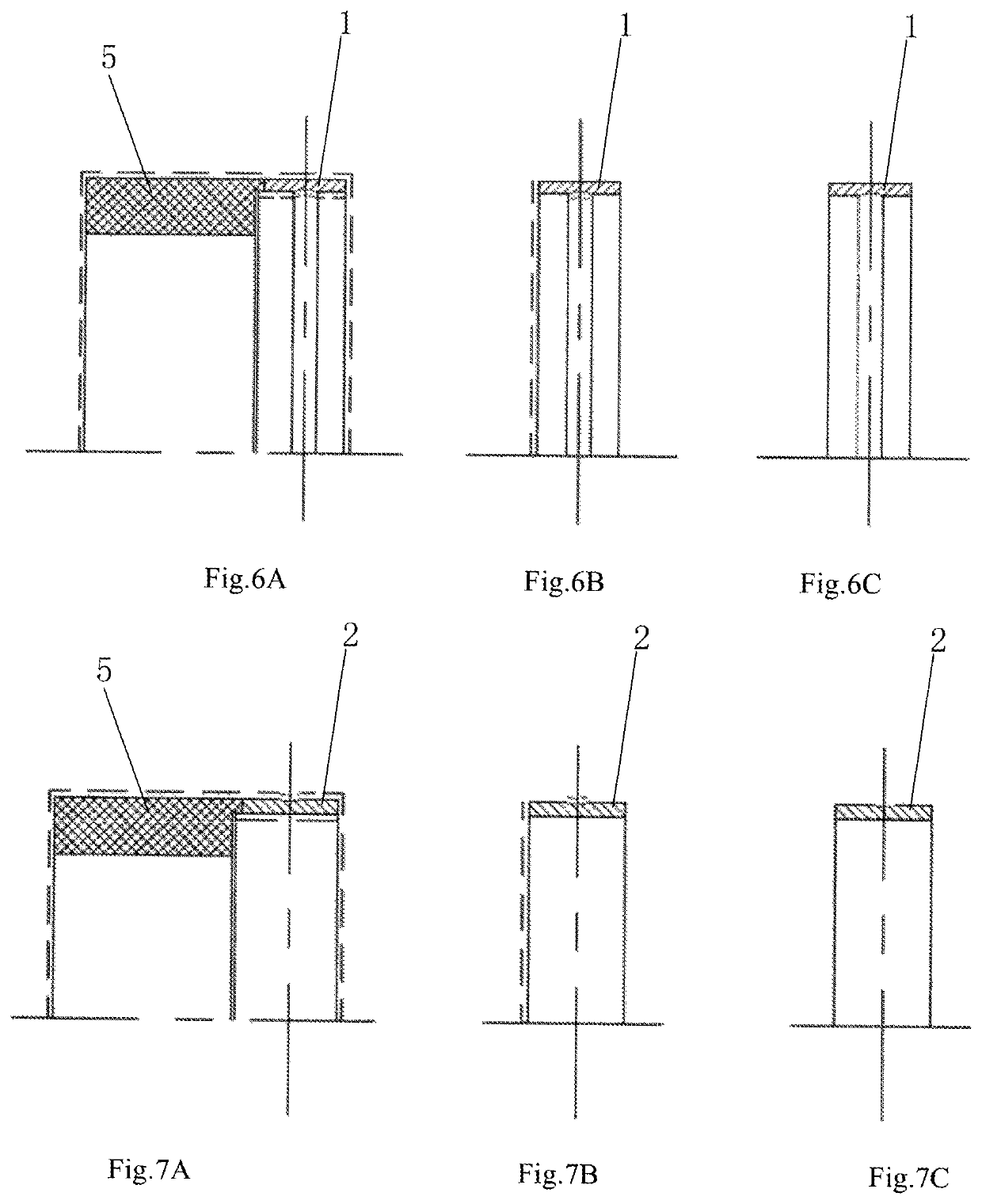

Manufacturing method of thin-wall bearing and method for machining thin-wall inner ring/outer ring of the thin-wall bearing as well as precise flexible bearing

ActiveUS20180328409A1Low efficiencyLow costBall bearingsBearing componentsBall bearingSuperfinishing

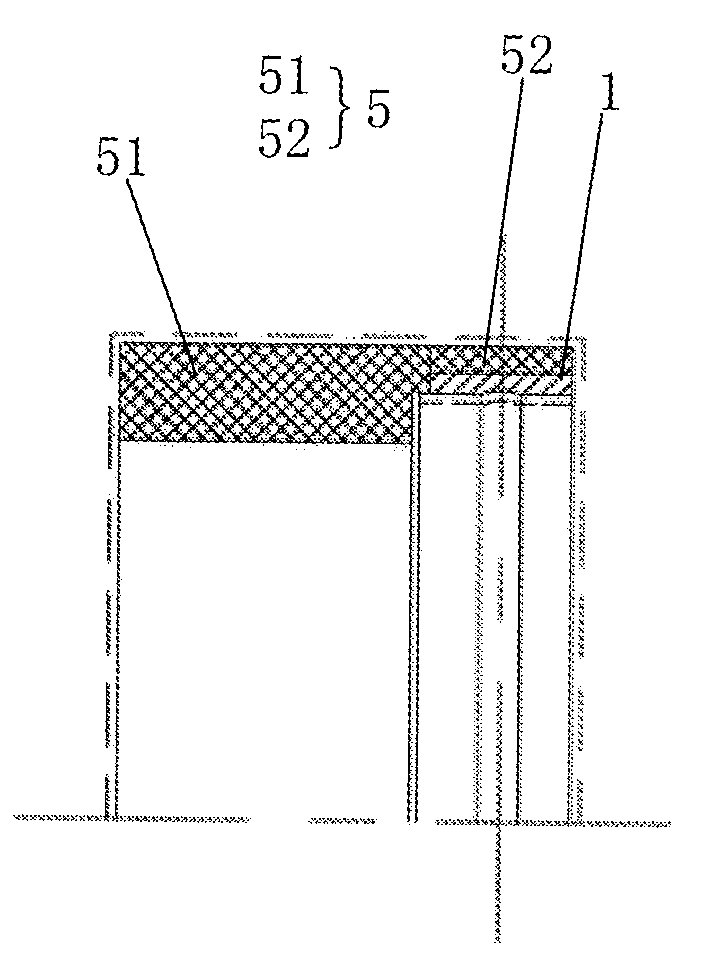

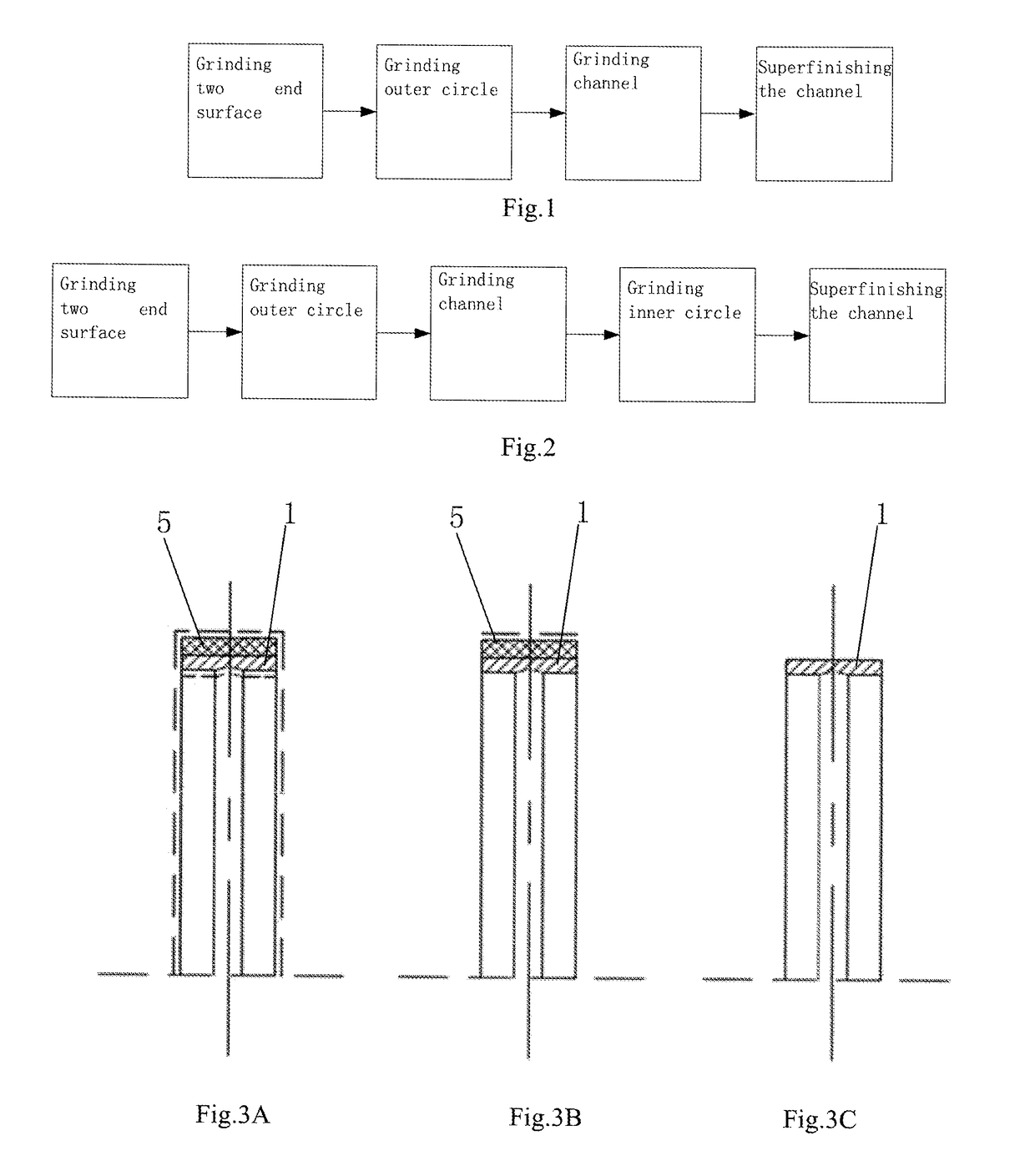

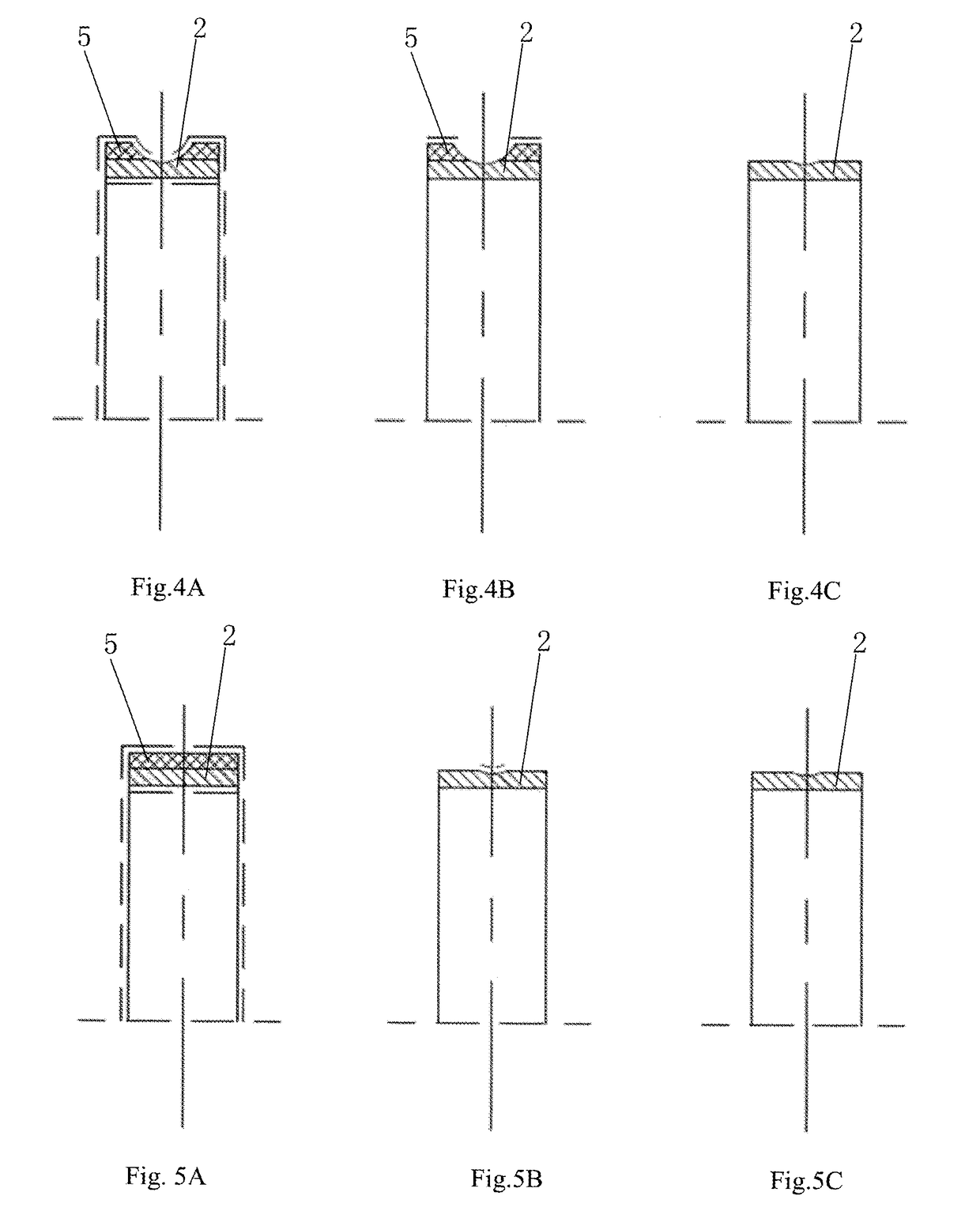

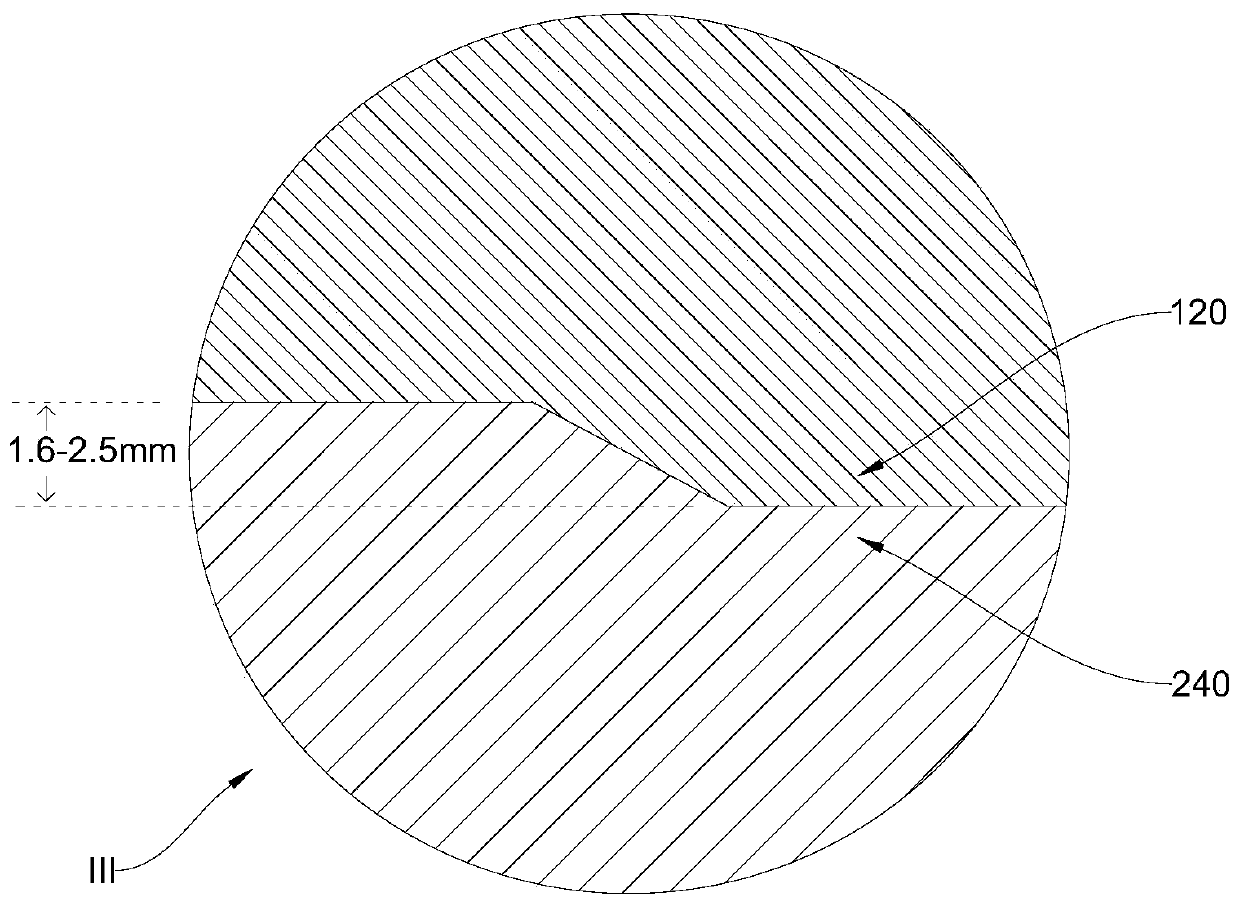

The invention provides a manufacturing method for thin-wall bearing and a method for machining a thin-wall inner ring / outer ring as well as a precision flexible bearing. The method for machining the thin-wall inner ring / outer ring comprises the following steps of: S0. providing a thin-wall ring with machining allowance left; S1: reinforcing along the radial direction and / or axial direction of the thin-wall ring; S2: carrying out quenching-tempering heat treatment on the reinforcing ring obtained by reinforcement in the S1; S3: carrying out corresponding grinding, hard cutting and super finishing on the reinforcing ring after receiving heat treatment, which includes removal of the machining allowance and a reinforcing part obtained by reinforcement in the S1, thereby obtaining finished thin-wall ring product. The thin-wall ring reinforced machining method substantially reduces and even avoids deformation of the thin-wall ring in all manufacturing links, thereby obtaining very high machining precision. The precision thin-wall bearing and the precision flexible bearing can be manufactured by fitting of the precision thin-wall ring and a precision rolling body.

