Target components and processing methods

A processing method and target technology, applied in the field of mechanical processing, can solve the problems of target sputtering performance degradation, target deformation, expansion, etc., and achieve the effect of improving sputtering performance and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

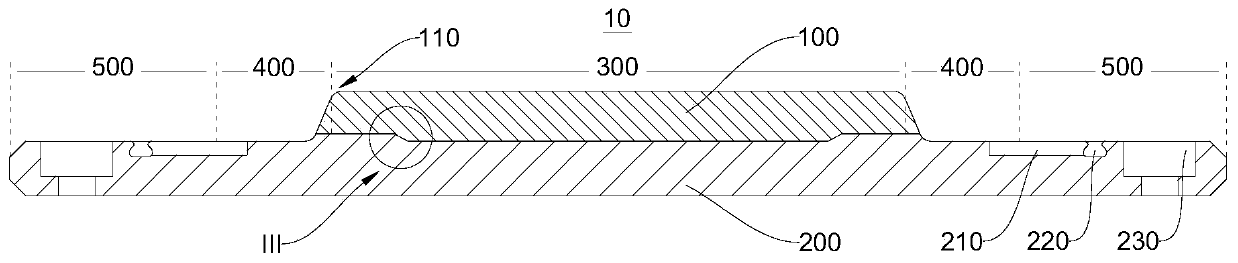

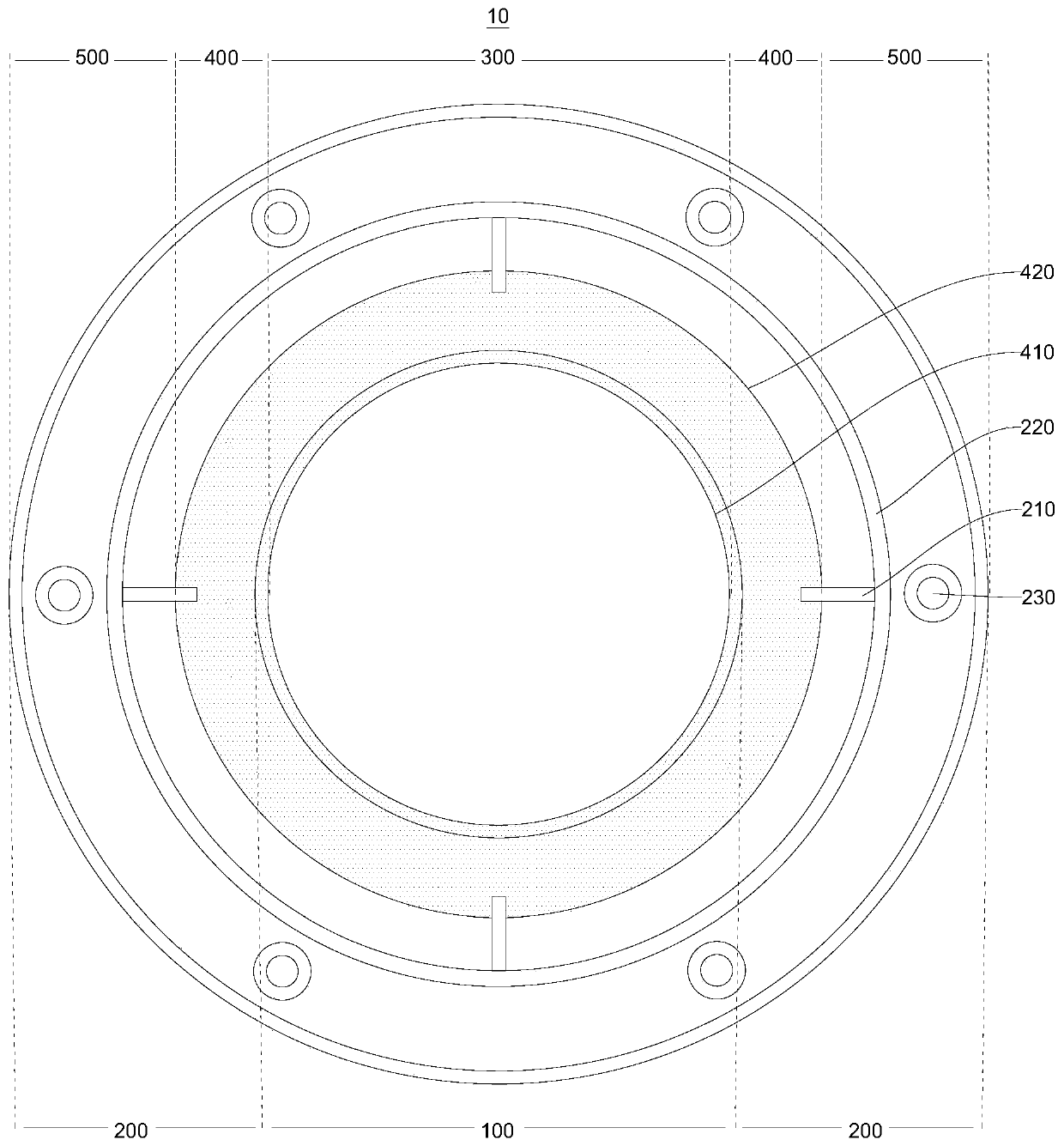

[0044] figure 1 A schematic structural view of the target assembly 10 provided by the embodiment of the present invention under a first viewing angle is shown. figure 2 A schematic structural view of the target assembly 10 provided by the embodiment of the present invention under the second viewing angle is shown. The target assembly 10 is used for sputtering coating in the semiconductor chip manufacturing process. combined reference figure 1 as well as figure 2 , the target assembly 10 includes a target 100 and a back plate 200 for carrying the target 100 . The target assembly 10 is usually made of metal, alloy, ceramics and other materials. For example, the target 100 is made of titanium, and the back plate 200 is made of aluminum. Of course, this is only a relatively common combination of materials. The target 100 and The backplane 200 can also use other combinations of materials.

