A multifunctional tool supporting body used for cylindrical lathe cutting of large-diameter thin-walled parts

A technology of parts and related structures, applied in the field of important parts, can solve the problems of low reuse rate and poor versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0006] The small end is used for the clamping of the three-jaw chuck, and the large section has six slots for the guide of the moving rod. The lock nut presses the sliding rod, and the moving rod moves outward through the four-bar mechanism to realize the expansion and contraction of the spreader. The 6 equal parts of the guide groove can make the blank center automatically.

[0007] Description of drawings:

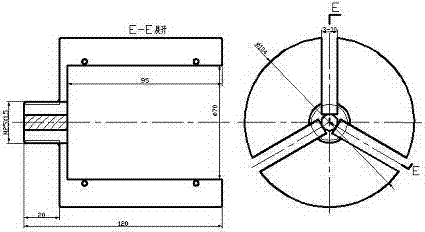

[0008] figure 1 is a schematic diagram of the support body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com