Owner:SHANGHAI F&S BEARING TECH

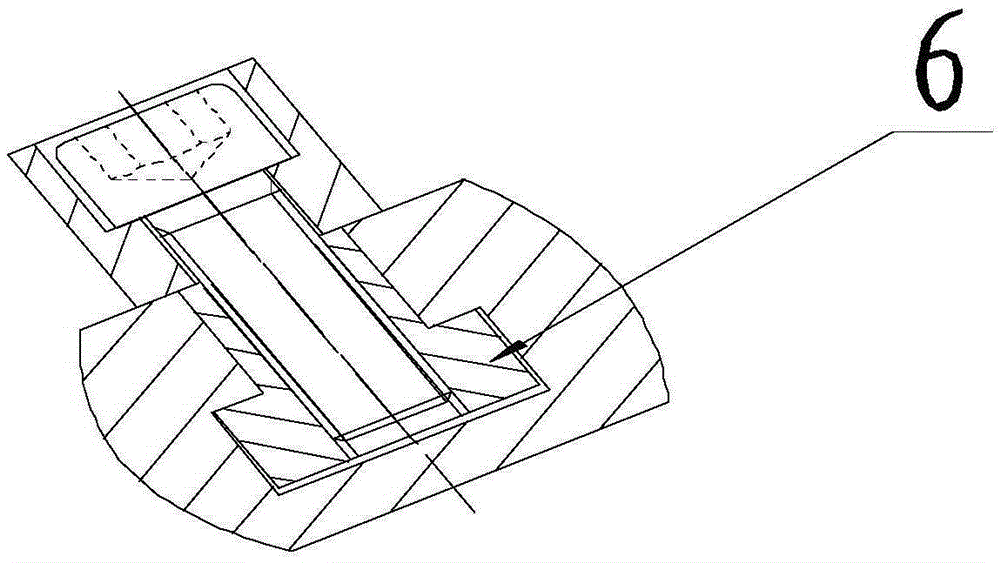

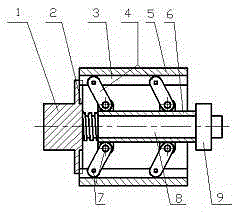

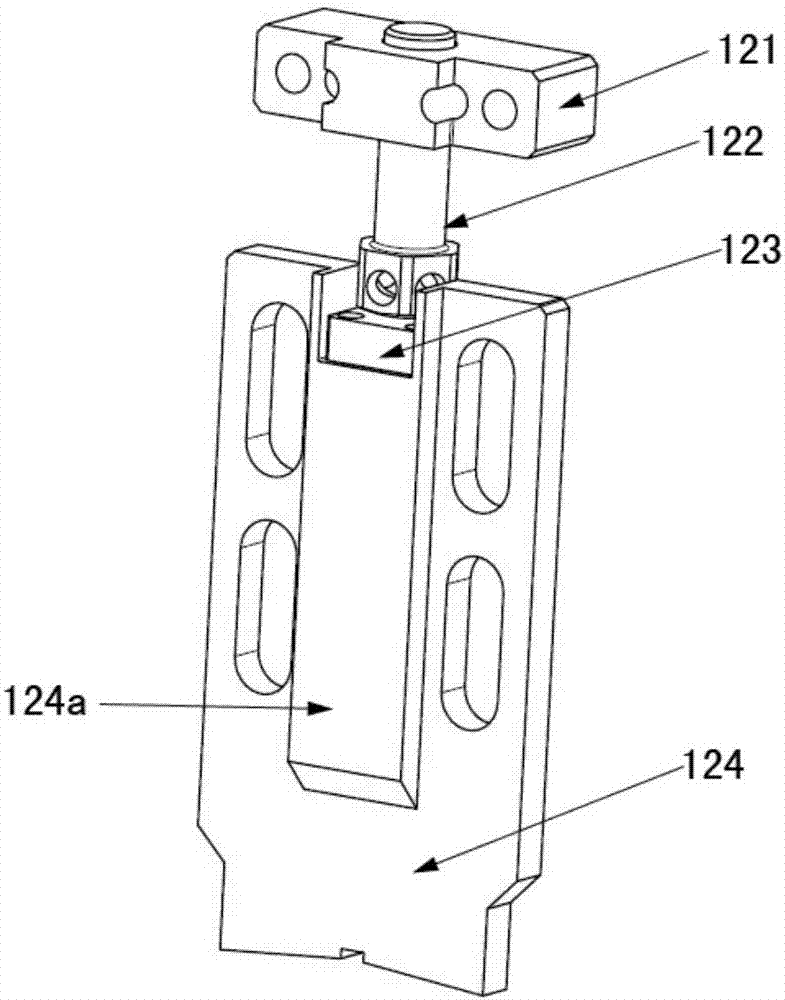

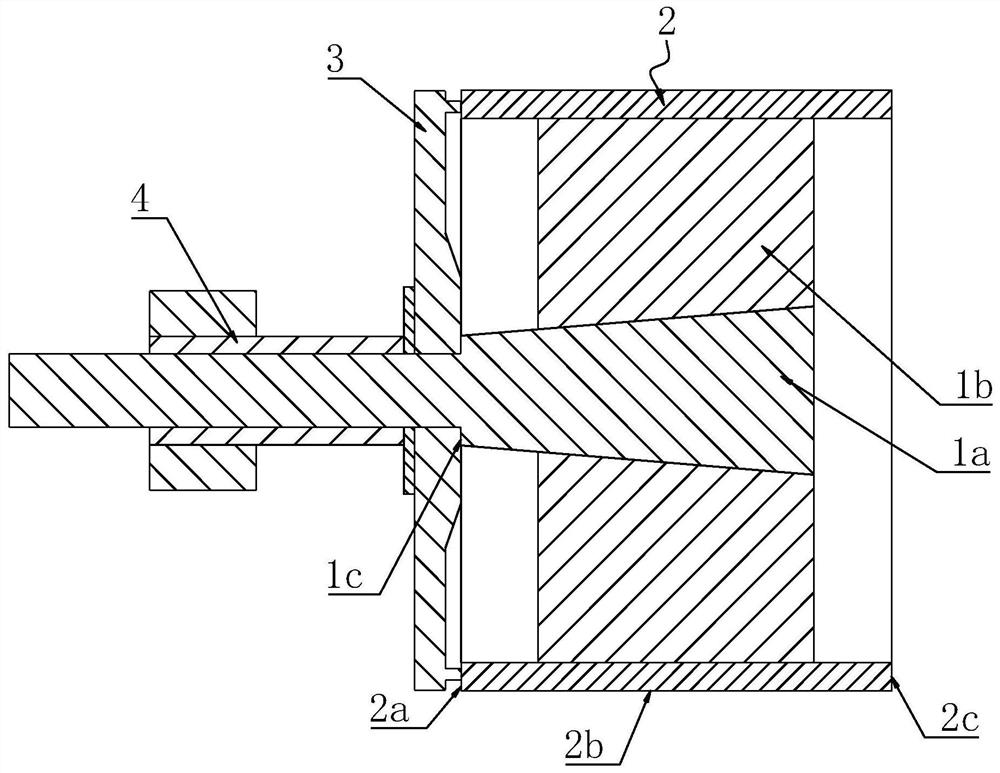

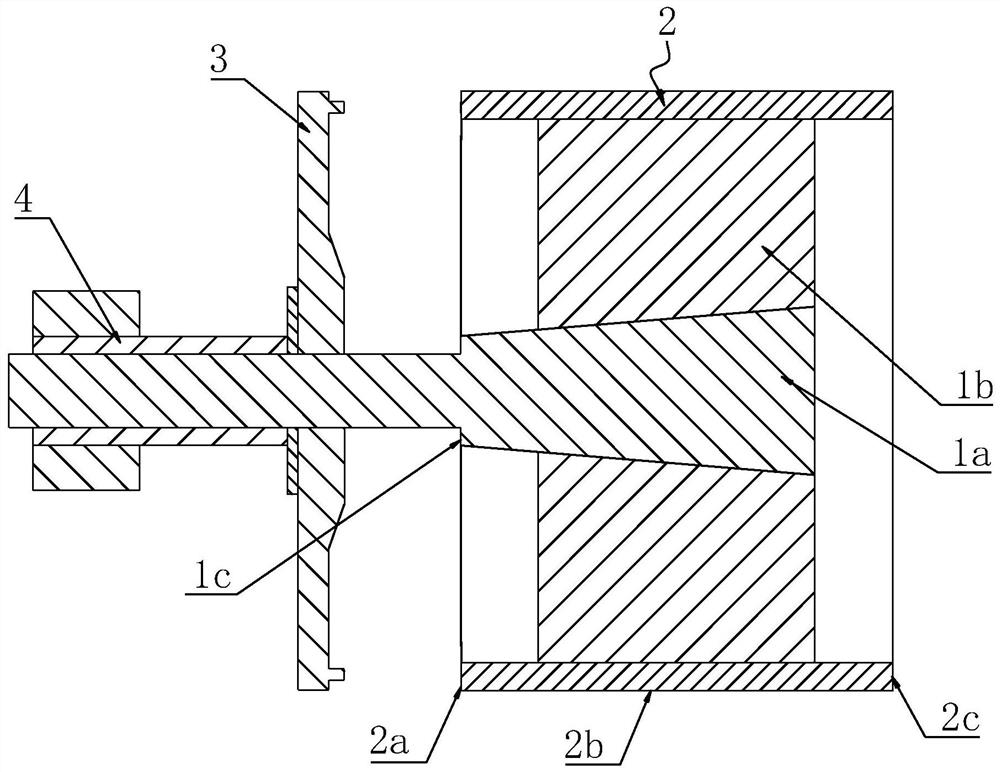

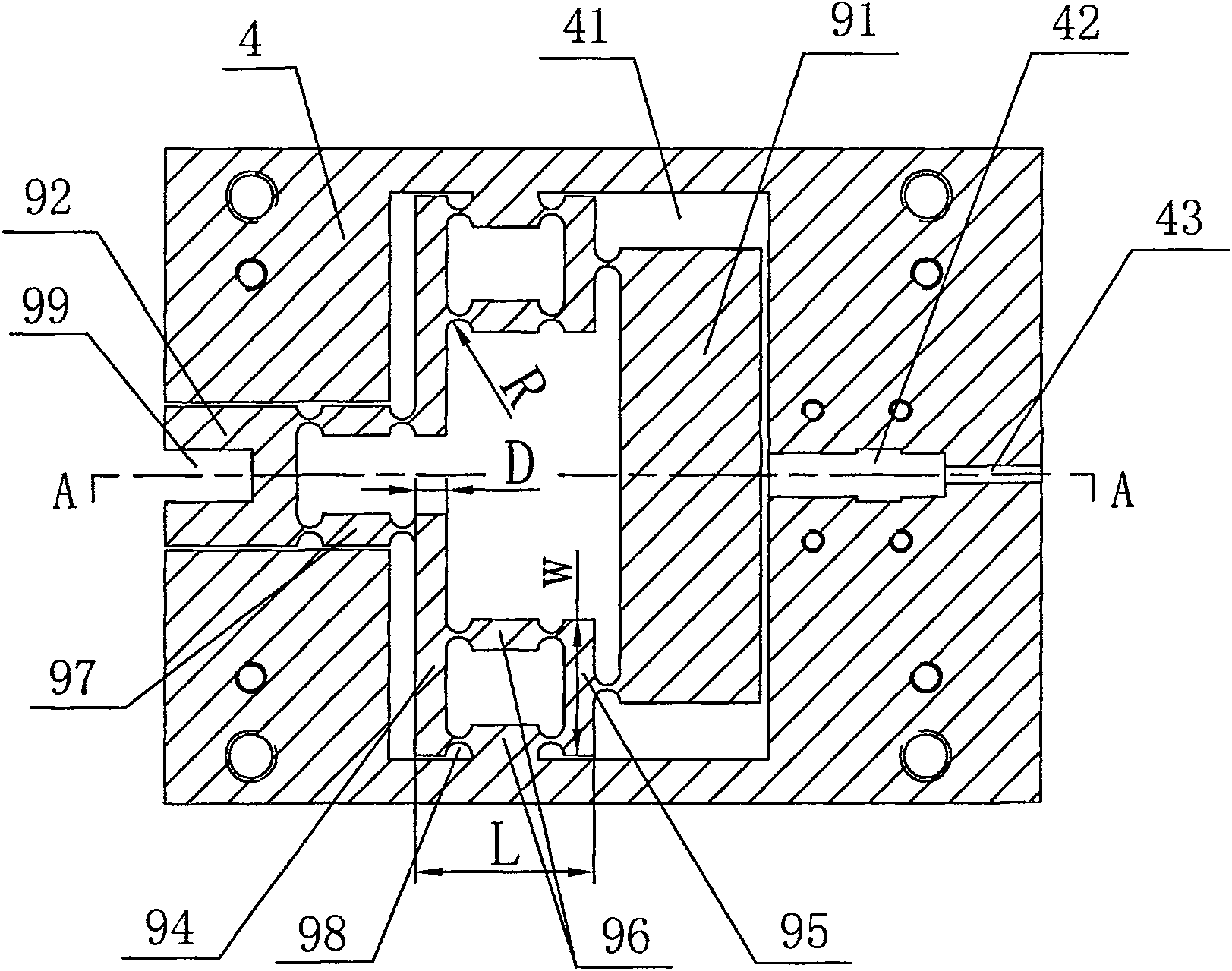

Intelligent-compensating anti-vibration lathe tool and control system thereof

ActiveCN105478813ASimple structureEasy to operateTurning toolsAdverse effect compensationSquare arrayControl system

The invention discloses an intelligent-compensating anti-vibration lathe tool. The intelligent-compensating anti-vibration lathe tool comprises a cutter body and a cutter head which are independent from each other, wherein an inner cavity is arranged in the cutter body; and the rear end of the cutter head horizontally extends into the inner cavity. The intelligent-compensating anti-vibration lathe tool is characterized in that at least four groups of two-way flexible hinges are fixedly arranged between the two sides of the rear end of the cutter head and the cavity wall of the inner wall, wherein all two-way flexible hinges are symmetrically arranged along the axial center line of the cutter head; and a piezoelectric ceramic driver group which is arranged in the form of a square array is arranged between the rear-end end surface of the cutter head and the cavity wall of the inner wall. The intelligent-compensating anti-vibration lathe tool has the advantages that the cutter head of the lathe tool is controlled to carry out corresponding position compensating in a radial direction of a workpiece by monitoring changes of turning force, so that changes of a turning thickness are within a stable turning range, and regenerated type turning vibration is avoided; the cutter head rotates by a slight angle to carry out multi-direction position compensating to meet needs of different turning occasions; the turning precision and the surface processing quality of products are improved; and the anti-vibration lathe tool is simple in structure, is convenient to operate, and is flexible and variable in use.

