Non-round cutting device of digital control lathes and control method thereof

A technology of CNC lathes and cutting devices, which is applied in the direction of digital control, turning equipment, turning equipment, etc., can solve the problems of high processing cost, poor processing accuracy, and low efficiency, and achieve the effect of protecting from damage and improving turning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

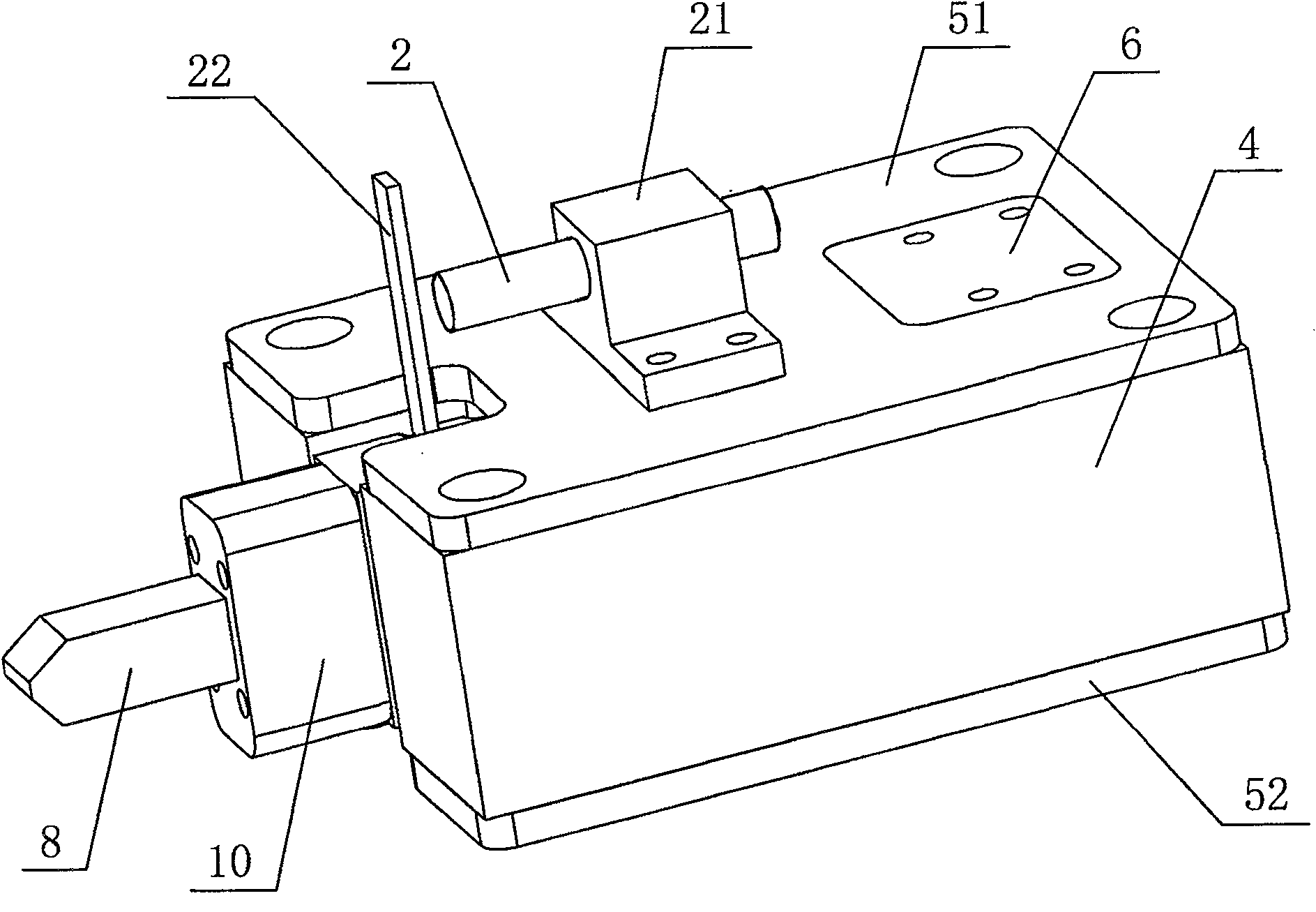

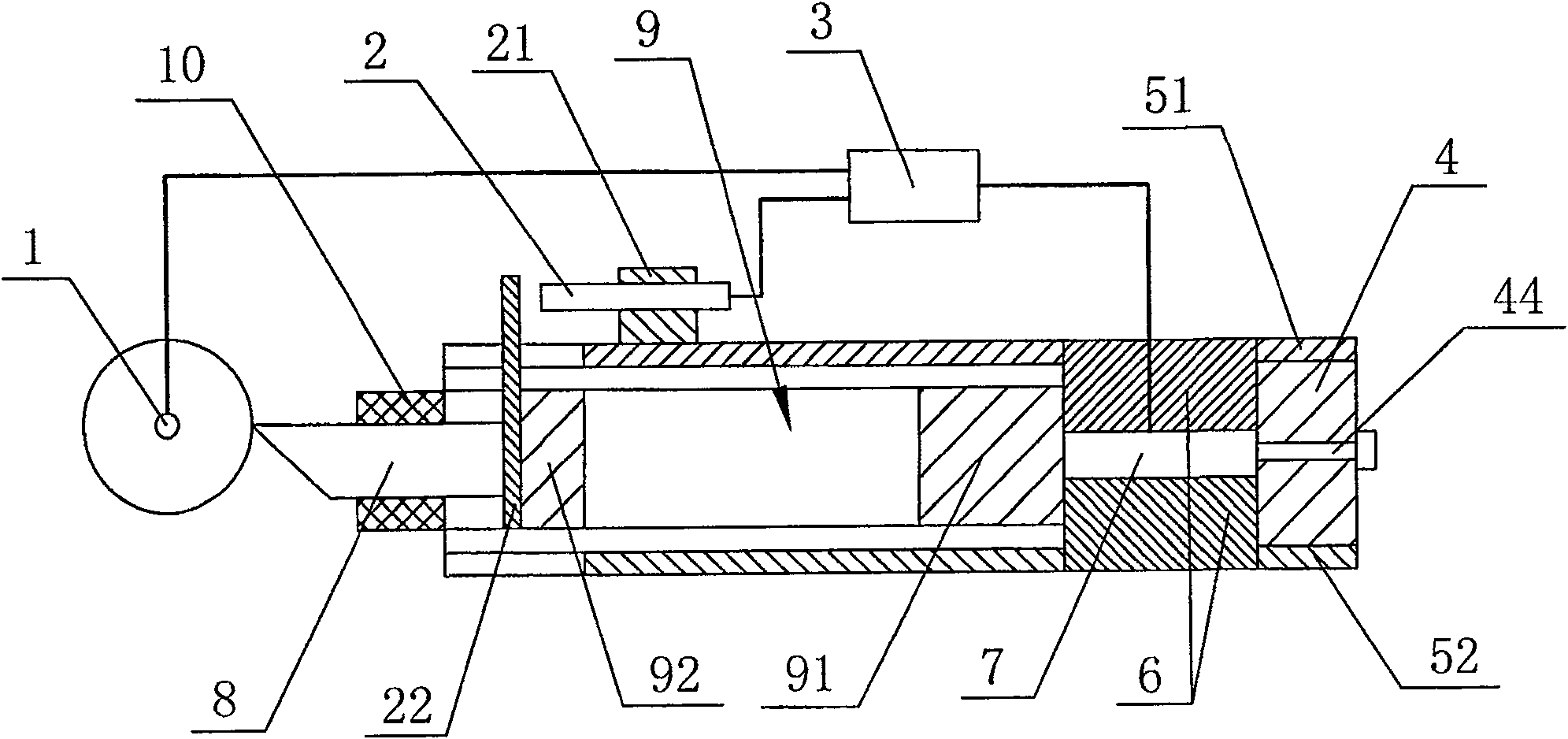

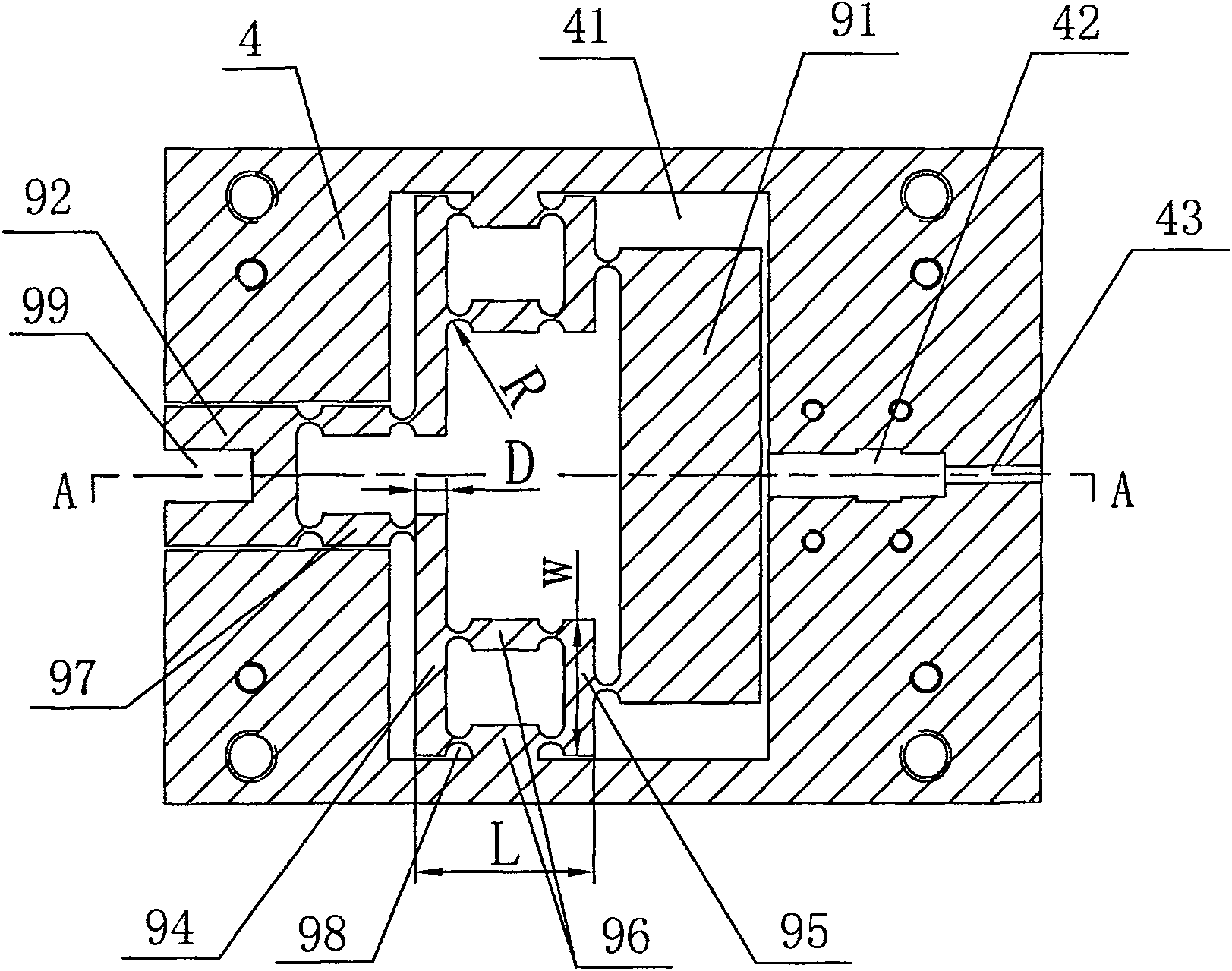

[0020] Embodiment 1: As shown in the figure, a non-circular cutting device of a CNC lathe, including a tool holder 4, a tool holder 10 with a tool 8 fixed thereon, a high-precision displacement sensor 2, a high-precision rotary encoder 1, and a piezoelectric ceramic actuator The controller 7 and the controller 3, the high-precision