Patents

Literature

31results about How to "High strength connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

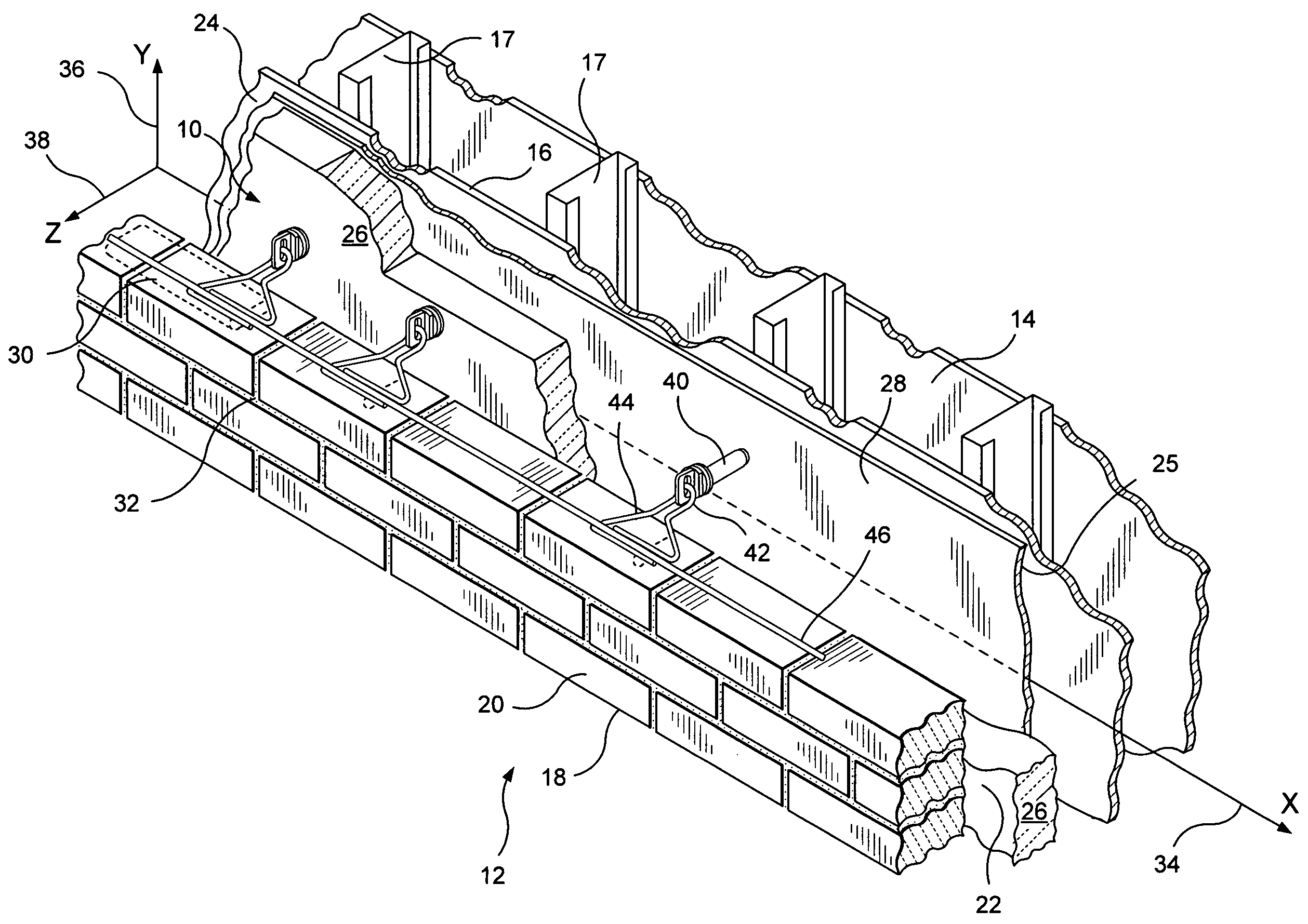

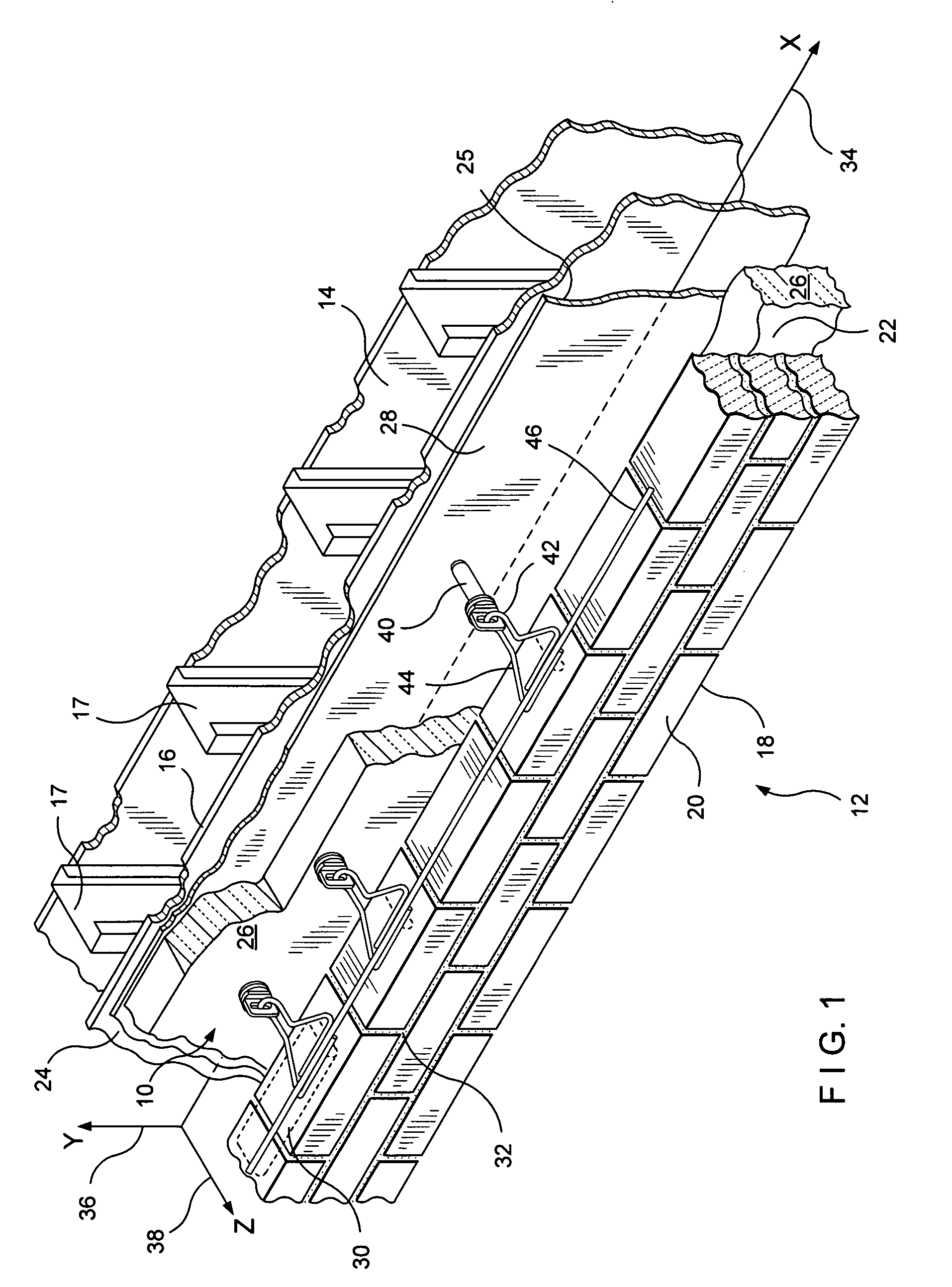

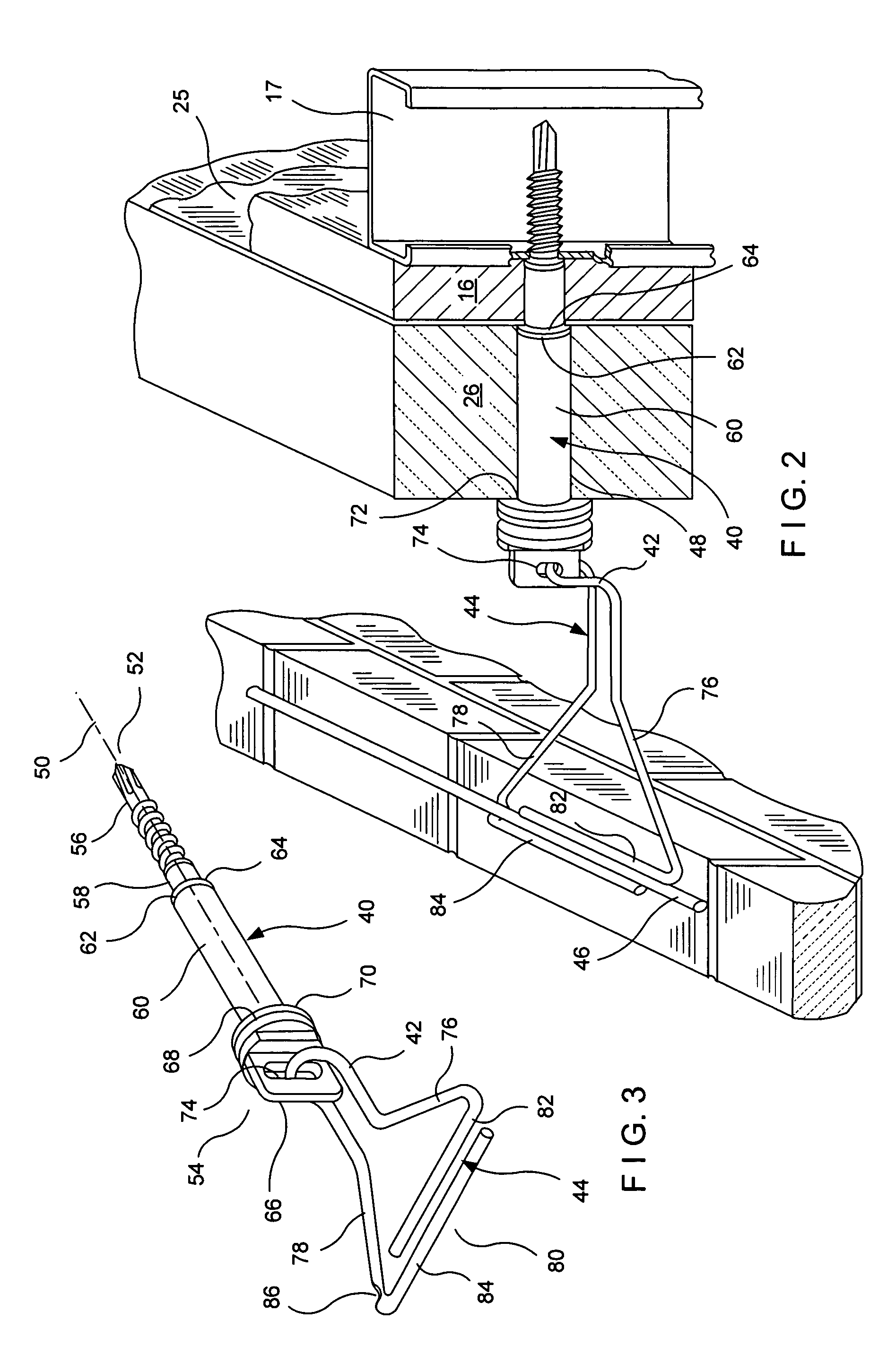

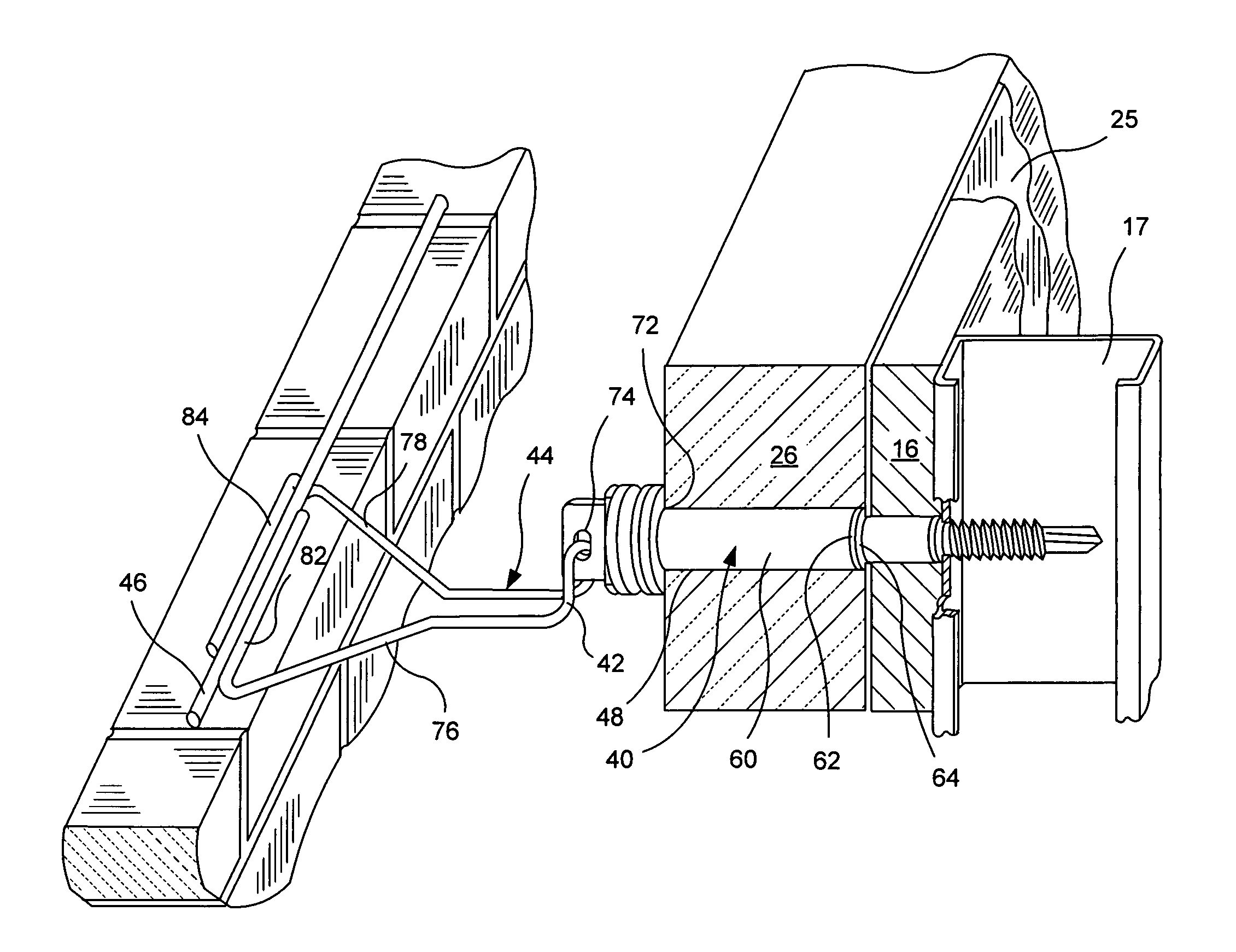

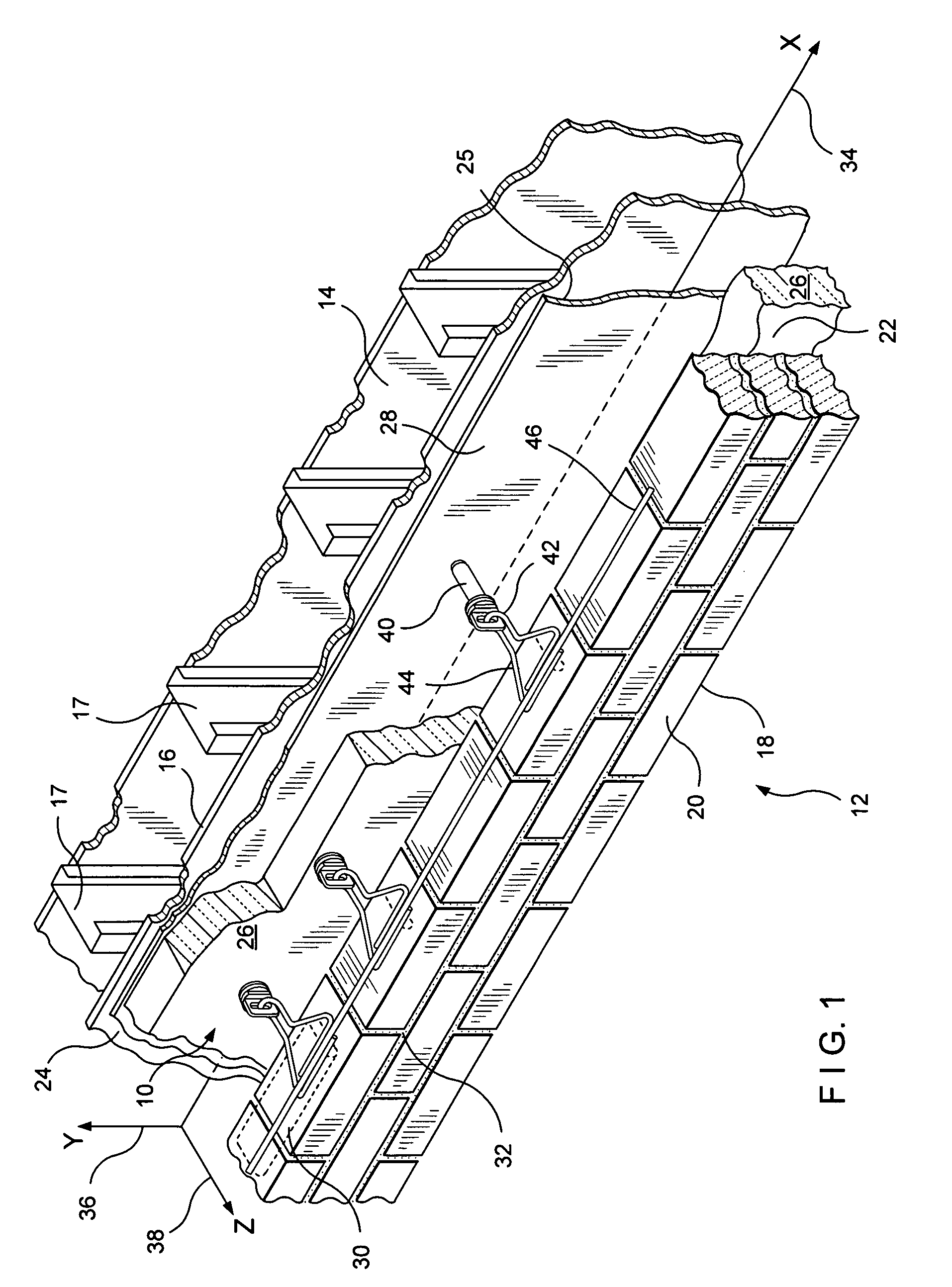

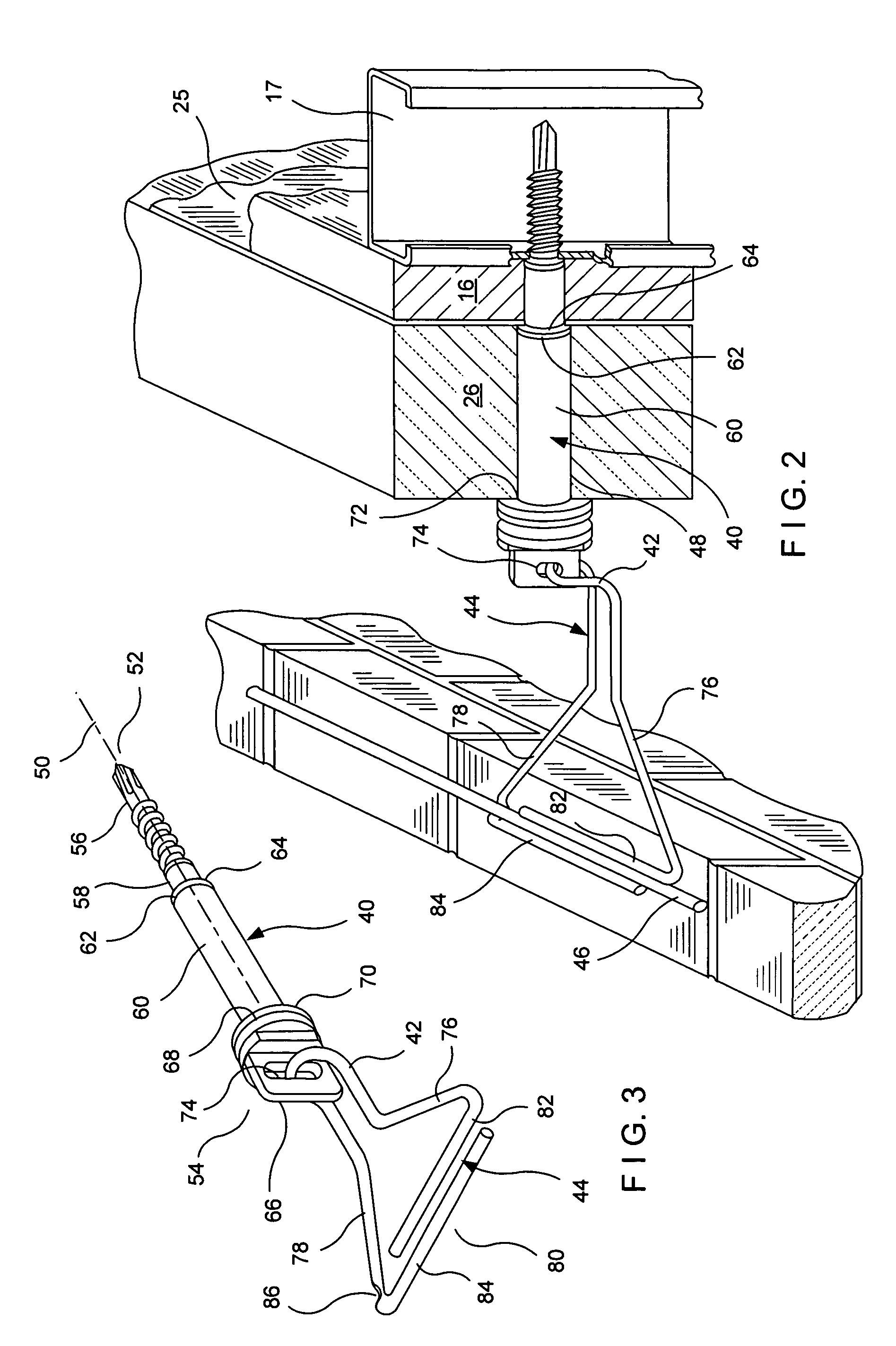

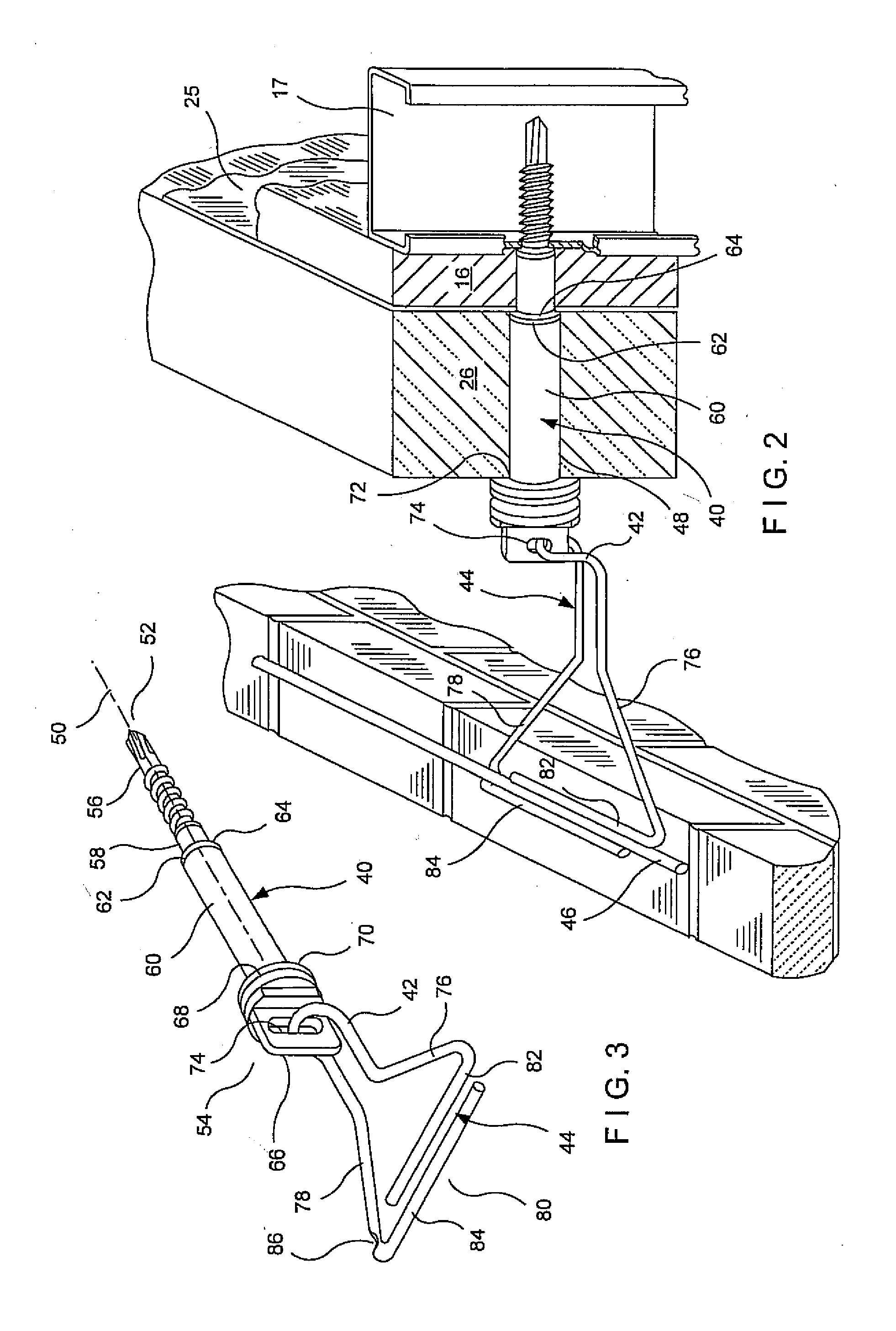

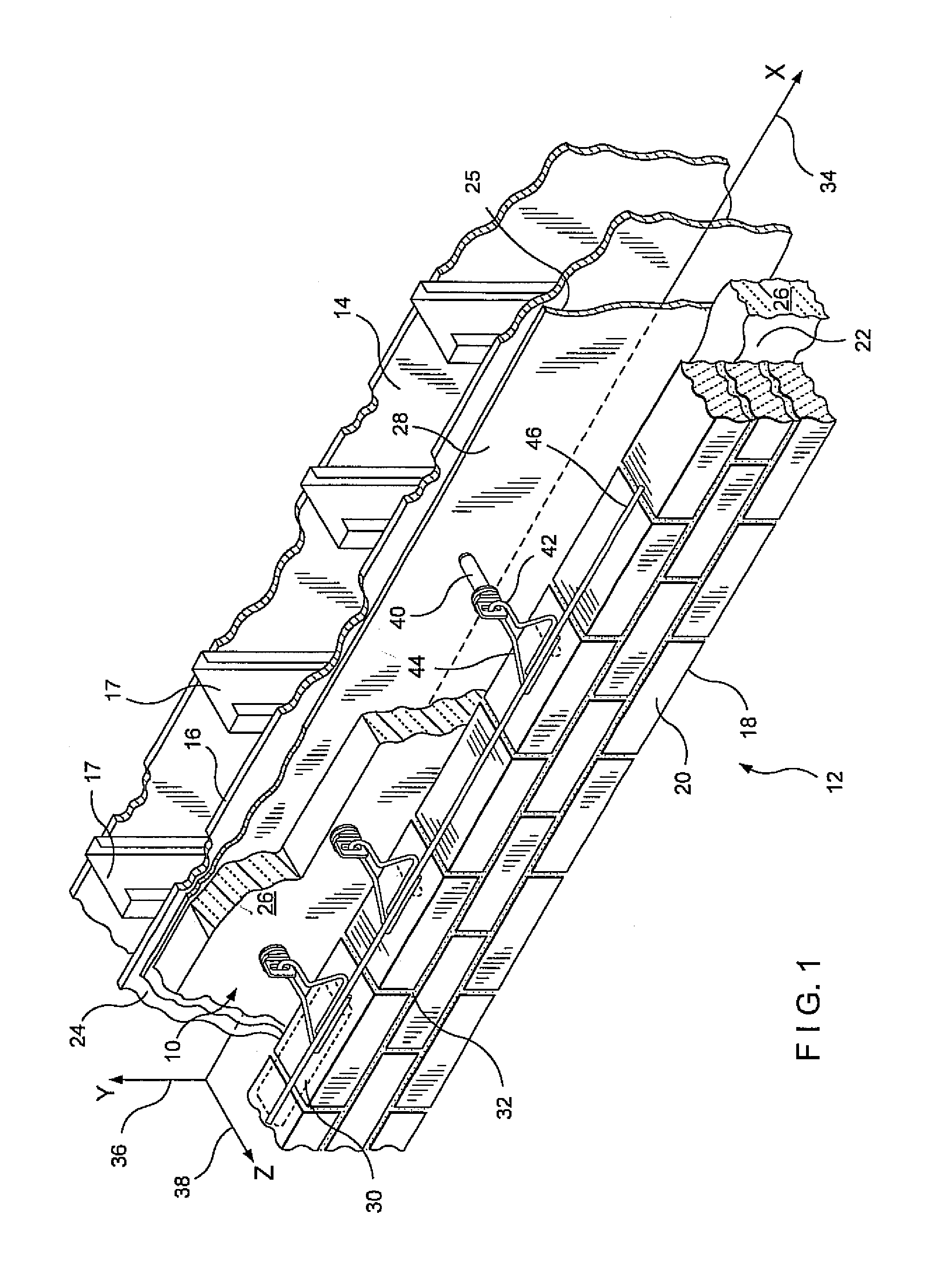

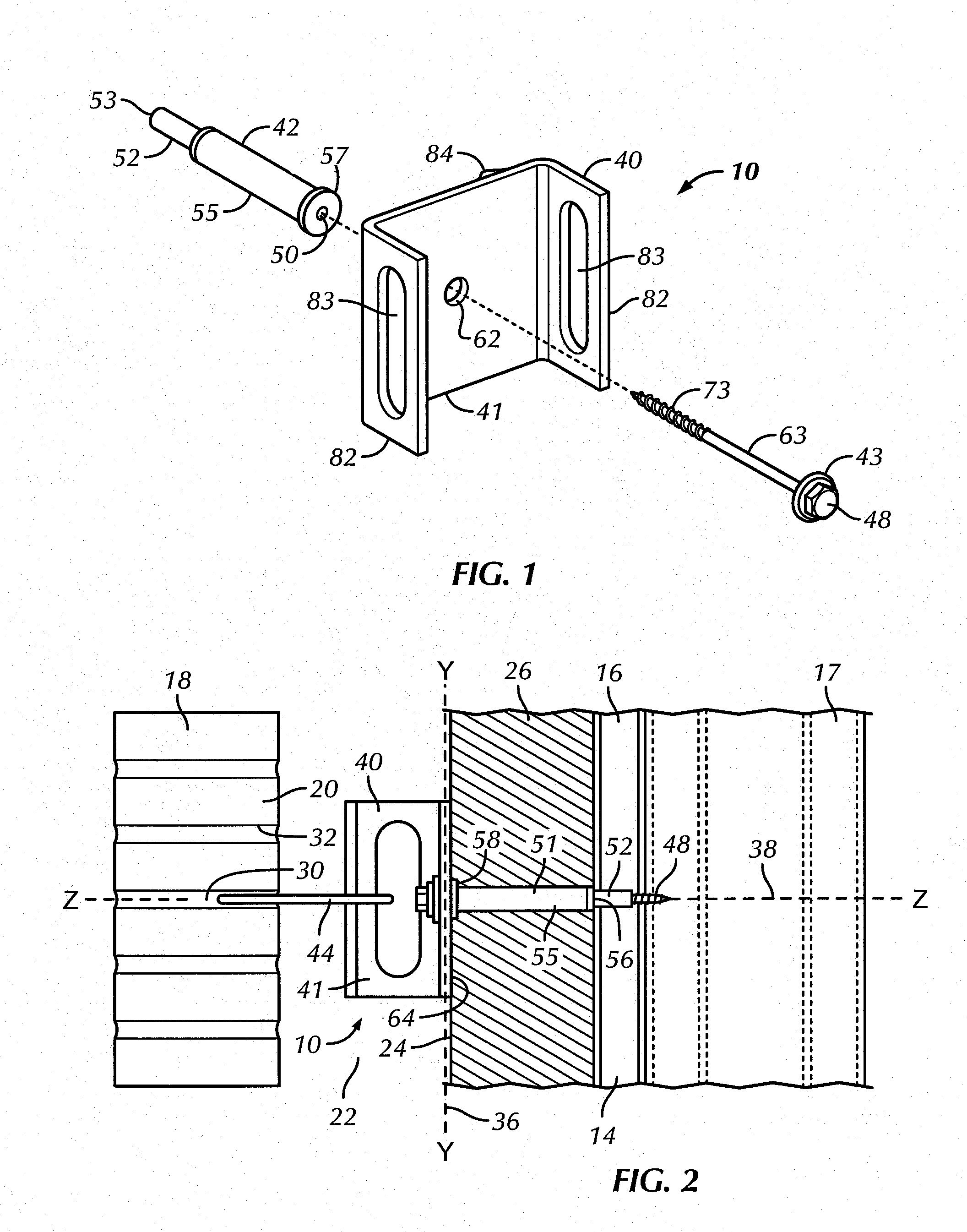

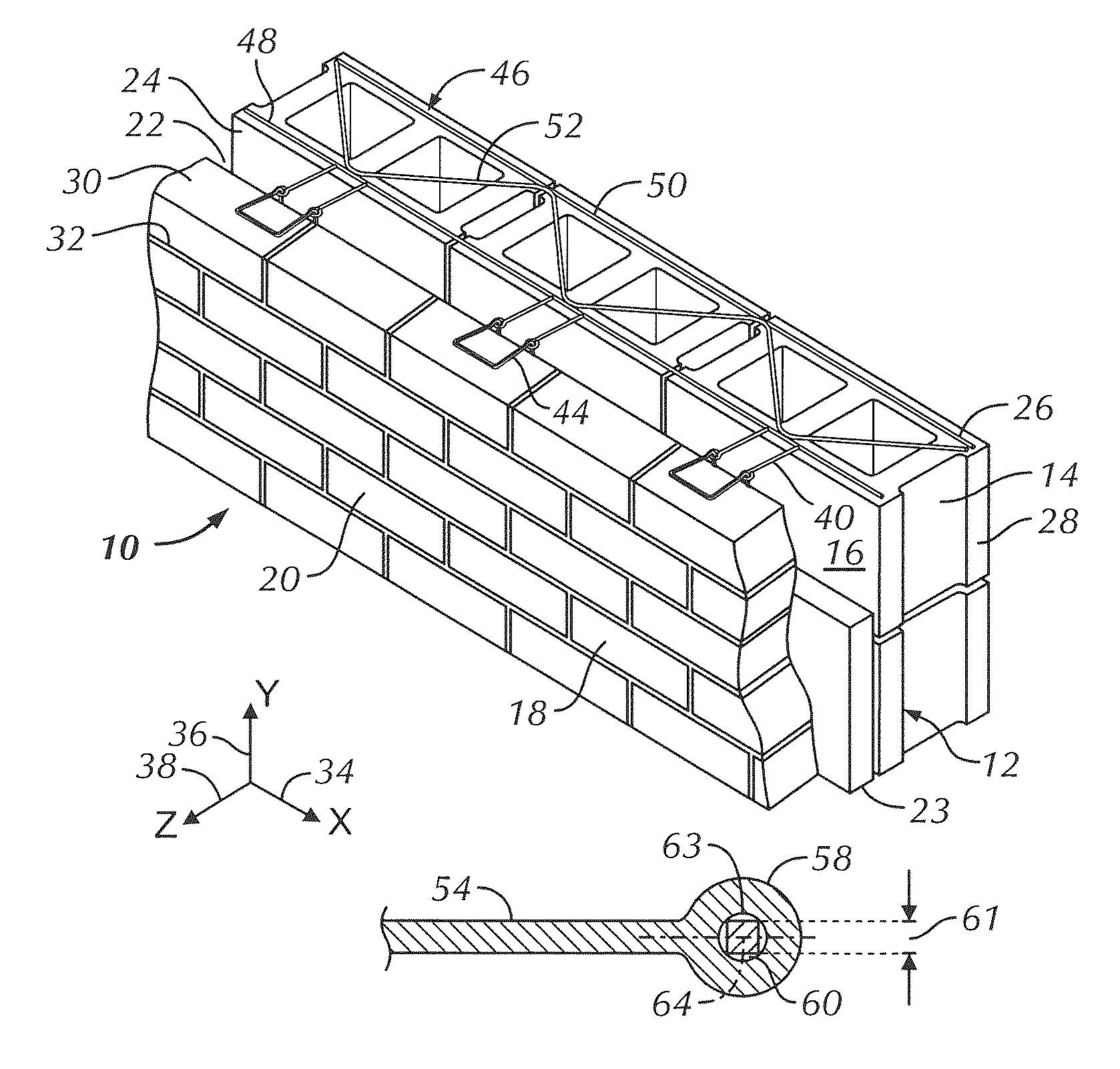

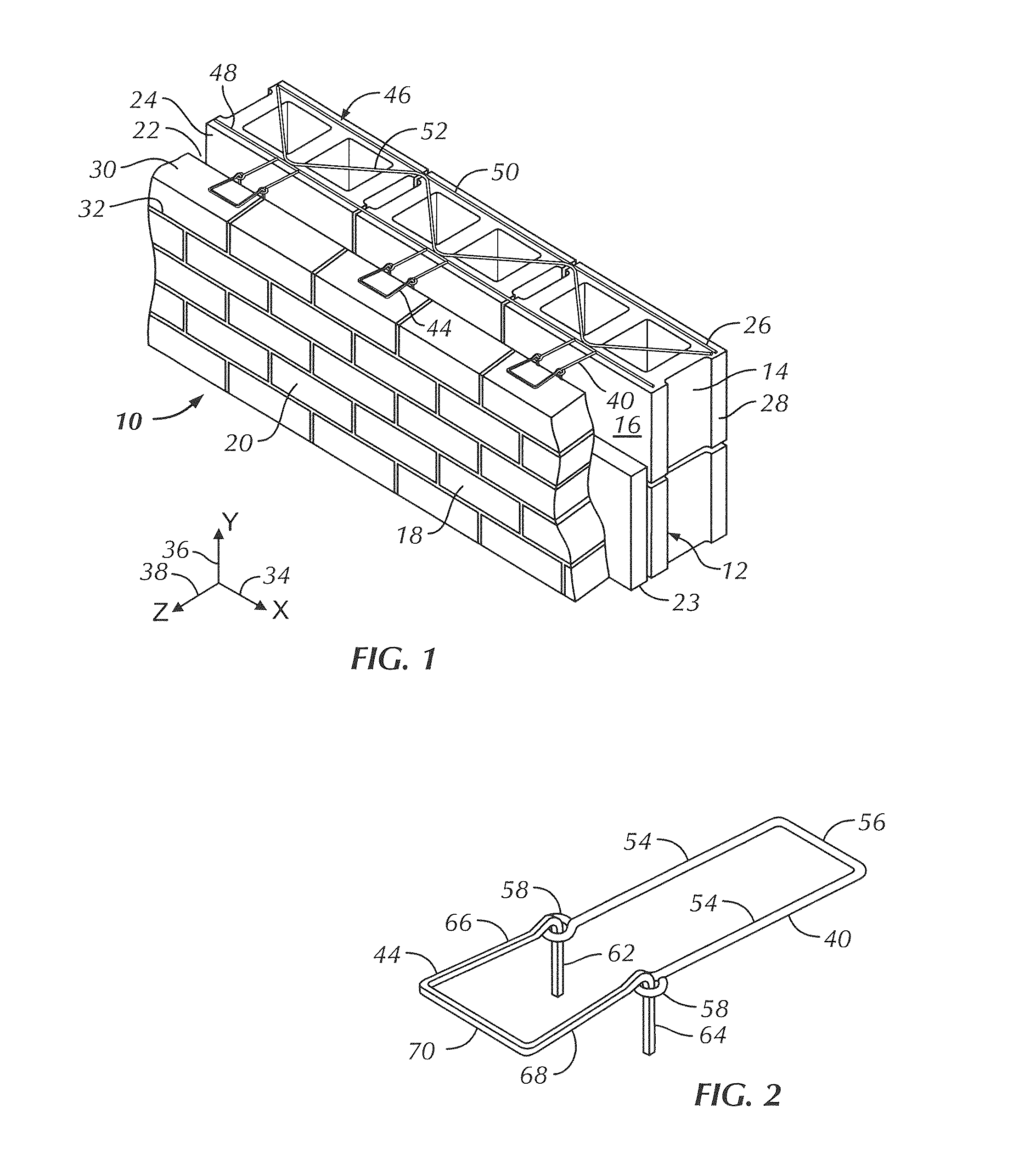

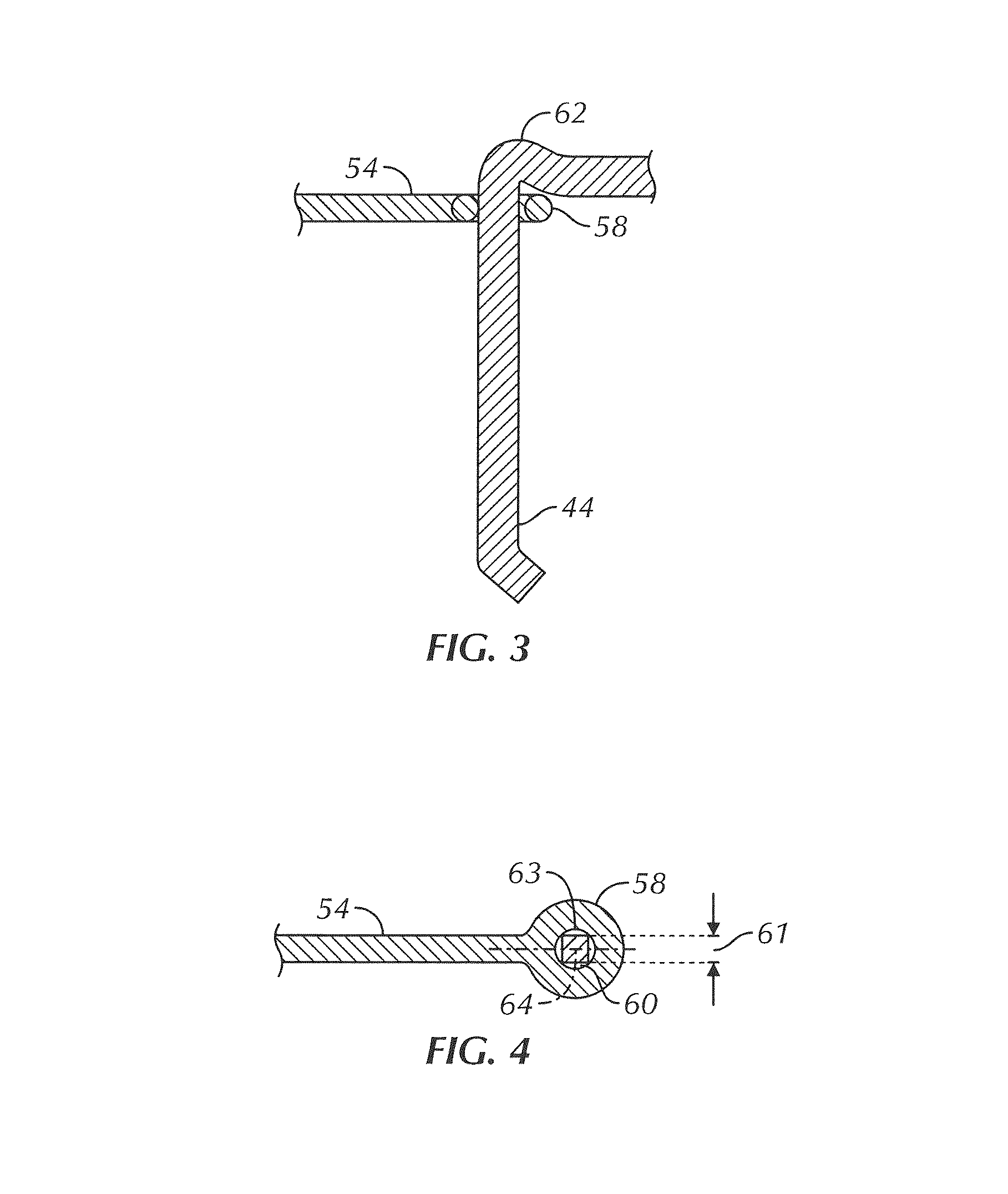

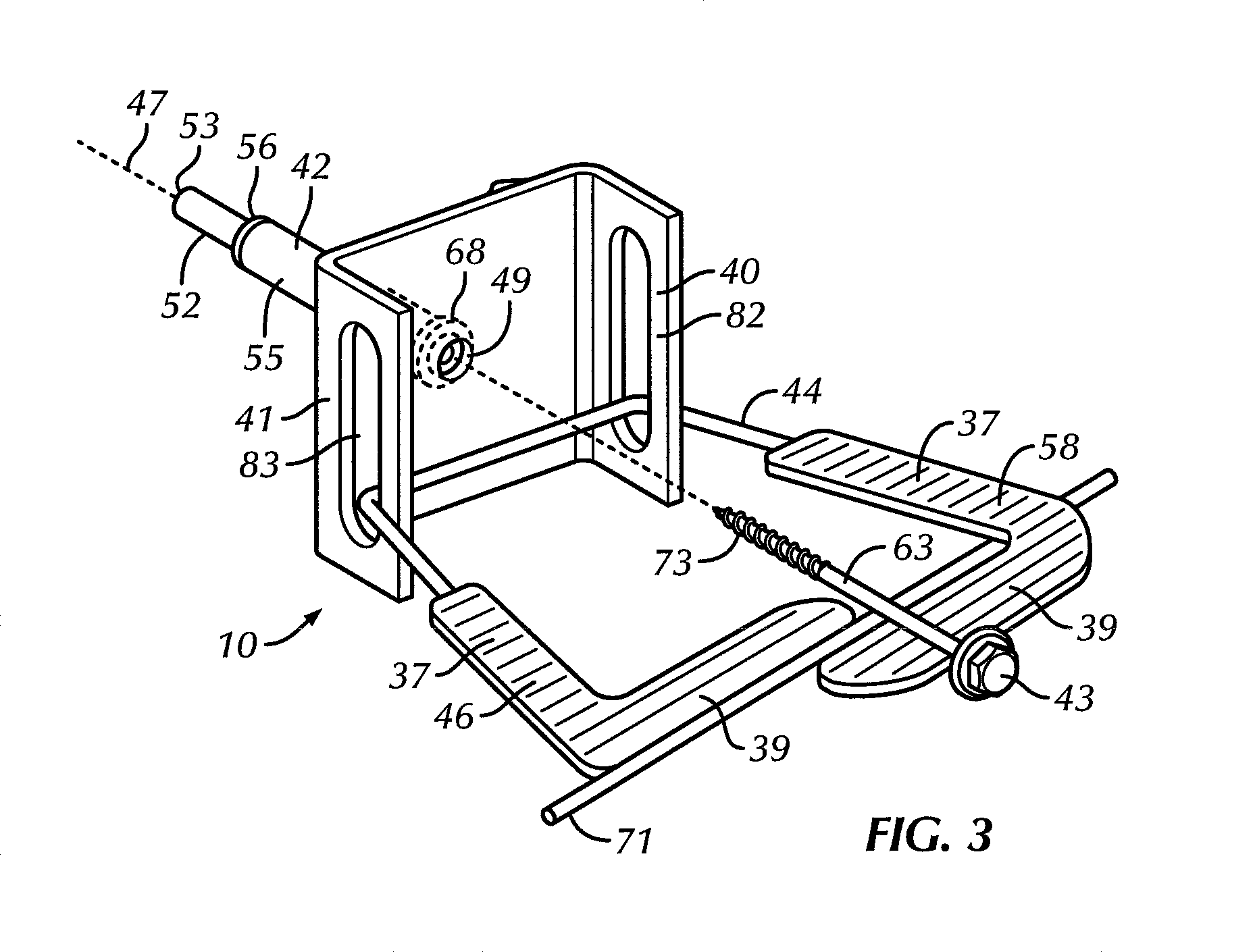

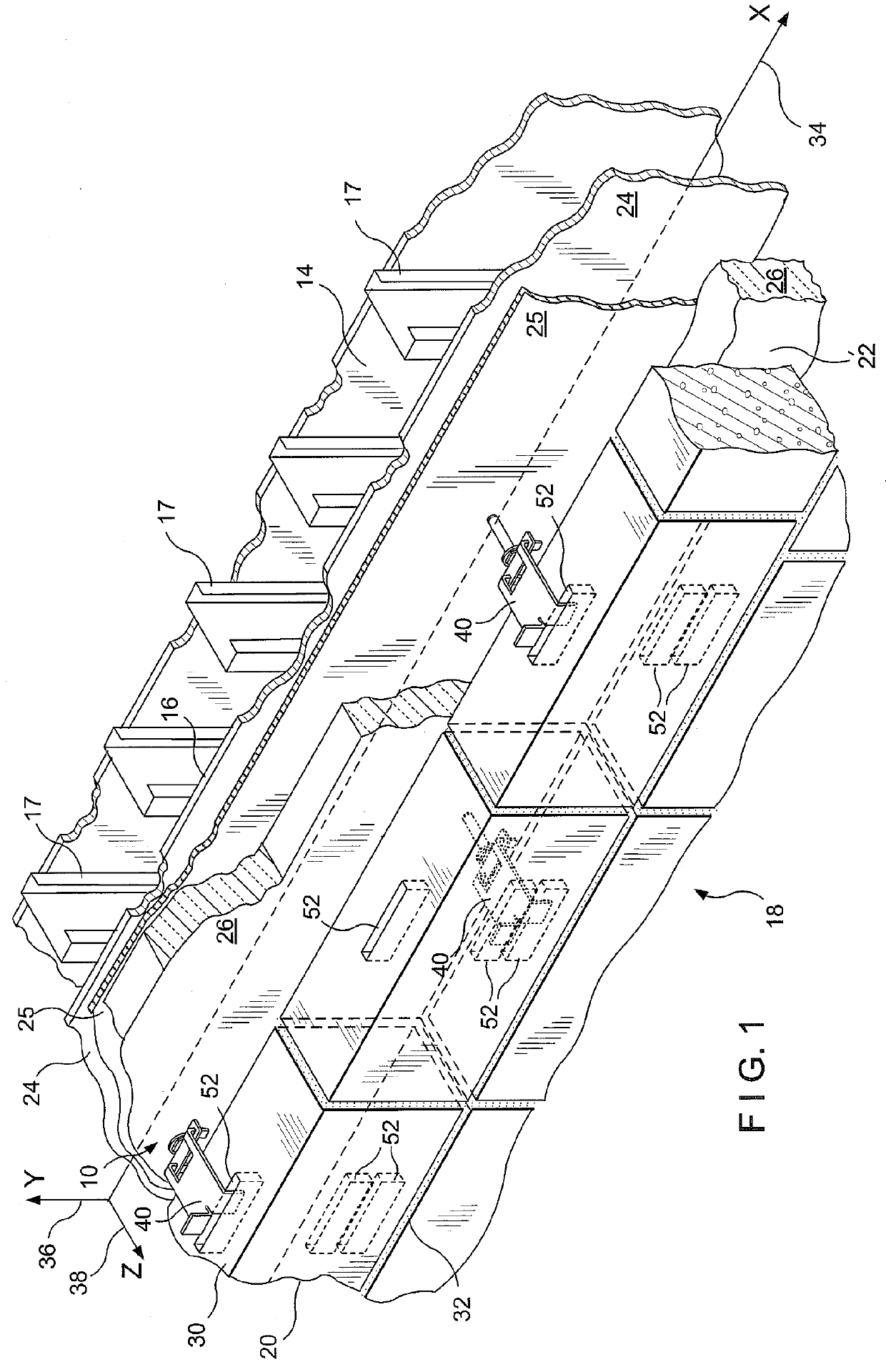

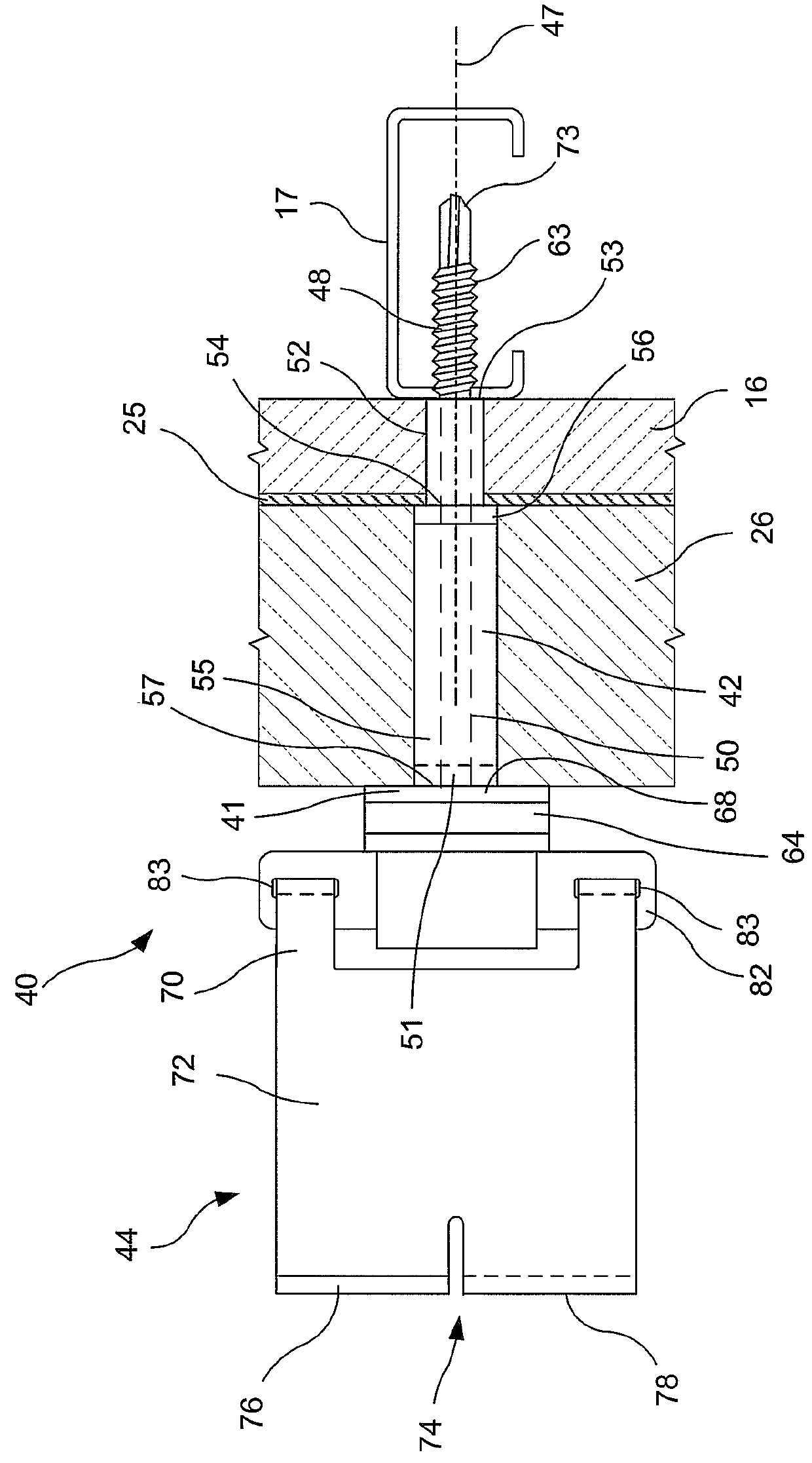

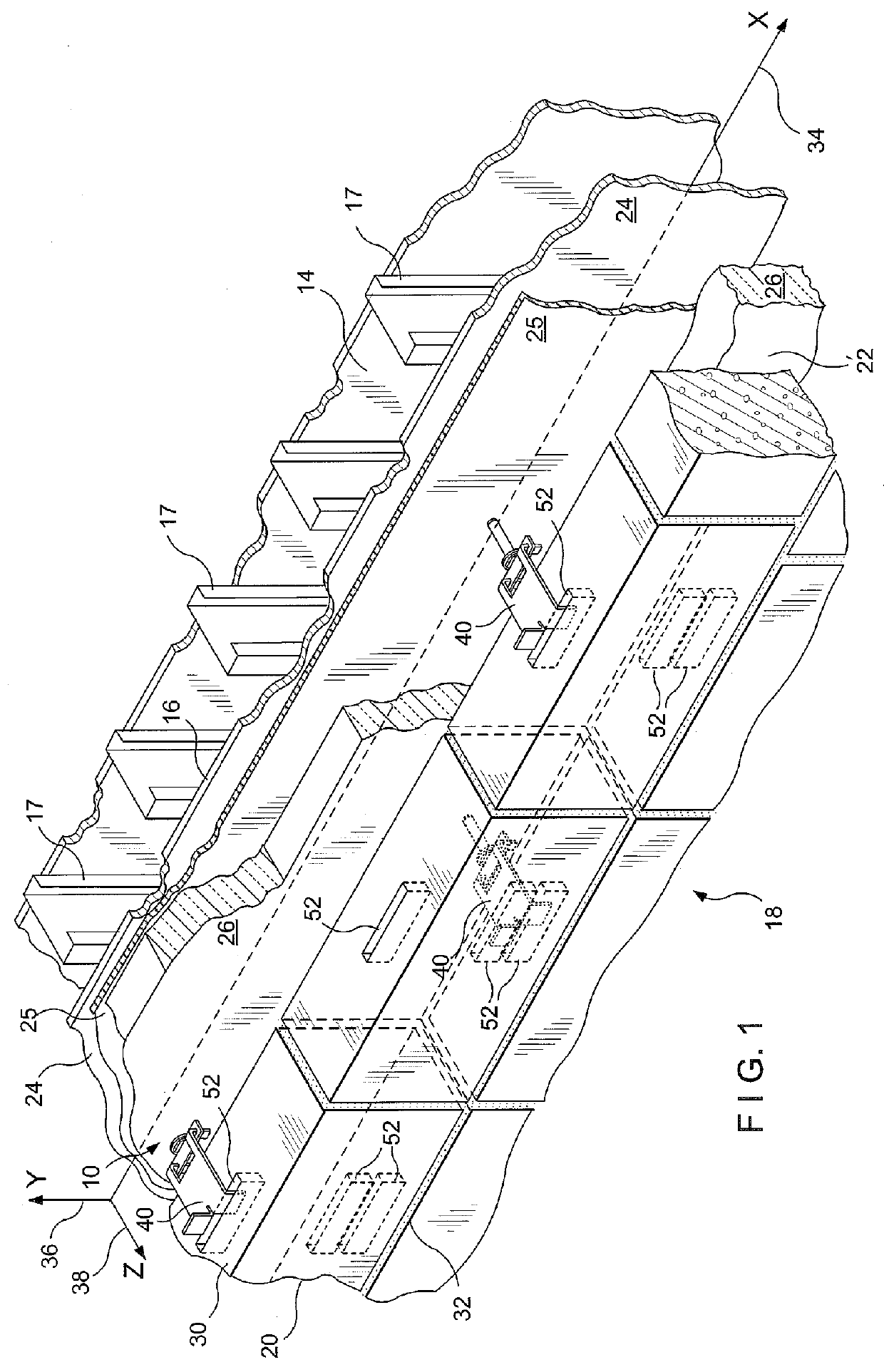

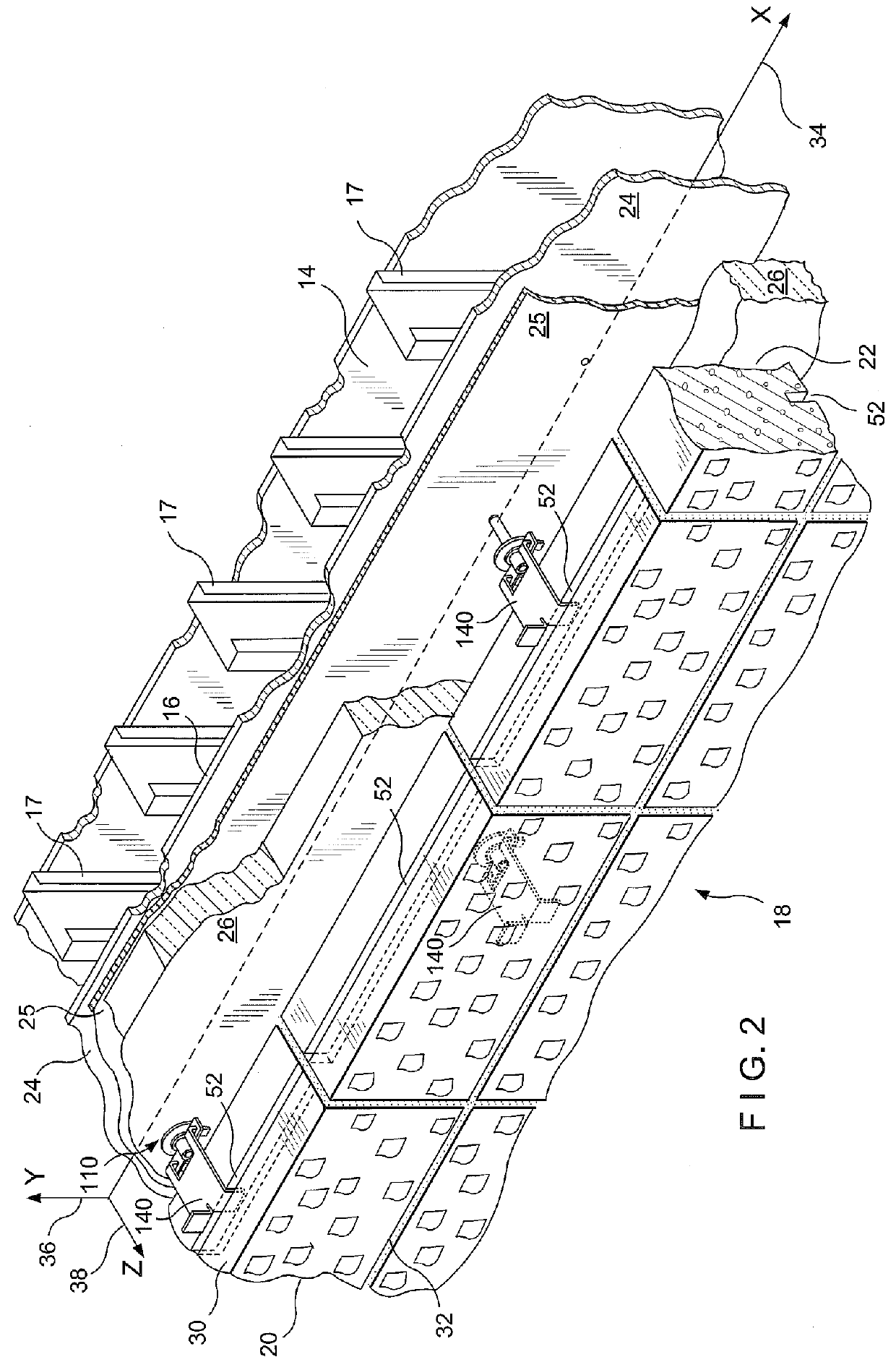

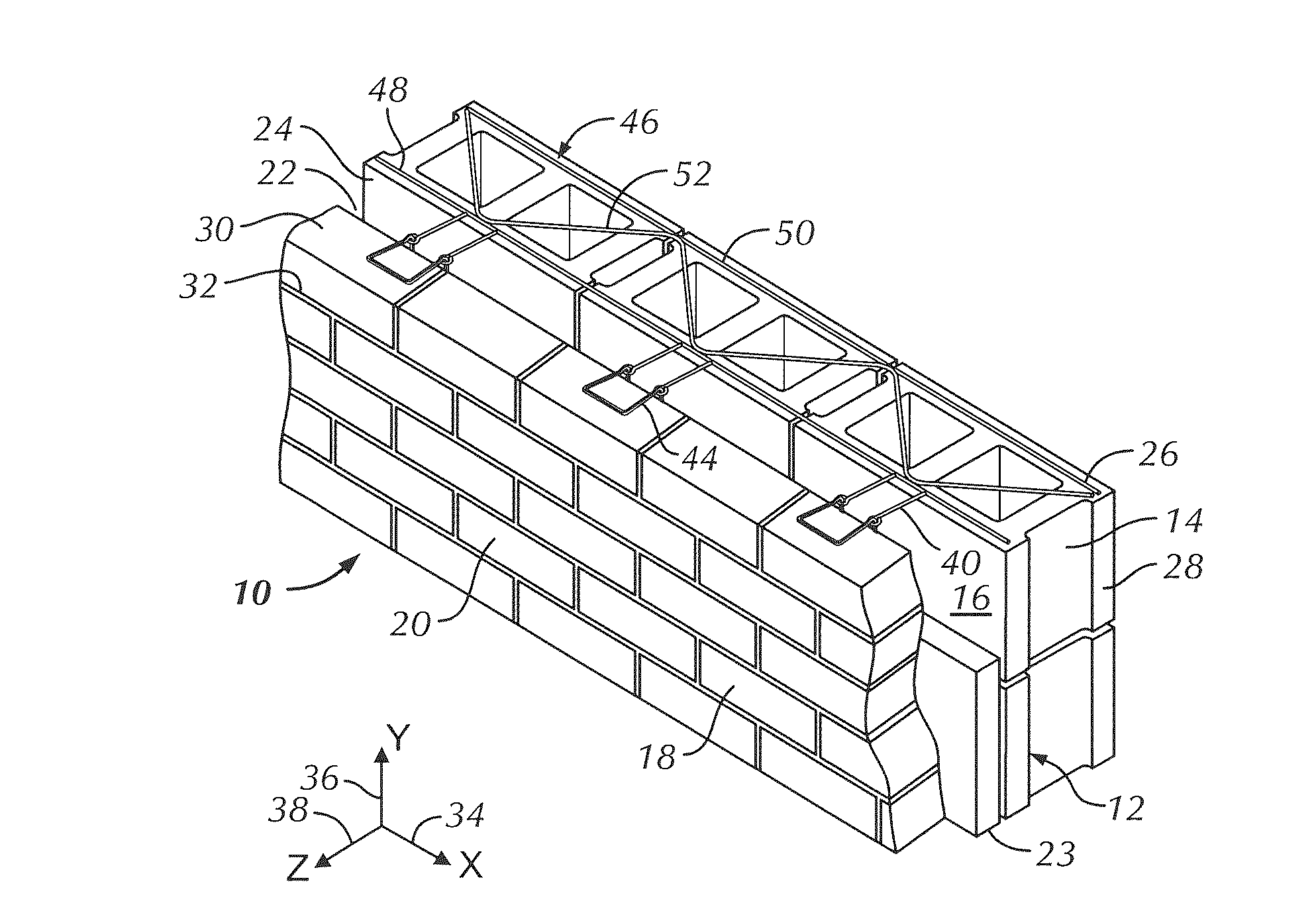

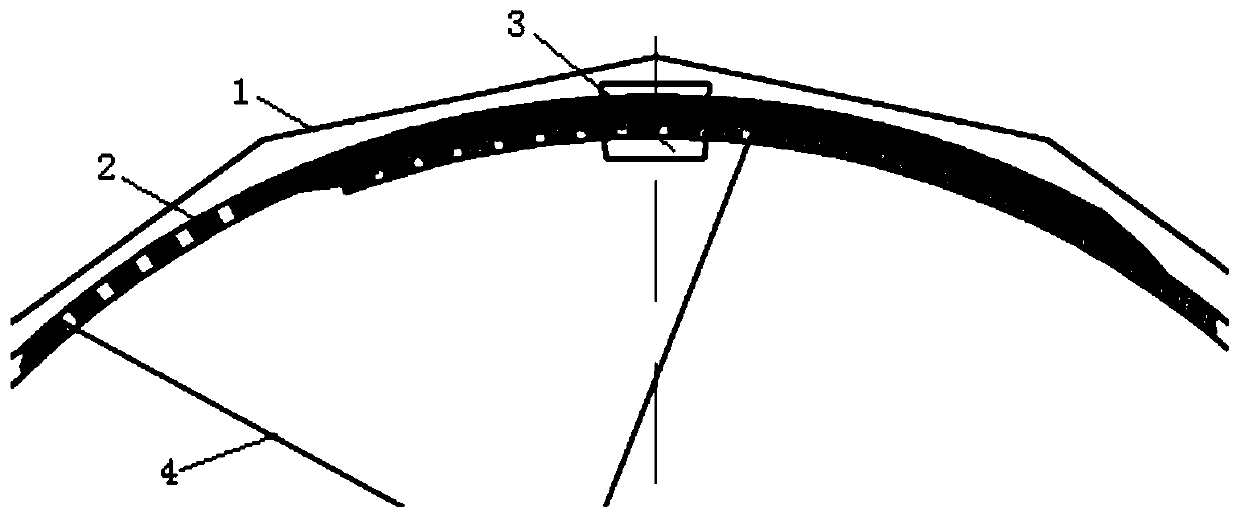

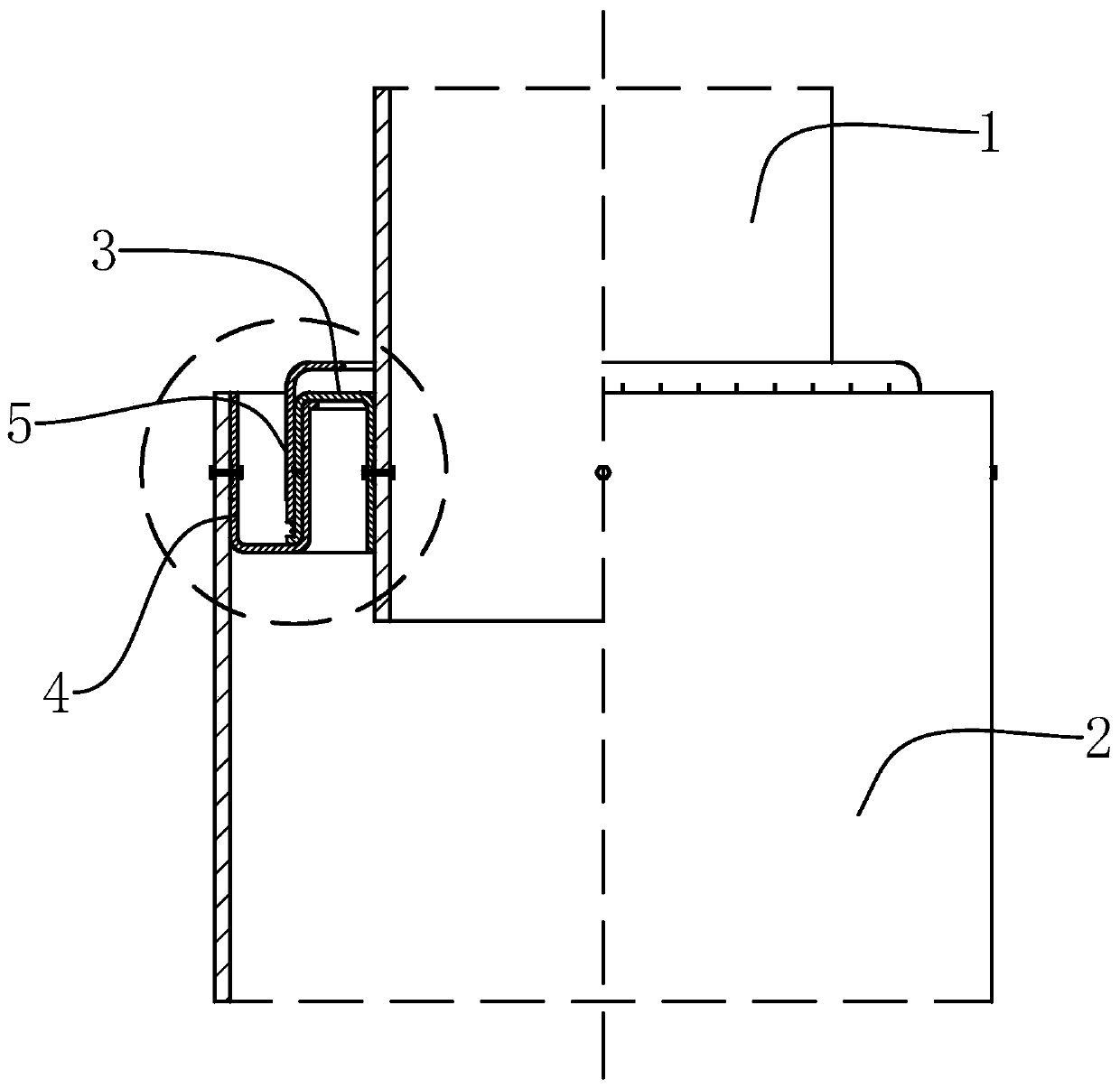

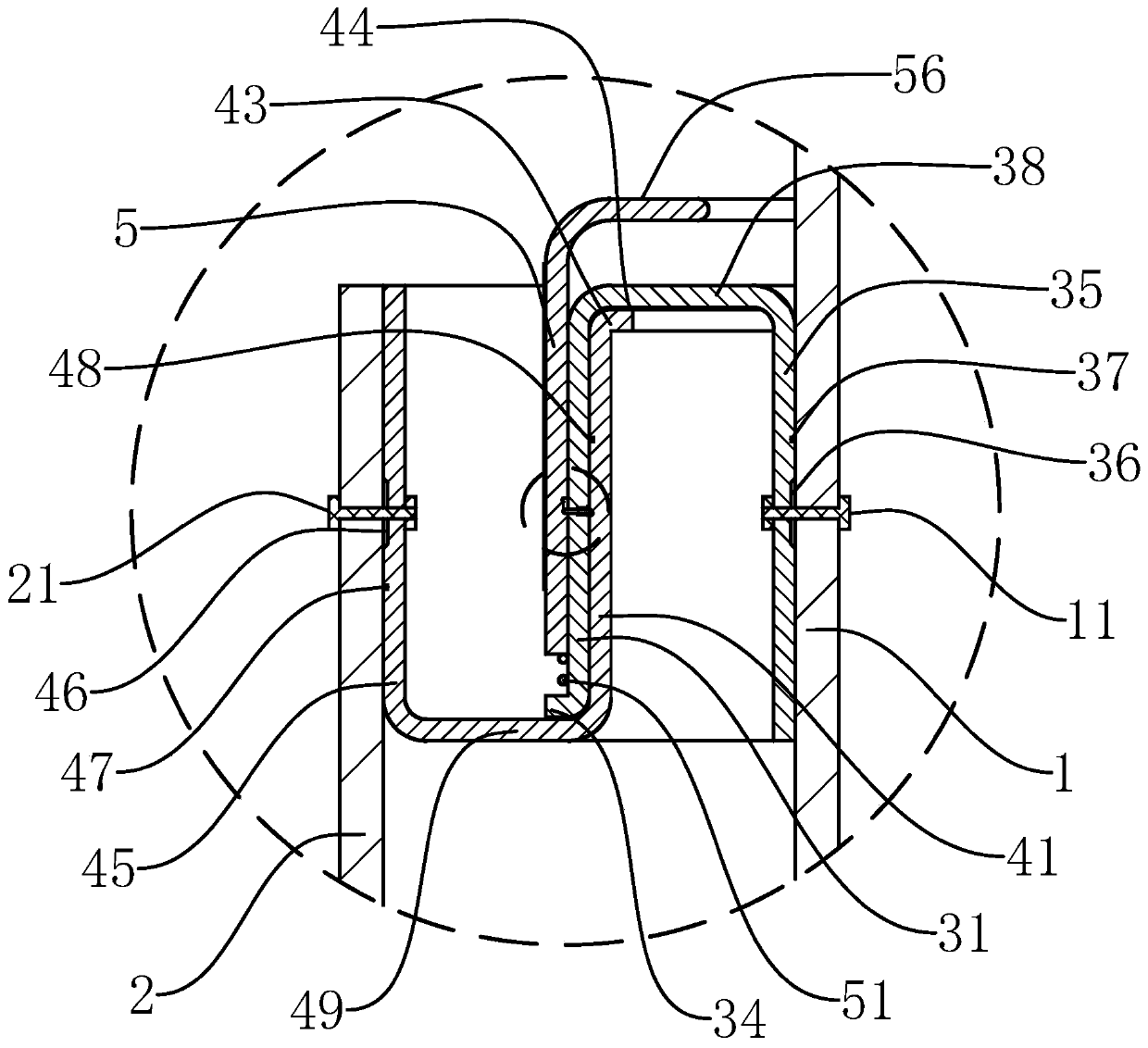

Dual seal anchoring systems for insulated cavity walls

ActiveUS20080141605A1Prevent air infiltrationPrevent water penetrationConstruction materialStrutsEngineeringCavity wall

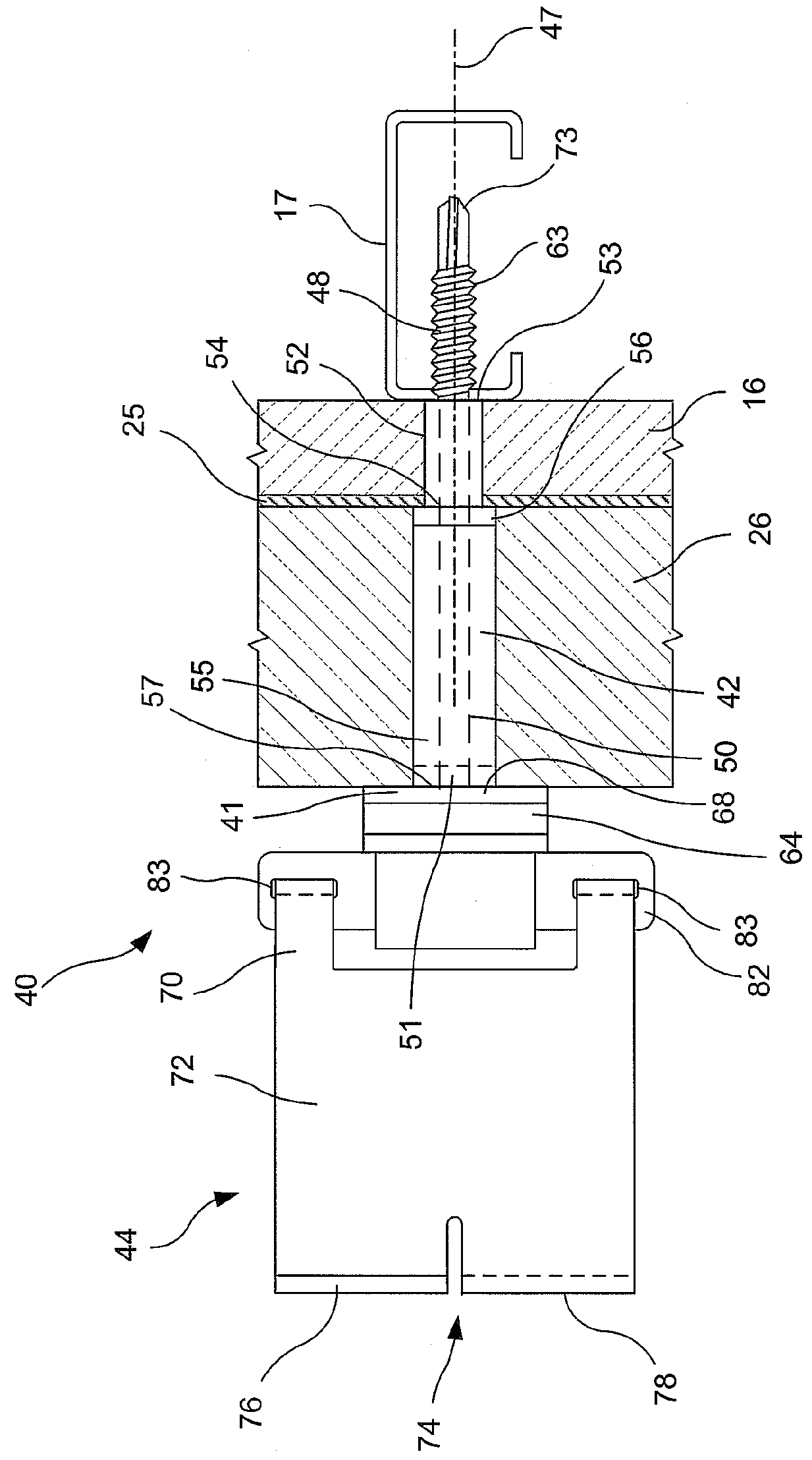