Owner:NINGBO KATE MAKER COOKING TECH CO LTD

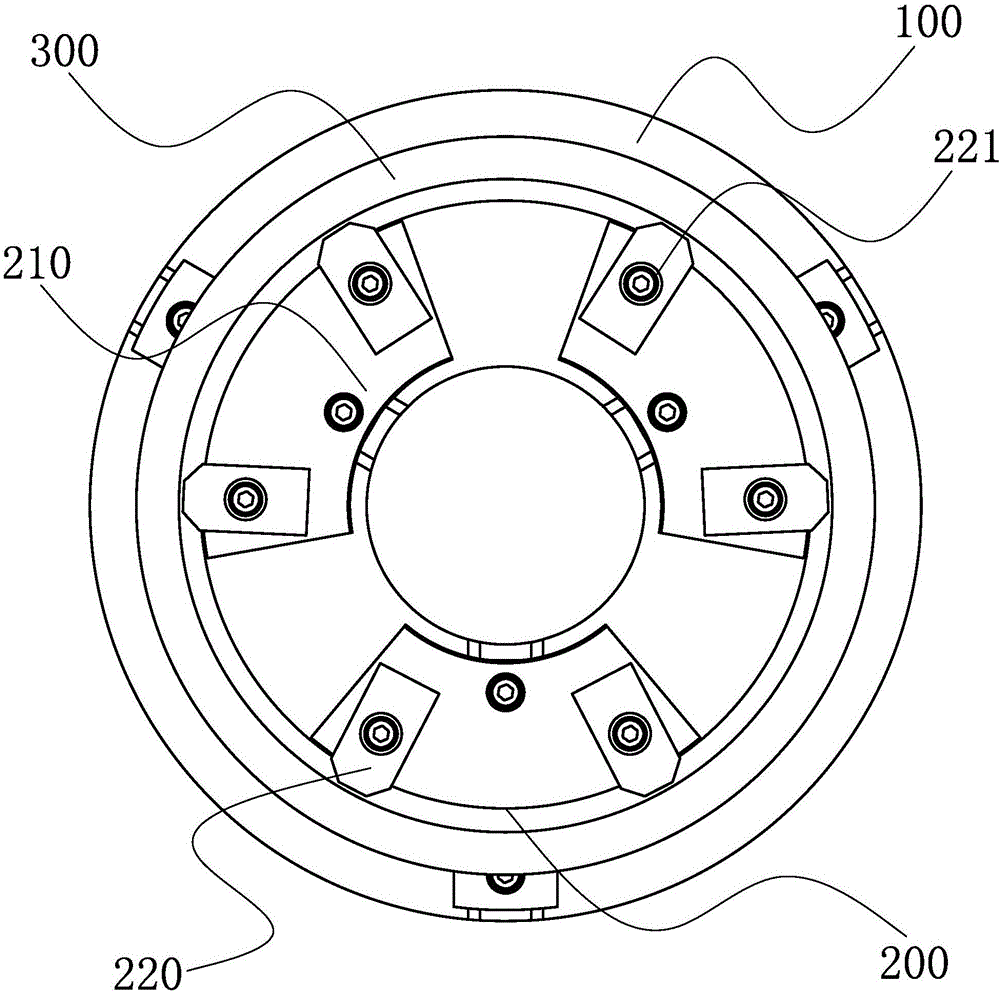

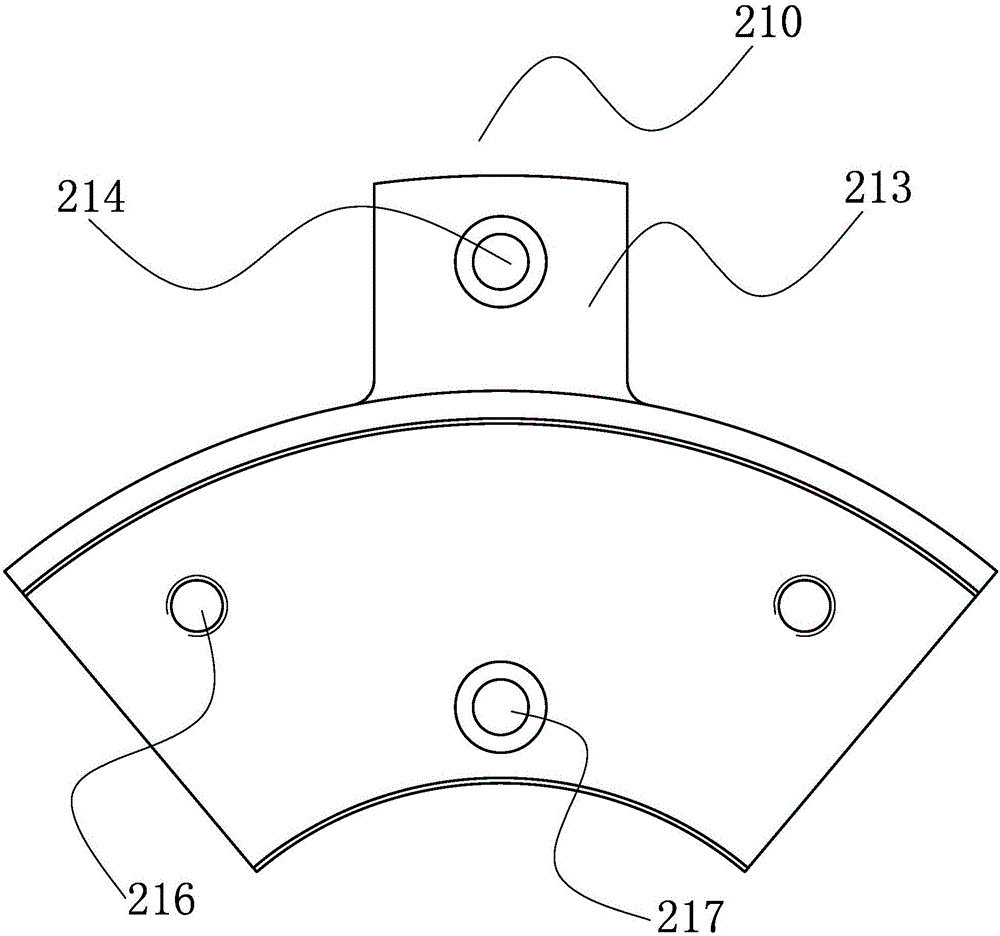

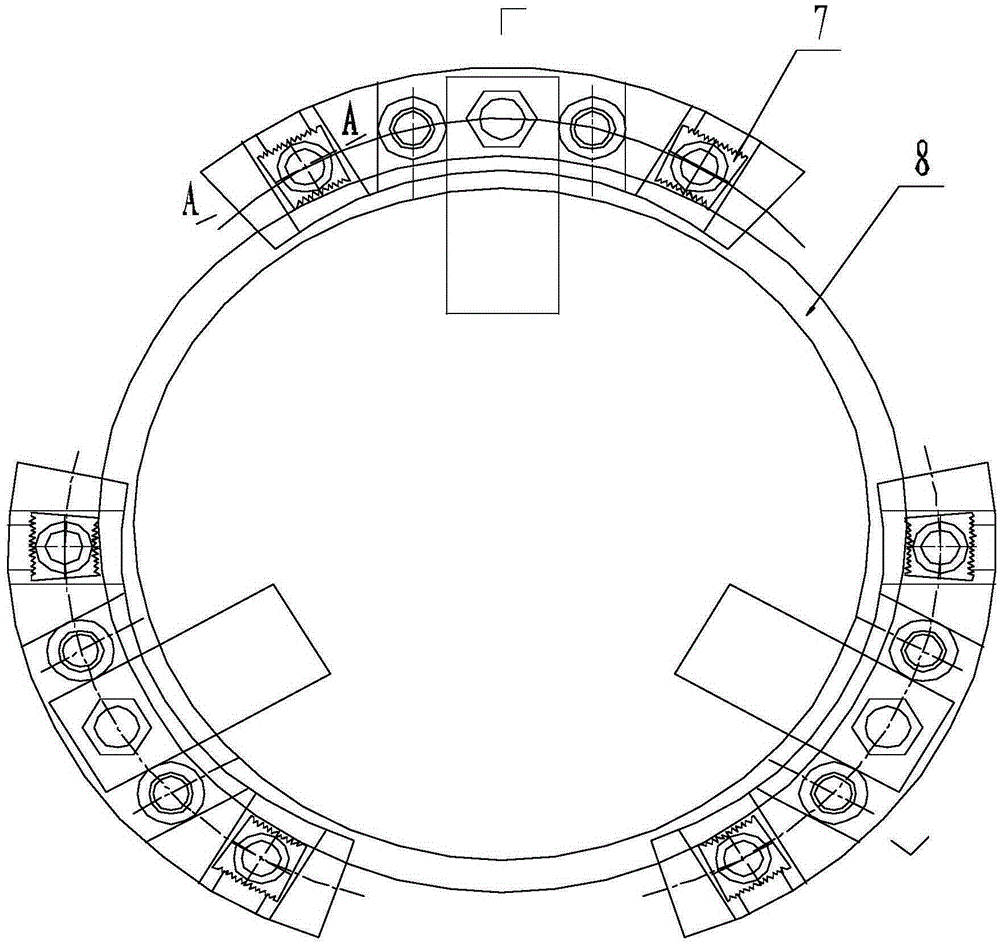

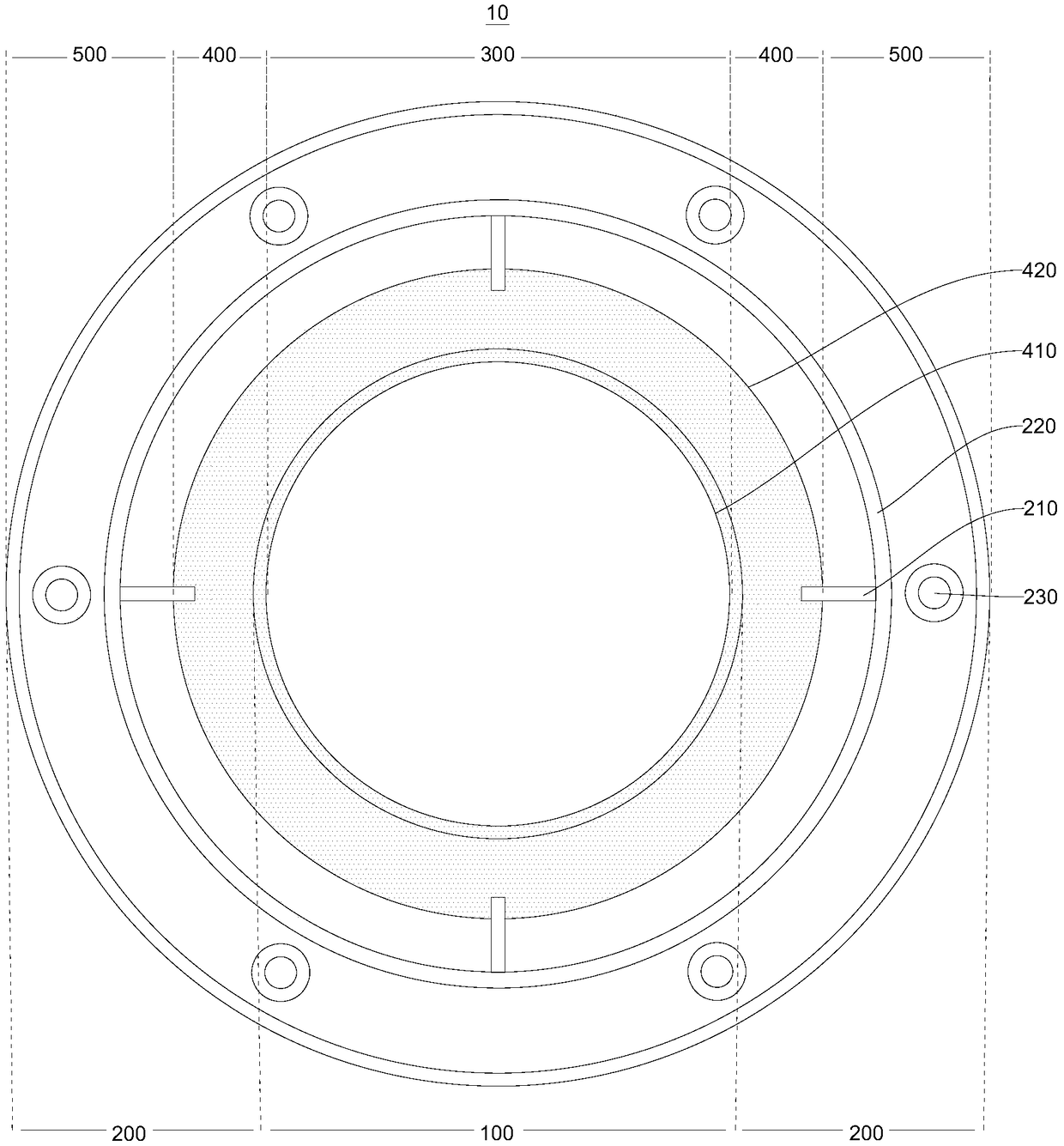

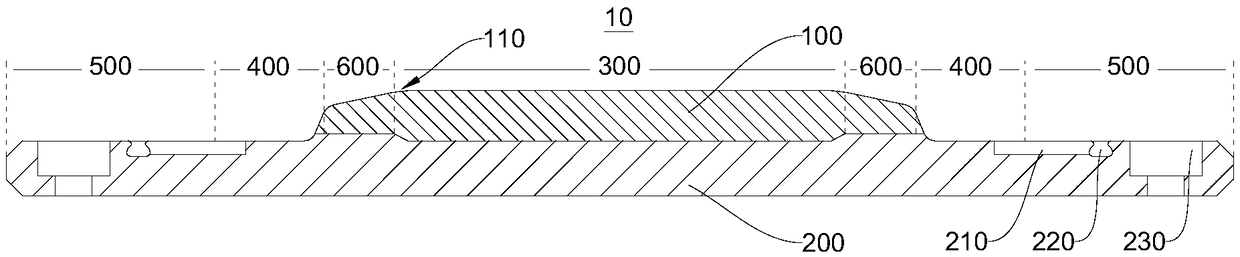

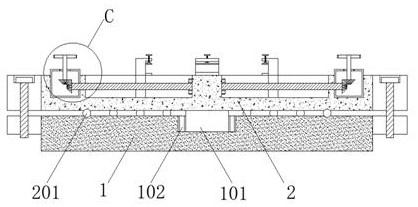

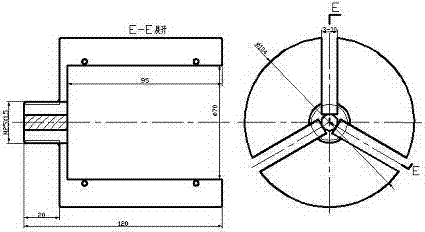

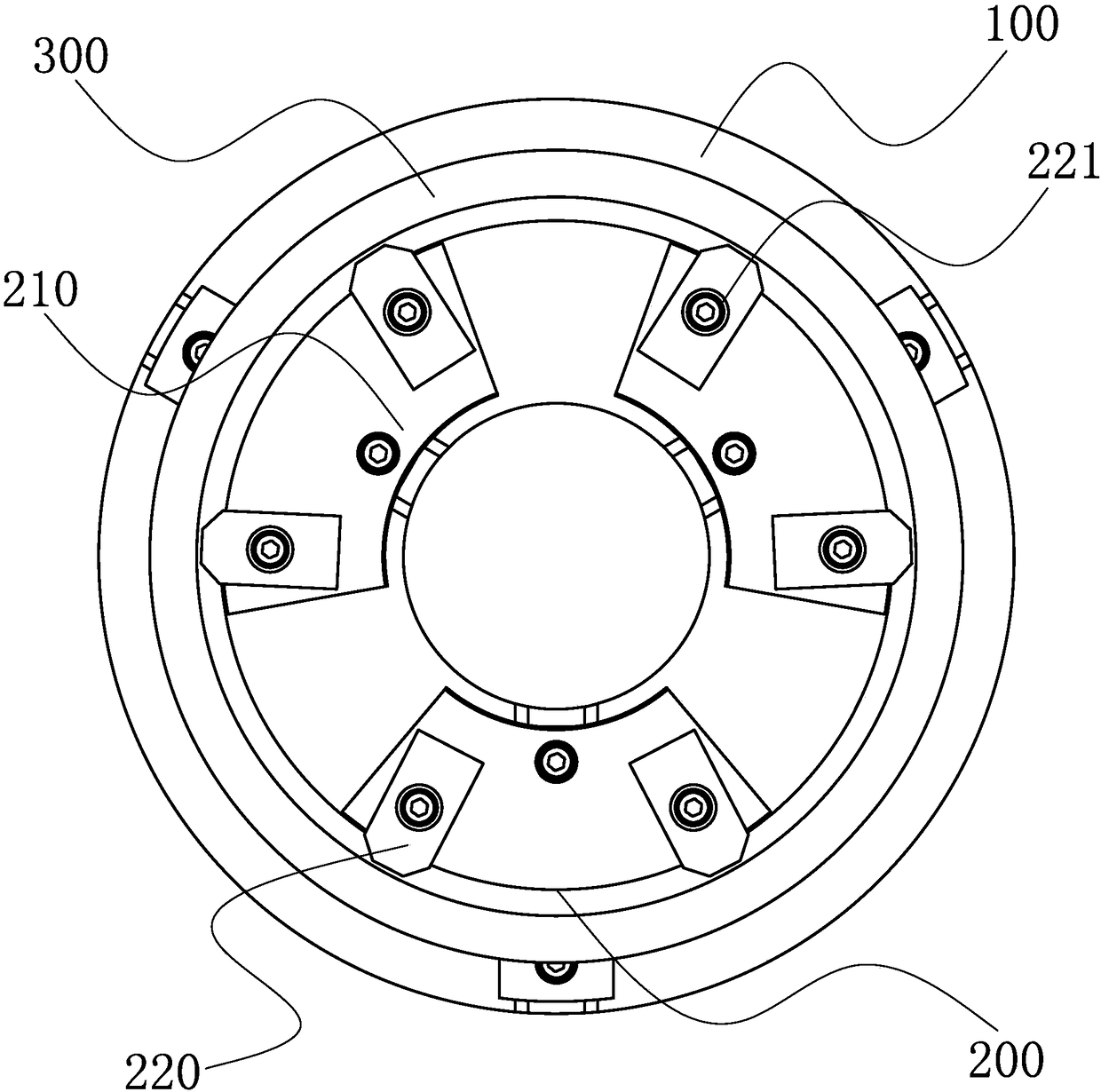

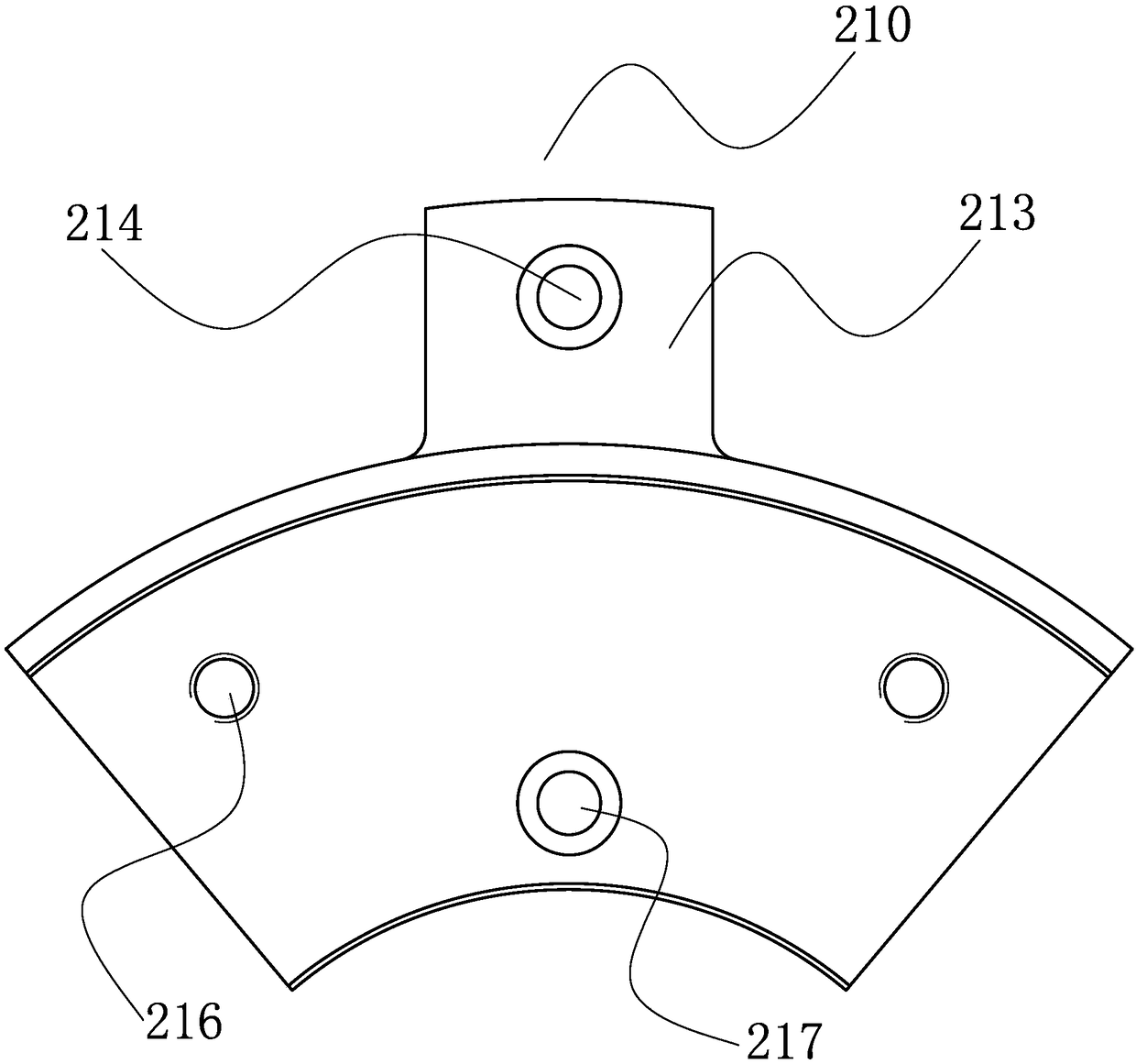

Precision excircle turning clamp for thin-wall flange

The invention provides a precision excircle turning clamp for a thin-wall flange. The precision excircle turning clamp comprises a chuck mounted on a machine tool, and a plurality of clamp bodies which are annularly arrayed along the axial direction of the chuck and are fixed on the chuck through threaded fasteners, wherein each clamp body comprises a clamping block with one end fixed on the chuck through the corresponding threaded fastener and the other end being an arc curved surface, and two pressing plates which are respectively located on two sides of the corresponding clamping block and are fixed on the clamping block through the threaded fasteners. According to the precision excircle turning clamp, provided by the invention, for the thin-wall flange, the thin-wall flange is circumferentially located by the clamping blocks mounted on the chuck and radially located by the pressing plates mounted on the clamping blocks, and the clamping blocks and the thin-wall flange as well as the pressing plates and the thin-wall flange are both in surface contact, so that the thin-wall flange can be located more precisely, and the turning accuracy is higher.

Owner:浙江金本汽车零部件有限公司

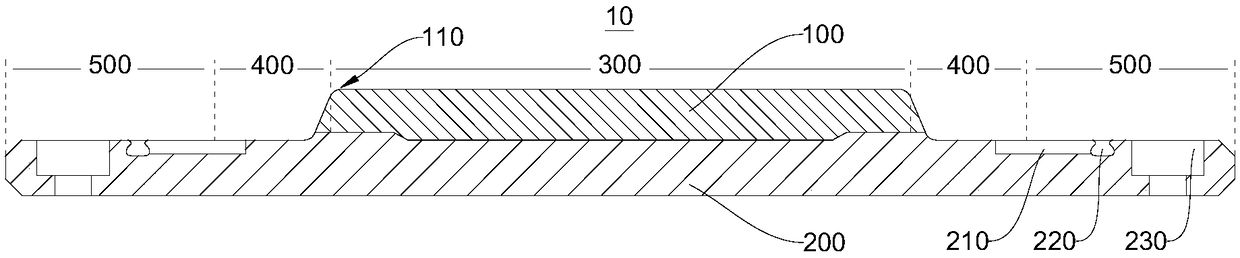

Target module and machining method

ActiveCN108581169AGood sputtering performanceQuality improvementNon-electric welding apparatusMachining processWeld line

The invention relates to the technical field of machining, and provides a target module and a machining method. The target module comprises a target and a back plate for bearing the target. The surface of the target comprises a front surface and a back surface; the front surface of the target is a sputtering surface of the target; the back surface of the target is opposite to the front surface ofthe target; a first step is projected on the back surface of the target; and the side surface of the first step is an inclined surface. A first groove matched with the first step is formed in the front surface of the back plate; the back surface of the target and the front surface of the back plate are connected through dispersion welding; and the first step is embedded in the first groove. In thedispersion welding process, the back surface of the target is tightly bonded with the front surface of the back plate; and a finally molded target module generates no welding line in the joint position of the two, so that the sputtering performance of the target can be improved, meanwhile, the problem related to the welding line cannot occur in subsequent machining process of the target module, and the quality of the produced target module is improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

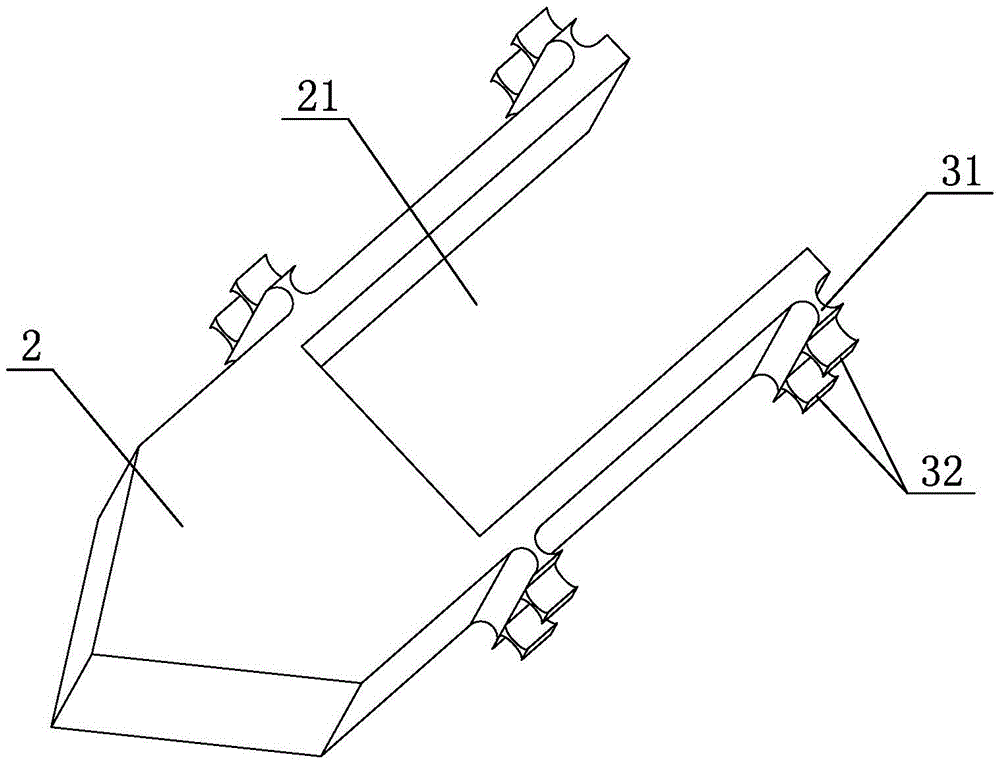

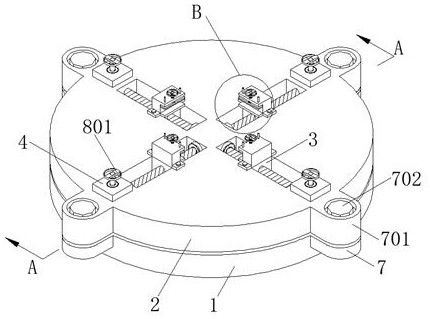

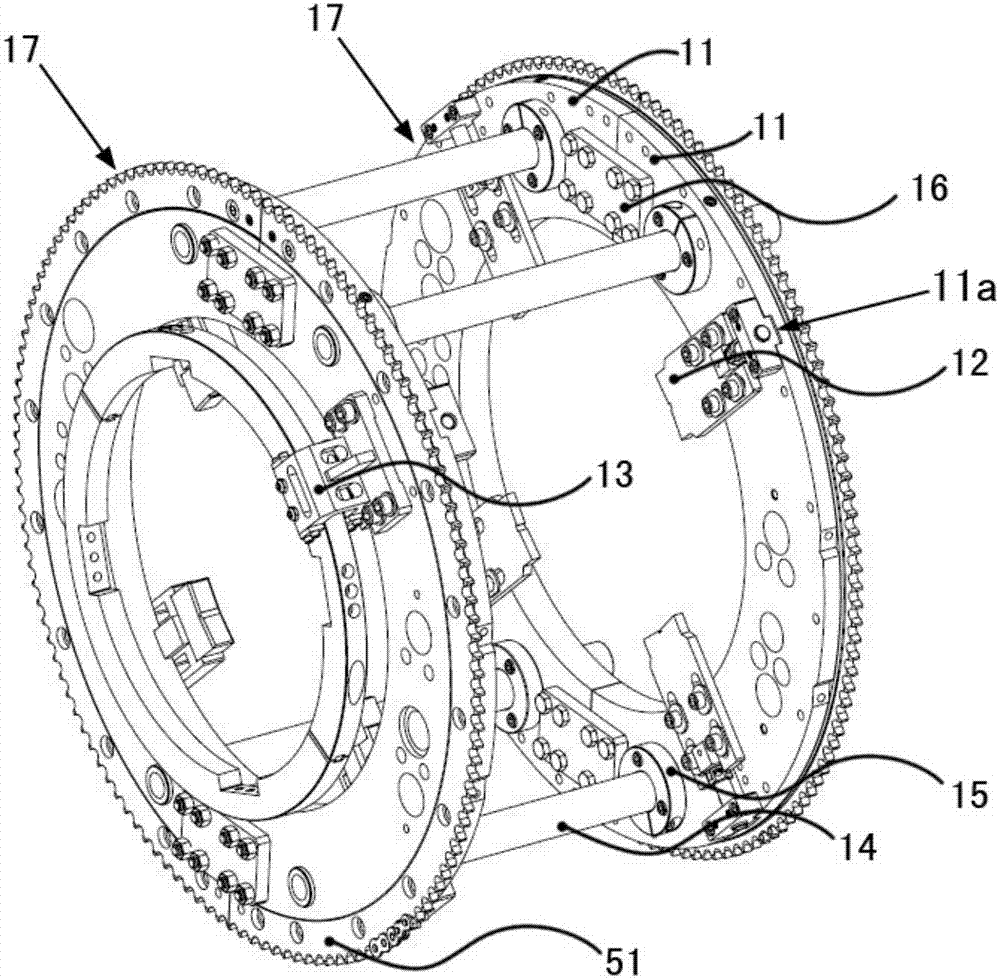

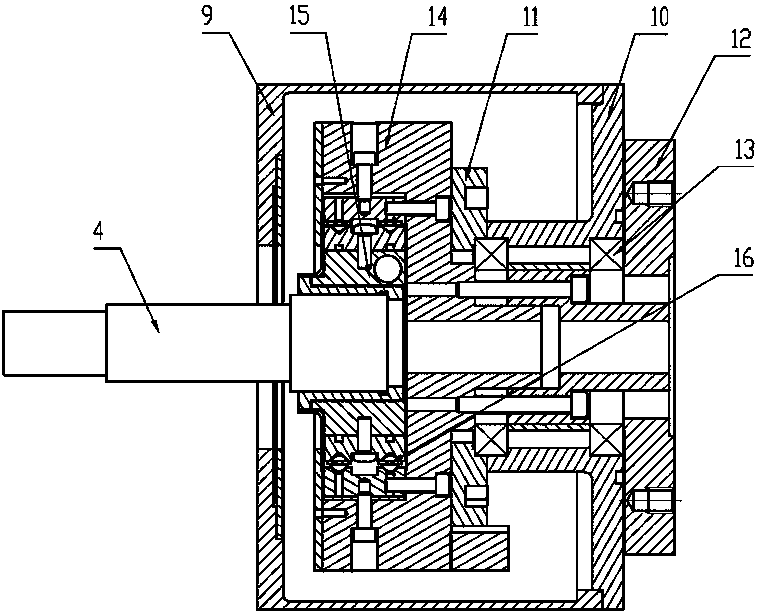

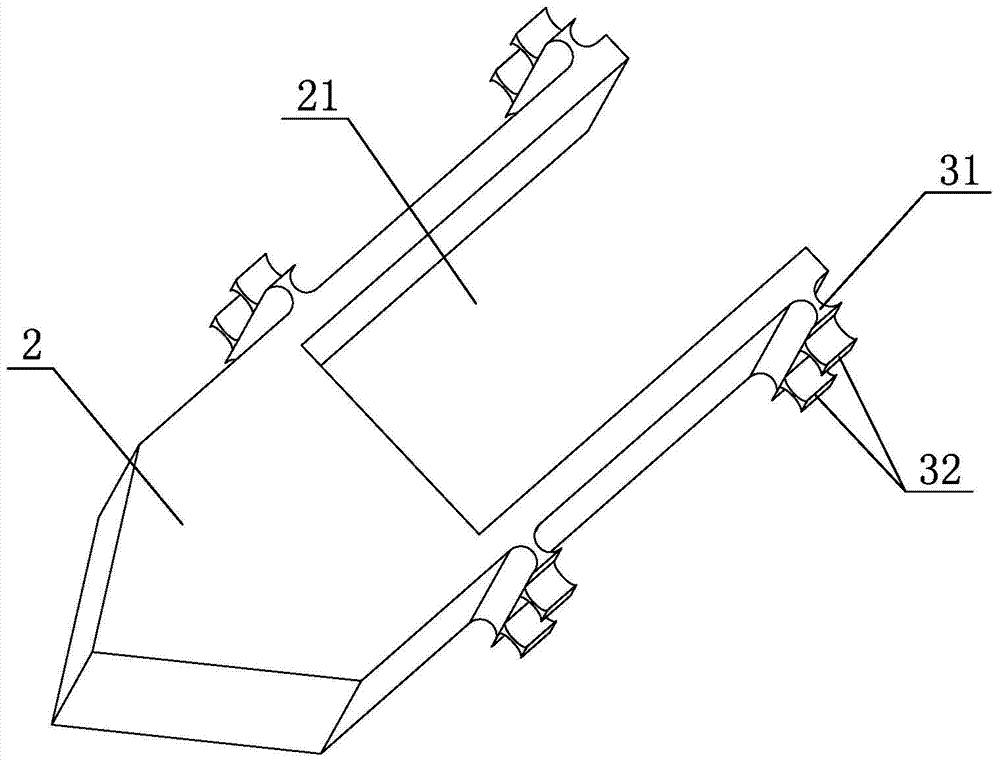

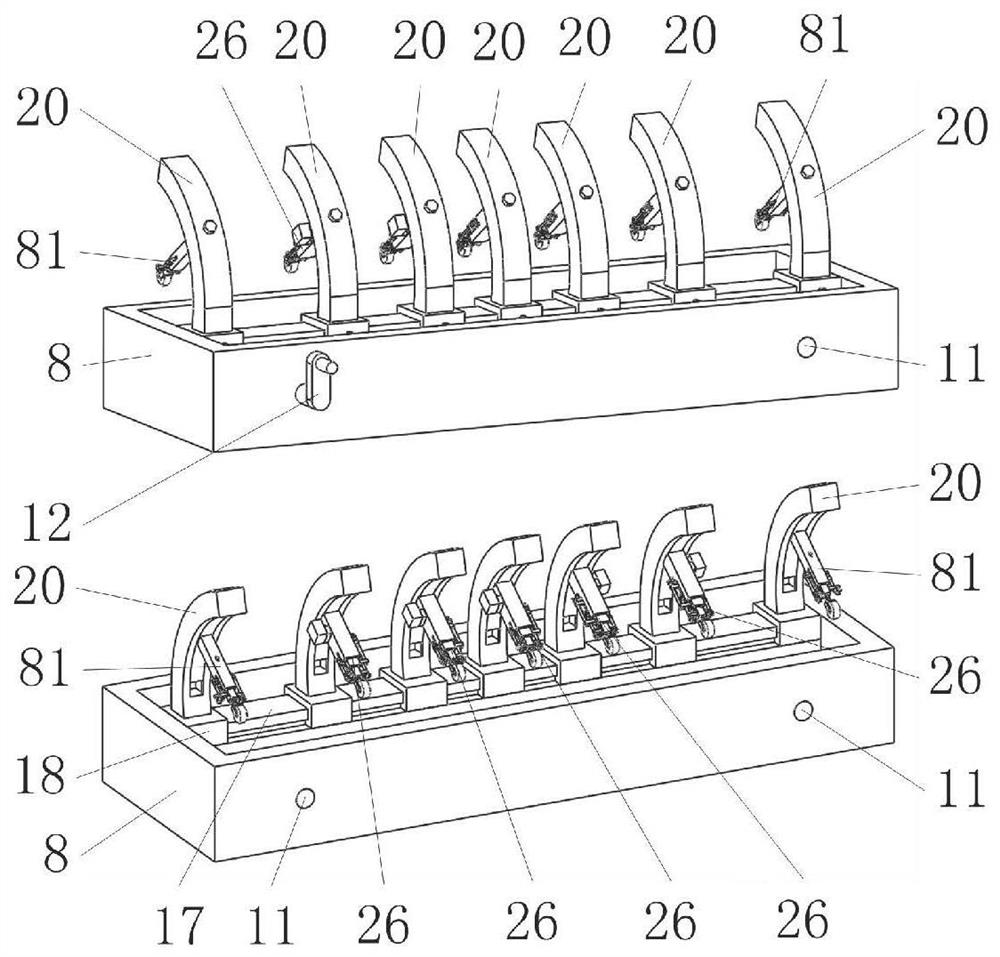

Floating fixture and method for processing inner and outer rings of single-row tapered roller bearing