rotary encoder 1 and the high-precision displacement sensor 2 are electrically connected to the controller 3, the controller 3 is electrically connected to the piezoelectric ceramic actuator 7, and the high-precision rotary encoder 1 is set on the CNC lathe On the spindle motor of the tool rest 4, the upper surface of the tool rest 4 is fixedly provided with an upper cover plate 51, the lower surface of the tool rest 4 is fixedly provided with a lower cover plate 52, and the tool rest 4 is provided with a first cavity 41 and a second cavity connected to each other. Cavity 42, flexible hinge structure 9 is arranged in the first cavity 41, and flexible...

Embodiment 2

[0025] Embodiment two: other structures are the same as embodiment one, the difference is that in the parallelogram elastic mechanism, the radius R of the semicircular groove 98 is 3mm, the first connecting rod 94, the second connecting rod 95, the third connecting rod 96, the fourth connecting rod The width D of the four connecting rods 97 is 7mm, the height H is 30mm, the distance L from the first connecting rod 94 to the second connecting rod 95 is 40mm, and the distance W between the two third connecting rods 96 is 30mm .

Embodiment 3

[0026] Embodiment three: other structures are the same as embodiment one, the difference is that in the parallelogram elastic mechanism, the radius R of the semicircular groove 98 is 3.5mm, the first connecting rod 94, the second connecting rod 95, the third connecting rod 96, the first connecting rod The width D of the four connecting rods 97 is 8mm, the height H is 32mm, the distance L from the first connecting rod 94 to the second connecting rod 95 is 40mm, and the distance W between the two third connecting rods 96 is 30mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com