An anchoring system for cavity walls is disclosed. The system includes a stud-type wall anchor and a wire formative veneer tie. The stud has a driver head, a dual-diameter barrel, and a driven tip. A flange at the juncture of the two barrels houses an interior seal; and a flange under the driver head, an exterior seal. The smaller diameter barrel is coextensive with the drywall installation; and the length of the larger diameter barrel, with the rigid insulation. The interior seal seals the insertion point into the drywall installation; and the exterior seal, the opening of the anchor-receiving channel. The interior seal and the larger barrel of the anchor fill the anchor-receiving channel and stabilize the wall anchor. Also, the wall anchor is clamped in place by the seals. The stud-type anchor operates with a variety of veneer ties for different applications.

Owner:HOHMANN & BARNARD INC

Dual seal anchoring systems for insulated cavity walls

ActiveUS8037653B2Increase profitHigh strength connectionConstruction materialStrutsEngineeringCavity wall

An anchoring system for cavity walls is disclosed. The system includes a stud-type wall anchor and a wire formative veneer tie. The stud has a driver head, a dual-diameter barrel, and a driven tip. A flange at the juncture of the two barrels houses an interior seal; and a flange under the driver head, an exterior seal. The smaller diameter barrel is coextensive with the drywall installation; and the length of the larger diameter barrel, with the rigid insulation. The interior seal seals the insertion point into the drywall installation; and the exterior seal, the opening of the anchor-receiving channel. The interior seal and the larger barrel of the anchor fill the anchor-receiving channel and stabilize the wall anchor. Also, the wall anchor is clamped in place by the seals. The stud-type anchor operates with a variety of veneer ties for different applications.

Owner:HOHMANN & BARNARD INC

Dual seal tubular anchor for cavity walls

ActiveUS20120304576A1Prevent air infiltrationPrevent water penetrationConstruction materialStrutsEngineeringInsertion point

An anchoring system for cavity walls is disclosed. The system includes a stud-type wall anchor and a wire formative veneer tie. The stud has a driver head, a dual-diameter barrel, and a driven tip. A flange at the juncture of the two barrels houses an interior seal; and a flange under the driver head, an exterior seal. The smaller diameter barrel is coextensive with the drywall installation; and the length of the larger diameter barrel, with the rigid insulation. The interior seal seals the insertion point into the drywall installation; and the exterior seal, the opening of the anchor-receiving channel. The interior seal and the larger barrel of the anchor fill the anchor-receiving channel and stabilize the wall anchor. Also, the wall anchor is clamped in place by the seals. The stud-type anchor operates with a variety of veneer ties for different applications.

Owner:HOHMANN & BARNARD INC

Dual seal tubular anchor for cavity walls

ActiveUS8555596B2Increase profitHigh strength connectionStrutsConstruction materialEngineeringInsertion point

An anchoring system for cavity walls is disclosed. The system includes a stud-type wall anchor and a wire formative veneer tie. The stud has a driver head, a dual-diameter barrel, and a driven tip. A flange at the juncture of the two barrels houses an interior seal; and a flange under the driver head, an exterior seal. The smaller diameter barrel is coextensive with the drywall installation; and the length of the larger diameter barrel, with the rigid insulation. The interior seal seals the insertion point into the drywall installation; and the exterior seal, the opening of the anchor-receiving channel. The interior seal and the larger barrel of the anchor fill the anchor-receiving channel and stabilize the wall anchor. Also, the wall anchor is clamped in place by the seals. The stud-type anchor operates with a variety of veneer ties for different applications.