InactiveCN105414584AShorten the inner and outer ring turning processFloating up and downBearing componentsChucksEngineeringMechanical engineering

The invention discloses a floating fixture and a method for processing inner and outer rings of a single-row tapered roller bearing. The floating fixture comprises a three-jaw chuck, three jaws, jaw clamping bodies, a floating connecting rod, and six clamping jaws. The three jaws are correspondingly connected with the three-jaw chuck. The number of the jaw clamping bodies is three. The three jaw clamping bodies are arranged respectively corresponding to the three jaws. The jaw clamping bodies are correspondingly connected with the three jaws through the floating connecting rod. Limiting screws are also connected between the jaw clamping bodies and the three jaws. The number of the limiting screws is two. The two limiting screws are respectively symmetrically arranged on two sides of the floating connecting rod. Each jaw clamping body is meshed and connected with the two clamping jaws through teeth. The three jaws and the jaw clamping bodies are connected through the floating connecting rod, and the limiting screws are connected between the jaw clamping bodies and the three jaws. Through the floating connecting rod, the limiting screws play certain up-down floating roles in a clamping process. In turning bearing forging, the fixture improves turning precision, and shortens a turnery process of the inner and outer rings of a single-row tapered roller bearing.

Owner:CHENGDU TIANMA RAILWAY BEARING

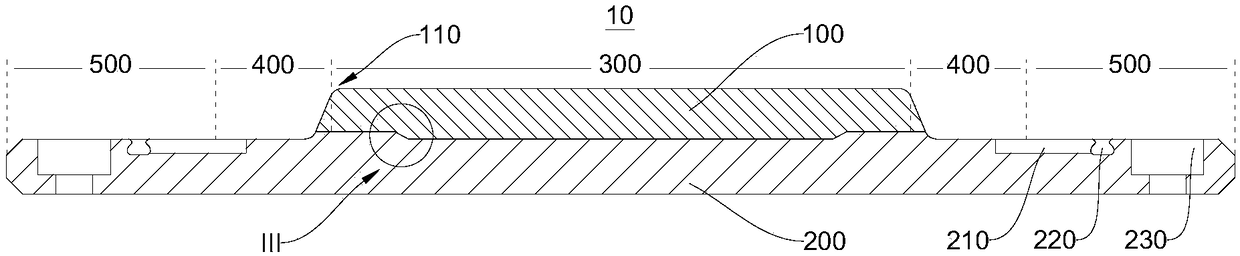

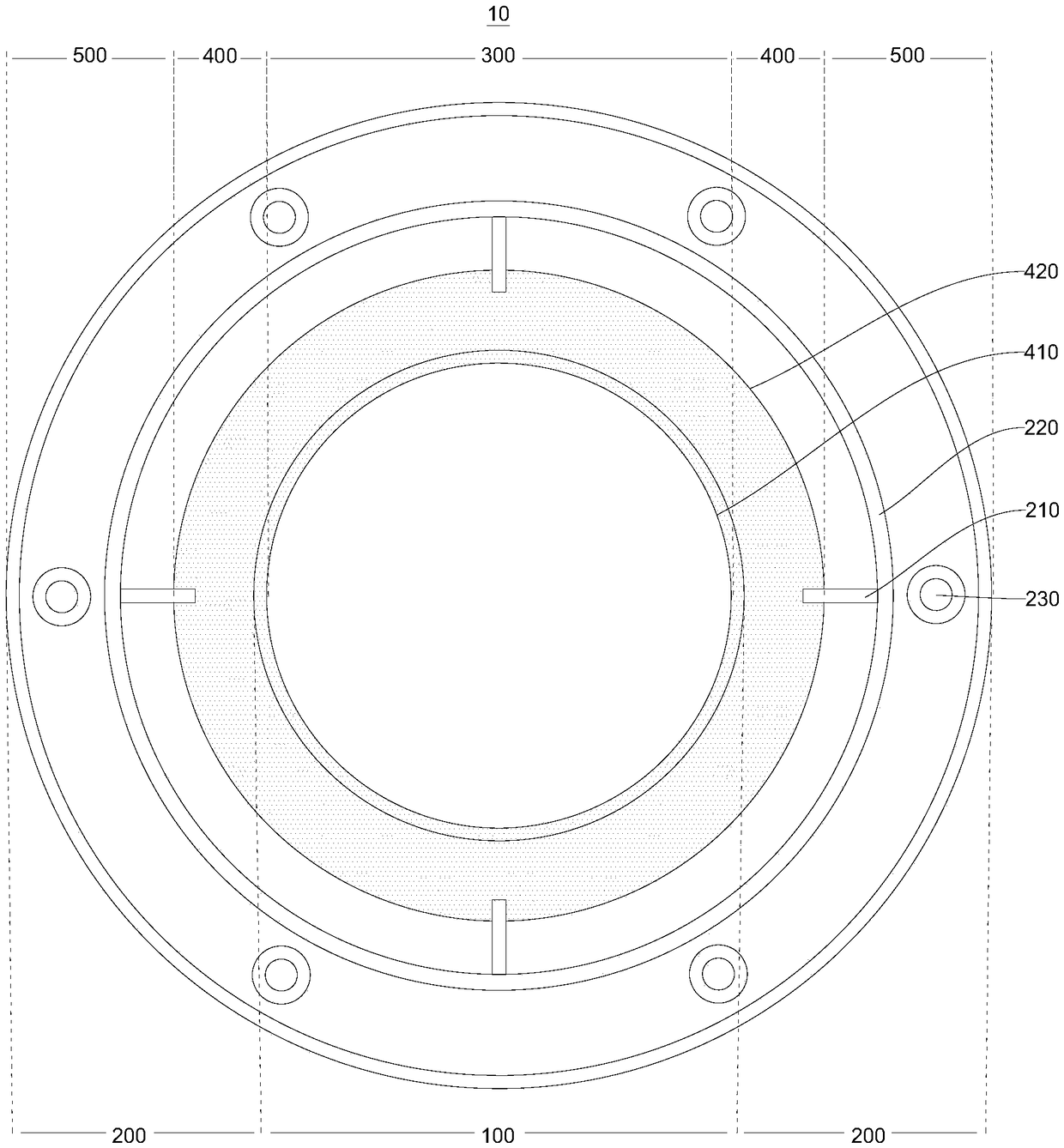

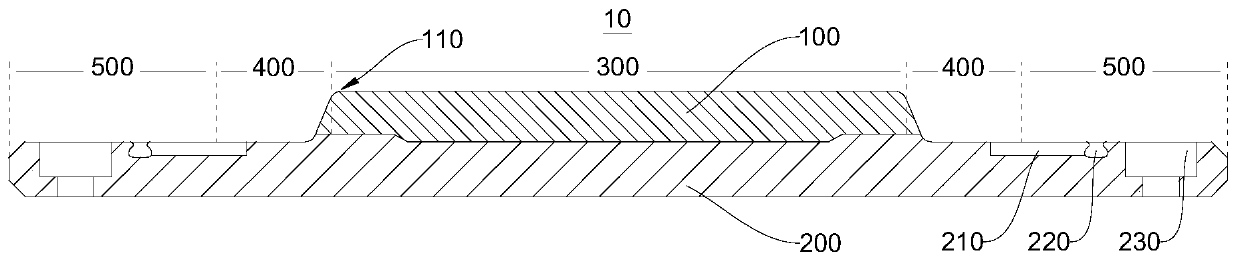

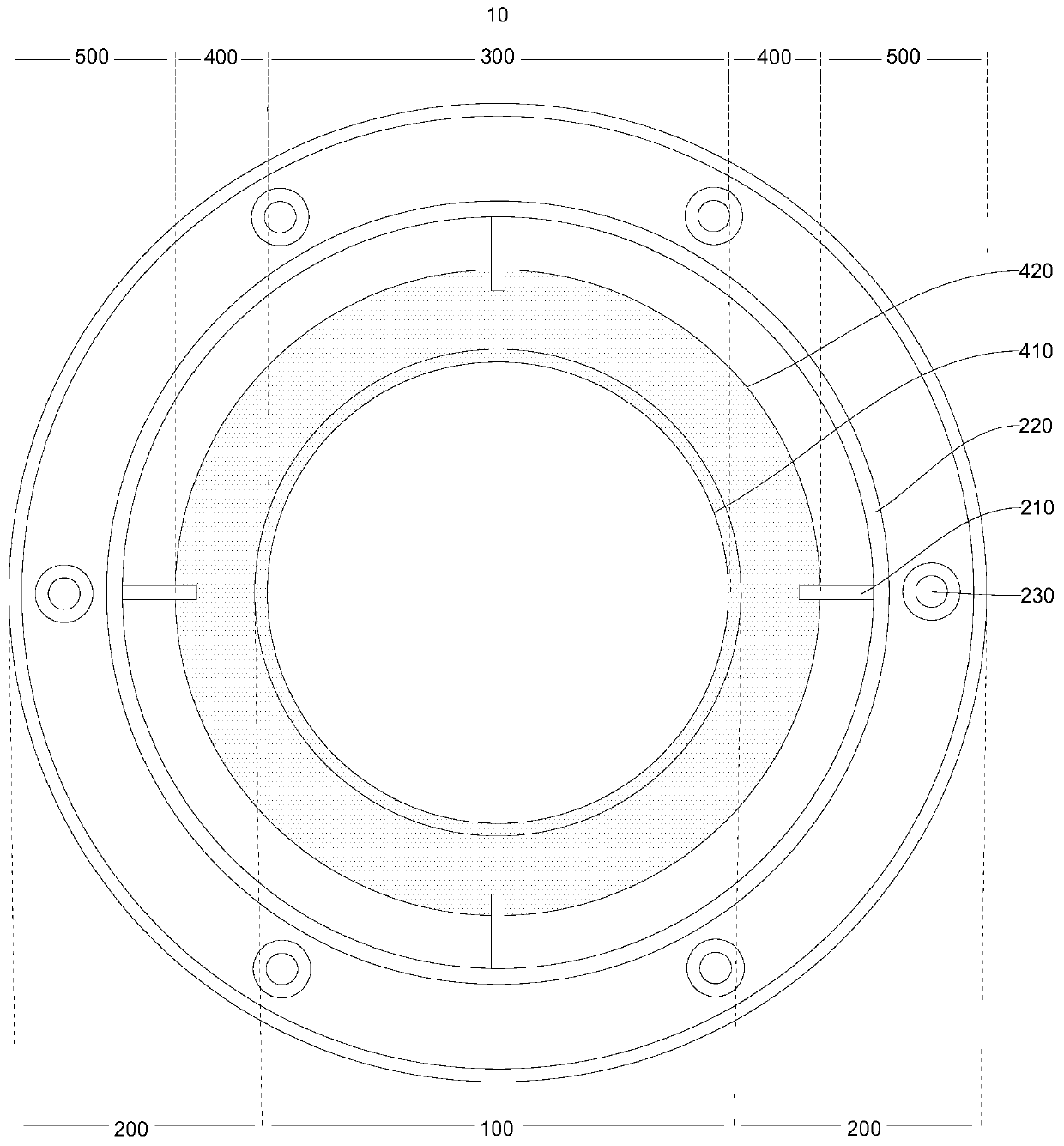

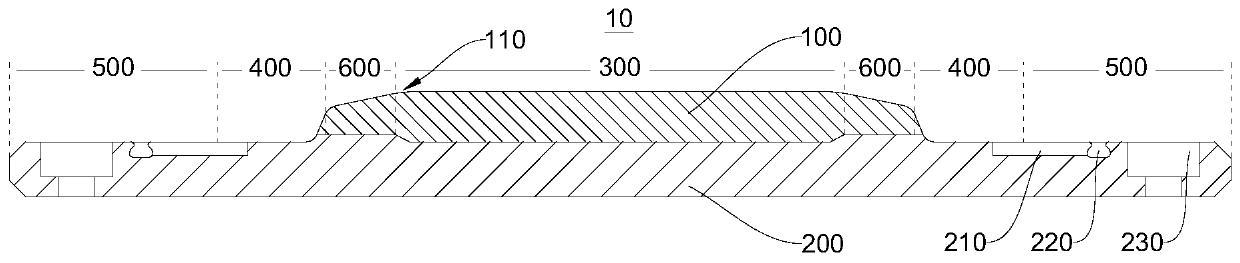

Target component and processing method

ActiveCN108611608AImprove turning accuracyMeet the process requirementsVacuum evaporation coatingSputtering coatingEngineeringBoundary line

The invention relates to the technical field of machining, and provides a target component and a processing method. The target component comprises a target and a backing plate used for bearing the target, wherein the surface of the target comprises a front side, a back side and sides, and the front side of the target is the sputtering surface of the target; and the back side of the target is opposite to the front side of the target, and the sides of the target are adjacent to the front side and the back side of the target separately. Meanwhile, the back side of the target is connected to the front side of the backing plate, and the sides of the target are adjacent to the front side of the backing plate; and the junction positions between the sides of the target and the front side of the backing plate are provided with sand blasting areas formed through sand blasting treatment and surrounding the sputtering surface, and the distances between the points of the same sand blasting line ofthe sand blasting areas and the center point of the sputtering surface are the same, wherein the sand blasting lines are the boundary lines of the sand blasting areas. The sand blasting areas of the target component have tidy sand blasting lines, so that abnormal sputtering is not generated in the sputtering process of the target, and semiconductor chips can be produced smoothly.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

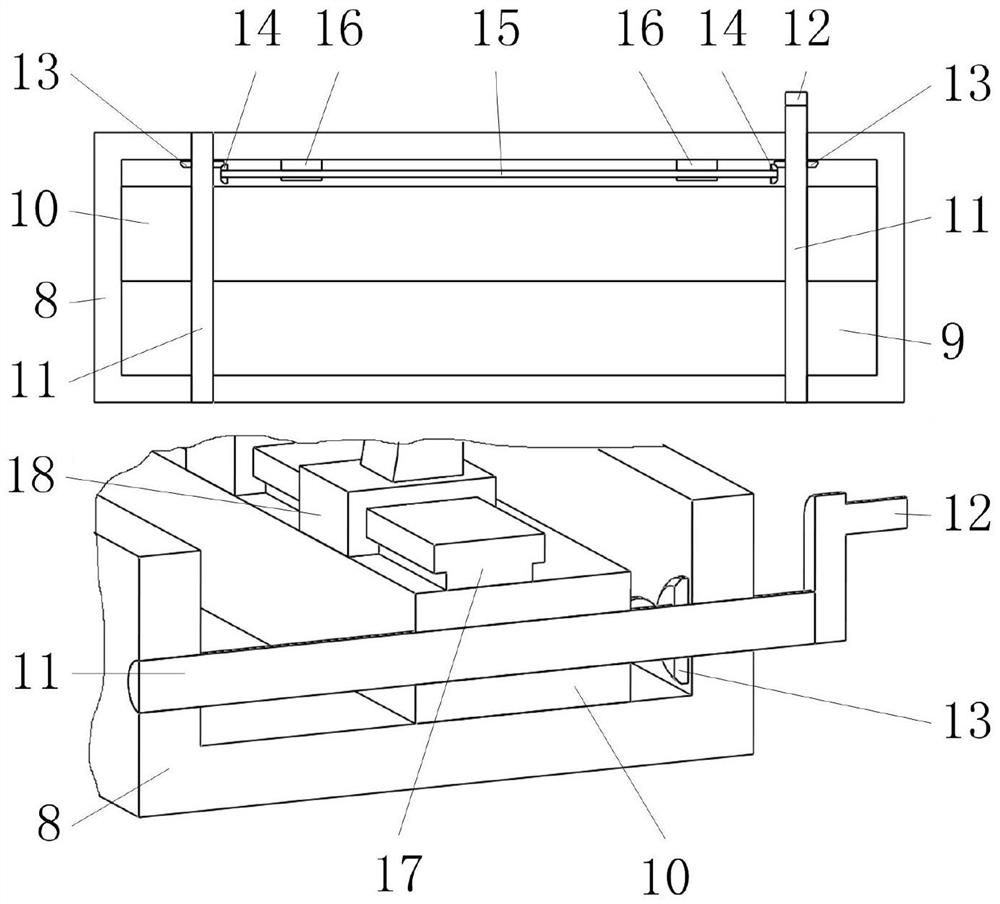

Multifunctional tool used for turning external circle of large-diameter thin-wall part

InactiveCN105750566AImprove turning accuracyReduce weightWorkpiecesBoring/drilling apparatusEngineeringMechanical engineering

The invention provides a multifunctional tool which is used when an external circle of a large-diameter thin-wall part is turned, and provides a multifunctional tool used for turning the external circle of the large-diameter thin-wall part. A locking nut tightly presses a slide rod, and the angle of a supporting rod is changed; a movable rod is expanded or reduced so that the diameter size is changed. The multifunctional tool used for turning the external circle of the large-diameter thin-wall part has the beneficial effects that the turning precision of the thin-wall part is improved, and parts with different lengths and diameters share one set of equipment and the equipment can also be used for revising the roundness of thin-wall blanks.