[0045] Wherein, the surface of the target 100 includes a front side and a back side o...

no. 2 example

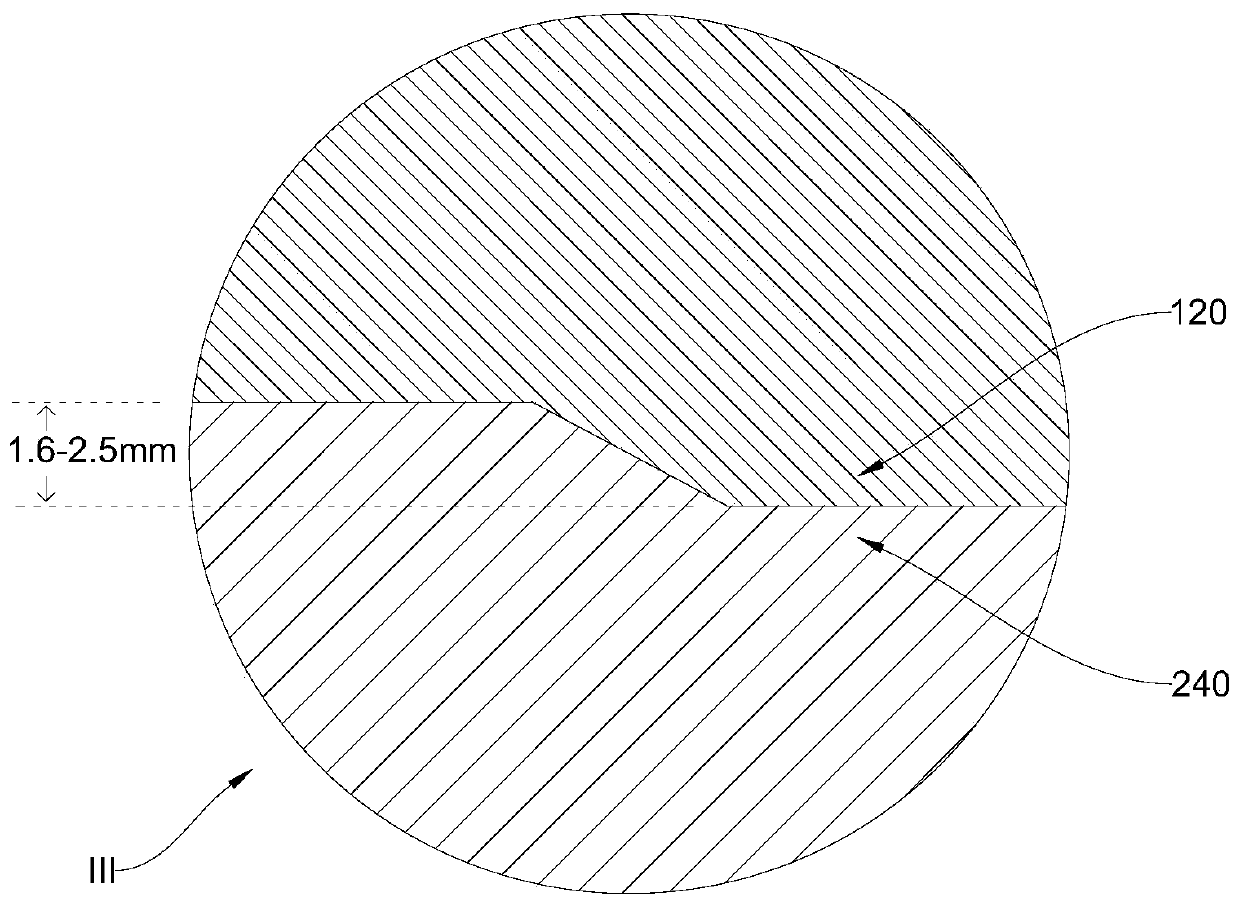

[0063] The embodiment of the present invention also provides a target assembly processing method for processing the target assembly 10 provided in the embodiment of the present invention, the method includes: turning a second surface protruding from the back of the target 100 on the back of the target 100 A step 120, the side of the first step 120 is a bevel; on the front of the back plate 200, according to the shape matching with the first step 120, the first groove 240 recessed in the front of the back plate 200 is turned; the first step 120 embedded in the first groove 240, and connect the back of the target 100 and the front of the back plate 200 together by diffusion welding.

[0064] The implementation principles and technical effects of the above methods have been described in the aforementioned product examples. For a brief description, for the parts not mentioned in the method examples, you can refer to the corresponding content in the aforementioned product examples. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com