Owner:HOHMANN & BARNARD INC

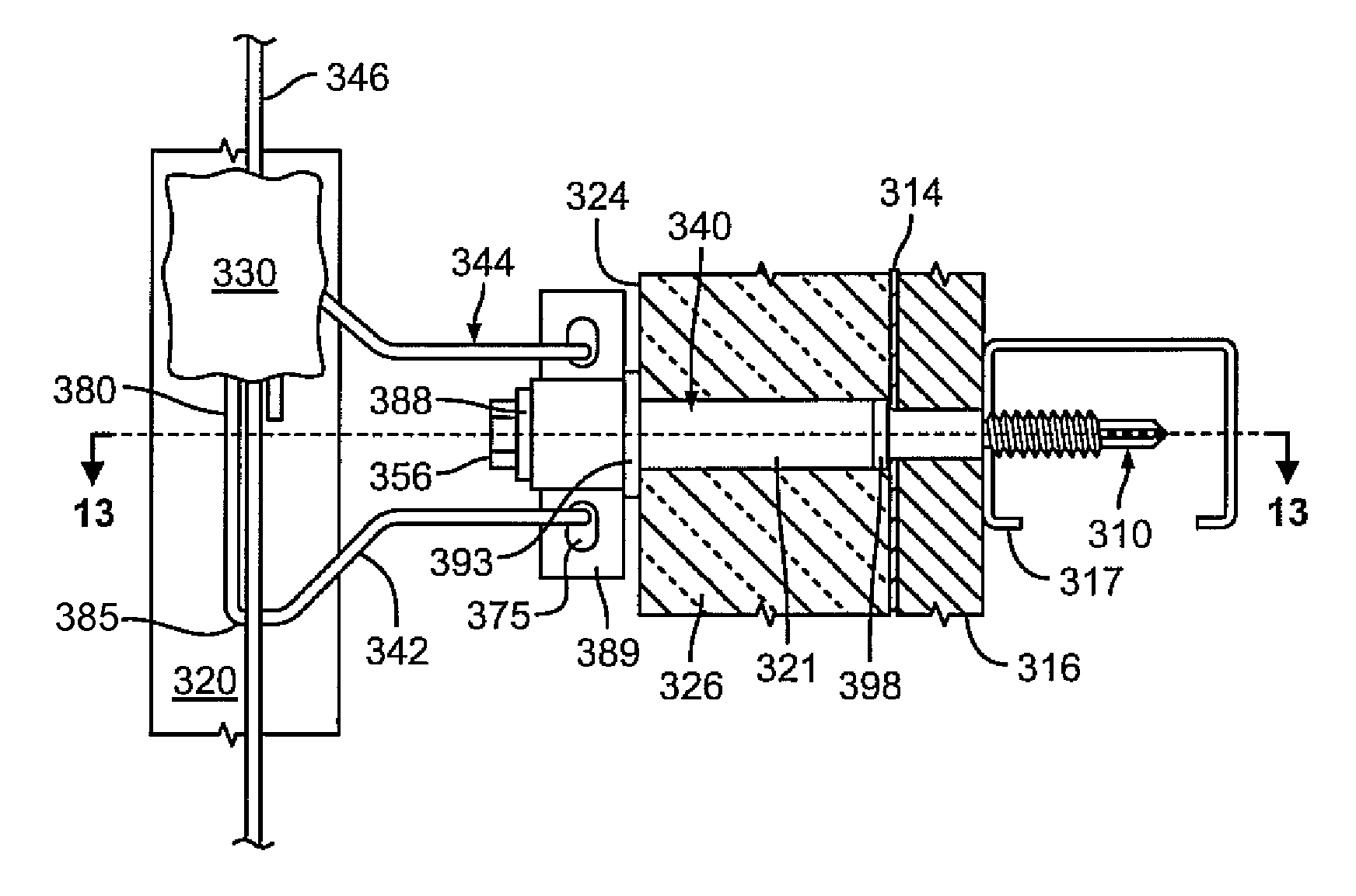

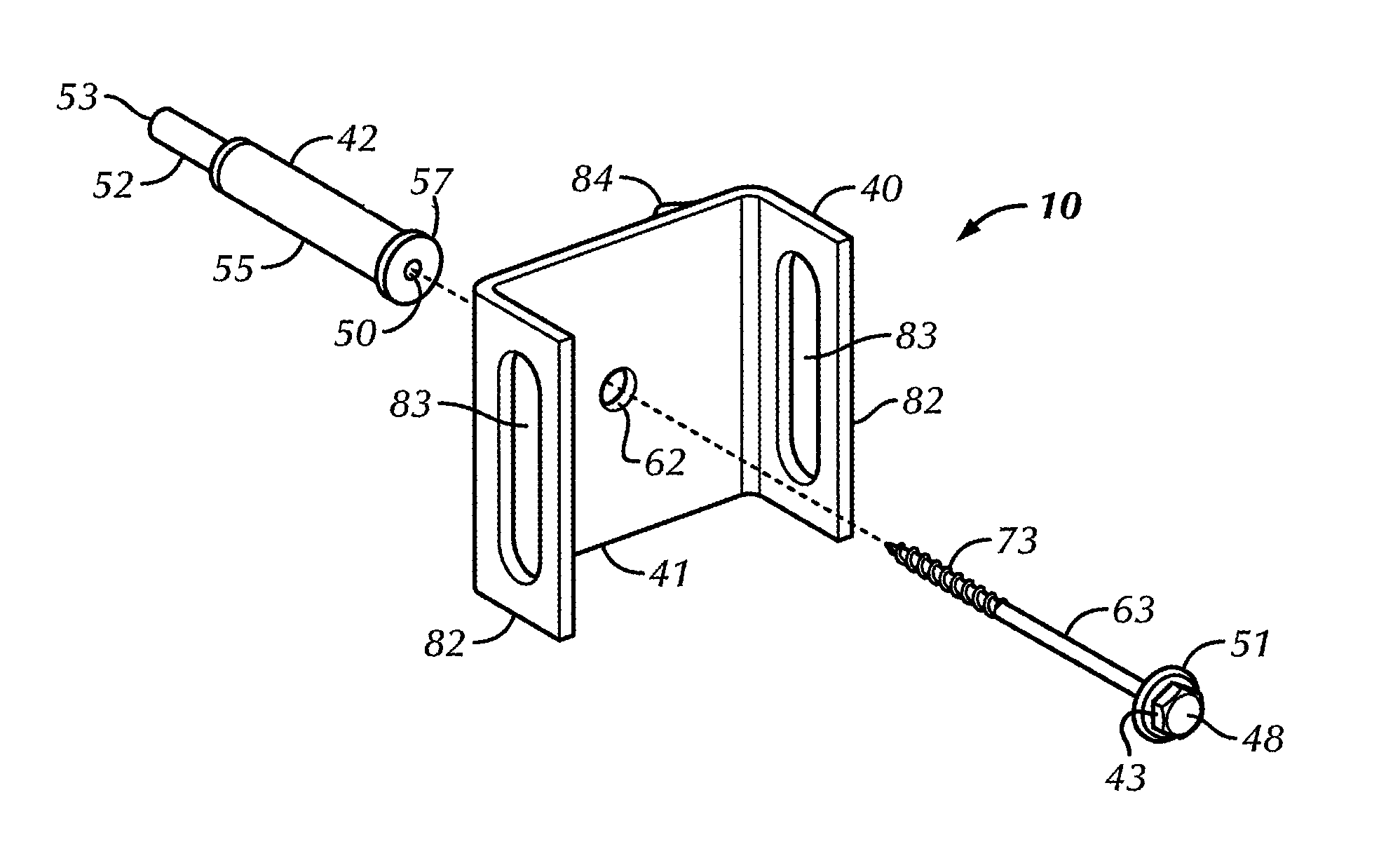

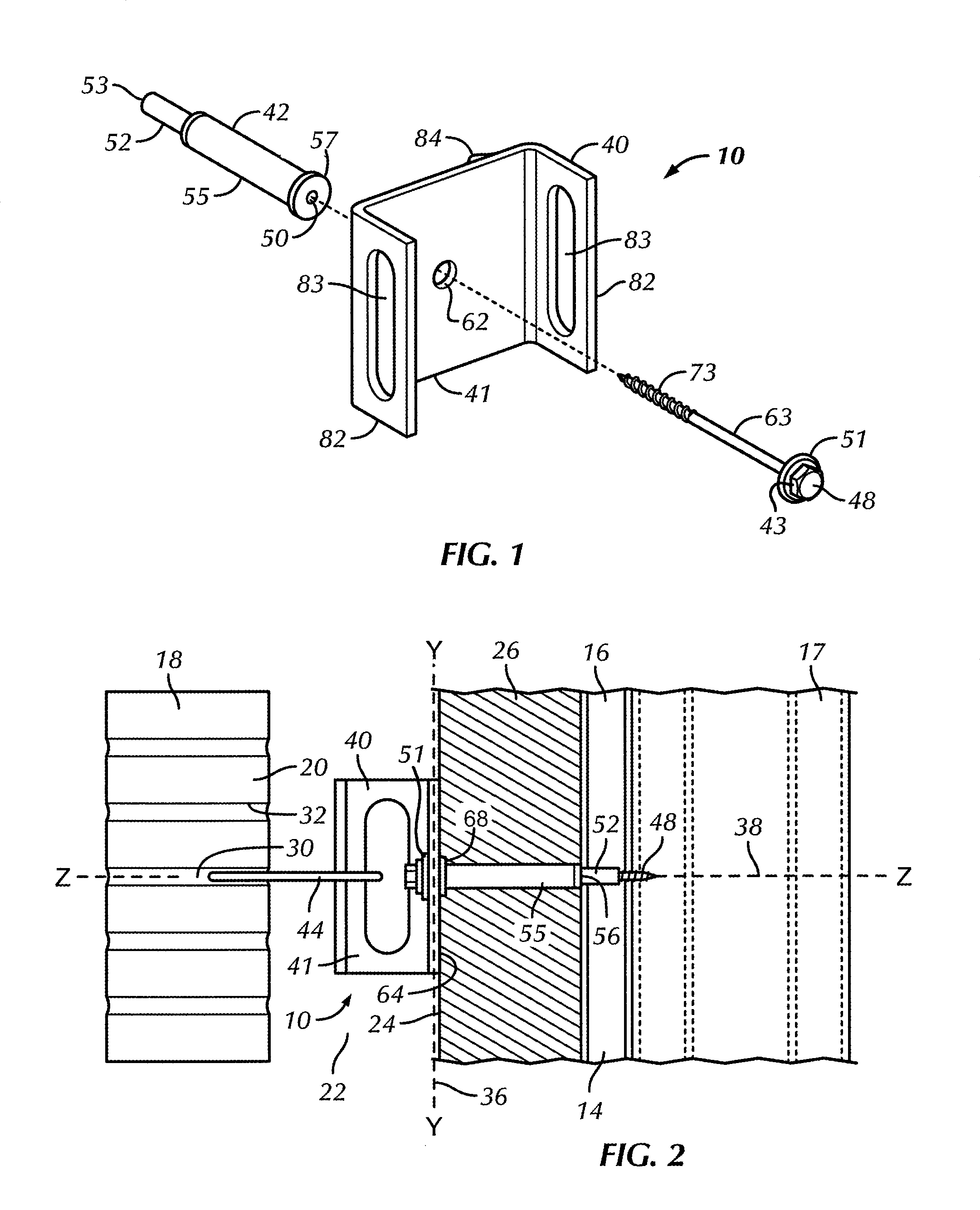

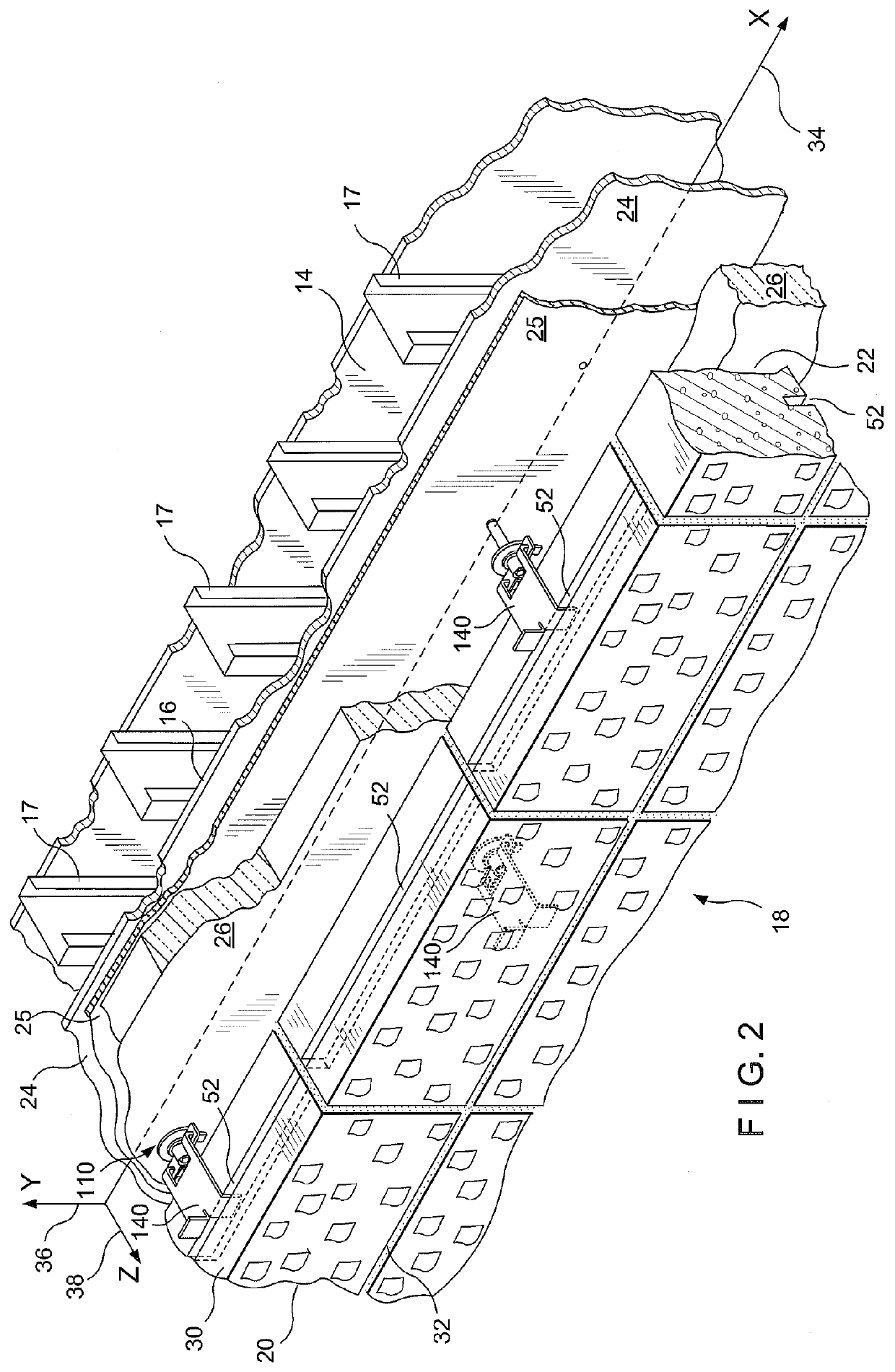

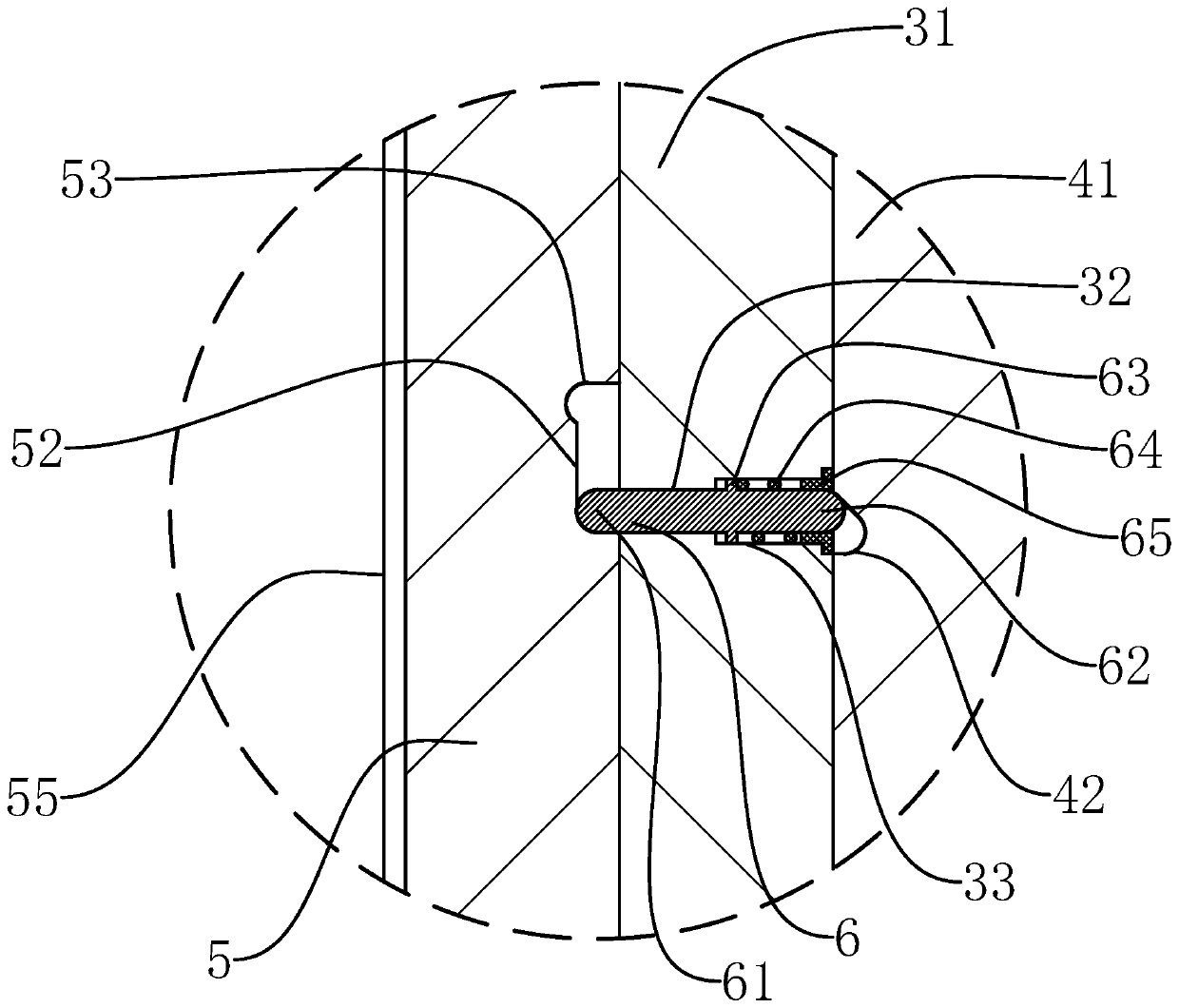

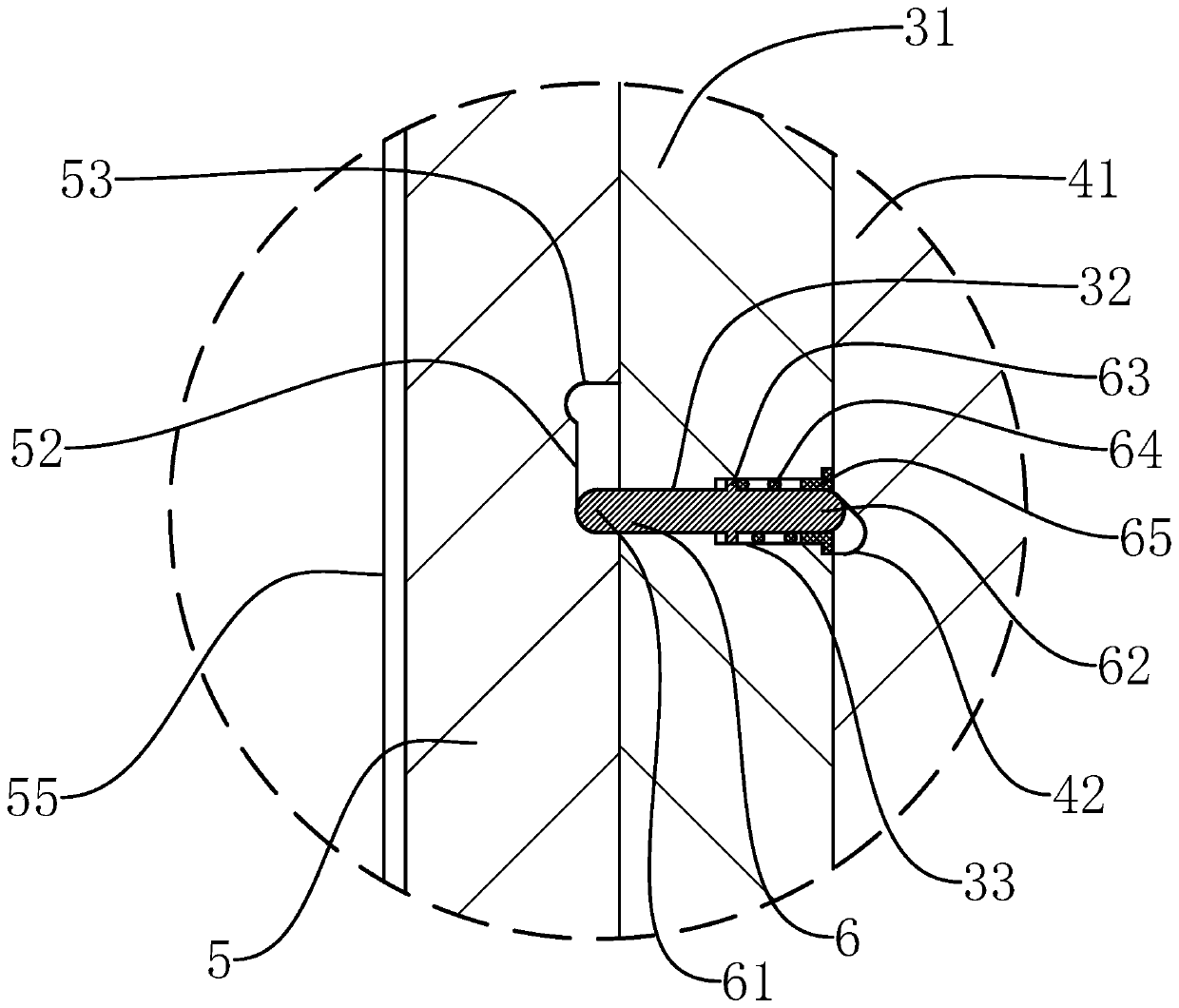

Thermally-isolated anchoring systems for cavity walls

InactiveUS20130247483A1Precludes pin-point loadingPrevent disengagementProtective buildings/sheltersBuilding reinforcementsWater vaporSurface mounting

A high-strength thermally-isolating surface-mounted anchoring system for a cavity wall is disclosed. The thermally-isolated anchoring system is adaptable to varied structures, including high-span applications, and for use with interlocking veneer ties and reinforcement wires. The anchoring system includes an anchor base and a stepped cylinder which sheaths the mounting hardware to limit insulation tearing and resultant loss of insulation integrity. The anchoring system is thermally-isolated through the use of a series of strategically placed compressible nonconductive fittings. Seals are formed which preclude penetration of air, moisture, and water vapor into the wall structure.

