A Thin-walled Flange Precision Turning Outer Circle Fixture

A technology of turning an outer circle and a flange, applied in the field of machinery, can solve the problems of insufficient turning accuracy of the processed workpiece, reduce the positioning accuracy of the processed workpiece, etc., and achieve the effect of high turning accuracy and accurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

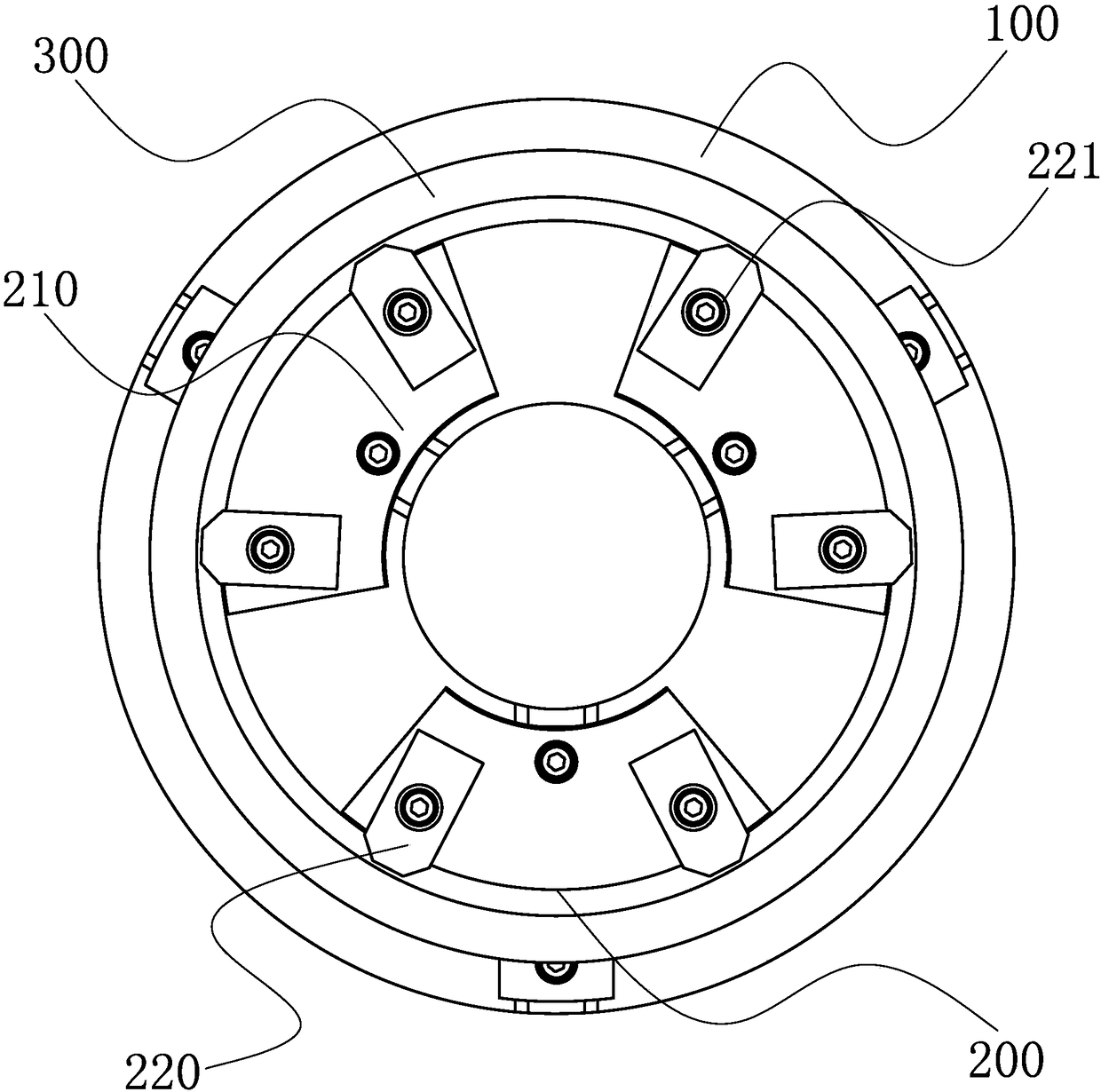