Owner:NINGXIA JIHUA ENVIRONMENTAL SAFETY SCI & TECH CO LTD

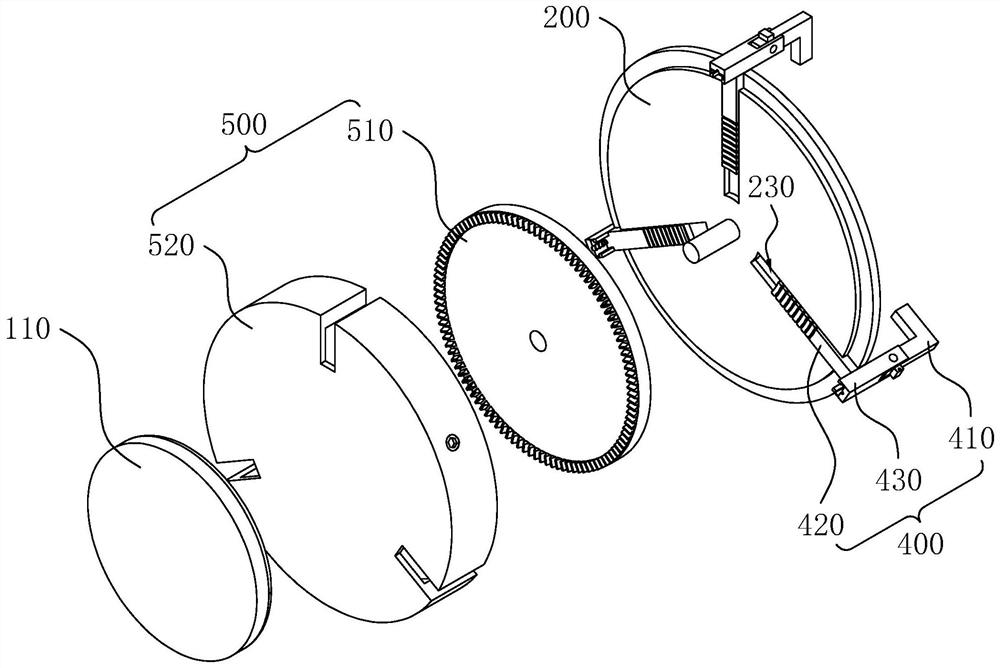

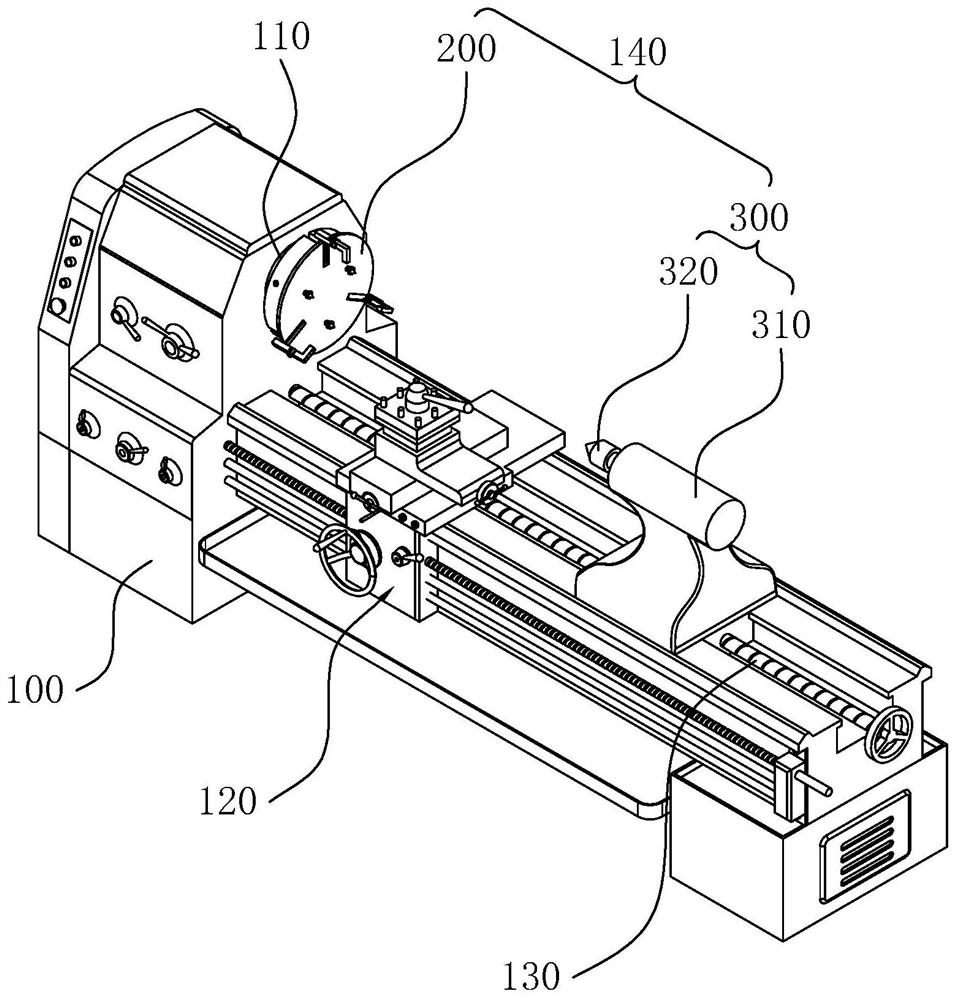

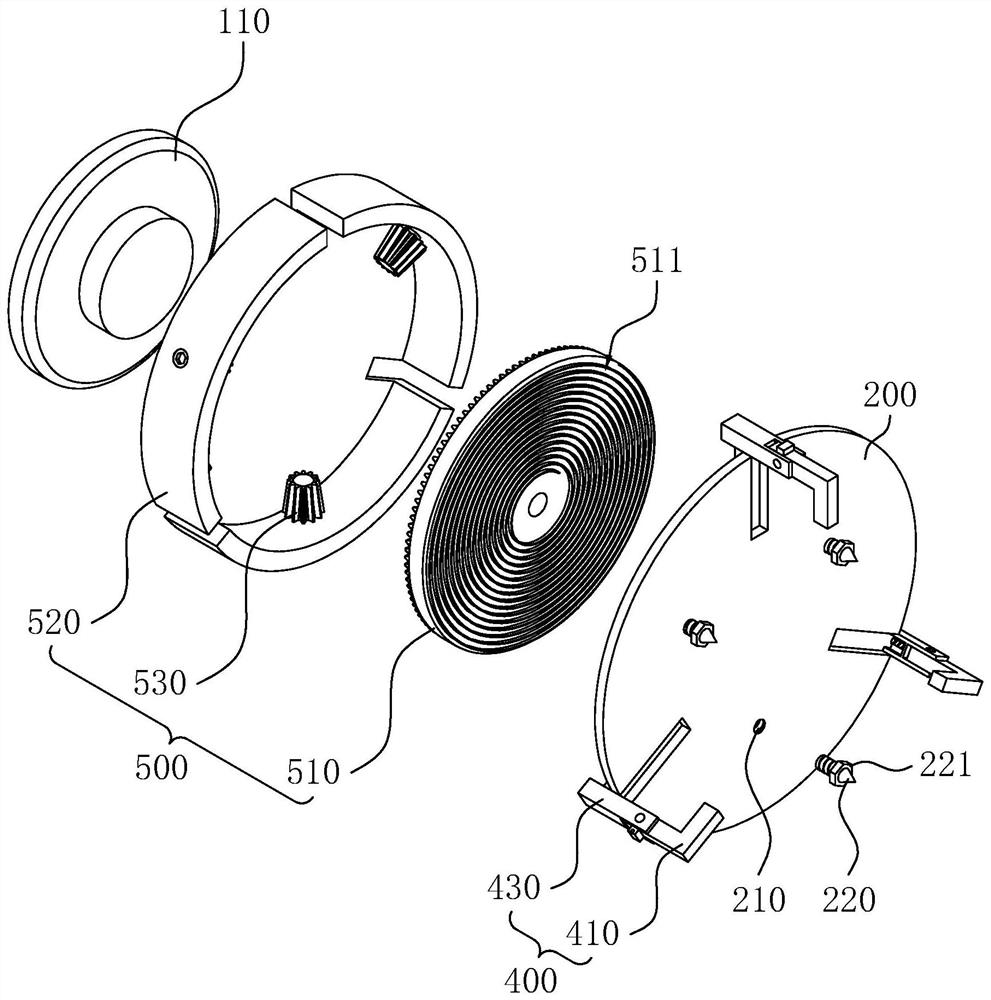

Bearing ring clamp

PendingCN112496790AAvoid clampingAvoid deformationWork clamping meansPositioning apparatusStructural engineeringAnnular array

The invention discloses a bearing ring clamp. The bearing ring clamp comprises a base, wherein a mounting groove allowing a first bearing to be fixedly arranged is formed in the center of the top endof the base, a shaft rod is movably connected into the first bearing, and a movable seat is fixedly welded to the end, away from the base, of the shaft rod; the top end of the base and the bottom endof the movable seat are provided with annular grooves allowing rollers to slide, the top end of the movable seat is provided with two sets of rectangular sliding grooves allowing rectangular sliding blocks to slide in an annular array, the top end of the movable seat is provided with two sets of rectangular grooves in an annular array, and the top ends of the rectangular sliding blocks are fixedlyconnected with L-shaped fixing parts; and a threaded hole is formed in the center of one side of the top end of each L-shaped fixing part. According to the bearing ring clamp, the situation that a bearing ring is clamped from the outer edge face is avoided, deformation of the bearing ring is avoided, the turning precision is improved, the practicability is high, rotation can be conducted, time and labor are saved when workers fix the bearing ring, and the installation speed is improved.

Owner:常熟缘阳机械制造有限公司

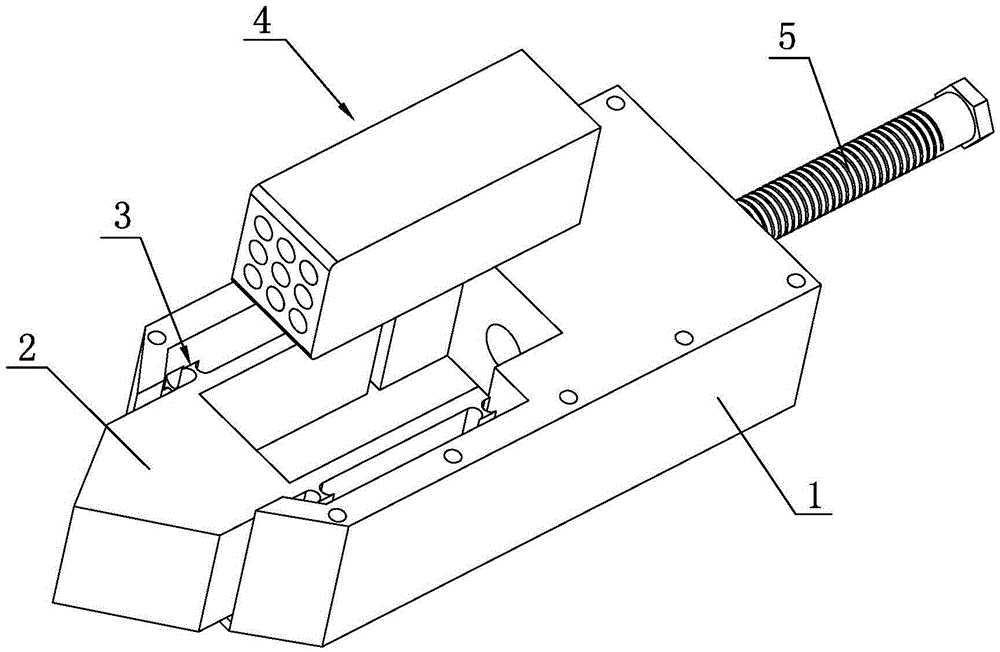

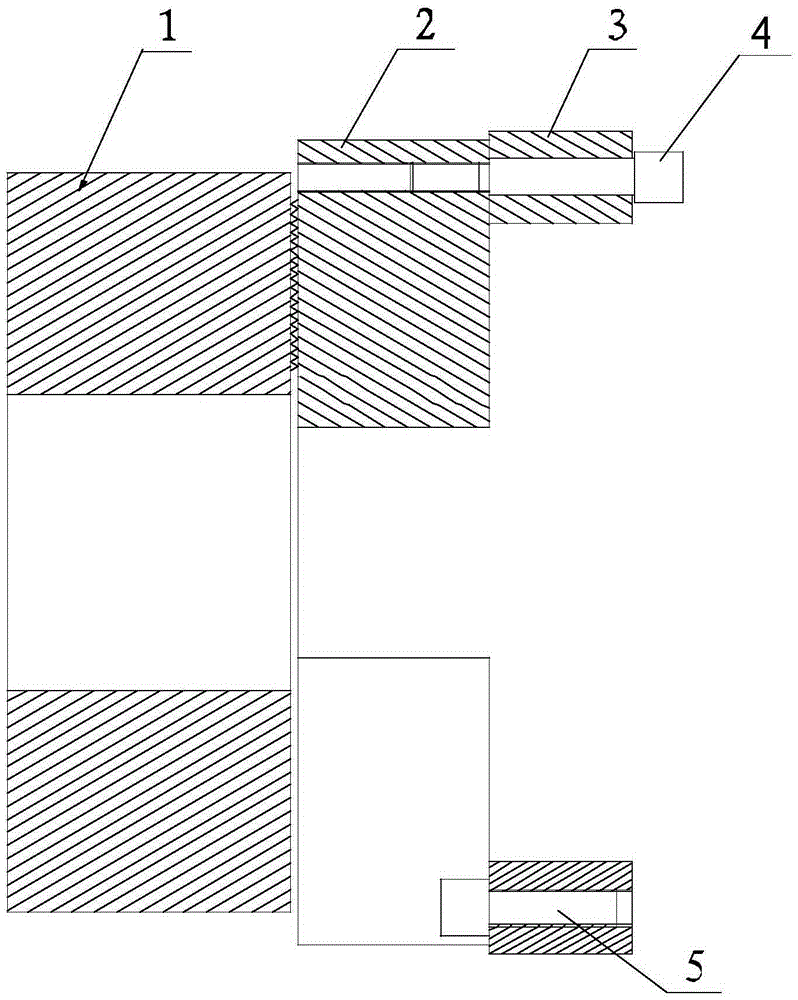

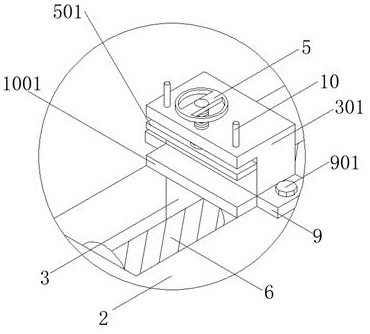

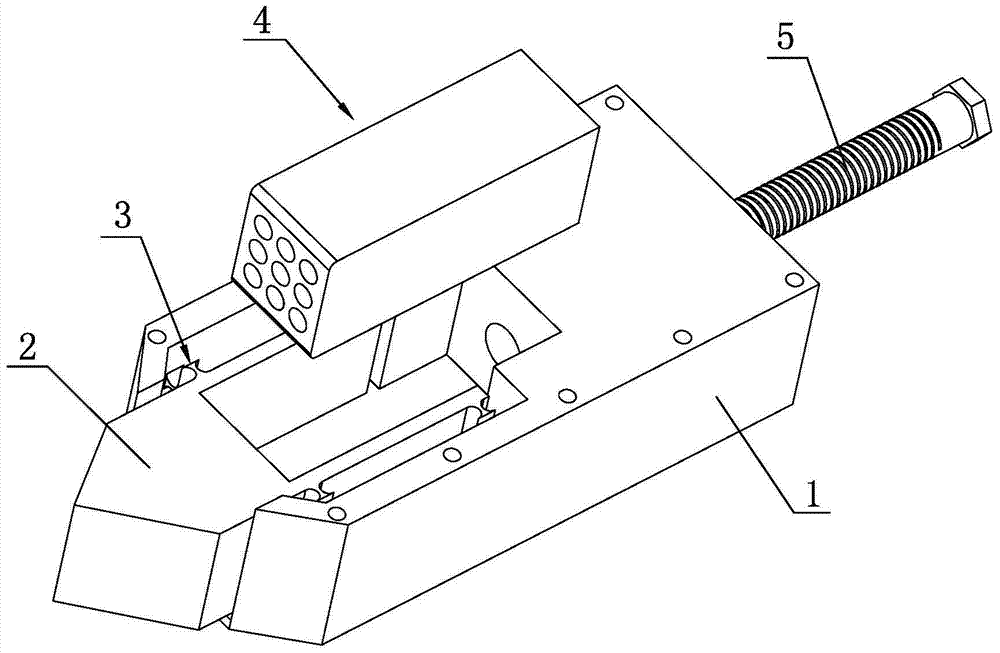

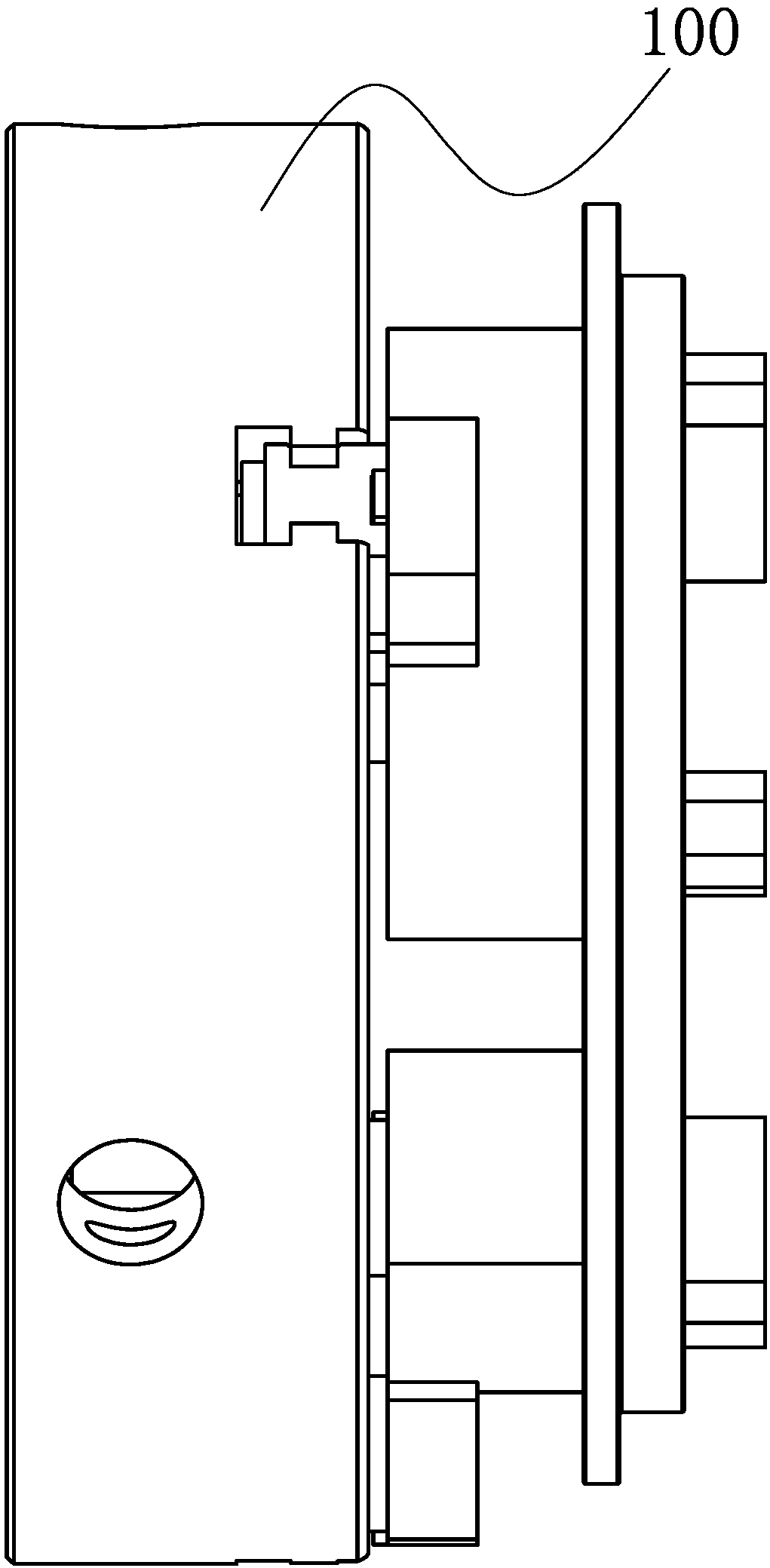

Turning tool with pushing mechanism

The invention relates to a turning tool with a pushing mechanism. The turning tool comprises a tool body, wherein a cavity structure is formed in the tool body; the tool body is internally provided with a tool rod capable of sliding along the axial direction of the tool body; a tool bit is arranged at the end part of the tool rod; a positioning bolt, which penetrates into the cavity, is arranged on the tool body; the positioning bolt is in butt joint with the tool rod; the pushing mechanism is further arranged at one end of the tool body; the pushing mechanism comprises an adjusting device, a push rod connected to the adjusting device and an ejection block fixed at the end part of the push rod; and the ejection block is in jacking joint with the end part of the tool rod. The pushing mechanism is further arranged at one end of the tool body and the tool rod in the tool body is pushed and pulled through the pushing mechanism, so that the displacement of the tool bit is realized. The pushing mechanism comprises the adjusting device, the push rod connected to the adjusting device and the ejection block fixed at the end part of the push rod; the ejection block is in jacking joint with the end part of the tool rod; and the accurate displacement of the push rod can be realized through fine adjustment of the adjusting device, so that the accurate displacement of the tool bit is driven and the turning precision is greatly improved.