Owner:HOHMANN & BARNARD INC

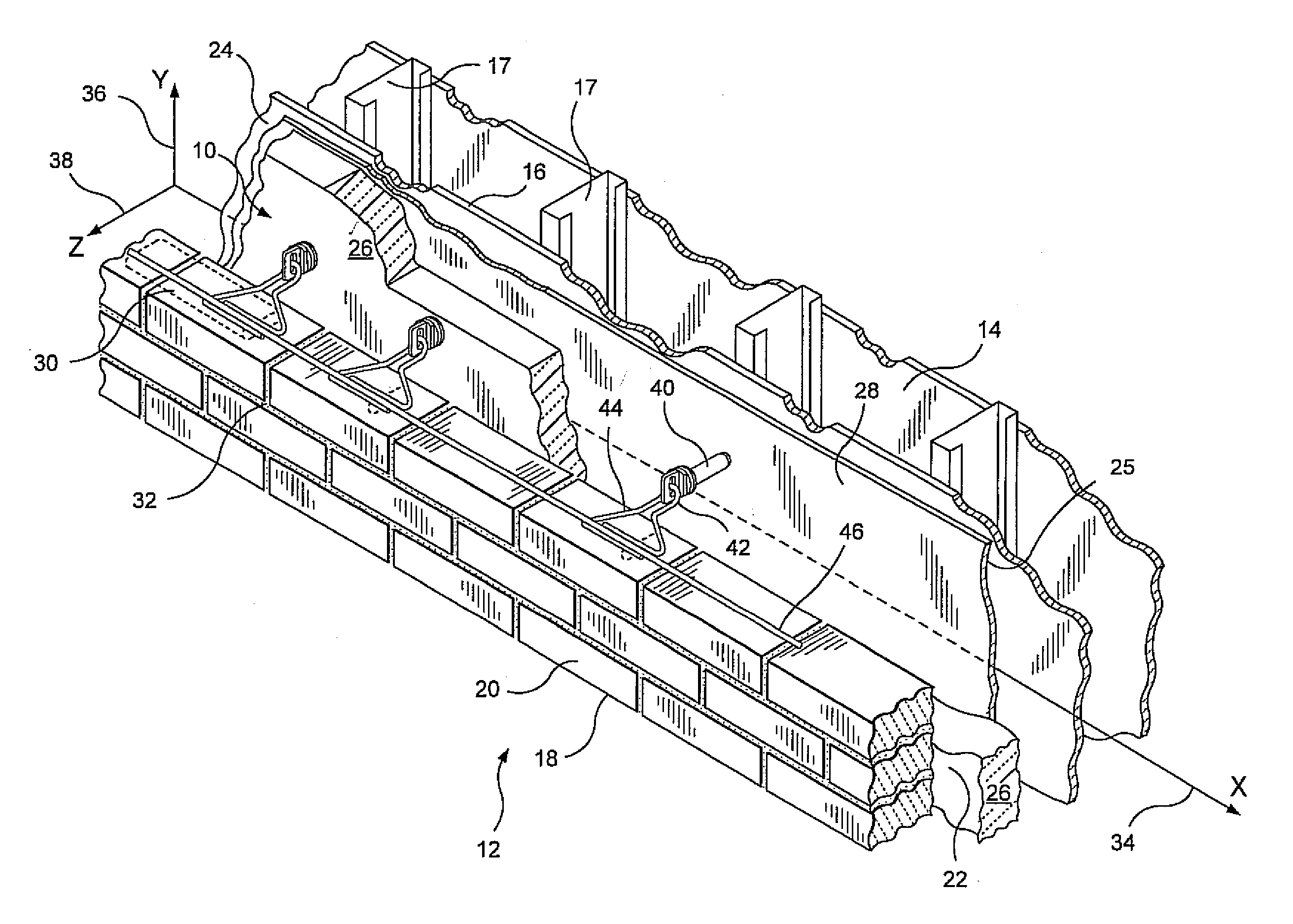

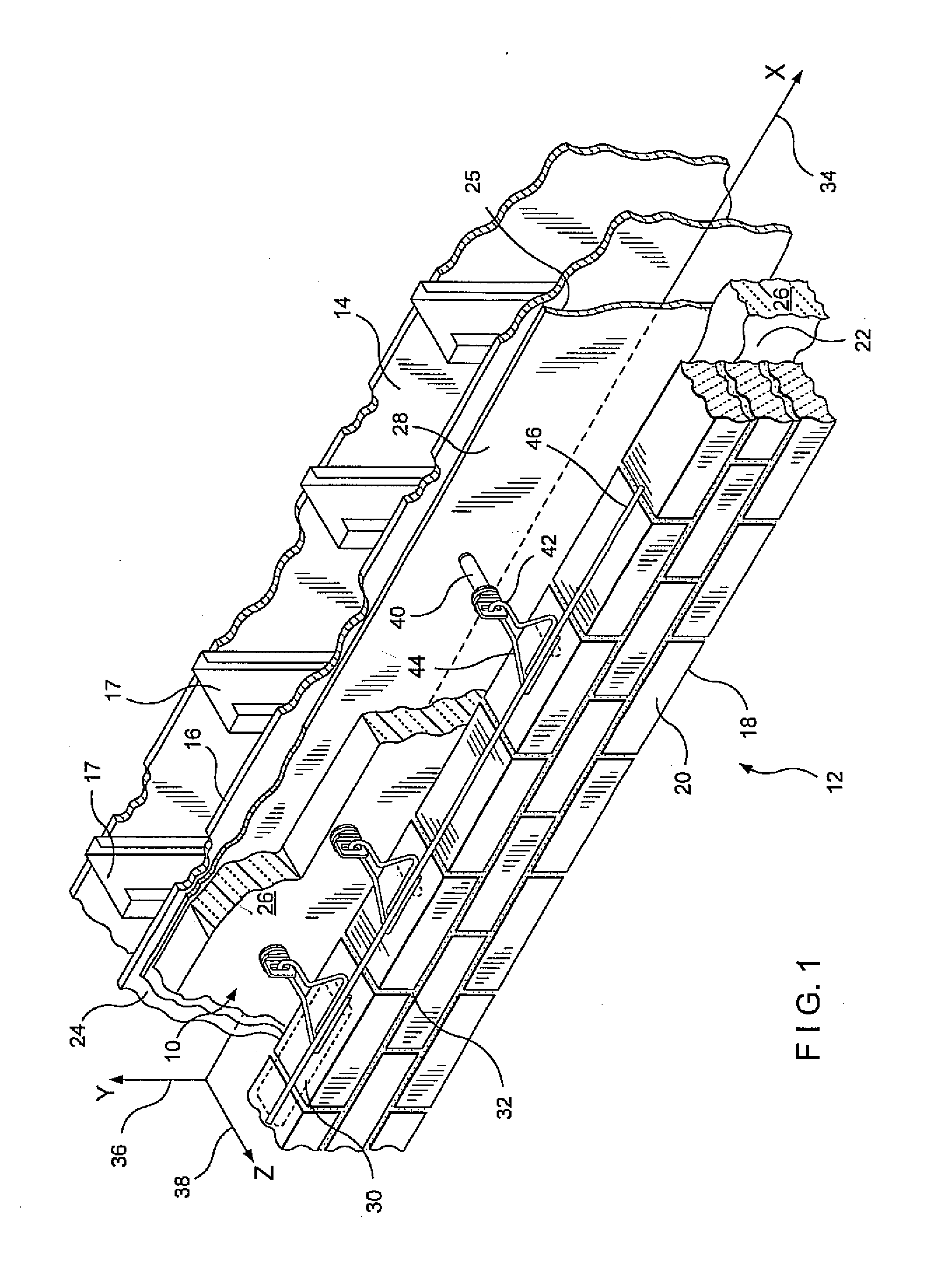

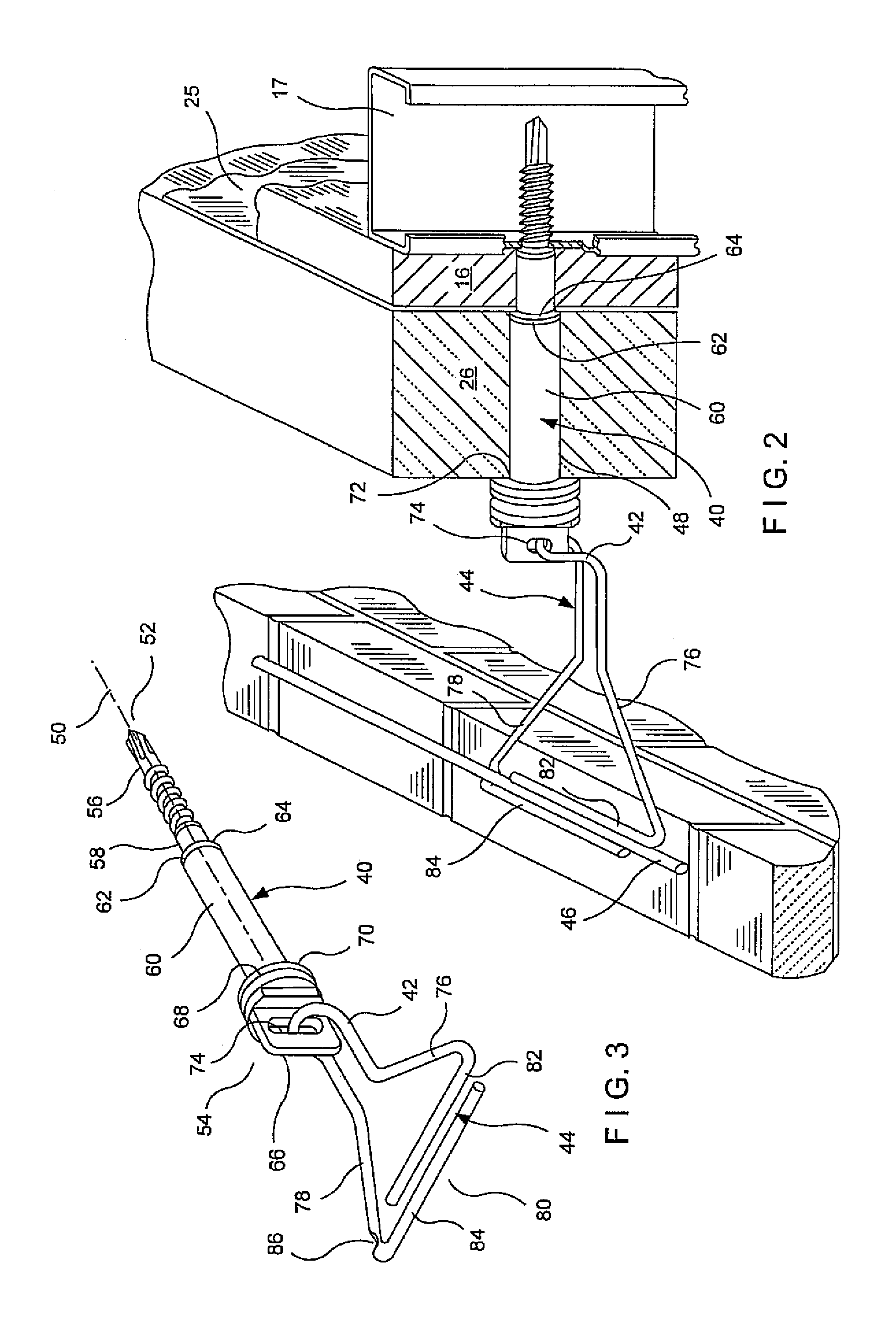

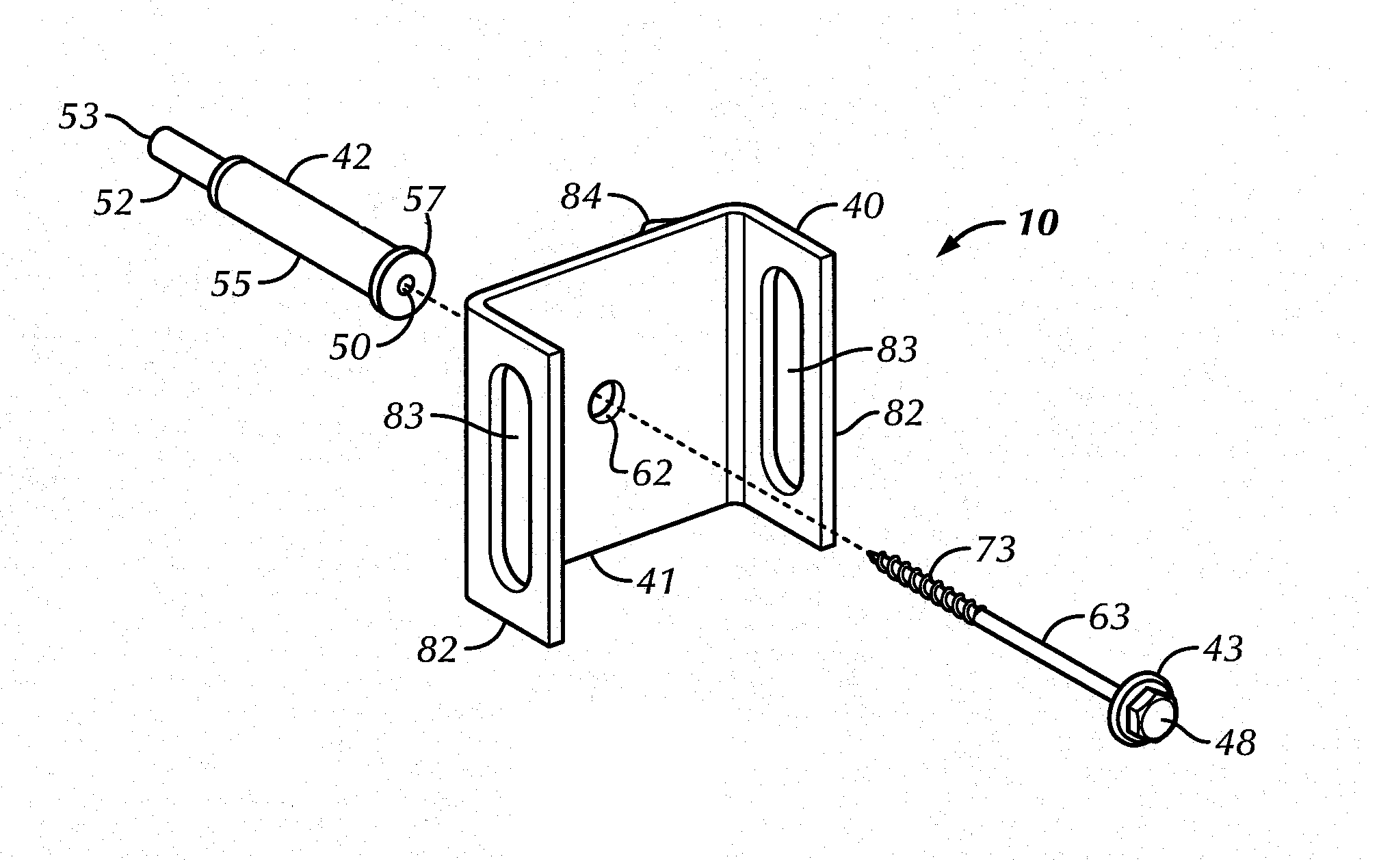

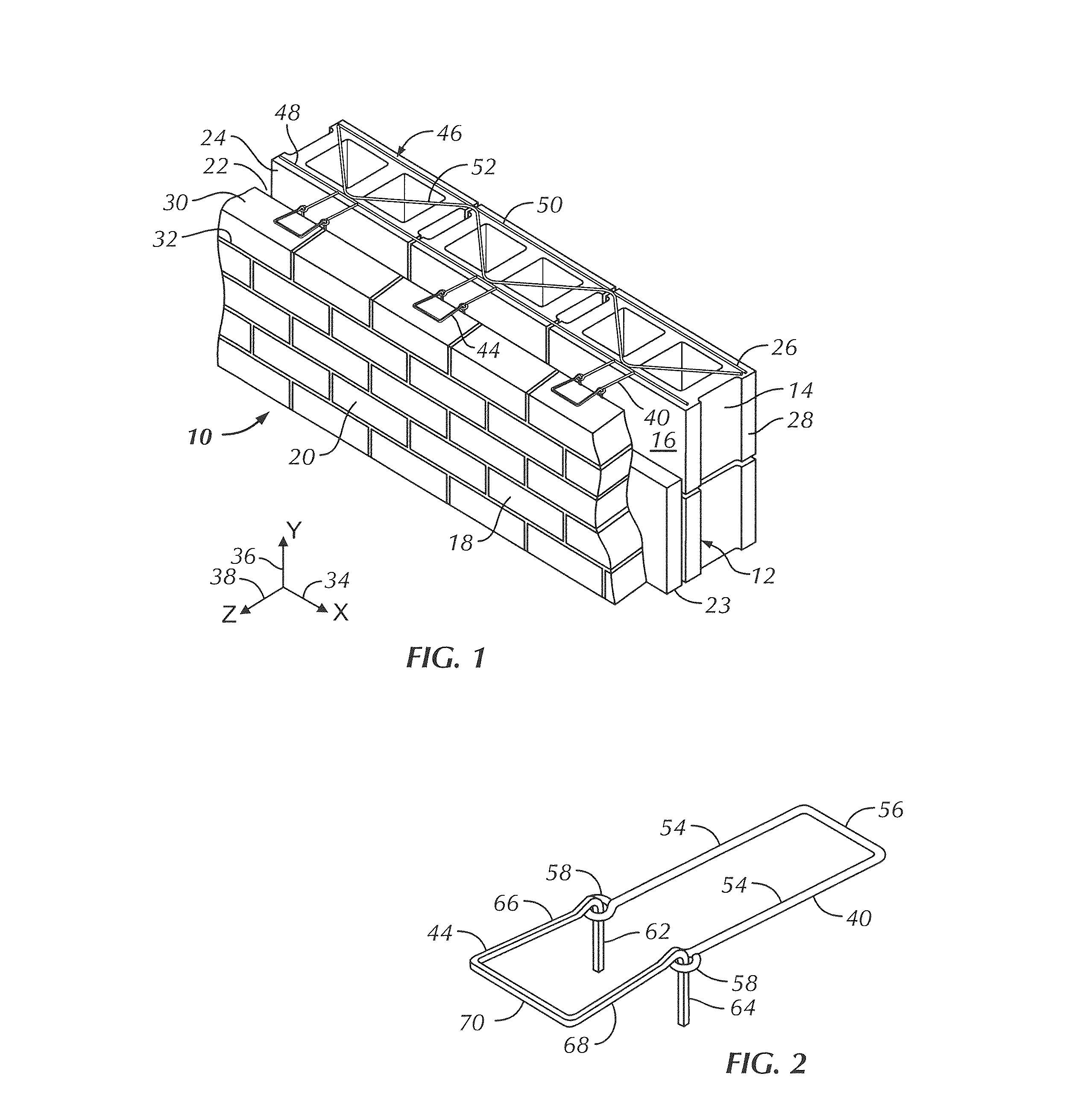

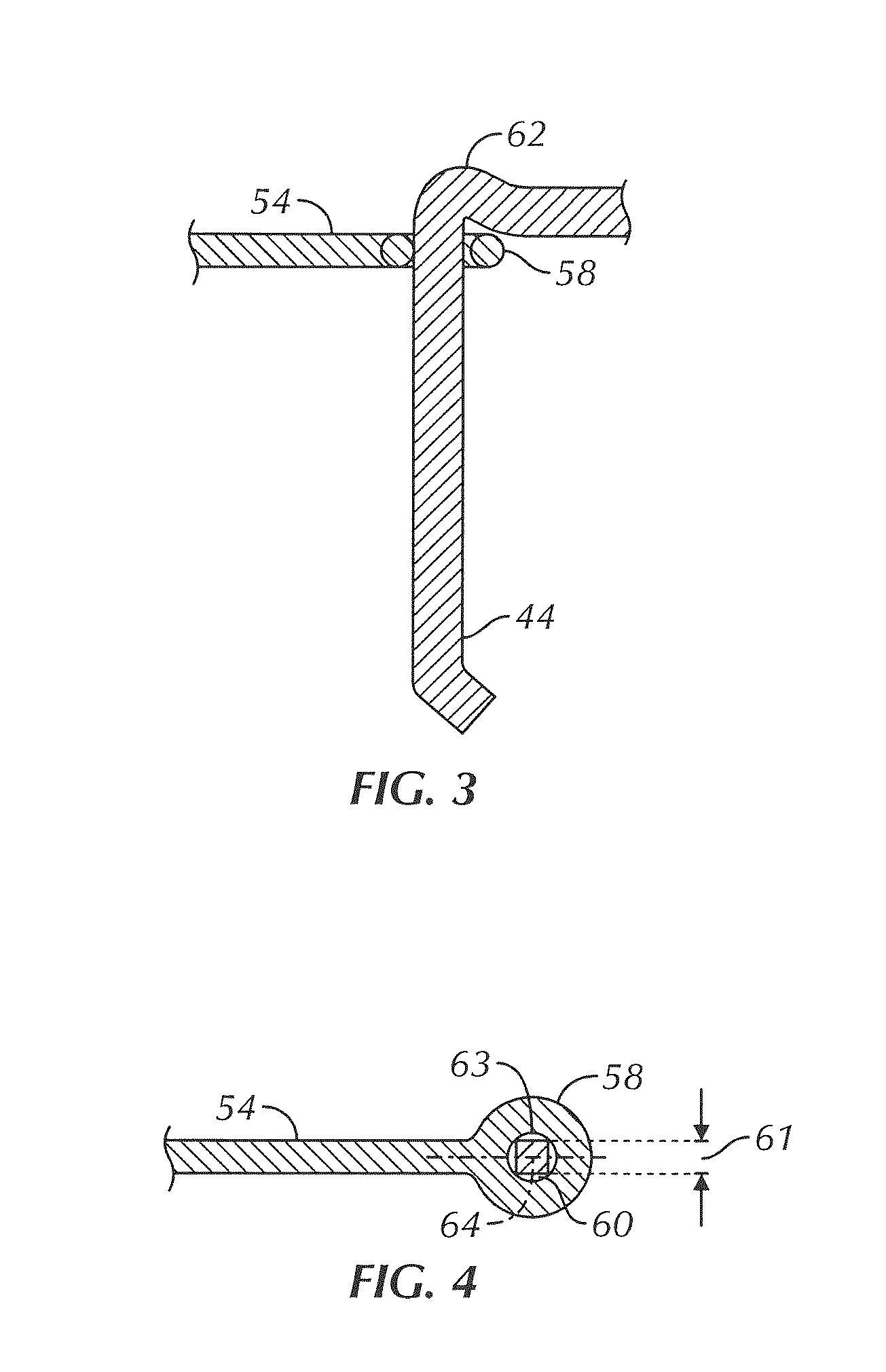

High-strength rectangular wire veneer tie and anchoring systems utilizing the same

ActiveUS8833003B1Easy to installIncrease volumetric occupancyProtective buildings/sheltersShock proofingSquare cross sectionSingle plate

A high-strength rectangular pintle veneer tie and cavity wall anchoring system employing the same is disclosed. The rectangular wire formative construct optionally includes a square cross-section that provides greater volumetric occupancy than that of a similar diameter circular wire formative. The interengaging portions and insertion portion are optionally compressed for greater strength and the rectangular shaped interengaging portion provides a locking interconnection within the anchor precluding significant movement lateral with or normal to the inner wythe.

Owner:HOHMANN & BARNARD INC

Thermally-isolated anchoring systems for cavity walls

InactiveUS8904730B2High strengthMaintain structural integrityProtective buildings/sheltersBuilding reinforcementsSurface mountingWater vapor

Owner:HOHMANN & BARNARD INC

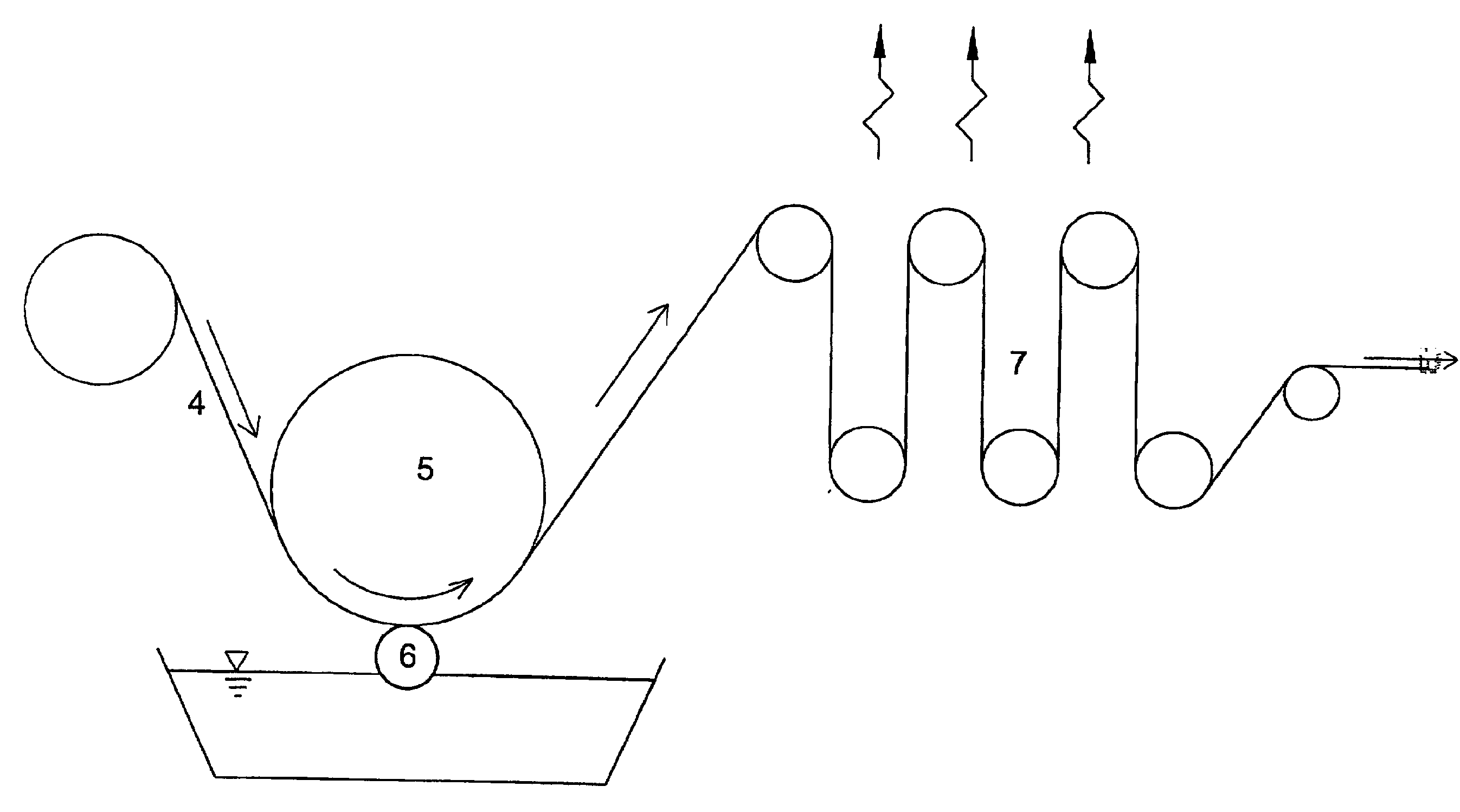

High Strength Joining System for Fiber Reinforced Composites

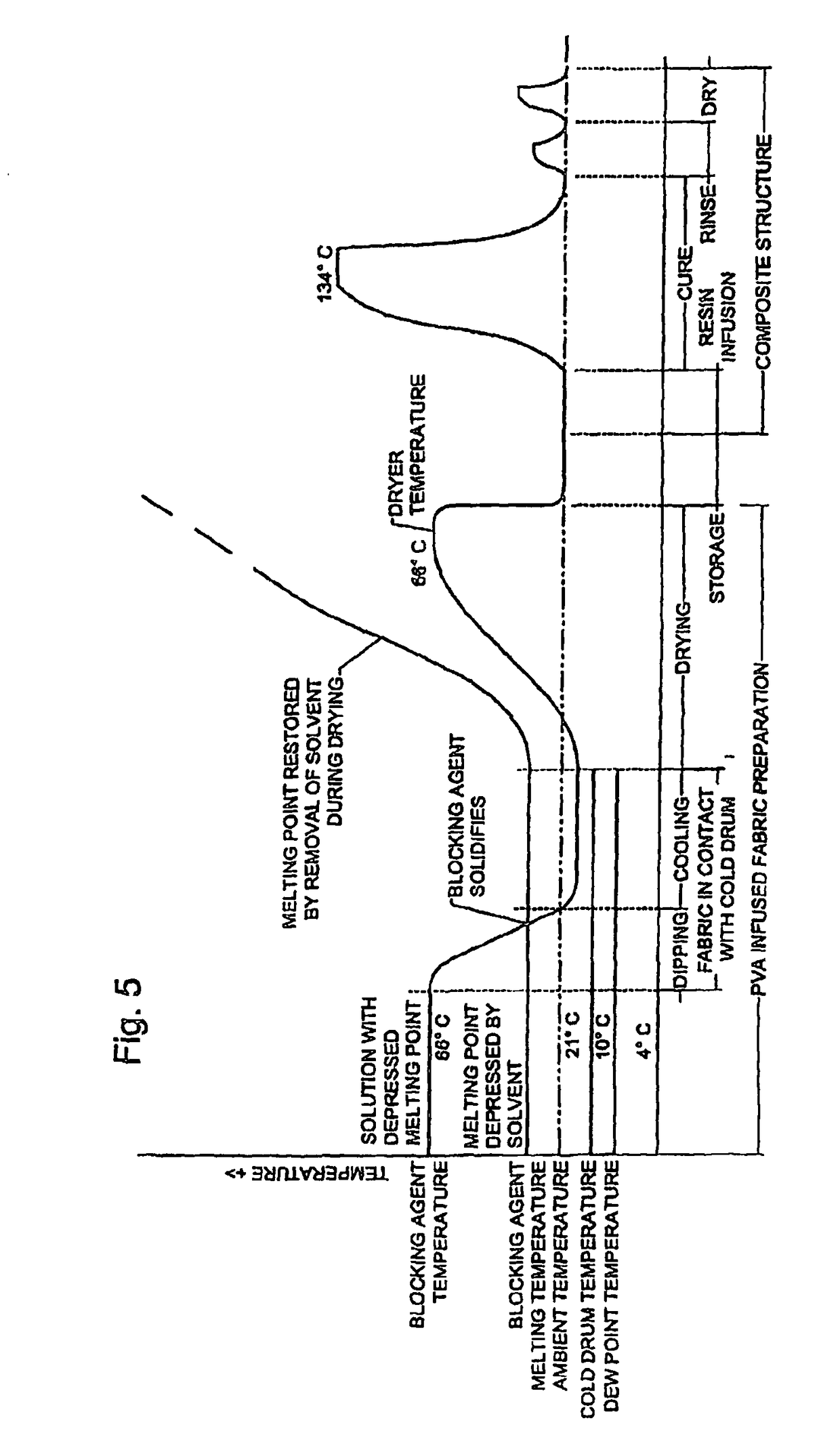

InactiveUS20090068365A1High strength connectionReliable transmissionLaminationPretreated surfacesAdhesiveHigh intensity

The invention relates to join fiber reinforced composite structures with continuity of fiber reinforcement across adhesive-to-substrate boundaries. Thermal gradient control of the extent of infusion of resins or resin blocking substances, during manufacture of components to be subsequently bonded, provides partially exposed reinforcing fibers which serve to reinforce a subsequently formed joint or boundary.

Owner:OBERMEYER HENRY K

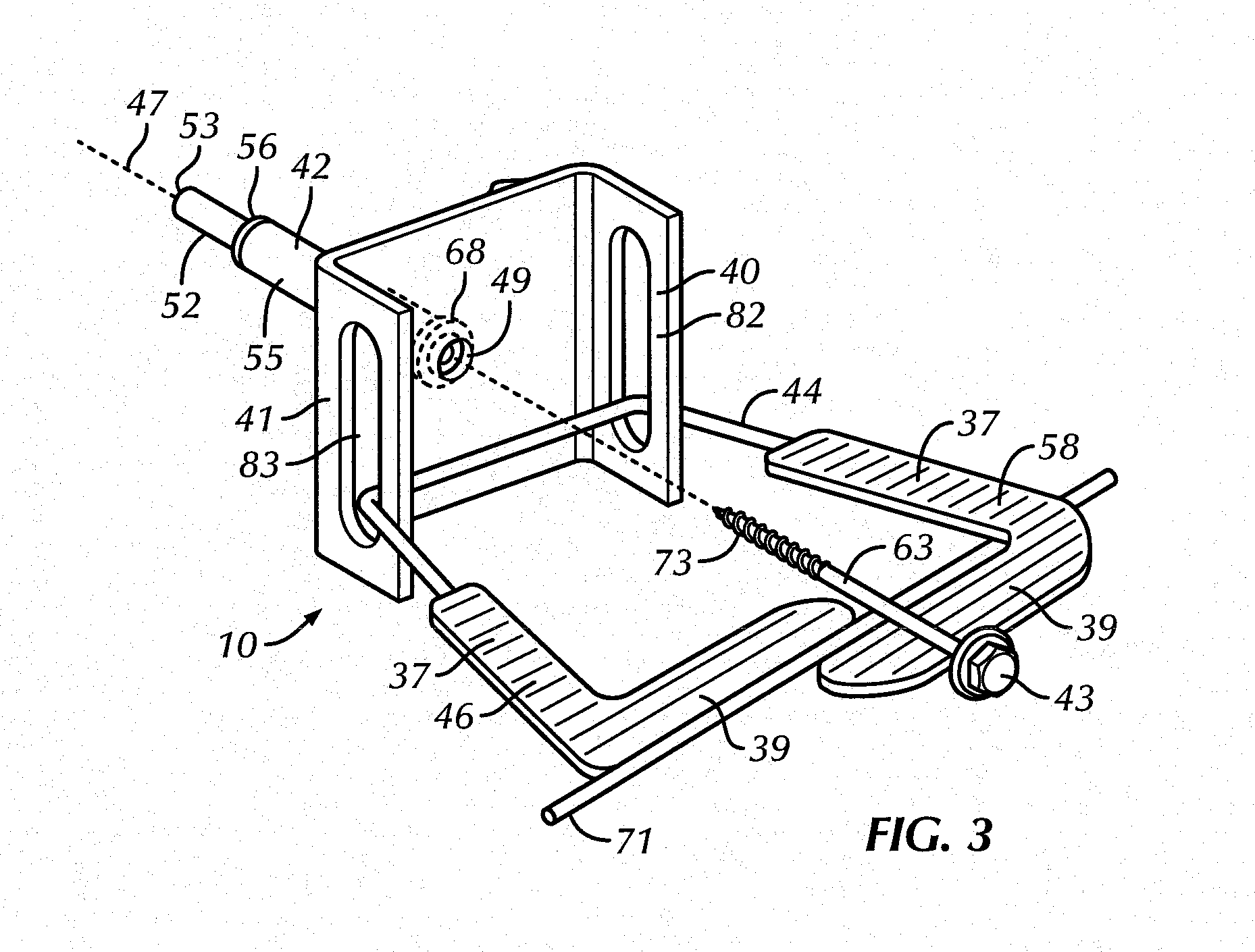

Thermally-isolated anchoring systems with split tail veneer tie for cavity walls

ActiveUS9334646B2Maintain structural integrityHigh strength connectionBuilding reinforcementsSurface mountingWater vapor

A high-strength thermally-isolating surface-mounted anchoring system for a cavity wall is disclosed. The thermally-isolated anchoring system is adaptable to various structures, including high-span applications, and for use with a split tail veneer tie. The anchoring system includes an anchor base and a stepped cylinder which sheaths the mounting hardware to limit insulation tearing and resultant loss of insulation integrity. The anchoring system is thermally-isolated through the use of multiple strategically placed compressible nonconductive seals or elements. Seals are also provided to preclude penetration of air, moisture, and water vapor into the wall structure.

