A kind of herringbone gear processing device and its turning and milling method

A processing device and herringbone gear technology, applied in the direction of belts/chains/gears, gear teeth, components with teeth, etc., can solve the problems of low efficiency, large time consumption, and large space occupation, so as to reduce the cost of use, Improved machining accuracy and small floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

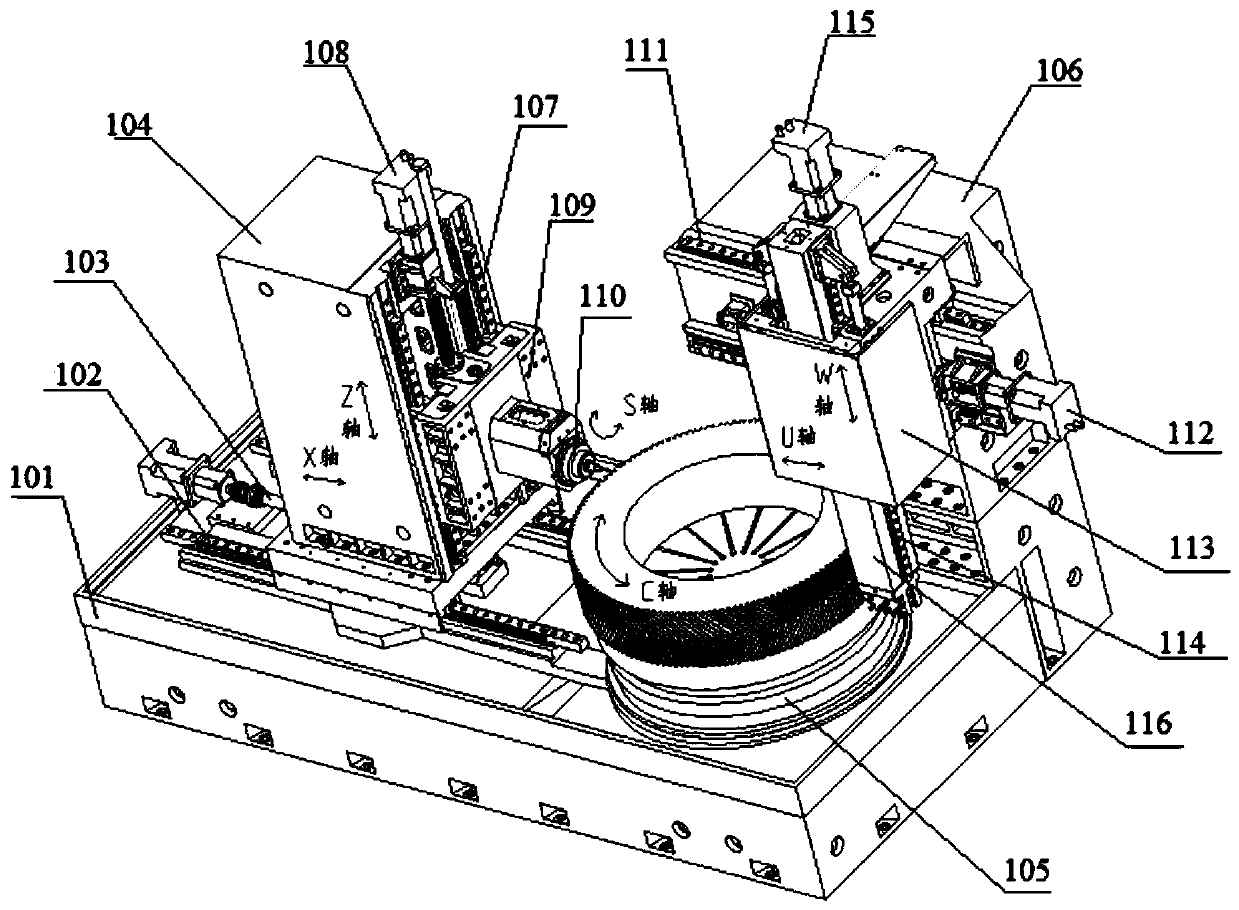

[0059] Such as figure 1 As shown, the present invention provides a herringbone gear processing device, including a main bed 101, which is characterized in that: the left part of the upper end surface of the main bed 101 is installed by a first linear guide 102 and a first ball screw 103 There is a milling column 104 that moves left and right along the X axis, a turning and milling common workbench 105 that rotates around the C axis is installed on the right front of the main bed 101, and a vertical lathe bed is fixed on the right rear of the main bed 101 106; the inner end surface of the milling column 104 is equipped with a milling tool holder 109 moving up and down along the Z axis through the second linear guide rail 107 and the second ball screw 108, and the milling tool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com