Owner:JIANGYIN SAITE PRECISION TOOL

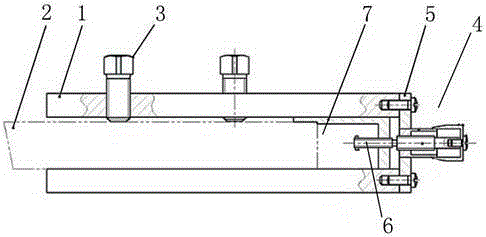

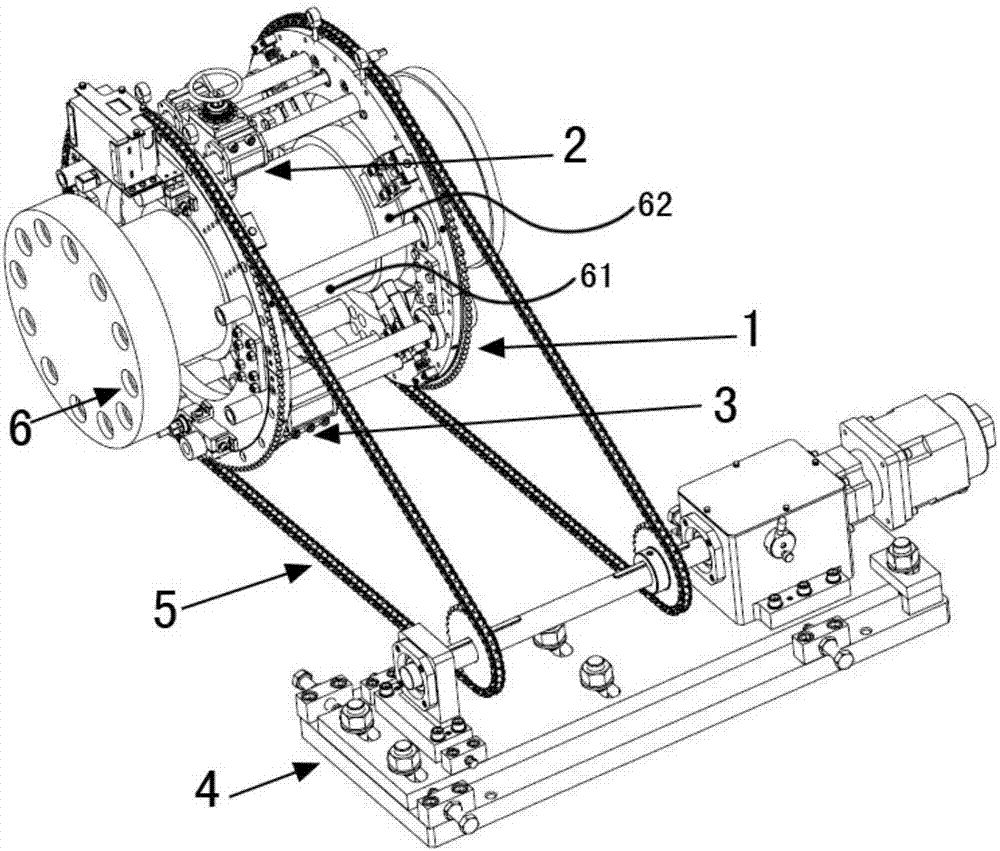

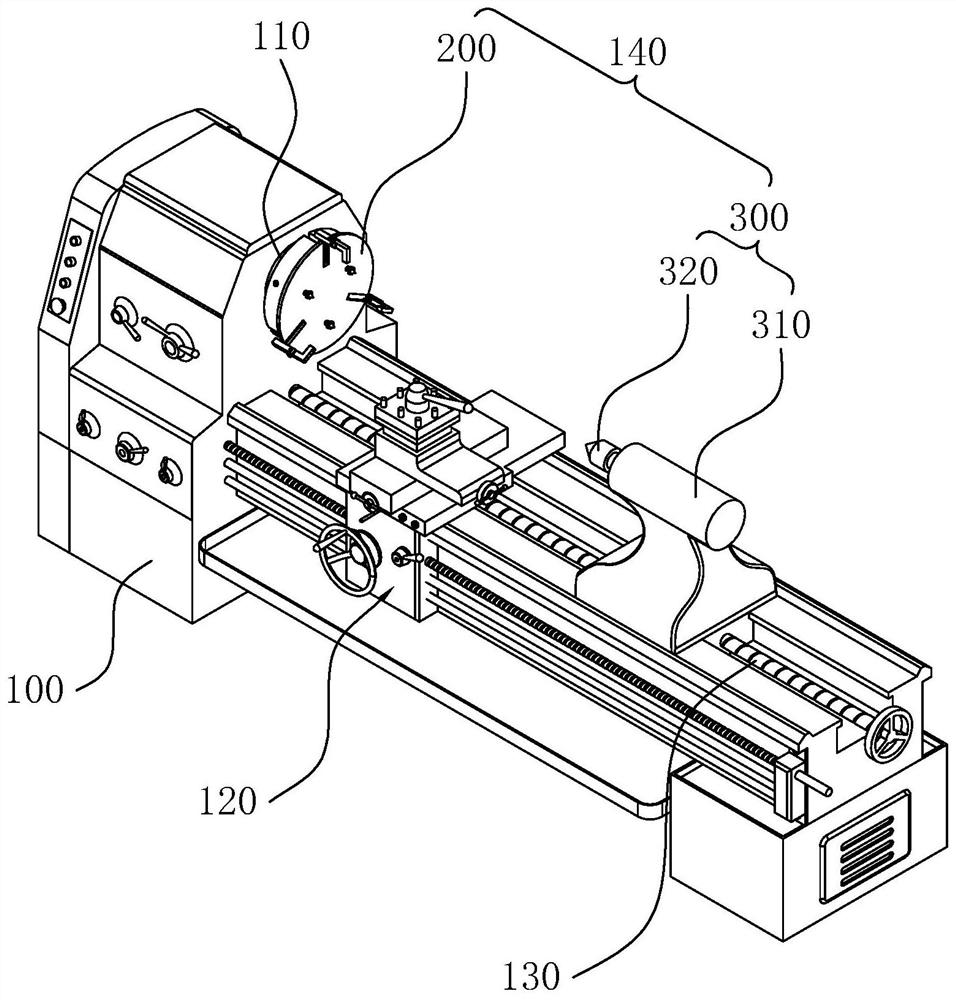

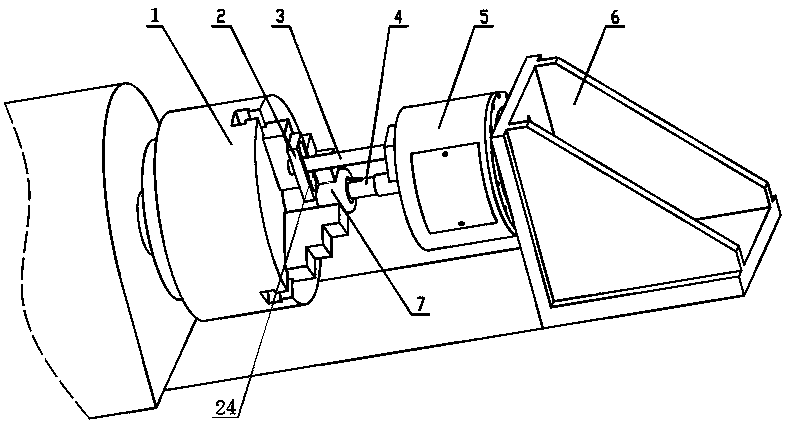

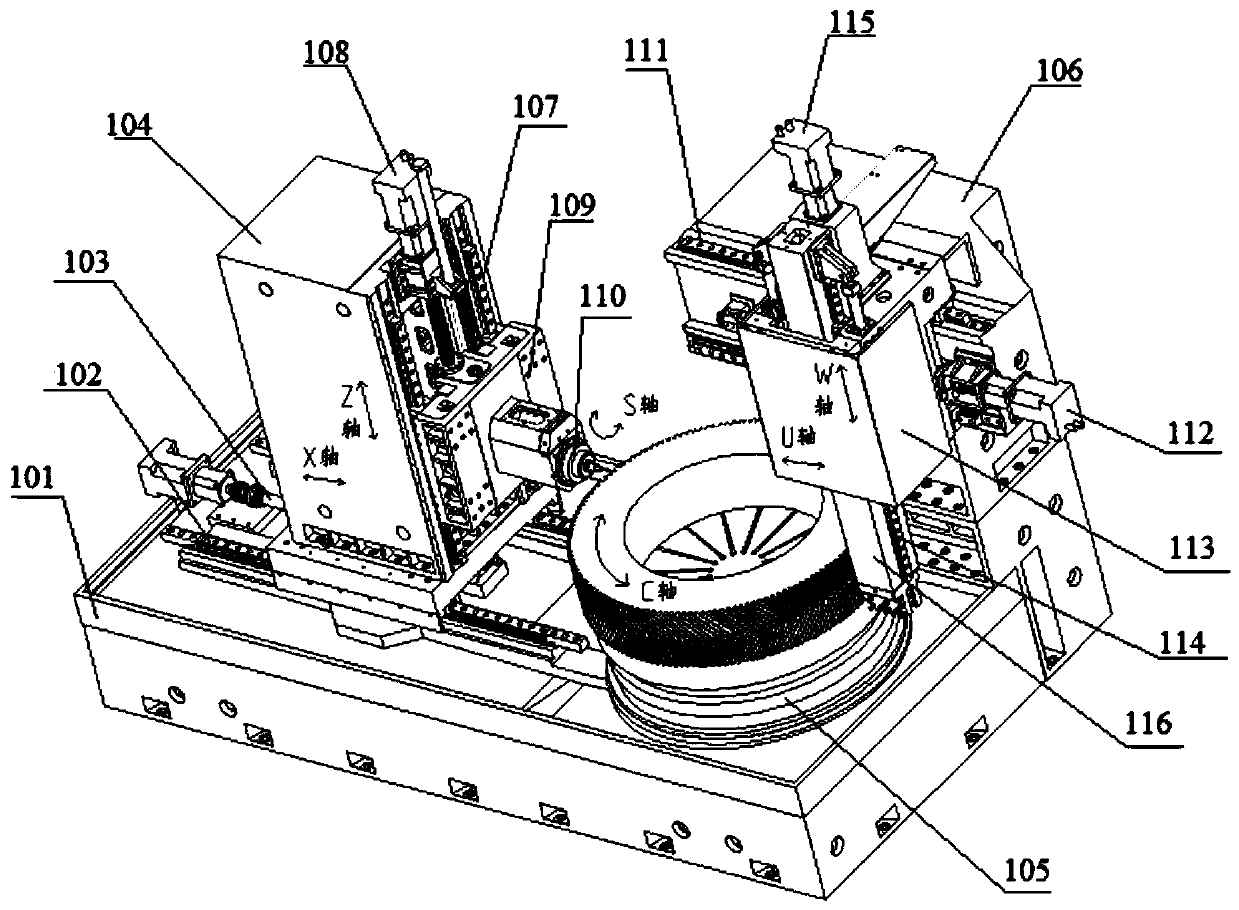

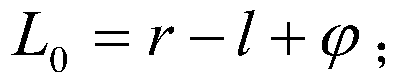

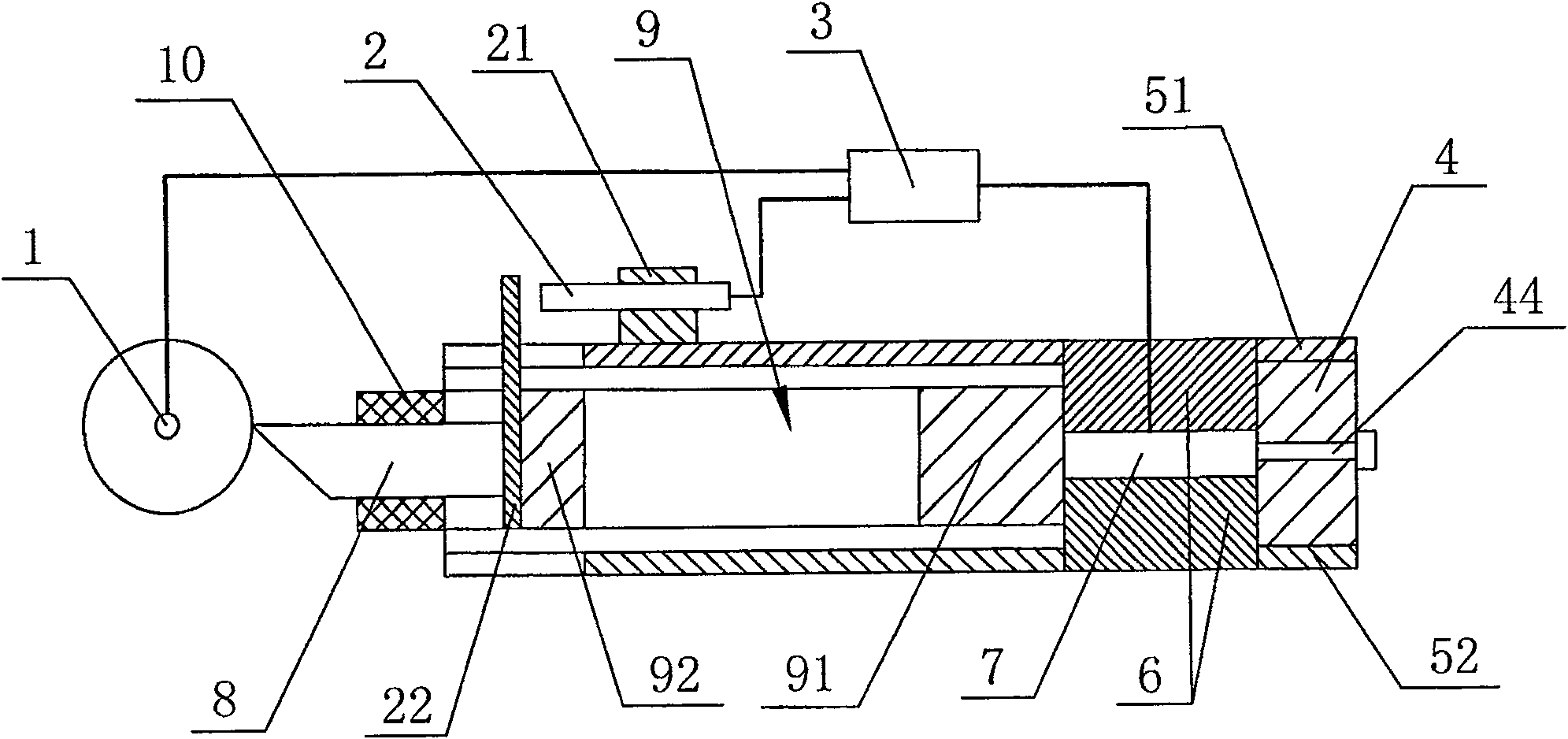

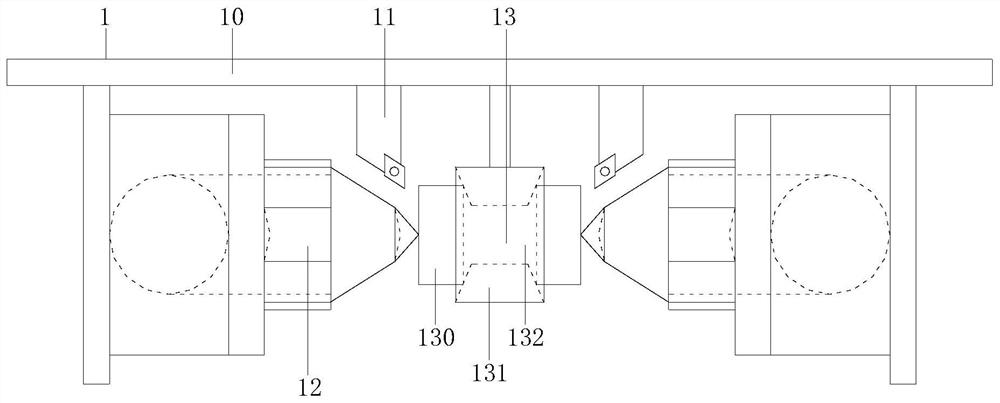

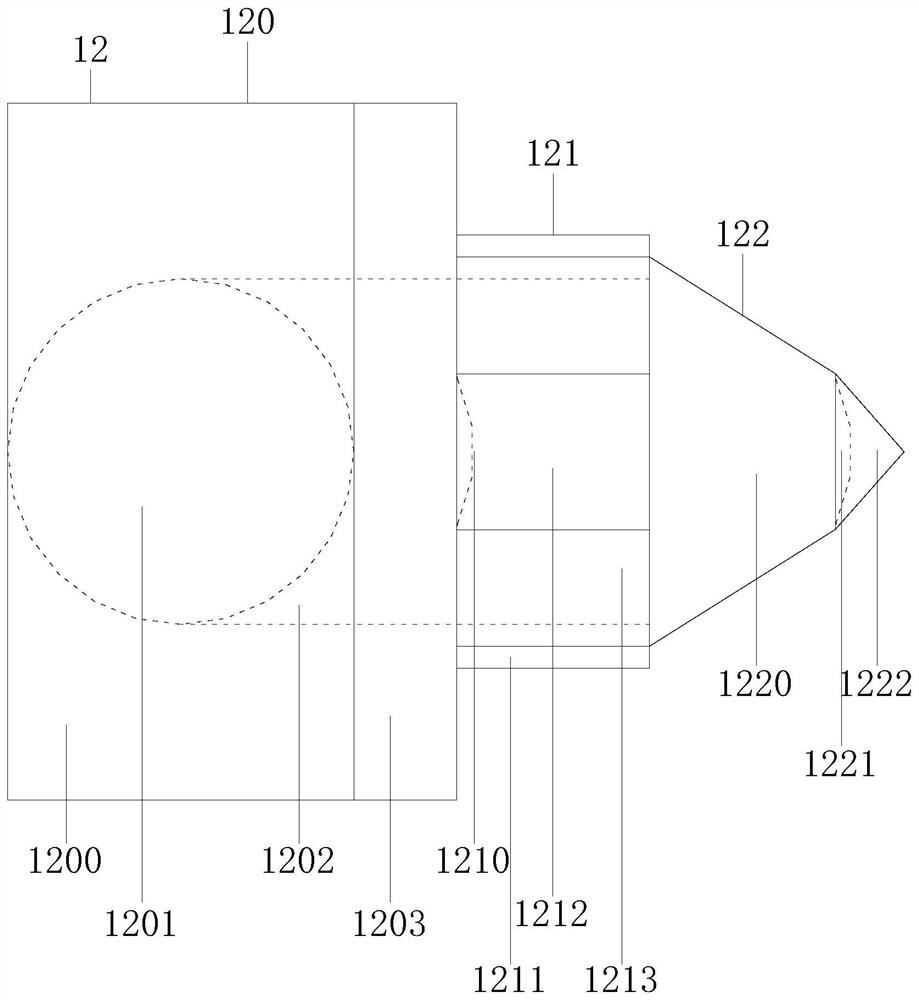

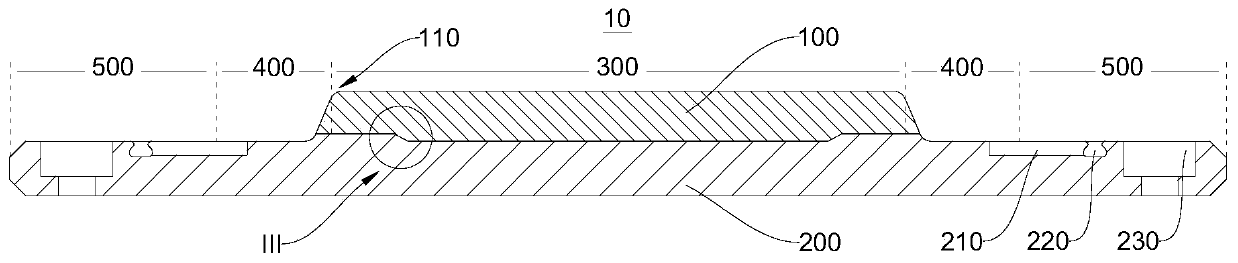

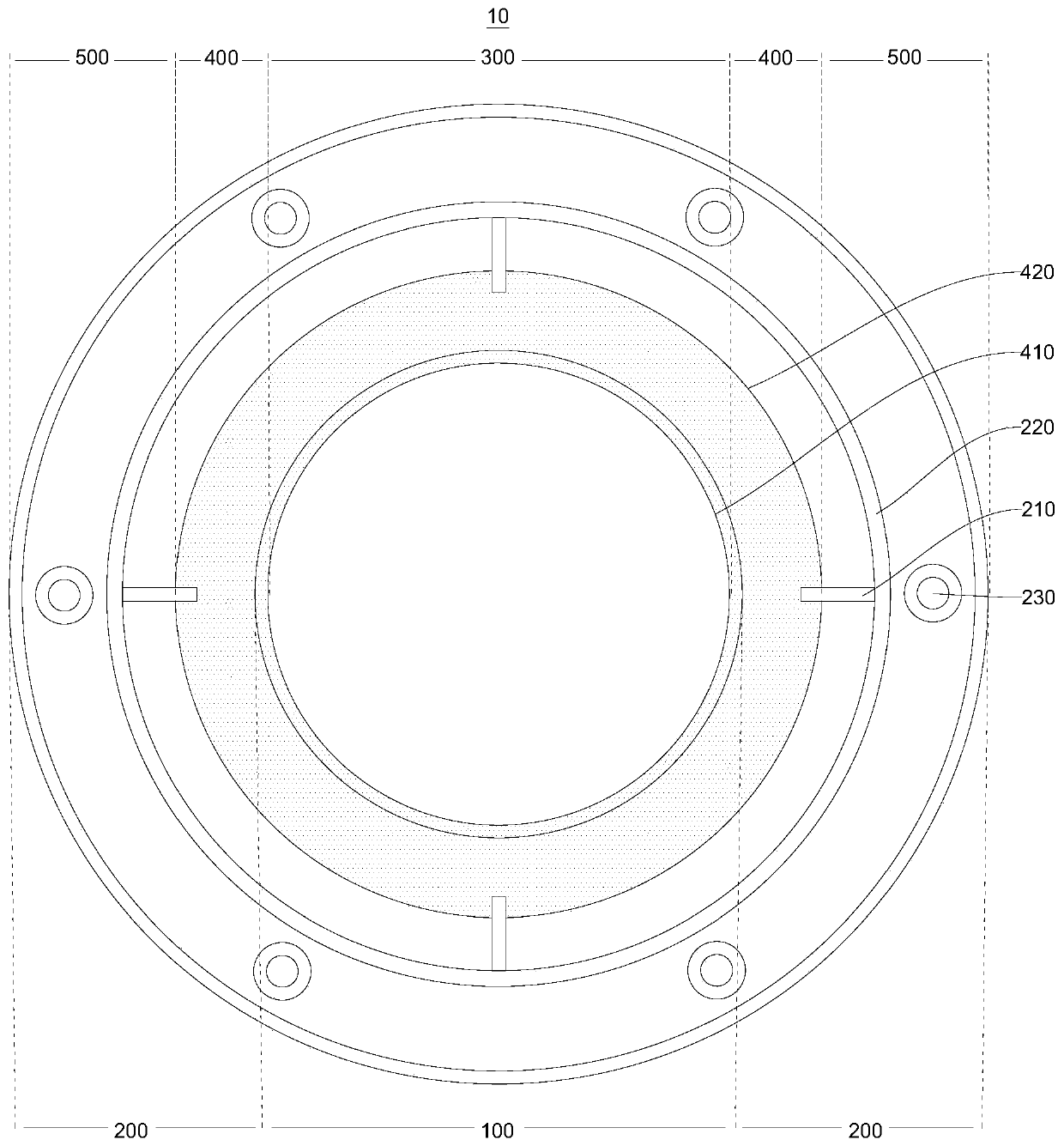

Large-scale shaft part shaft neck turning equipment and turning process

InactiveCN106862591AAvoid vibrationHigh dimensional accuracyLarge fixed membersTurning machinesEngineeringMachining

The invention provides an equipment and turning process for journal turning of large shaft parts, including a turning assembly, a power mechanism, and a turning mechanism clamped on the large shaft parts. The turning mechanism includes two clamping parts arranged at intervals in the axial direction , the turning assembly can be disassembled and assembled between two clamping parts. There are center holes on both clamping parts. The two center holes are set coaxially and are used to pass through large shaft parts. Both are equipped with a positioning assembly connected to the orientation of large shaft parts. Each clamping part is connected to the power mechanism through a transmission assembly. Driven by the power mechanism, the two clamping parts rotate around the large shaft parts synchronously to realize driving turning. Components are used for turning repair of the journal of large shaft parts. The present invention can control the amount of cutting and the cutting amount of the back, and adopt different processing parameters such as cutting speed according to the rough and finishing processing, so as to avoid equipment vibration and achieve high dimensional accuracy and shape and position tolerance.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD +1

Turning clamp for blind flange

ActiveCN112872394ATurn easilyReduce clamping errorsChucksTurning machinesClassical mechanicsMetal machining

The invention relates to a turning clamp for a blind flange, and relates to the technical field of metal machining equipment. The turning clamp for the blind flange comprises a base plate, a first pressing mechanism and a second pressing mechanism, wherein the first pressing mechanism comprises a tailstock and a tail cone; the tail cone is rotatably connected onto the tailstock; the tail cone and the base plate are coaxially arranged; the base plate is coaxially and fixedly connected onto a main shaft of a lathe; the second pressing mechanism comprises a clamping jaw; and the clamping jaw is connected onto the base plate in a sliding mode. According to the turning clamp for the blind flange provided by the invention, when the peripheral face of a workblank is machined, the base plate and the tail cone are used for clamping the workblank, so that the peripheral face of the workblank can be completely exposed outside; and when a boss of theworkblank is machined, the workblank is clamped by the base plate and the clamping jaw, so that the axis part of the workblank can be completely exposed outside, and feeding of a turning tool is facilitated.