Owner:HOHMANN & BARNARD INC

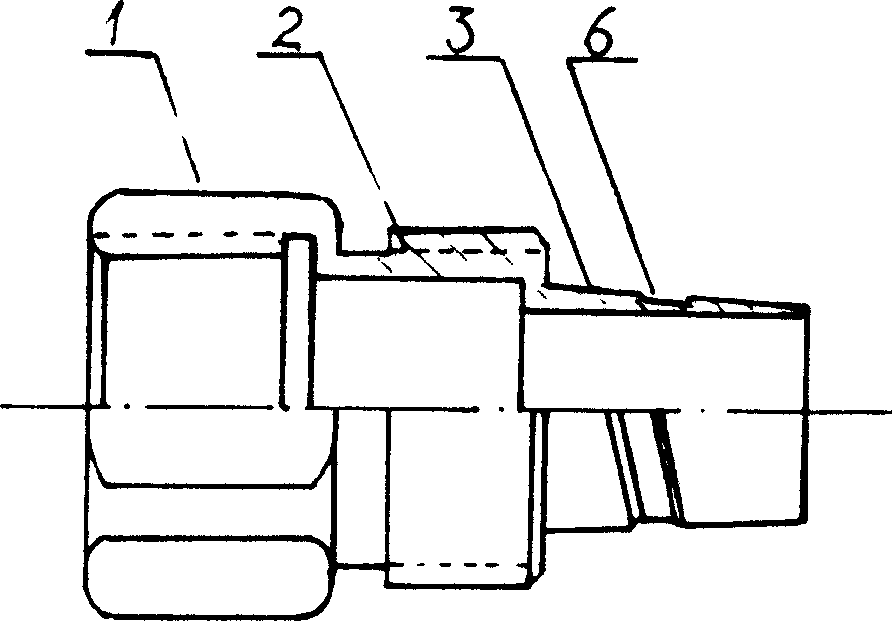

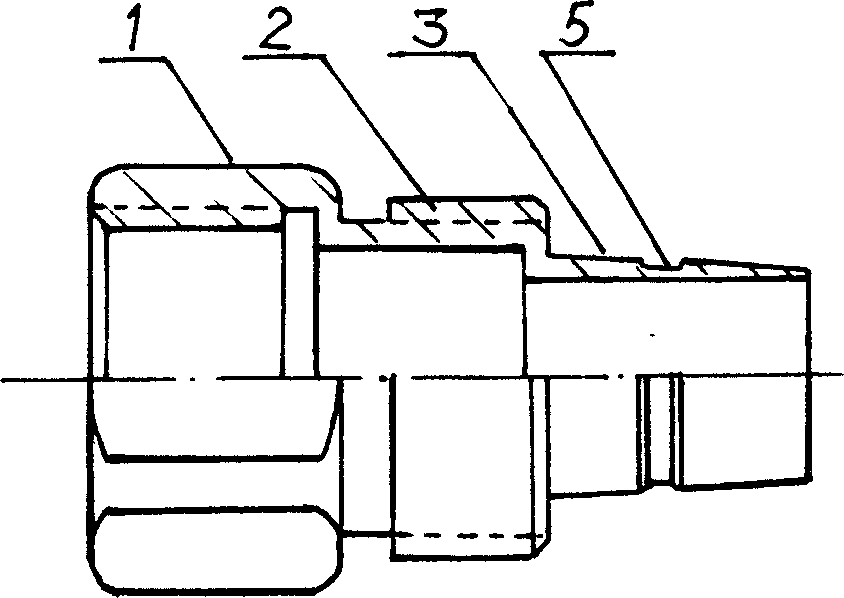

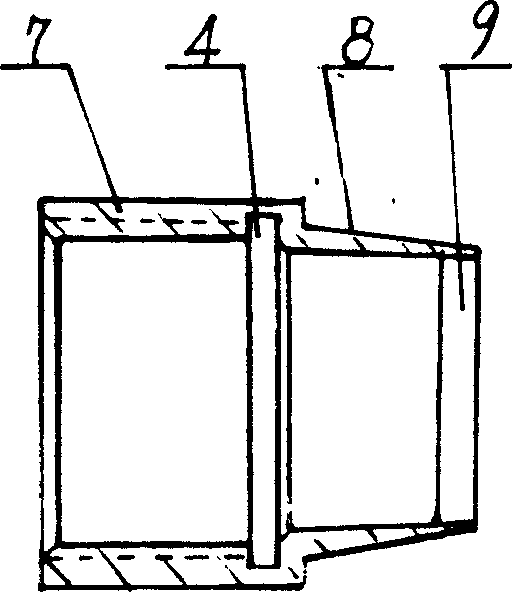

Production process of high strength self-sealing composite aluminium-plastic pipe union

ActiveCN1887508AHigh strengthHigh strength connectionScrew threaded jointsHigh intensityScrew thread

The present invention is production process of high strength self-sealing composite aluminum-plastic pipe union. The production process includes producing main pipe union body and auxiliary parts, and has the specific steps of: 1. selecting stainless steel for producing pipe union; 2. machining at least one external thread on the main pipe union body, forming conic sealing stage of 3-7 deg cone apex angle, and forming end port with outer diameter greater than the inner diameter by up to 1.5 mm and height between the inner diameter and the outer diameter of the composite pipe; and 3. machining one locking stage comprising inner conic surface and outer conic surface on one end of the locking nut, with the locking stage possessing inner surface of the same cone apex angle as the outer surface of the sealing stage.

Owner:张天林

Thermally-isolated anchoring systems with split tail veneer tie for cavity walls

ActiveUS20160032582A1Maintain structural integrityHigh strength connectionBuilding reinforcementsEngineeringCavity wall

A high-strength thermally-isolating surface-mounted anchoring system for a cavity wall is disclosed. The thermally-isolated anchoring system is adaptable to various structures, including high-span applications, and for use with a split tail veneer tie. The anchoring system includes an anchor base and a stepped cylinder which sheaths the mounting hardware to limit insulation tearing and resultant loss of insulation integrity. The anchoring system is thermally-isolated through the use of multiple strategically placed compressible nonconductive seals or elements. Seals are also provided to preclude penetration of air, moisture, and water vapor into the wall structure.

Owner:HOHMANN & BARNARD INC

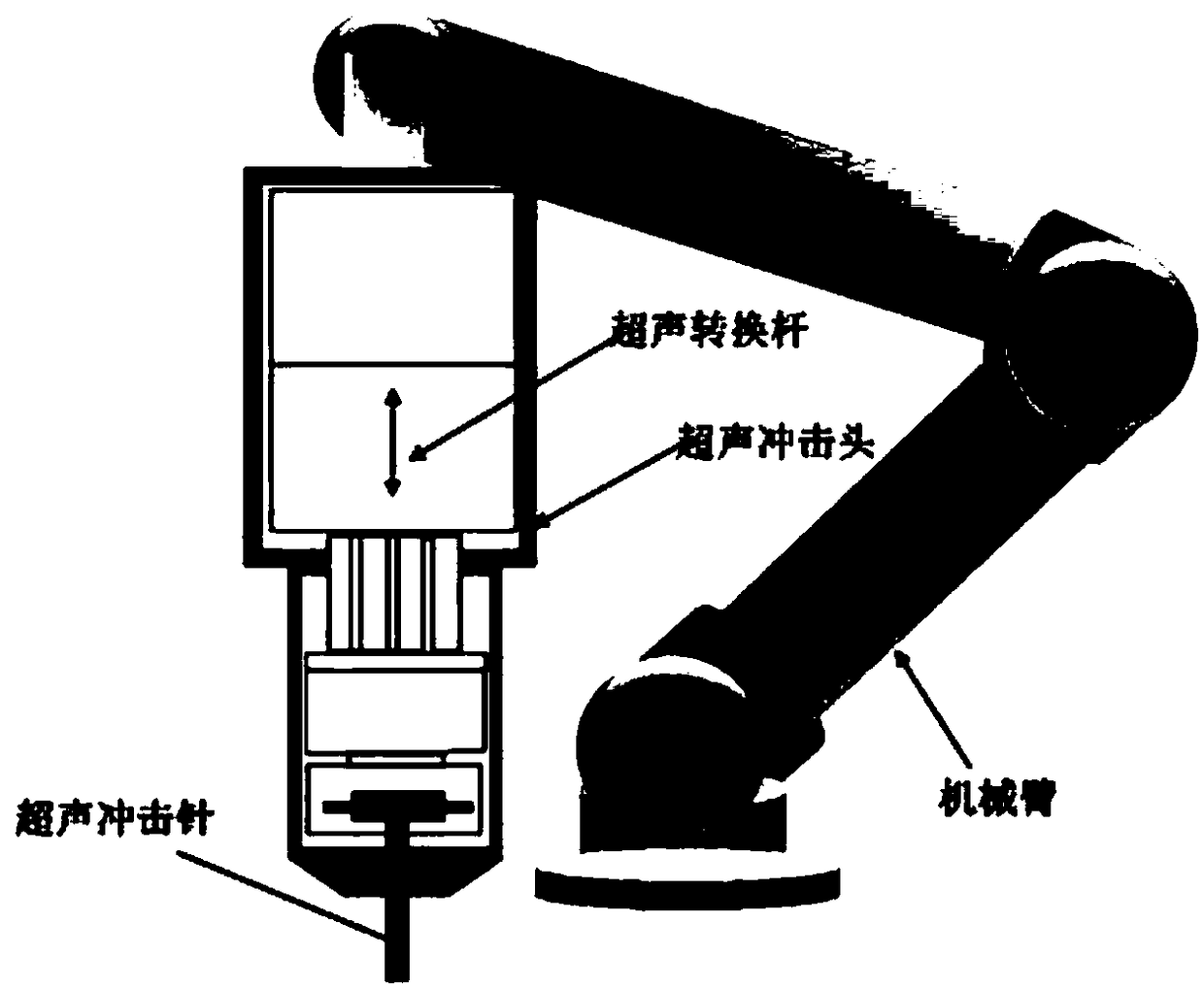

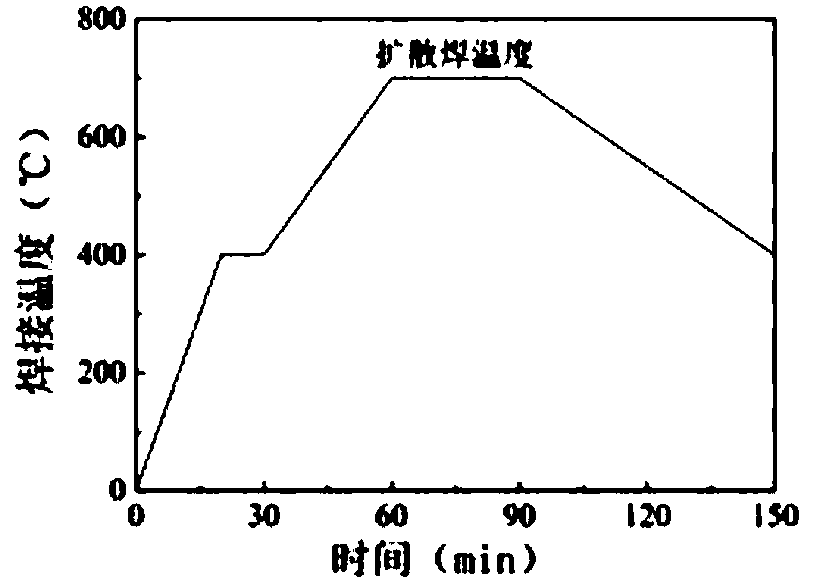

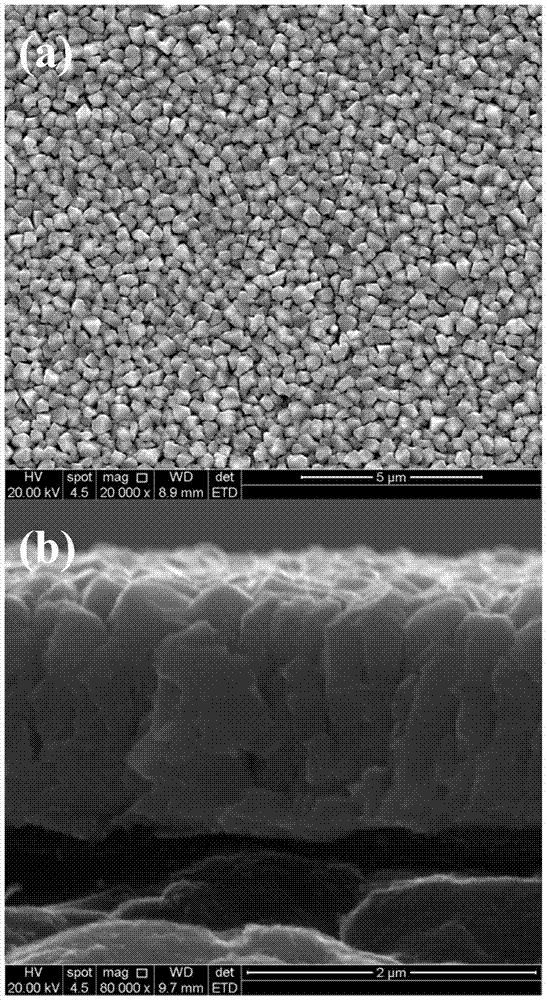

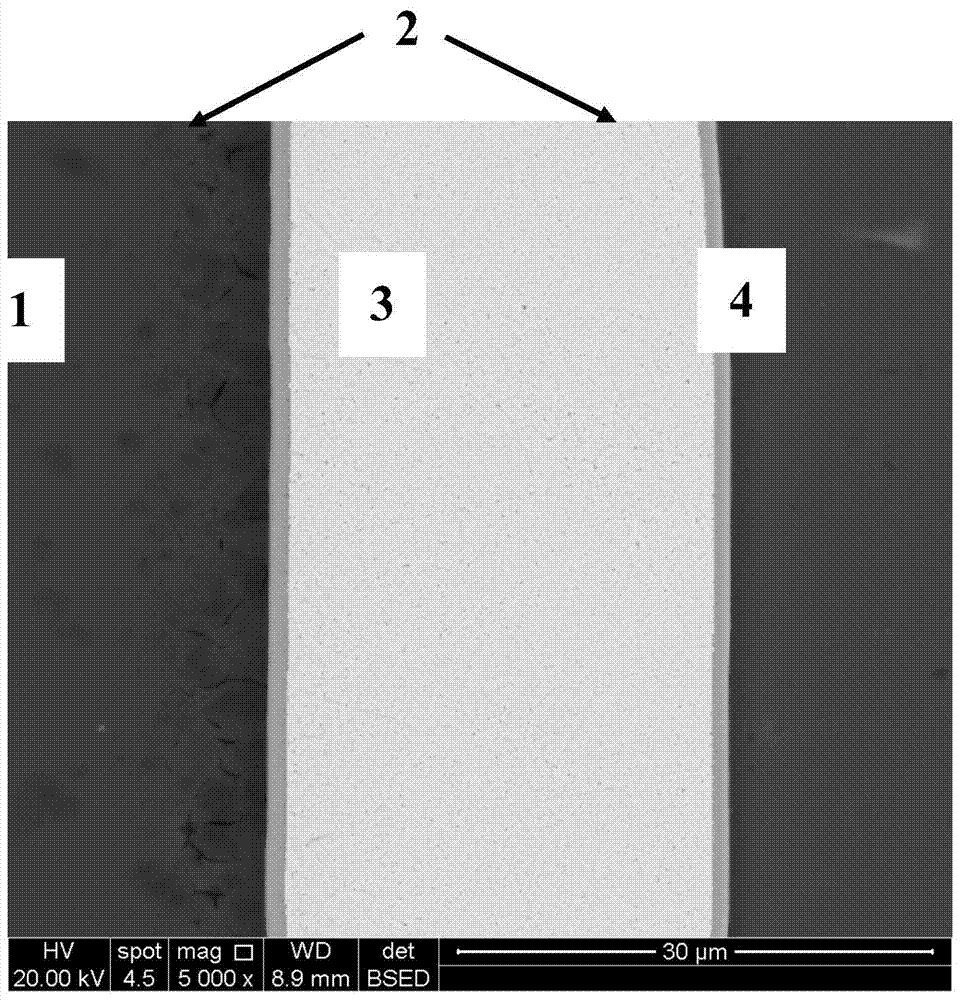

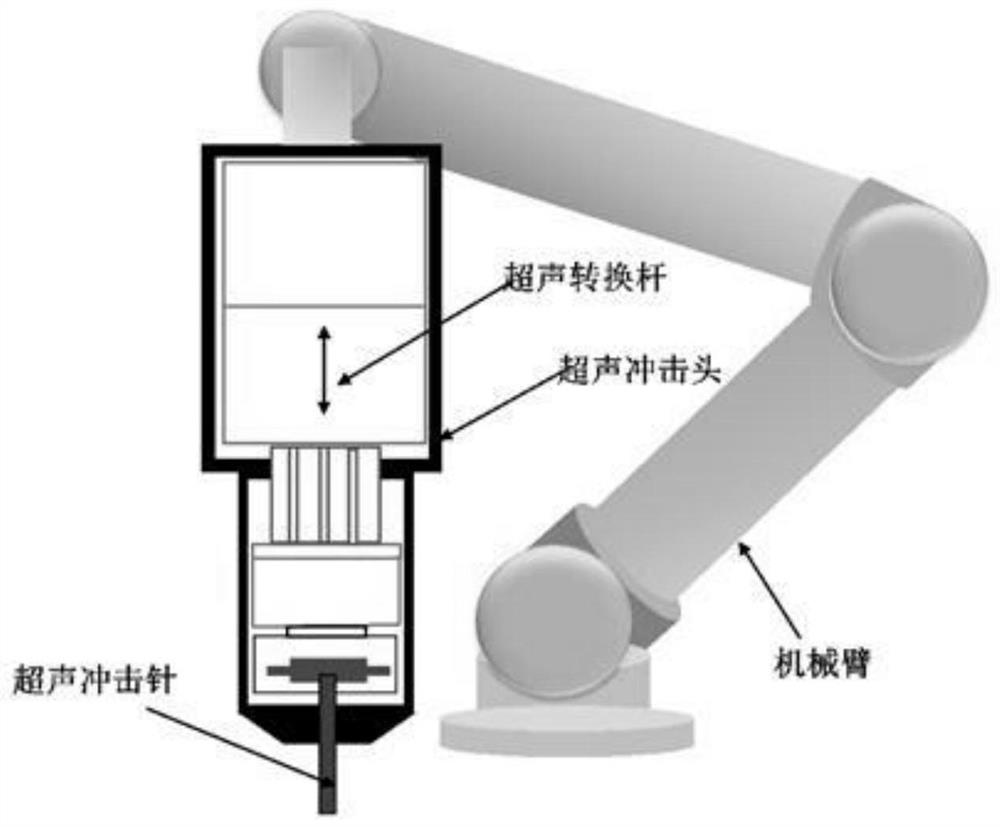

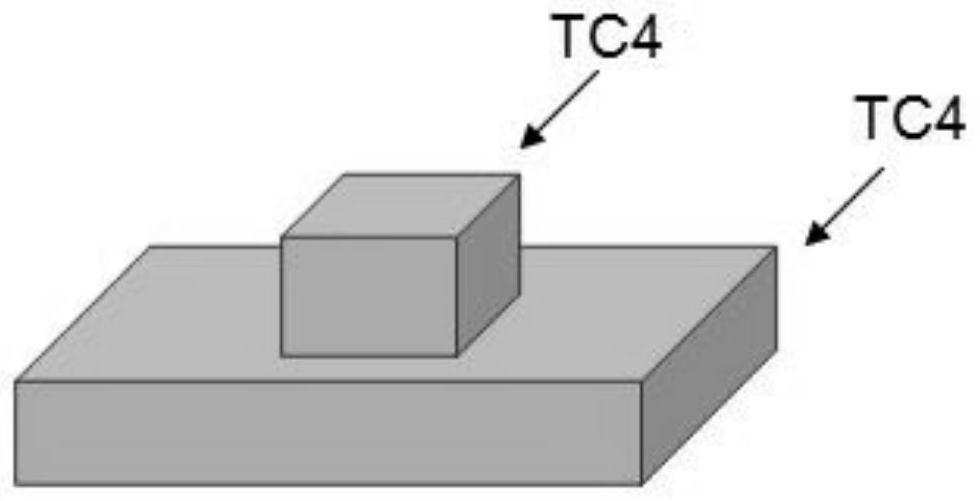

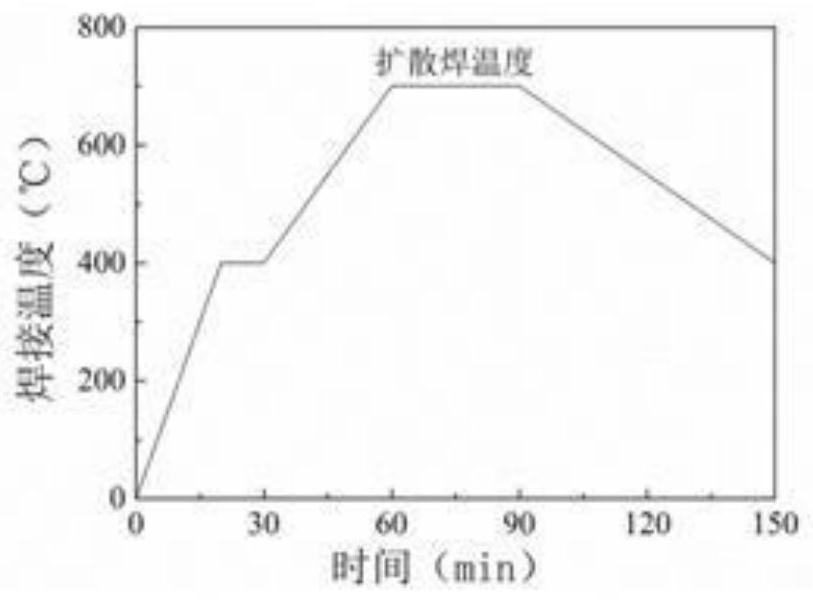

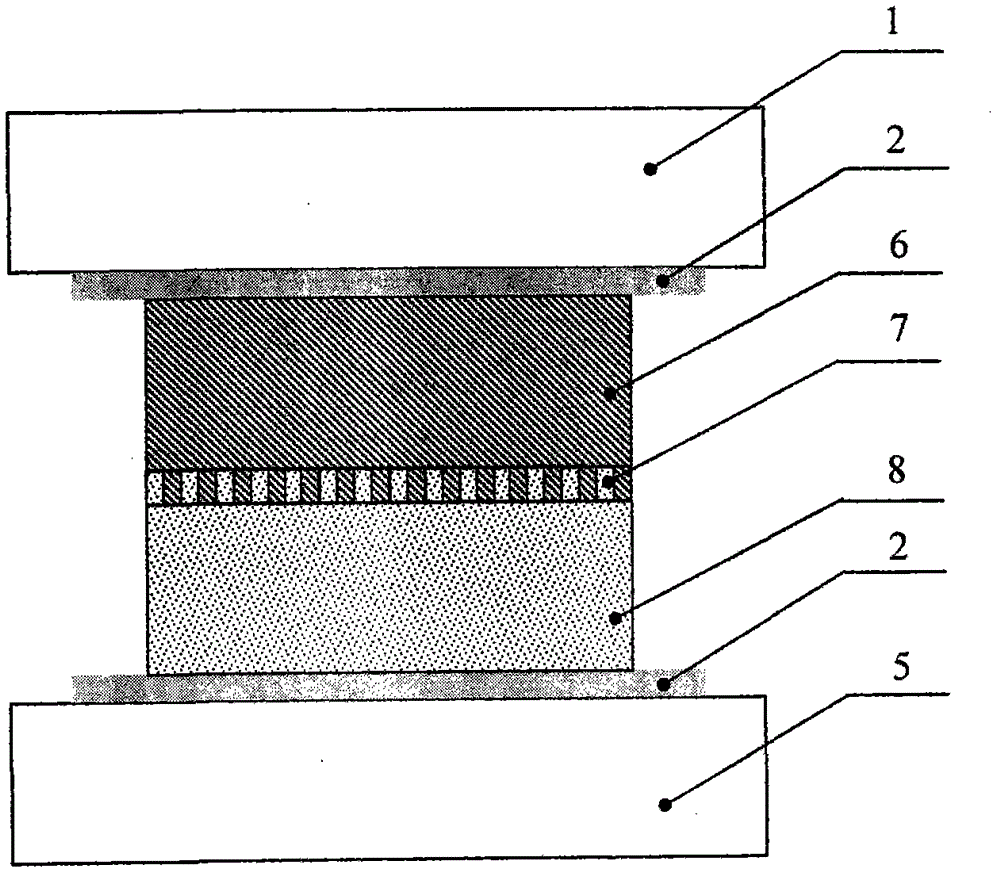

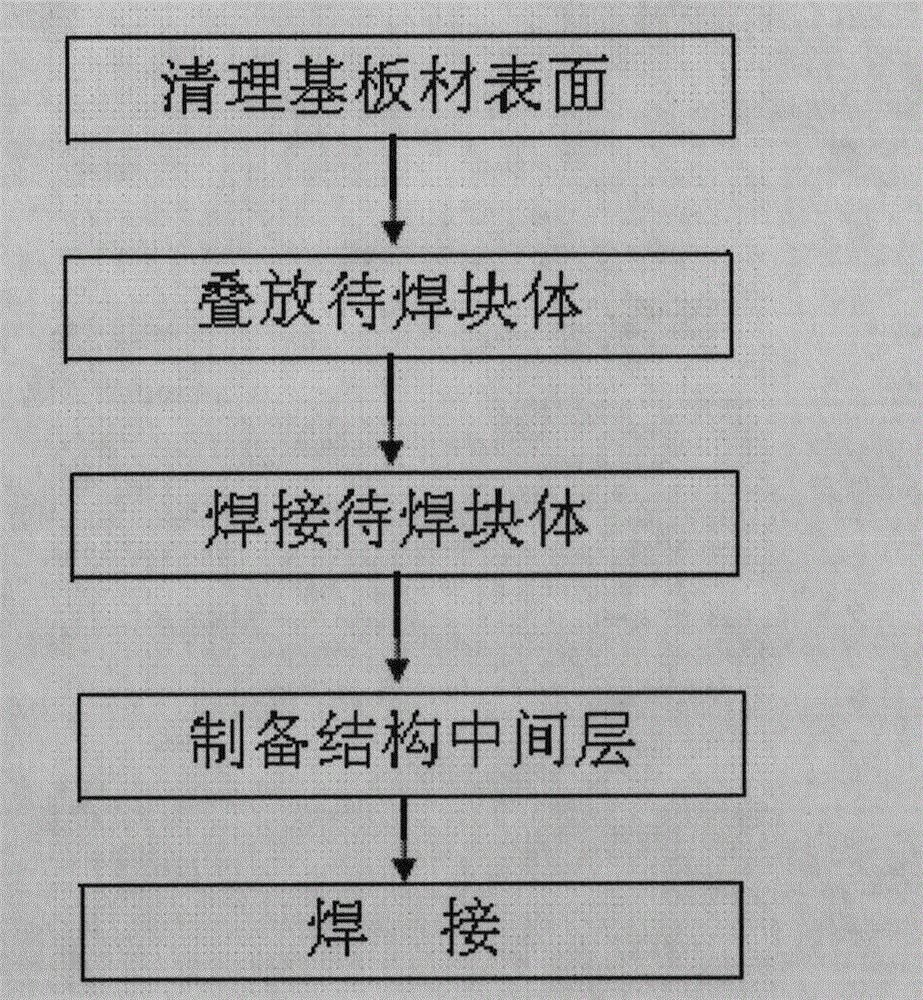

Ultrasonic impact surface modification auxiliary titanium alloy diffusion connection method

ActiveCN109423587AReduce energy consumptionRealize green and energy-saving weldingSurface modificationAtomic diffusion

The invention discloses an ultrasonic impact surface modification auxiliary titanium alloy diffusion connection method. According to the method, ultrasonic impact is conducted on the surface of a titanium alloy plate, the titanium alloy plate is heated and diffused, so that joints can be tightly combined, and the high-strength connection of a titanium alloy is realized. According to the method, agrain refinement layer is obtained through ultrasonic impact surface modification, the atomic diffusion rate is increased, diffusion connection parameters of the titanium alloy are reduced, and low-temperature diffusion connection of the titanium alloy is realized; and the method is simple and convenient to operate, good in adaptability, high in repeatability, green and energy-saving, and can greatly improve the industrial production efficiency.

