Target component and processing method

A processing method and target material technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve problems such as abnormal discharge of sandblasting line, affecting the production process of semiconductor chips, and the sputtering process cannot be carried out normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

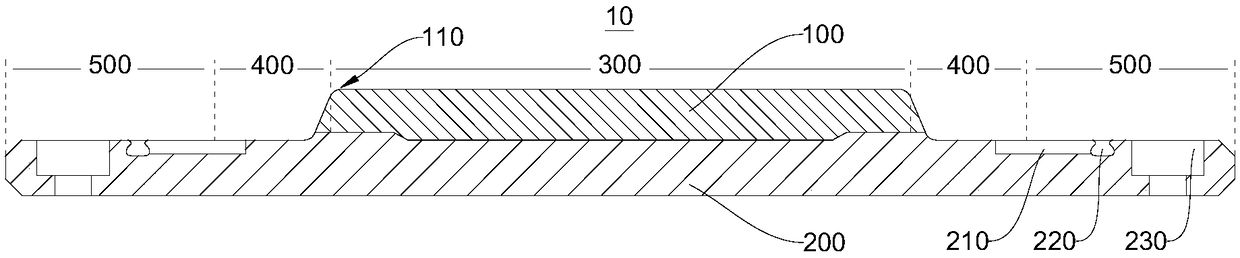

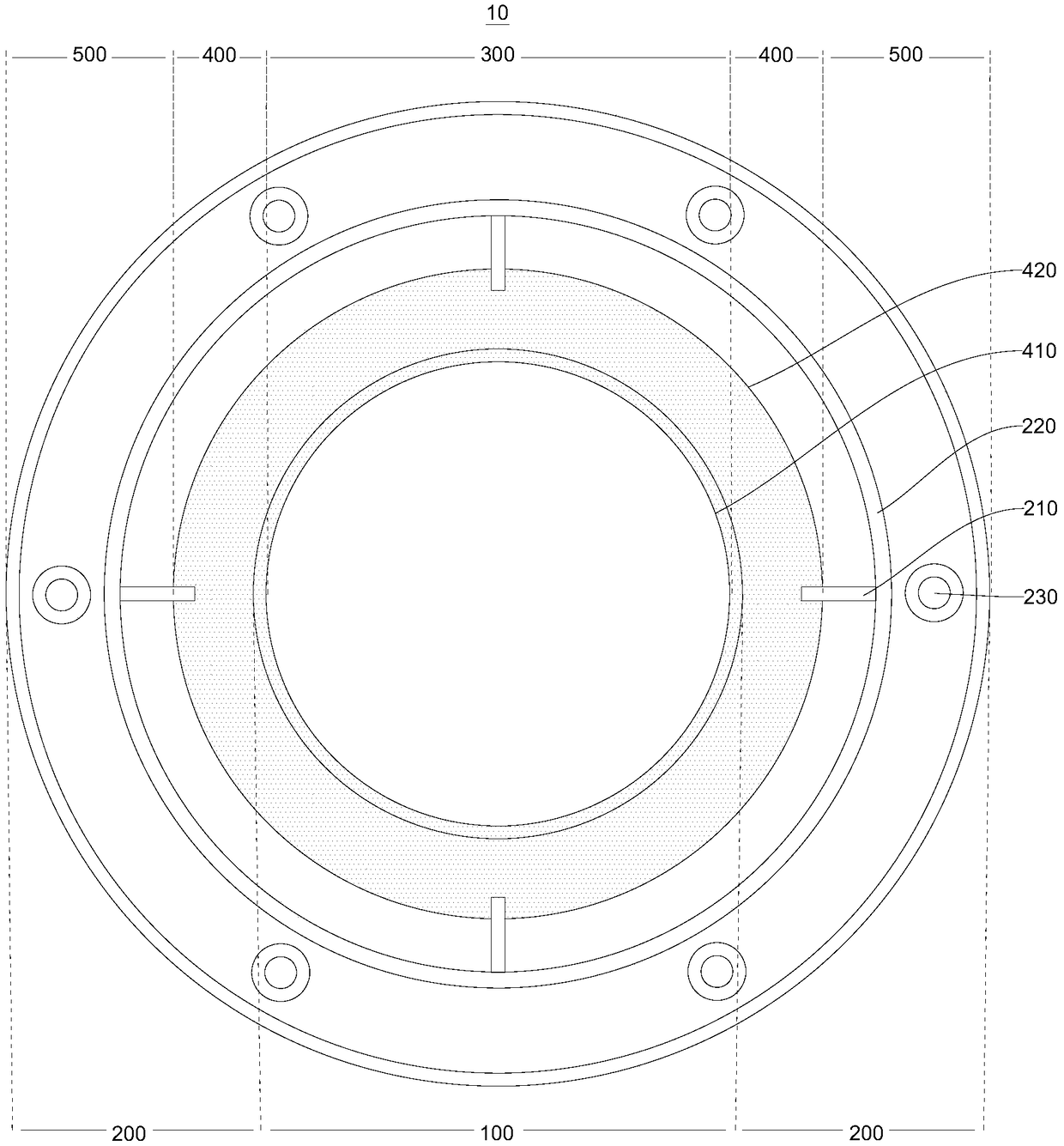

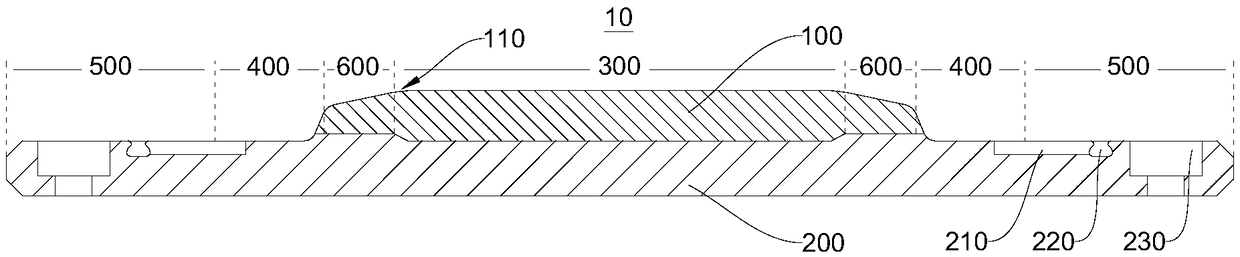

[0040] figure 1 It shows a schematic structural view of the first target assembly 10 provided by the embodiment of the present invention under a first viewing angle, figure 2A schematic structural view of the first target assembly 10 provided by the embodiment of the present invention under the second viewing angle is shown. The target assembly 10 is used for sputtering coating in the semiconductor chip manufacturing process. combined reference figure 1 as well as figure 2 , the target assembly 10 includes a target 100 and a back plate 200 for carrying the target 100 . The target assembly 10 is usually made of metal, alloy, ceramics and other materials. For example, the target 100 is made of titanium, and the back plate 200 is made of aluminum. Of course, this is only a relatively common combination of materials. The target 100 and The backplane 200 can also use other combinations of materials.

[0041] Wherein, the surface of the target 100 includes a front, a back and...

no. 2 example

[0054] The embodiment of the present invention also provides a target assembly processing method for processing the target assembly 10 provided in the embodiment of the present invention, the method includes: fixing the target assembly 10; Turning is carried out until each point on the first sandblasting line 410 has the same distance to the center point of the sputtering surface 300; the second sandblasting line 420 of the sandblasting area 400 is turned until the distance between the points on the second sandblasting line 420 The distances from each point to the center point of the sputtering surface 300 are the same.

[0055] Further, before the step of turning the first sandblasting line 410 of the sandblasting area 400 until the distances from each point on the first sandblasting line 410 to the center point of the sputtering surface 300 are the same, the method further includes: The R angle 110 is turned at the boundary position between the sputtering surface 300 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com