Owner:济南江华锻铸机械有限公司

Piston ring manufacturing process beneficial to chromium plating quality

The invention discloses a piston ring manufacturing process beneficial to chromium plating quality. The piston ring manufacturing process comprises the steps of clamping, inner and outer circle profiling, inlaying groove shaping, chamfering of an external angle, chromium plating, outer circle shaping grinding and honing; the inlaying groove shaping step adopts turning treatment; the turning treatment comprises two processes of rough turning and finish turning; the finish turning process comprises two process steps of half finish turning and finish turning. The process route is high in processing efficiency, uniform in thickness of a chromium coating, high in turning precision and long in service life of the cutting tool.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

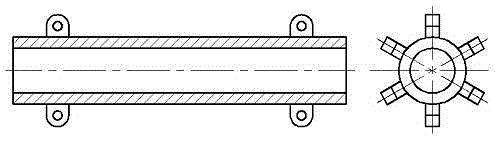

Machine tool laser compensation device for slender shaft machining and compensation method conducted though machine tool laser compensation device

InactiveCN112719951ASolve the machining accuracyEasy to useMeasurement/indication equipmentsLarge fixed membersElectric machineryStructural engineering

The invention discloses a machine tool laser compensation device for slender shaft machining and a compensation method conducted though the machine tool laser compensation device. The device comprises a self-compensation center frame, springs, supporting rods, lead screws and motors. The self-compensation center frame is provided with a groove body which is formed in the thickness direction of the self-compensation center frame in a penetrating manner, and the groove body is round. The springs are arranged on the supporting rods in a sleeving manner and located on the outer side of the self-compensation center frame, one end of each spring is connected with the corresponding supporting rod, the other ends of the springs are connected to the self-compensation center frame, and the supporting rods are arranged on the self-compensation center frame in a sliding manner and arranged in the axial direction of the groove body. The first ends of the supporting rods face the center of the groove body, the second ends of the supporting rods are connected with nuts, the nuts are in threaded connection to the lead screws, and the lead screws are in transmission connection with the motors. According to the machine tool laser compensation device for slender shaft machining, the problem that when a slender shaft is turned and machined, machining precision is affected due to bending deformation of a workpiece can be solved, the response speed is high, and accurate compensation resetting can be conducted through a reverse compensation method.

Owner:PINGDINGSHAN UNIVERSITY

Machining process of inner blocking cover of motor bearing

The invention relates to machining process of an inner blocking cover of a motor bearing. The aim of the machining process is achieved by adoption of the technical scheme. The technical scheme comprises following steps: starting and pre-heating a numerical-control turning and milling composite machine tool within the time ranging from 20 to 30 minutes; preparing tools including a numerical-control coarse tool, a numerical-control finishing tool, drill bits and screw taps; utilizing the numerical-control coarse tool to carry out coarse machining on sizes in need of turning of the inner blocking cover of the motor bearing and keeping 0.15mm remaining amount for precise machining in axial and radial directions; utilizing the numerical-control finishing tool to carry out finish machining on all turning sizes such that the turning surface is exquisite and attractive; starting a C-axis of the numerical-control turning composite machine tool, selecting drill bits of corresponding specifications and types to process drill bit positions required by the process and carrying out turning operation on bottom holes of tapping positions; and selecting the screw taps of corresponding specifications and types to carry out tapping operation on all the tapping positions required by the process. By implementation of machining procedures, machining parameters of the inner blocking cover of the motor bearing can be standardized and normalized such that turning precision of products is greatly improved; and turning surfaces are exquisite and attractive.

Owner:QINGDAO SANLI INTELLIGENT POWER

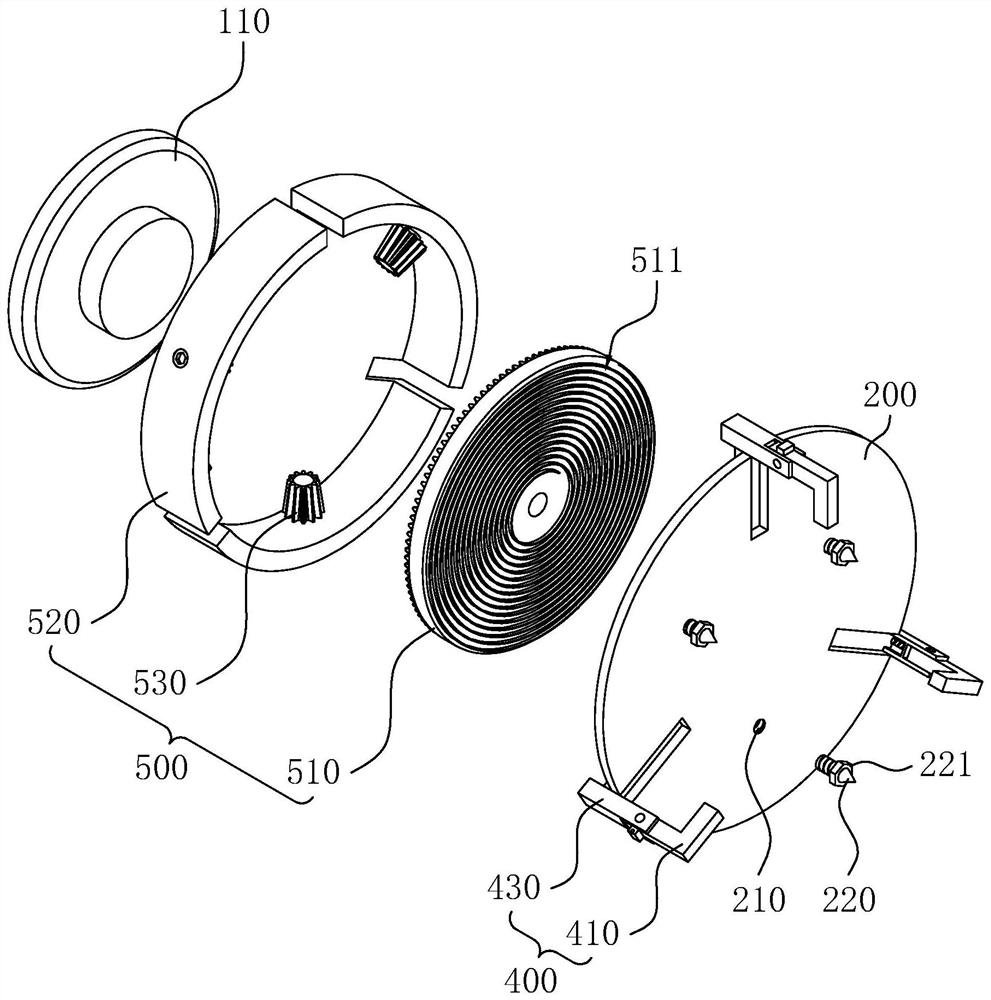

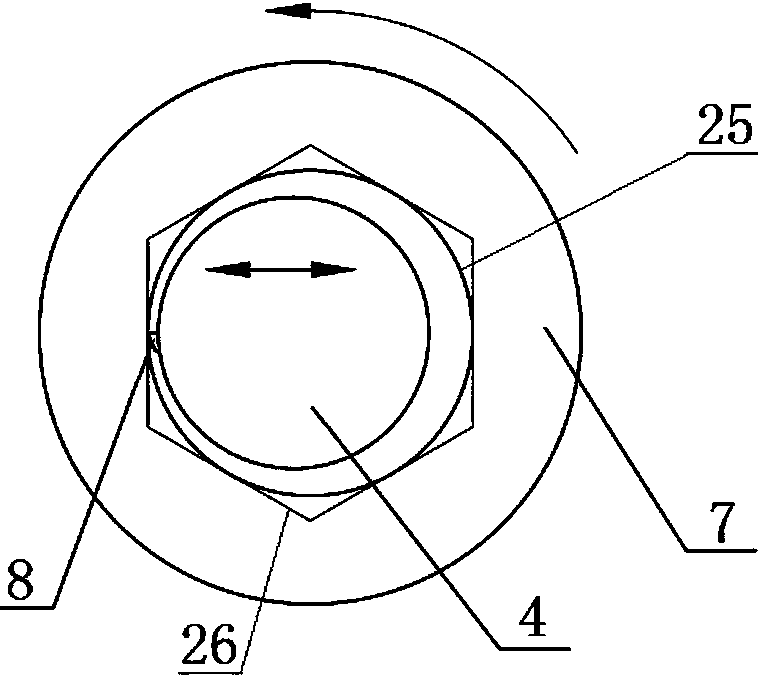

Turning Tool for Regular Polygon Inner Hole Machining

ActiveCN106513710BImprove machining accuracyImprove processing efficiencyLarge fixed membersChucksEngineeringCam

The invention discloses a turning tool for machining regular polygonal inner holes, which includes a lathe, the lathe has a chuck and a tool rest arranged oppositely; It has a circular bottom hole inscribed in the designed regular polygonal inner hole, and a guide block with a linear guide hole is provided on the chuck; a knife feed mechanism is fixed on the knife holder, and the knife mechanism includes a fixed component, a rotating component, Shift assembly and conversion assembly, the circumferential rotation of the chuck is transmitted to the cam plate through the lever of the rotation assembly, and then the cam plate converts the circumferential rotation displacement into the linear displacement of the translation assembly through the conversion assembly, and the linear displacement of the translation assembly The displacement tool rod drives the tool to realize the cutting process of the regular polygon inner hole on the bottom hole on the workpiece. The invention has the characteristics of high processing precision, easy processing process, high processing efficiency, light labor intensity, low processing cost, etc., and is reliable and practical.

Owner:DONGFANG TURBINE CO LTD

An Intelligent Compensation and Anti-vibration Turning Tool and Its Control System

ActiveCN105478813BSimple structureEasy to operateTurning toolsAdverse effect compensationTool bitControl system

Owner:NINGBO KATE MAKER COOKING TECH CO LTD

Clamping and positioning device for ring-sleeve parts and processing method for ring-sleeve parts

ActiveCN111195736BReduce the number of clampingGood form and position toleranceExpansion mandrelsTurning machinesEngineeringCircular surface

The invention discloses a processing device and method for ring sleeve parts. The device includes a support shaft coaxially rotating with the main shaft of a machine tool, and an inner expansion fixture arranged at the end of the support shaft. The inner expansion fixture is used for clamping parts. On the wall of the inner hole, a positioning mechanism is installed on the supporting shaft in a movably connected manner, which can be used to position the inner end surface of the supporting part. The method includes: step 1, clamping the workpiece on the lathe: firstly send the internal expansion fixture into the inner hole of the part through the end surface I, and clamp and fix the part on the machine tool in the way of internal support, and then put the positioning mechanism against the On the end face Ⅰ; step 2: process the outer circular surface and end face Ⅱ of the part; step 3: move the positioning mechanism away to leave a processing space at the position of the end face Ⅰ; step 4: change the tool of the machine tool, and process the end face Ⅰ of the part. The beneficial effect of the invention is that the machining of the two end surfaces, the outer circular surface and part of the inner circular surface of the part can be completed by only one clamping, and the machining accuracy is high.

Owner:重庆众联齿轮传动有限公司

Multifunctional tool expanding rod used for turning outer circle of large-diameter thin-walled part

InactiveCN106670868AImprove turning accuracyConvenient cornerPositioning apparatusMetal-working holdersMechanical engineeringThin walled

The invention discloses a multifunctional tool expanding rod used for turning the outer circle of a large-diameter thin-walled part and aims at providing the multifunctional tool used for turning the outer circle of the thin-walled part. A lock nut presses a sliding rod, a supporting rod changes the angle, a moving rod is expanded or shrunk, and the diameter is changed. The multifunctional tool expanding rod has the beneficial effects that the turning precision of the thin-walled part is improved, and one set of equipment can be used for obtaining parts with different diameters and meanwhile correcting the roundness of thin-walled blanks.

Owner:NINGXIA JIHUA ENVIRONMENTAL SAFETY SCI & TECH CO LTD

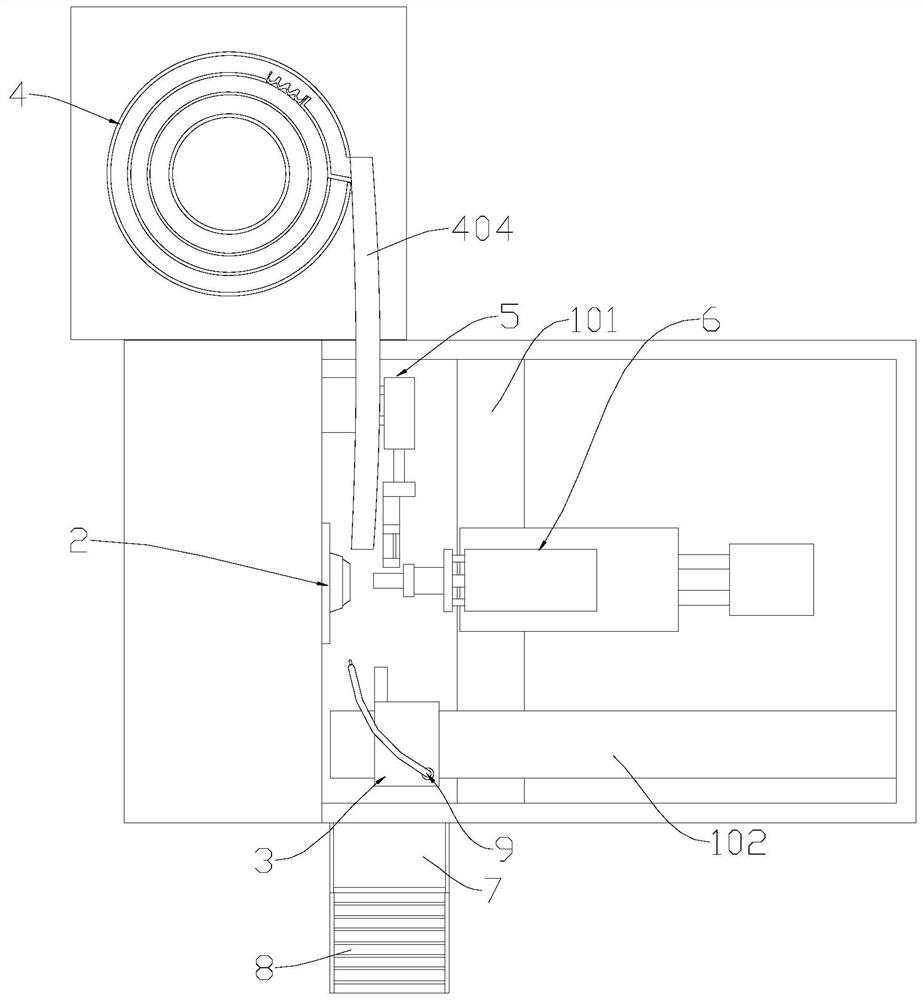

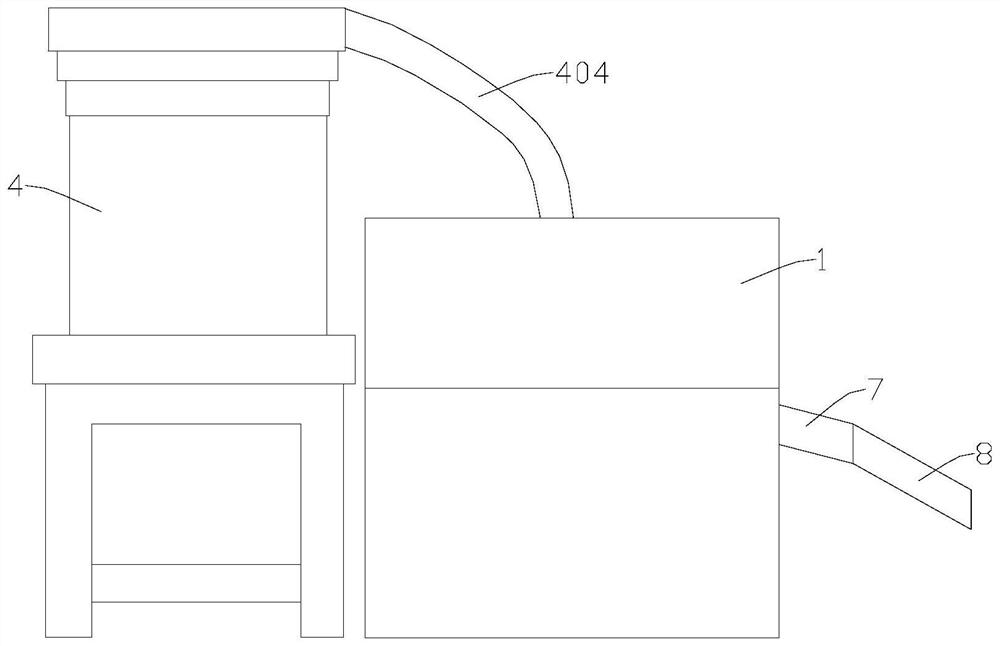

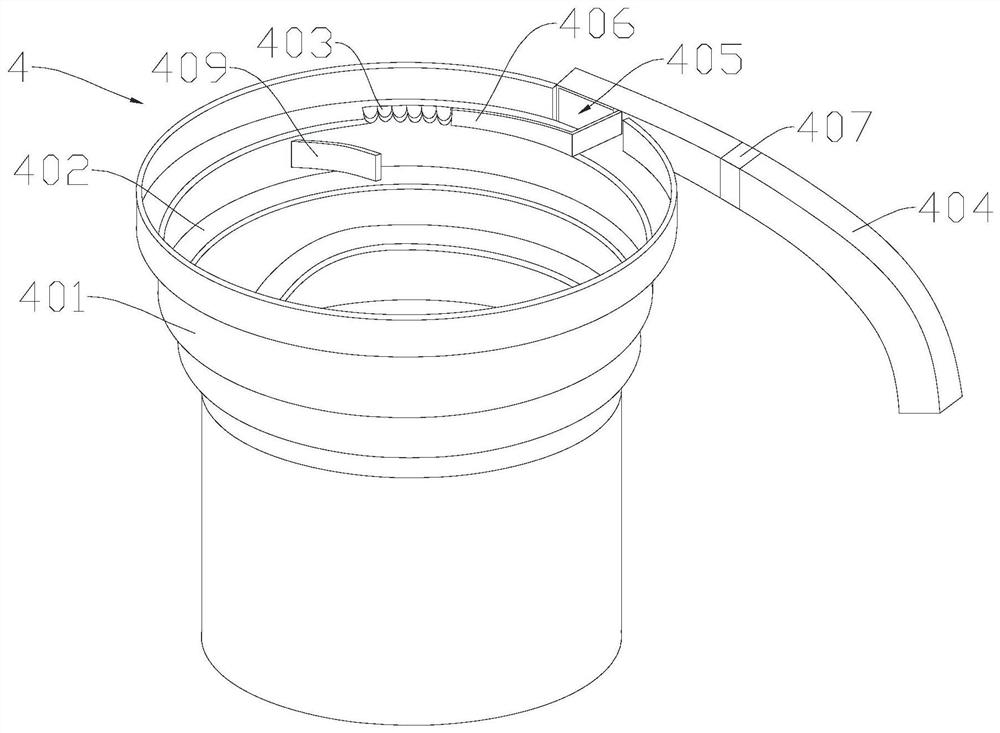

Hollow hemisphere plane turning device

PendingCN111715897AImprove turning accuracyImprove work efficiencyMetal working apparatusMaintainance and safety accessoriesEngineeringClip device

The invention relates to the field of hollow hemisphere production devices, and discloses a hollow hemisphere plane turning device. The hollow hemisphere plane turning device comprises a lathe body, wherein a clamp and a cutting mechanism are sequentially arranged on the lathe body from left to right horizontally, an automatic feeding mechanism and a positioning mechanism are further arranged on the lathe body, the automatic feeding mechanism comprises a feeding device and a clamping device, the feeding device is used for conveying hollow hemispheres to the clamping device, the clamping deviceis used for clamping the hollow hemispheres to the clamp, and the positioning mechanism is used for accurately clamping the hollow hemispheres in the clamp. According to the hollow hemisphere plane turning device, workpieces can be clamped and aligned through simple operation, the turning precision is high, and the working efficiency is high.

