Multifunctional tool expanding rod used for turning outer circle of large-diameter thin-walled part

A technology for thin-walled parts and external turning, which is applied to metal processing machinery parts, positioning devices, manufacturing tools, etc., and can solve the problems of low reuse rate and poor versatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

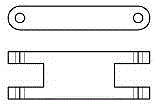

[0005] The support rod is used to transmit the force and motion on the sliding rod to the moving rod. It is an important part of the four-bar mechanism. The two ends adopt the original design to facilitate the corner when moving, and the middle adopts the groove to match the pin and the sliding rod and the moving rod. The connection ensures the matching accuracy, and at the same time, it adopts grease lubrication to ensure long-term effectiveness.

[0006] Description of drawings:

[0007] figure 1 It is a schematic diagram of the sliding rod part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com