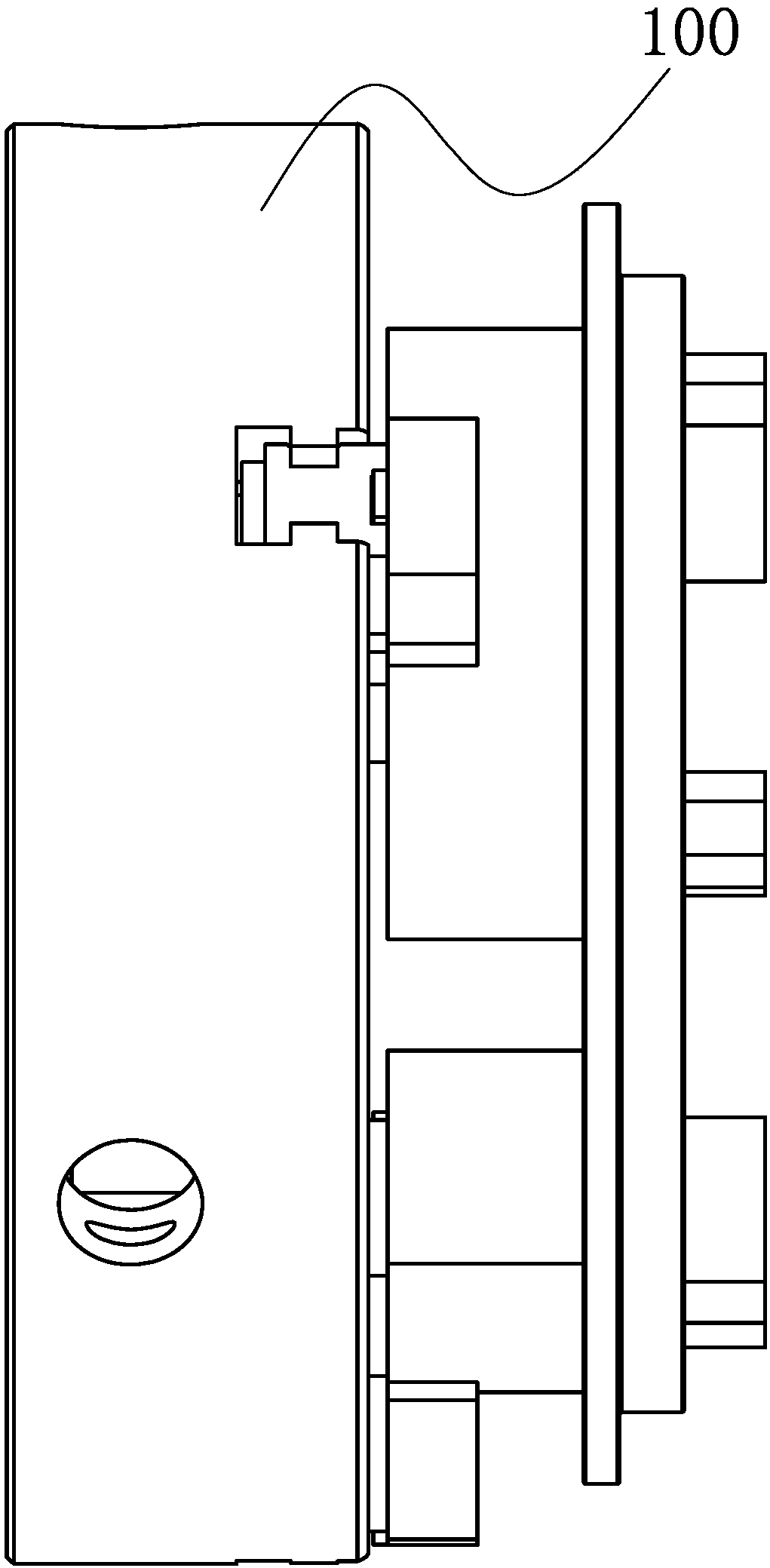

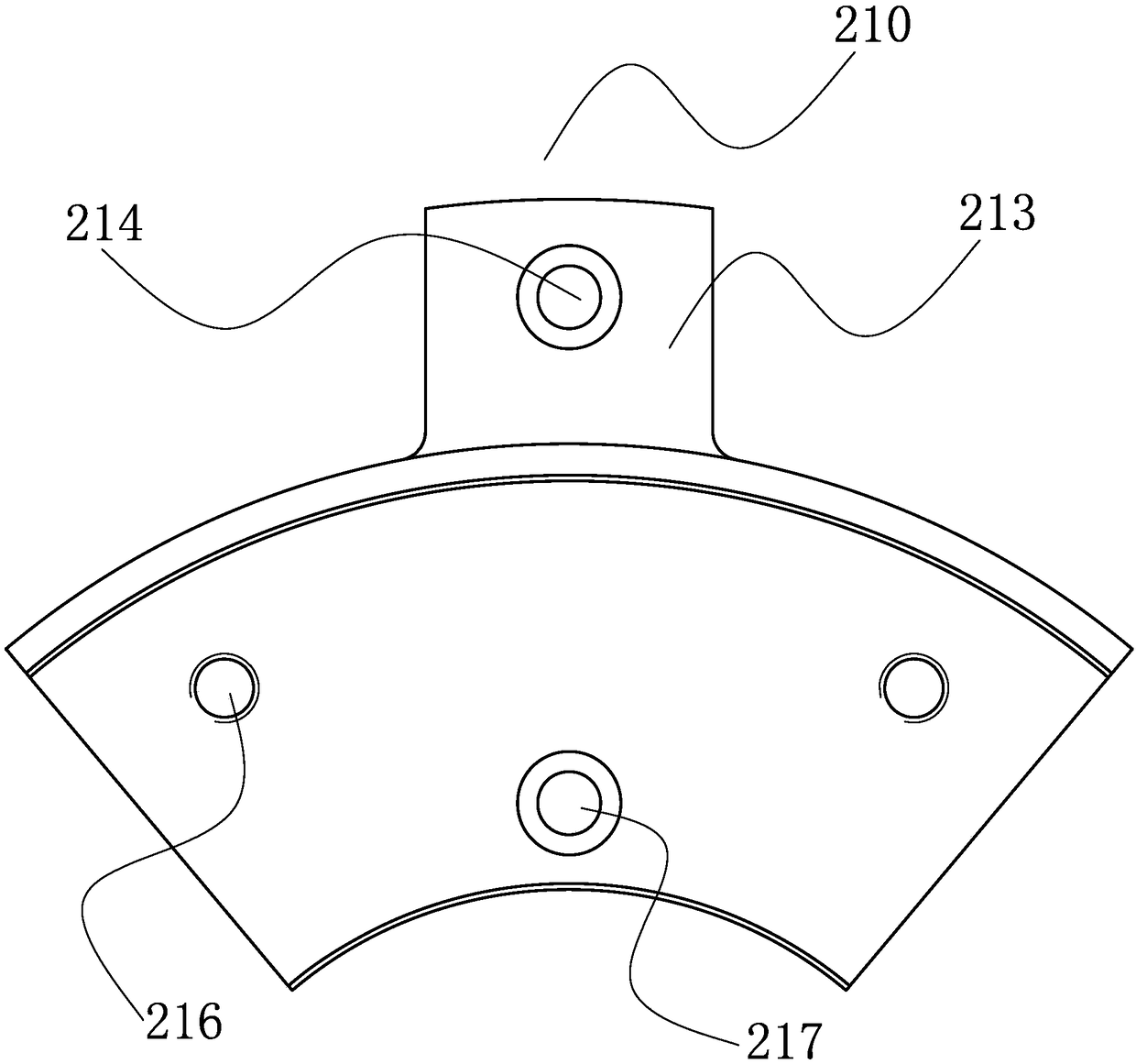

[0031] Such as figure 1 and figure 2 As shown, a thin-walled flange precision turning outer circle fixture provided by the present invention includes: a chuck 100 installed on a machine tool; several chuck bodies 200 arranged in a circular array along the axis of the chuck 100, and thread The fastener is fixed on the chuck 100; wherein, the clamp body 200 includes: a clamp block 210, one end of which is fixed on the chuck 100 by a threaded fastener, and the other end is an arc surface; The two sides of the block 210 are fixed on the clamp block 210 by threaded fasteners. Preferably, the number of clamp bodies 200 is three. The three-point positioning of the thin-walled flange 300 during clamping makes the positioning of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com