Owner:广汉市恒锐钢球制造有限公司

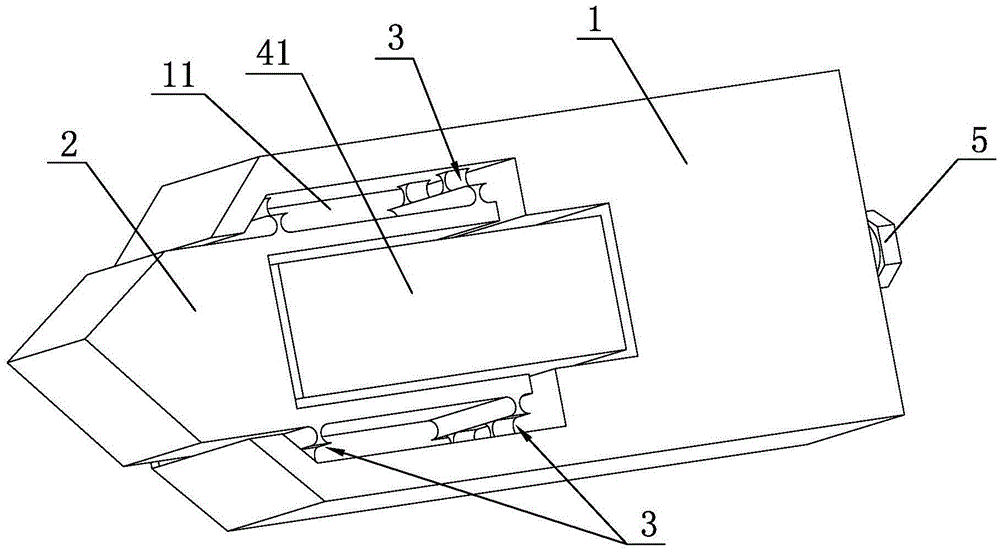

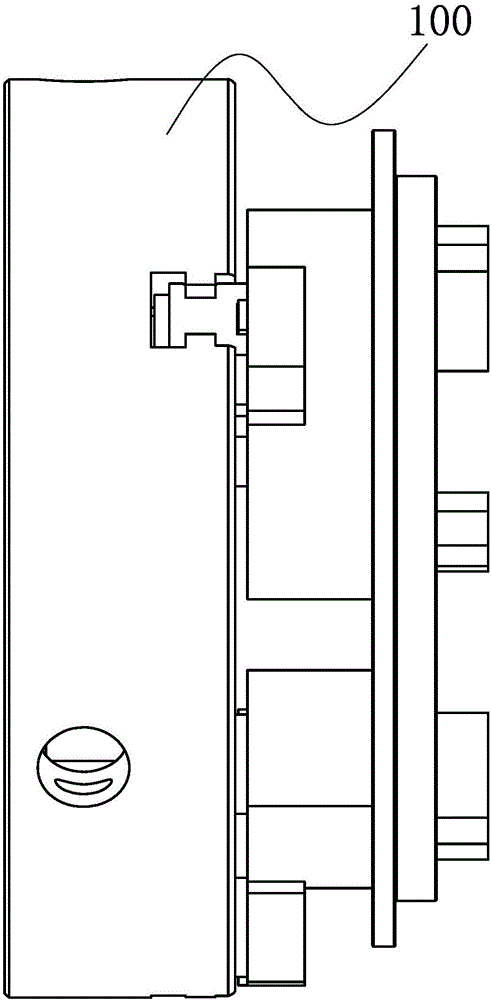

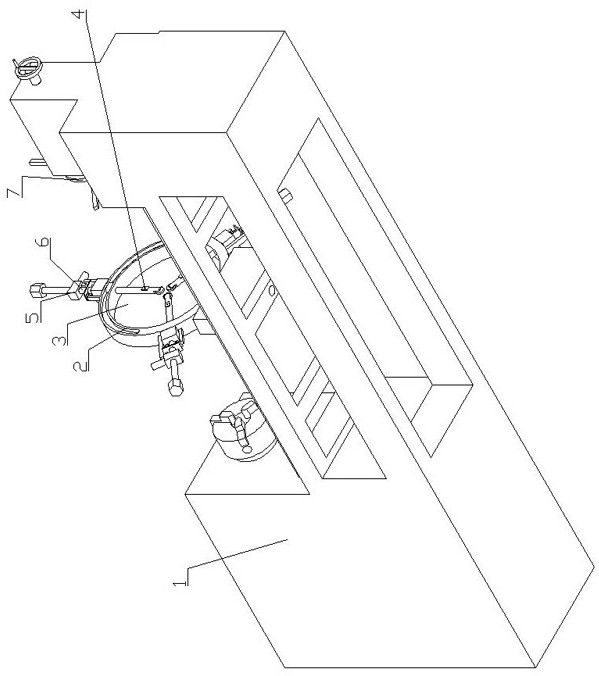

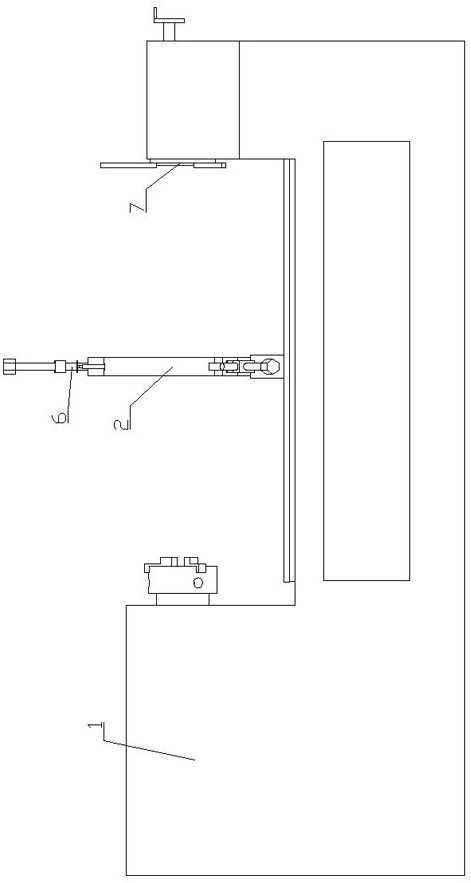

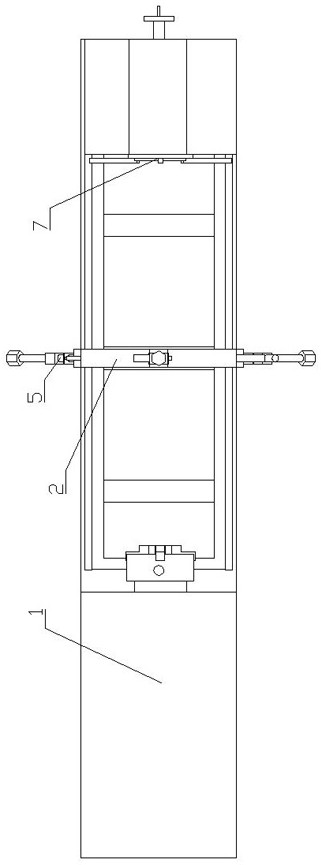

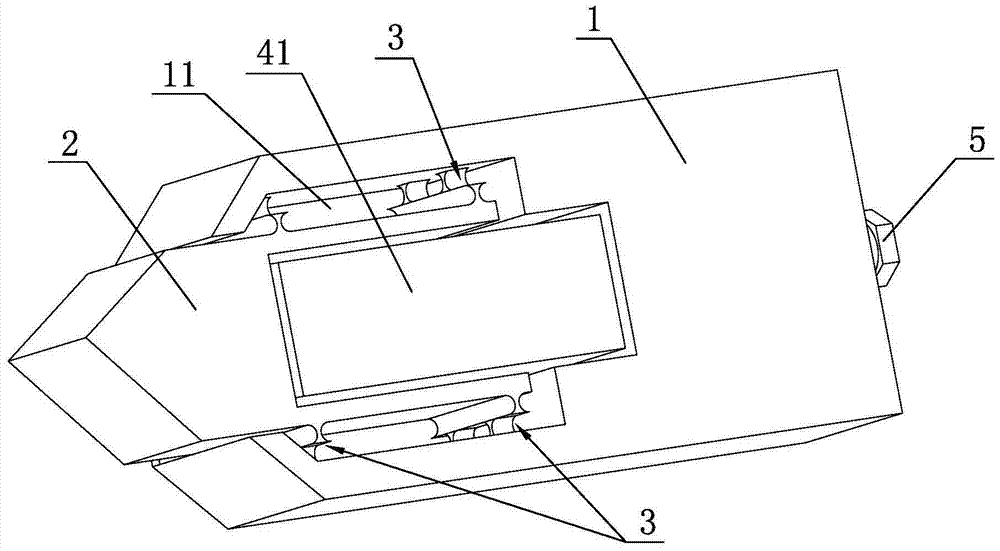

A multifunctional tool supporting body used for cylindrical lathe cutting of large-diameter thin-walled parts

InactiveCN106891025AImprove turning accuracyAchieve expansion and contractionExpansion mandrelsEngineeringMechanical engineering

The present invention is a tooling for turning parts with large diameter and thin wall. The purpose is to improve the rigidity and processing quality of the workpiece. At the same time, the roundness of the blank can be corrected. It mainly includes: 1, support body; 2, spring; 3, moving rod ; 4, stretching rod; 5, stretching body; 6, sliding rod; 7, pin; 8, guide post; 9, composed of locking nut. The invention has the beneficial effects of improving the turning precision of thin-walled parts and realizing the use of a set of equipment for parts with different diameters.

Owner:NINGXIA JIHUA ENVIRONMENTAL SAFETY SCI & TECH CO LTD

Multi-functional tool sliding bar for turning of excircle of large-diameter thin-wall part

InactiveCN106563955AReduce tensionImprove turning accuracyPositioning apparatusMetal-working holdersMechanical engineeringThin walled

The invention relates to a multi-functional tool for turning of an excircle of a thin-wall part, particularly to a multi-functional tool for turning of an excircle of a large-diameter thin-wall part. A sliding bar is compressed by a locking nut, a support rod changes the angle, and a moving rod is expanded or reduced, so that the diameter is changed. The multi-functional tool has the following beneficial effects: the turning precision of the thin-wall part can be improved; one set of equipment for simultaneous correction of the roundness of the thin-wall blanks of parts with different diameters can be realized.

Owner:NINGXIA JIHUA ENVIRONMENTAL SAFETY SCI & TECH CO LTD

A kind of herringbone gear processing device and its turning and milling method

ActiveCN108356364BReduce processing costsReduce use costGear teethHerringbone gearMechanical engineering

The invention discloses a herringbone gear machining device. The herringbone gear machining device comprises a main lathe bed, a tooth milling stand column, a tooth milling blade, a workbench, a vertical lathe bed, a vertical lathe stand column and a turning blade, wherein the tooth milling blade is arranged on the tooth milling stand column in a sliding manner in the axial direction of the toothmilling stand column through a tooth milling tool rest, the workbench is rotationally arranged on the other side of the axial direction of the main lathe bed, the turning blade is arranged in a hollowstructure of the vertical lathe stand column in a sliding manner in the axial direction of the vertical lathe stand column, turning and milling share one rotation workbench, and a herringbone gear can be machined with high precision. The invention discloses a turning method for the herringbone gear machining device. The turning rotation speed, the cutting feed distance and the turning time of a workpiece are controlled on the basis of the BP neural network, and the turning precision is high. The invention further discloses a milling method for the herringbone gear machining device, the rotation speed of the workbench, the axial motion speed of the gear milling blade and the forward and reverse rotation time of the workbench can be accurately controlled, and the herringbone gear machiningprecision is improved.

Owner:BAOJI XINFUQUAN MACHINERY TECH DEV

A turning fixture for flange blind plate

ActiveCN112872394BTurn easilyReduce clamping errorsChucksTurning machinesClassical mechanicsMetal machining

The application relates to a turning fixture for a flanged blind plate, and relates to the technical field of metal processing equipment. It includes a base plate, a first pressing mechanism and a second pressing mechanism. The vertebra is rotatably connected to the tailstock, the tail vertebra is coaxially arranged with the base plate, the base plate is coaxially fixedly connected to the main shaft of the lathe, and the second pressing mechanism includes a clamping claw which is slidably connected to the base plate. In this application, when processing the outer peripheral surface of the blank, the base plate and the tail cone are used to clamp the blank, so that the outer peripheral surface of the blank is completely exposed; when processing the boss of the blank, the base plate and the clamping jaw are used to clamp the blank. In this way, the axial part of the blank part will be completely exposed, which is convenient for the feeding of the turning tool.

Owner:济南江华锻铸机械有限公司

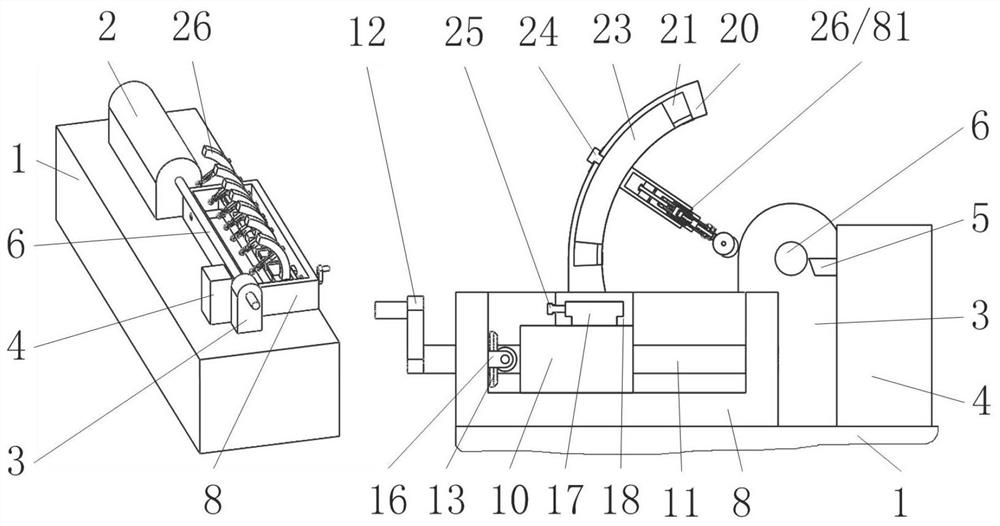

Slender shaft numerical control lathe fixture

InactiveCN112045452AImprove turning accuracySimple structureWork clamping meansPositioning apparatusStructural engineeringMechanical engineering

The invention belongs to the field of numerical control lathe fixtures, and particularly relates to a slender shaft numerical control lathe fixture. The slender shaft numerical control lathe fixture comprises a base, a sliding seat, a screw rod A, an arc-shaped support, a T-shaped guide block, a telescopic rod structure A and a telescopic rod mechanism B, wherein the sliding seat slides in a sliding groove A in the base in the direction perpendicular to the axial direction of a slender shaft; and the base is mounted on a lathe body. According to the slender shaft numerical control lathe fixture, the plurality of telescopic rod mechanisms A staggered at a certain angle wrap the slender shaft at a certain angle while effectively abutting against the slender shaft in the turning process, so that vibration caused by lower strength of the slender shaft in the rotating process is avoided, and the turning precision of the slender shaft is improved.

Owner:杨兰

A Thin-walled Flange Precision Turning Outer Circle Fixture

The invention provides a precision excircle turning clamp for a thin-wall flange. The precision excircle turning clamp comprises a chuck mounted on a machine tool, and a plurality of clamp bodies which are annularly arrayed along the axial direction of the chuck and are fixed on the chuck through threaded fasteners, wherein each clamp body comprises a clamping block with one end fixed on the chuck through the corresponding threaded fastener and the other end being an arc curved surface, and two pressing plates which are respectively located on two sides of the corresponding clamping block and are fixed on the clamping block through the threaded fasteners. According to the precision excircle turning clamp, provided by the invention, for the thin-wall flange, the thin-wall flange is circumferentially located by the clamping blocks mounted on the chuck and radially located by the pressing plates mounted on the clamping blocks, and the clamping blocks and the thin-wall flange as well as the pressing plates and the thin-wall flange are both in surface contact, so that the thin-wall flange can be located more precisely, and the turning accuracy is higher.

Owner:浙江金本汽车零部件有限公司

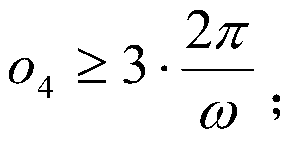

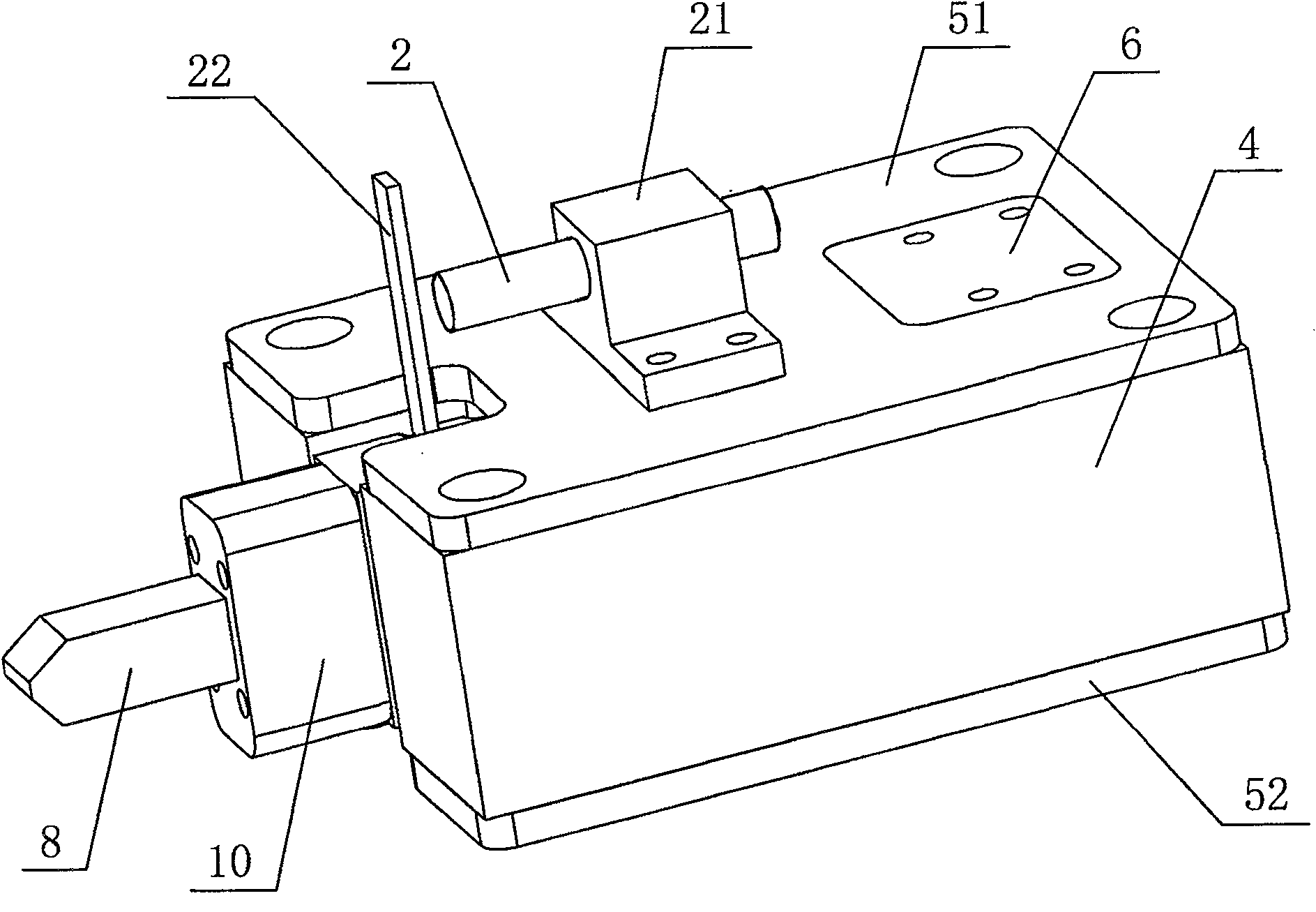

Non-round cutting device of digital control lathes and control method thereof

InactiveCN100579694CSo as not to damageNo mechanical frictionTurning machinesNumerical controlVibration controlControl engineering

The invention discloses a non-circular cutting device for a numerically controlled lathe, which comprises a cutter head, a cutter holder fixed with cutters, a displacement sensor, a main shaft coder, an actuator, and a controller, wherein the main shaft coder is arranged on a main shaft motor of the numerically controlled lathe. The non-circular cutting device is characterized in that the cutter head is provided with a first cavity and a second cavity which are communicated with each other, a flexible hinge structure is arranged in the first cavity integrally, the front end part of the flexible hinge structure is integrally provided with a permanent seat of the cutter holder, the cutter holder is fixedly arranged on the permanent seat of the cutter holder, the actuator is fixedly arranged in the second cavity, the end part of the actuator leans against the rear end face of the flexible hinge structure, the main shaft coder and the displacement sensor are both electrically connected with the controller, and the controller is electrically connected with the actuator. The non-circular cutting device has the advantages that the cutter head has the functions of micro positioning and precision cutting vibration control to realize micro feeding movements of the cutters in a non-circular precise cutting system, the cutting vibration in axial and tangential directions of a workpiece can be controlled effectively, and the turning precision of non-circular cutting is improved.

Owner:NINGBO UNIV

Target components and processing methods

ActiveCN108611608BImprove turning accuracyMeet the process requirementsVacuum evaporation coatingSputtering coatingSputteringSand blasting

The invention relates to the technical field of machining, and provides a target component and a processing method. The target component comprises a target and a backing plate used for bearing the target, wherein the surface of the target comprises a front side, a back side and sides, and the front side of the target is the sputtering surface of the target; and the back side of the target is opposite to the front side of the target, and the sides of the target are adjacent to the front side and the back side of the target separately. Meanwhile, the back side of the target is connected to the front side of the backing plate, and the sides of the target are adjacent to the front side of the backing plate; and the junction positions between the sides of the target and the front side of the backing plate are provided with sand blasting areas formed through sand blasting treatment and surrounding the sputtering surface, and the distances between the points of the same sand blasting line ofthe sand blasting areas and the center point of the sputtering surface are the same, wherein the sand blasting lines are the boundary lines of the sand blasting areas. The sand blasting areas of the target component have tidy sand blasting lines, so that abnormal sputtering is not generated in the sputtering process of the target, and semiconductor chips can be produced smoothly.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Manufacturing method of thin-wall bearing and method for machining thin-wall inner ring/outer ring of the thin-wall bearing as well as precise flexible bearing

The invention provides a manufacturing method for thin-wall bearing and a method for machining a thin-wall inner ring / outer ring as well as a precision flexible bearing. The method for machining the thin-wall inner ring / outer ring comprises the following steps of: S0, providing a thin-wall ring with machining allowance left; S1: reinforcing along the radial direction and / or axial direction of the thin-wall ring; S2: carrying out quenching-tempering heat treatment on the reinforcing ring obtained by reinforcement in the S1; S3: carrying out corresponding grinding, hard cutting and super finishing on the reinforcing ring after receiving heat treatment, which includes removal of the machining allowance and a reinforcing part obtained by reinforcement in the S1, thereby obtaining finished thin-wall ring product. The thin-wall ring reinforced machining method substantially reduces and even avoids deformation of the thin-wall ring in all manufacturing links, thereby obtaining very high machining precision. The precision thin-wall bearing and the precision flexible bearing can be manufactured by fitting of the precision thin-wall ring and a precision rolling body.

Owner:SHANGHAI F&S BEARING TECH

Numerical control turning machining center

InactiveCN112091238AImprove machining accuracyImprove processing efficiencyAutomatic/semiautomatic turning machinesTailstocks/centresNumerical controlStructural engineering

The invention discloses a numerical control turning machining center. The numerical control turning machining center structurally comprises a turning device, a turning machine and a control console, the turning device is installed on the turning machine, the turning machine and the control console are locked and electrically connected, the turning device is composed of an installation frame, a turning cutter, a side end material fixing device and a middle material fixing device, the installation frame is connected with the turning cutter, the installation frame is locked with the side end material fixing device and the middle material fixing device, the middle material fixing device comprises a material position, an inner fixer and a middle pile, the material position is mounted on the middle pile, the inner fixer is connected with the middle pile in an installed mode, the side end material fixing device comprises a main adjusting structure, an auxiliary adjusting structure and a conical fixing structure, and the auxiliary adjusting structure is connected with the main adjusting structure and the conical fixing structure in an installed mode. According to the numerical control turning machining center, raw materials are located at the material position and are moved and adjusted through the side end material fixing device and the middle material fixing device, meanwhile, turning machining is carried out through the turning cutter, and turning machining is carried out by replacing turning cutter path movement with material moving, so that the machining precision and efficiency are improved.

Owner:卢锦锋

Target components and processing methods

ActiveCN108581169BImprove turning accuracyMeet the process requirementsNon-electric welding apparatusEngineeringMachining process

The invention relates to the technical field of machining, and provides a target module and a machining method. The target module comprises a target and a back plate for bearing the target. The surface of the target comprises a front surface and a back surface; the front surface of the target is a sputtering surface of the target; the back surface of the target is opposite to the front surface ofthe target; a first step is projected on the back surface of the target; and the side surface of the first step is an inclined surface. A first groove matched with the first step is formed in the front surface of the back plate; the back surface of the target and the front surface of the back plate are connected through dispersion welding; and the first step is embedded in the first groove. In thedispersion welding process, the back surface of the target is tightly bonded with the front surface of the back plate; and a finally molded target module generates no welding line in the joint position of the two, so that the sputtering performance of the target can be improved, meanwhile, the problem related to the welding line cannot occur in subsequent machining process of the target module, and the quality of the produced target module is improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com