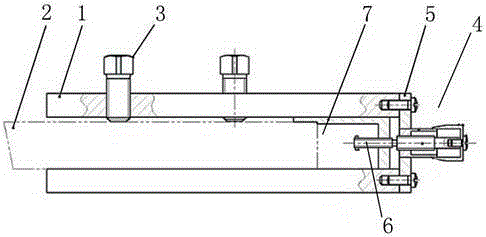

Turning tool with pushing mechanism

A technology of propulsion mechanism and turning tool, applied in the direction of tool holder, etc., can solve the problems of low production efficiency, unsatisfactory, uneconomical part processing technology, etc., and achieve the effect of prolonging service life, easy adjustment and improving turning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0018] Types and uses of turning tools Turning tools are the most widely used single-edged tools. Turning tools are used on various lathes to process outer circles, inner holes, end faces, threads, grooves, etc. According to the structure, turning tools can be divided into integral turning tools, welding turning tools, machine clamp turning tools, indexable turning tools and forming turning tools. Among them, the application of indexable turning tools is becoming more and more extensive, and the proportion of turning tools is gradually increasing.

[0019] The cutting part of the turning tool is composed of the main cutting edge, the auxiliary cutting edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com