Owner:TIANJIN UNIV

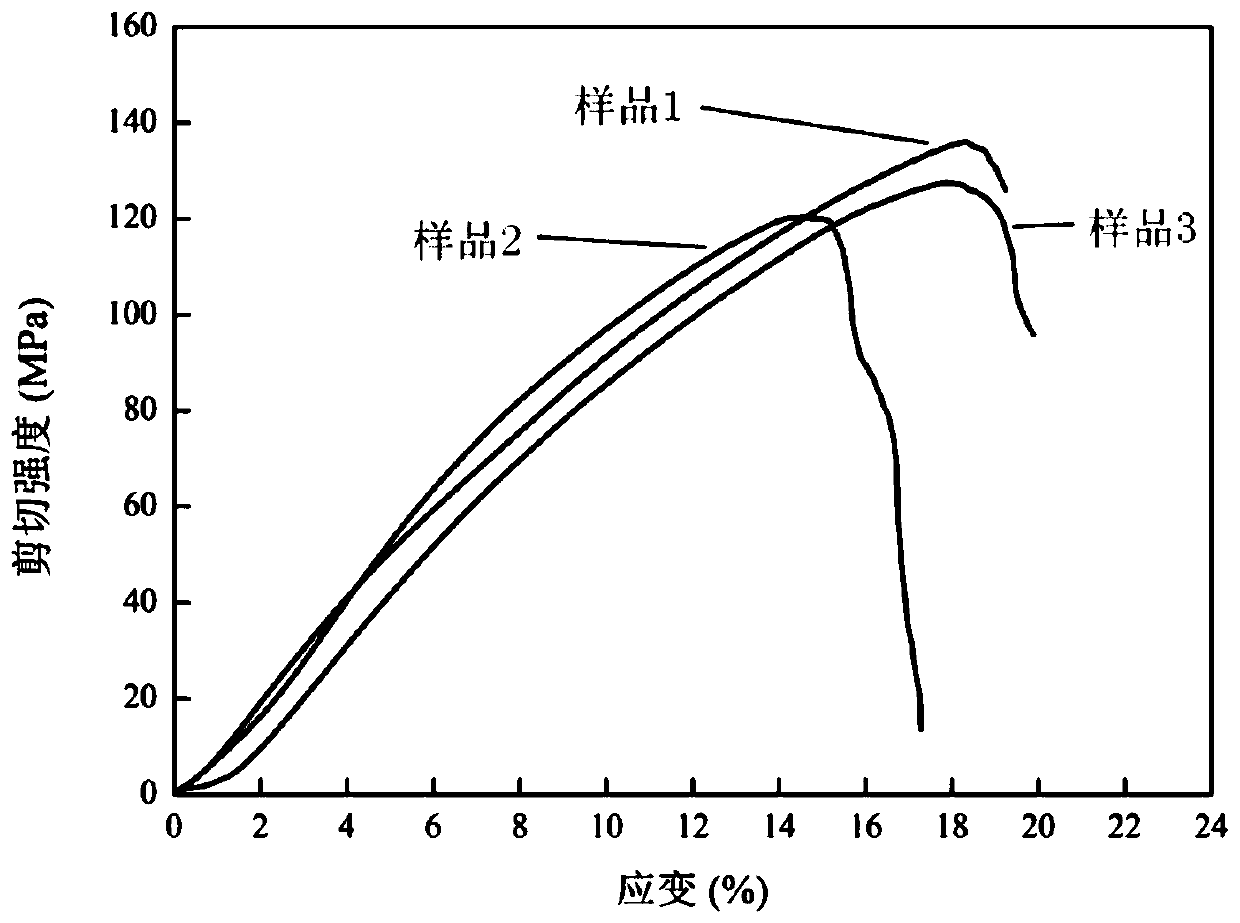

Medium-and-low-temperature direct diffusion bonding method of oxygen-free copper and chromium-zirconium-copper

InactiveCN110576252AHigh strength connectionAvoid secondary quenchingWelding/soldering/cutting articlesNon-electric welding apparatusChromiumDiffusion bonding

The invention discloses a medium-and-low-temperature direct diffusion bonding method of oxygen-free copper and chromium-zirconium-copper. The method comprises the following steps of carrying out pretreatment including grinding, polishing, ultrasonic cleaning on to-be-bonded surfaces of an oxygen-free copper block body and a chromium-zirconium-copper block body; performing butting and pressurizingfixation on the to-be-bonded surfaces of the pre-treated oxygen-free copper block body and chromium-zirconium-copper block body; and carrying out heat preservation and bonding in an argon protection atmosphere. The bonding method successfully realizes the diffusion and metallurgical bonding of the interfaces between the oxygen-free copper and the chromium-zirconium-copper, the high-strength bonding between the oxygen-free copper / chromium-zirconium-copper, and the maximum shear strength reaches about 136 MPa, and the hardness of the annealed chromium-zirconium-copper meets the requirements that the Brinell hardness of the chromium-zirconium-copper is greater than or equal to 120 in the ITER.

Owner:TIANJIN UNIV

Process of manufacturing fiber reinforced composite via selective infusion of resin and resin blocking substance

InactiveUS8470404B2High strength connectionReliable transmissionLaminationPretreated surfacesAdhesiveFiber-reinforced composite

The invention relates to joined fiber reinforced composite structures with continuity of fiber reinforcement across adhesive-to-substrate boundaries. Use of a thermal gradient to control the extent of infusion of resin blocking substances into fiber reinforced material, and subsequent resin infusion and resin blocking substance removal, during manufacture of components to be subsequently bonded, provides partially exposed reinforcing fibers which serve to reinforce a subsequently formed joint or boundary.

Owner:OBERMEYER HENRY K

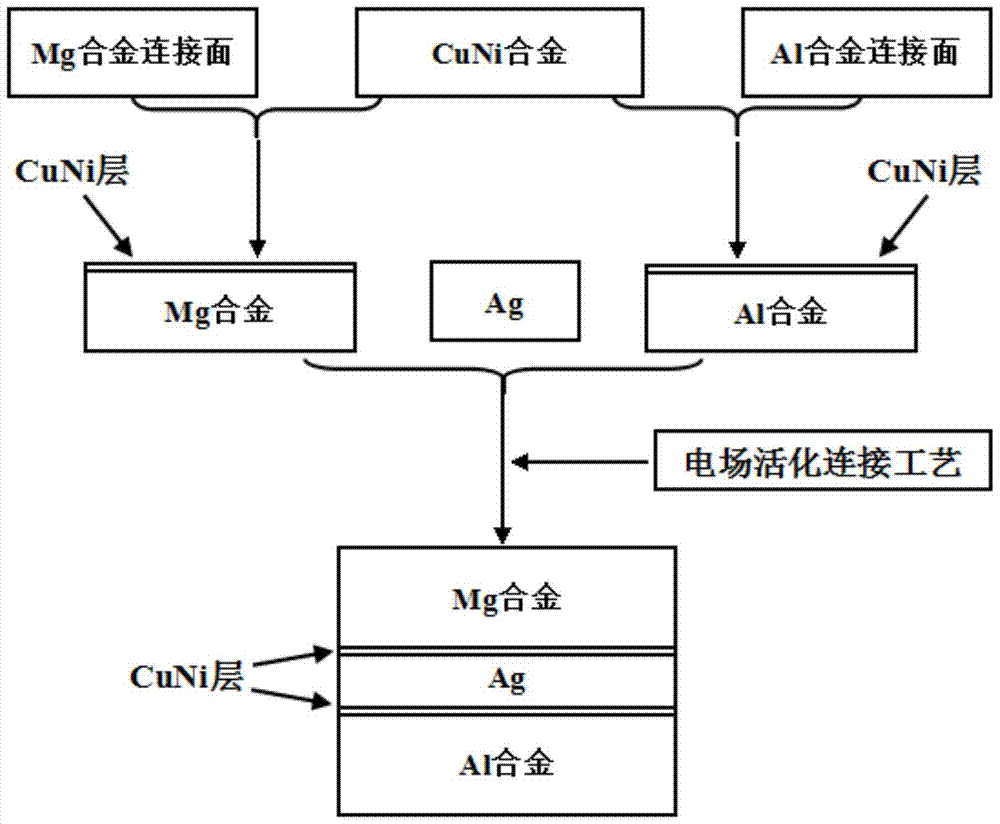

The design of laminated composite interlayers introduces a method for joining magnesium alloys to aluminum alloys

ActiveCN105149769BReduce oxidationIncrease contactWelding/soldering/cutting articlesNon-electric welding apparatusSurface oxidationAlloy thin film

The invention provides a method for introducing the design of laminated compound interlayers to enable magnesium alloy and aluminium alloy to be connected. The method comprises the steps that first, CuNi alloy thin films are deposited on the surface of the magnesium alloy and the surface of the aluminium alloy to be used as obstructing interlayers for preventing surface oxidation of aluminium and magnesium matrixes and intermetallic compound generation; then Ag is added between CuNi alloy thin film layers to lower the connecting temperature of a CuNi interlayer, and a CuNi-Ag-CuNi laminated compound interlayer is formed; and then a to-be-connected magnesium alloy piece and a to-be-connected aluminium alloy piece of the compound interlayer are assembled and are subjected to heat preservation for 0-750 s at the temperature of 380-420 DEG C. According to the method, the compound interlayer avoids the generation of Mg-Al-based intermetallic compounds with connecting interface brittleness and other intermetallic compounds; an electric field activation connecting technology is adopted, so that quick low-temperature and high-strength welding of the magnesium alloy and the aluminium alloy is achieved under vacuum, the connecting temperature is lowered, the connecting technology cycle is shortened, and the reliability of connecting joints is improved.

Owner:WUHAN UNIV OF TECH

Production process of high strength self-sealing composite aluminium-plastic pipe union

ActiveCN100410001CHigh strengthHigh strength connectionScrew threaded jointsHigh intensityScrew thread

Owner:张天林

High-Strength Rectangular Wire Veneer Tie and Anchoring Systems Utilizing the Same

ActiveUS20140259992A1Increase tensile and compressive strengthHigh strength connectionProtective buildings/sheltersBuilding reinforcementsSquare cross sectionHigh intensity

A high-strength rectangular pintle veneer tie and cavity wall anchoring system employing the same is disclosed. The rectangular wire formative construct optionally includes a square cross-section that provides greater volumetric occupancy than that of a similar diameter circular wire formative. The interengaging portions and insertion portion are optionally compressed for greater strength and the rectangular shaped interengaging portion provides a locking interconnection within the anchor precluding significant movement lateral with or normal to the inner wythe.

Owner:HOHMANN & BARNARD INC

Transient liquid phase infiltration repair method for large gap defects in superalloy hot end parts

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

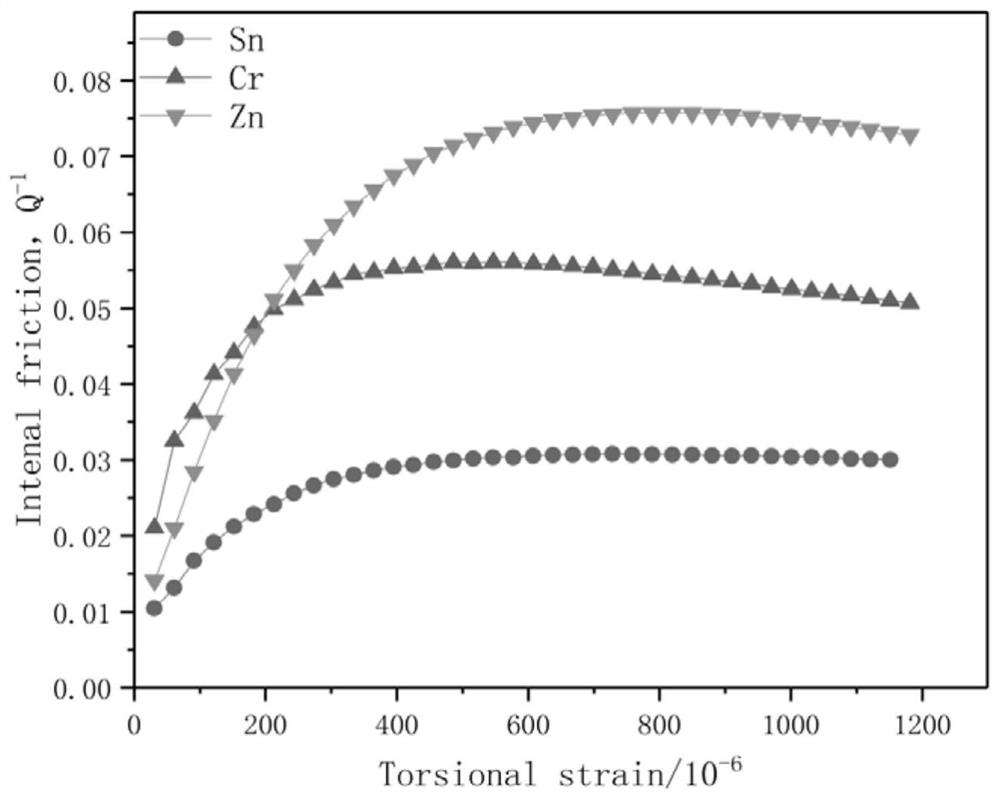

A kind of mn-cu based welding wire and its preparation method and application

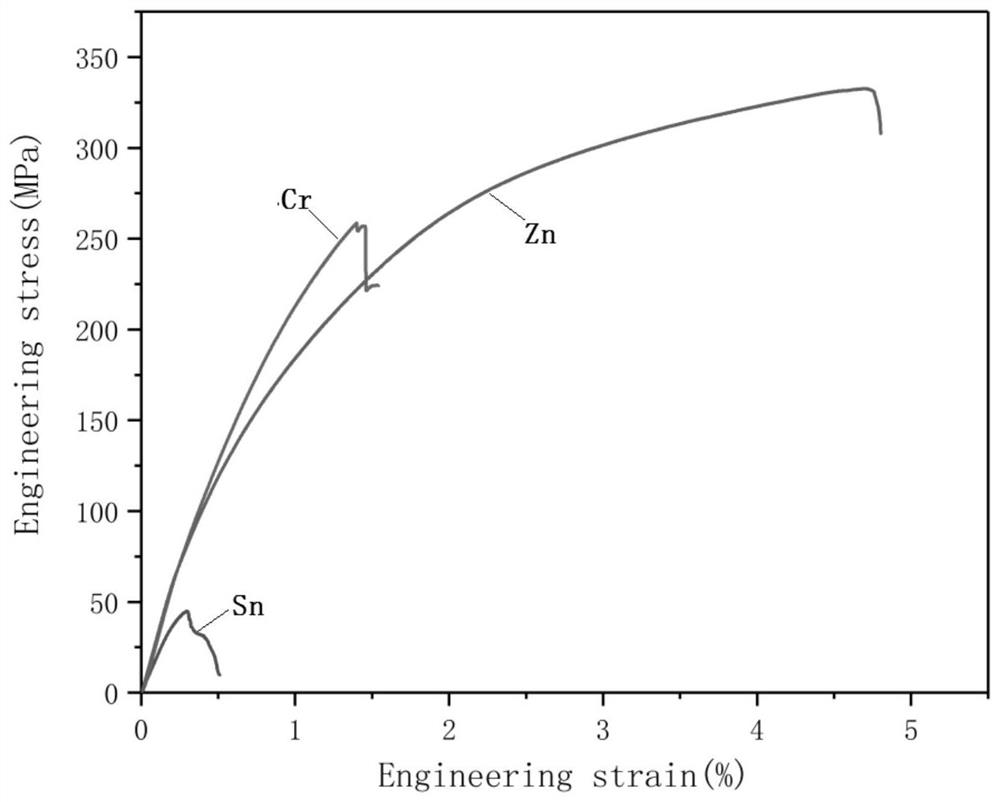

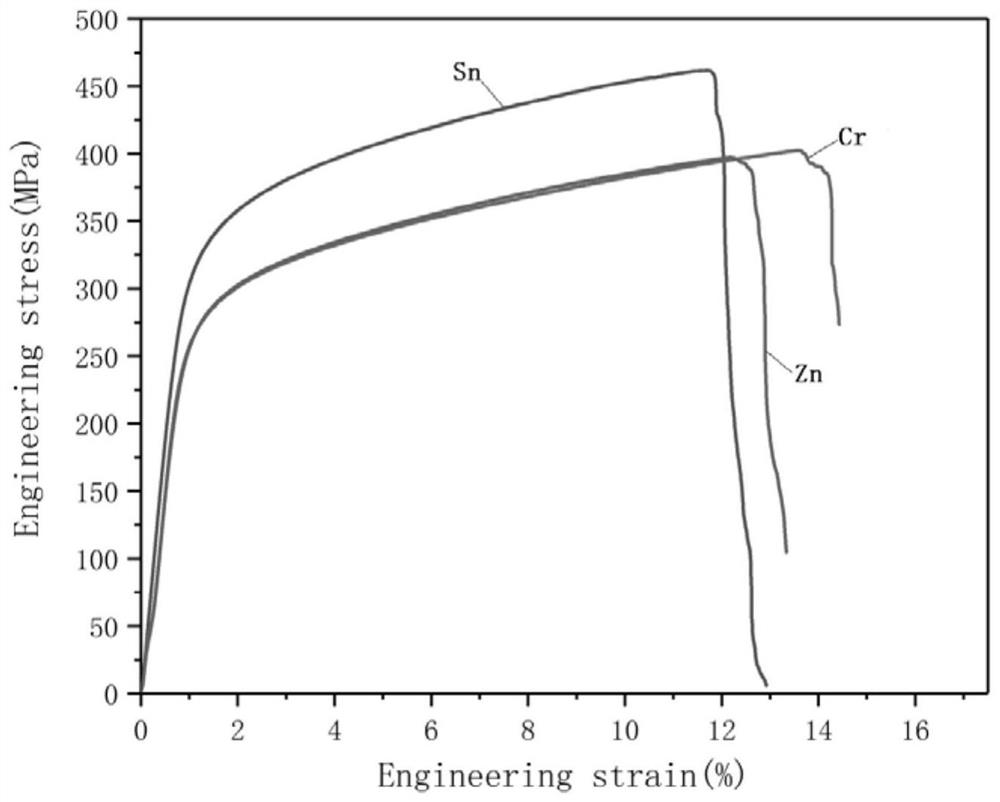

InactiveCN111015017BHigh strengthHigh strength connectionWelding/cutting media/materialsSoldering mediaManganeseAlloy

The invention discloses a Mn-Cu-based welding wire and its preparation method and application. The Mn-Cu-based welding wire comprises the following components in mass percentage: copper 35-43%, manganese 50-60%, aluminum 0.5-2%, tin 0.5-1%, zinc ≤ 3%, chromium ≤ 0.9%. The welding wire preparation method includes: charging; melting; refining; casting; homogenizing; forging; extruding; drawing; annealing. The welding wire in the present invention is mainly used for the welding of Mn-Cu alloy and Mn-Cu alloy or steel. The welding wire of the invention solves the problem of severe welding hot cracks during fusion welding of Mn-Cu alloy and steel, resulting in poor mechanical properties of weld metal and joints. The weld metal has higher damping performance after heat treatment using the existing alloy welding wire. By realizing the connection of Mn-Cu alloy and steel to obtain high-strength and high-damping composite materials, the application prospects of Mn-Cu alloy can be broadened.

Owner:SOUTHWEST JIAOTONG UNIV

Ultrasonic Impact Surface Modification Assisted Diffusion Bonding Method of Titanium Alloy

Owner:TIANJIN UNIV

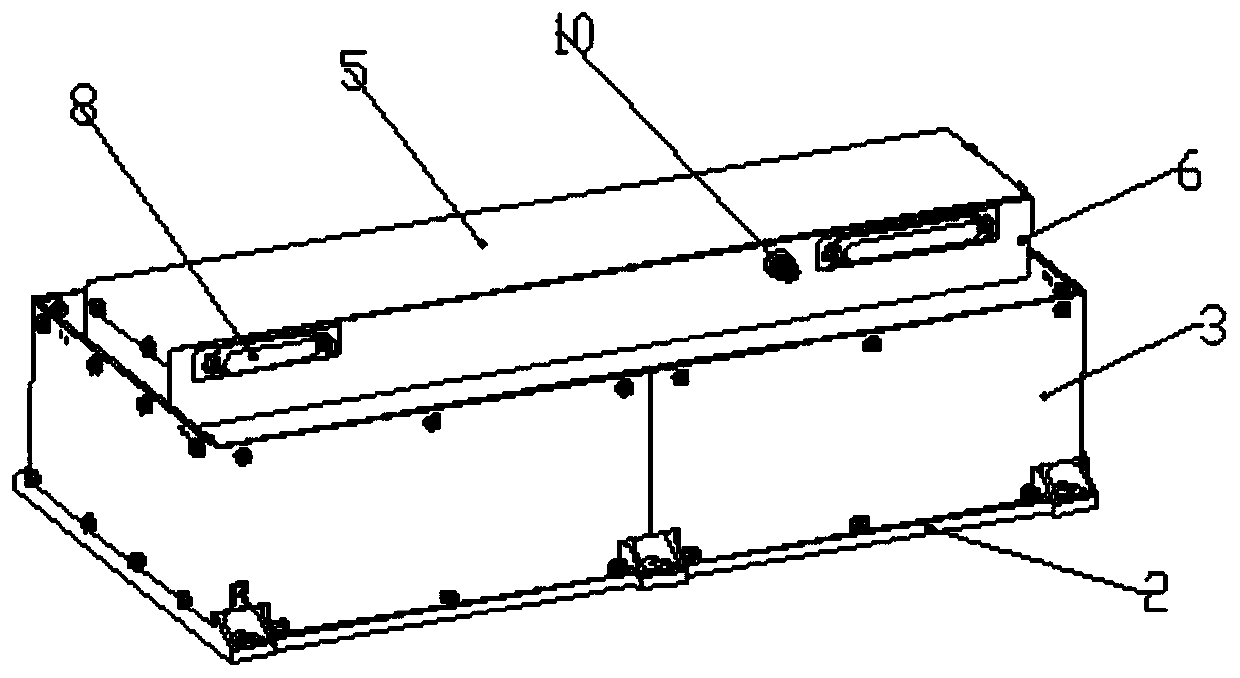

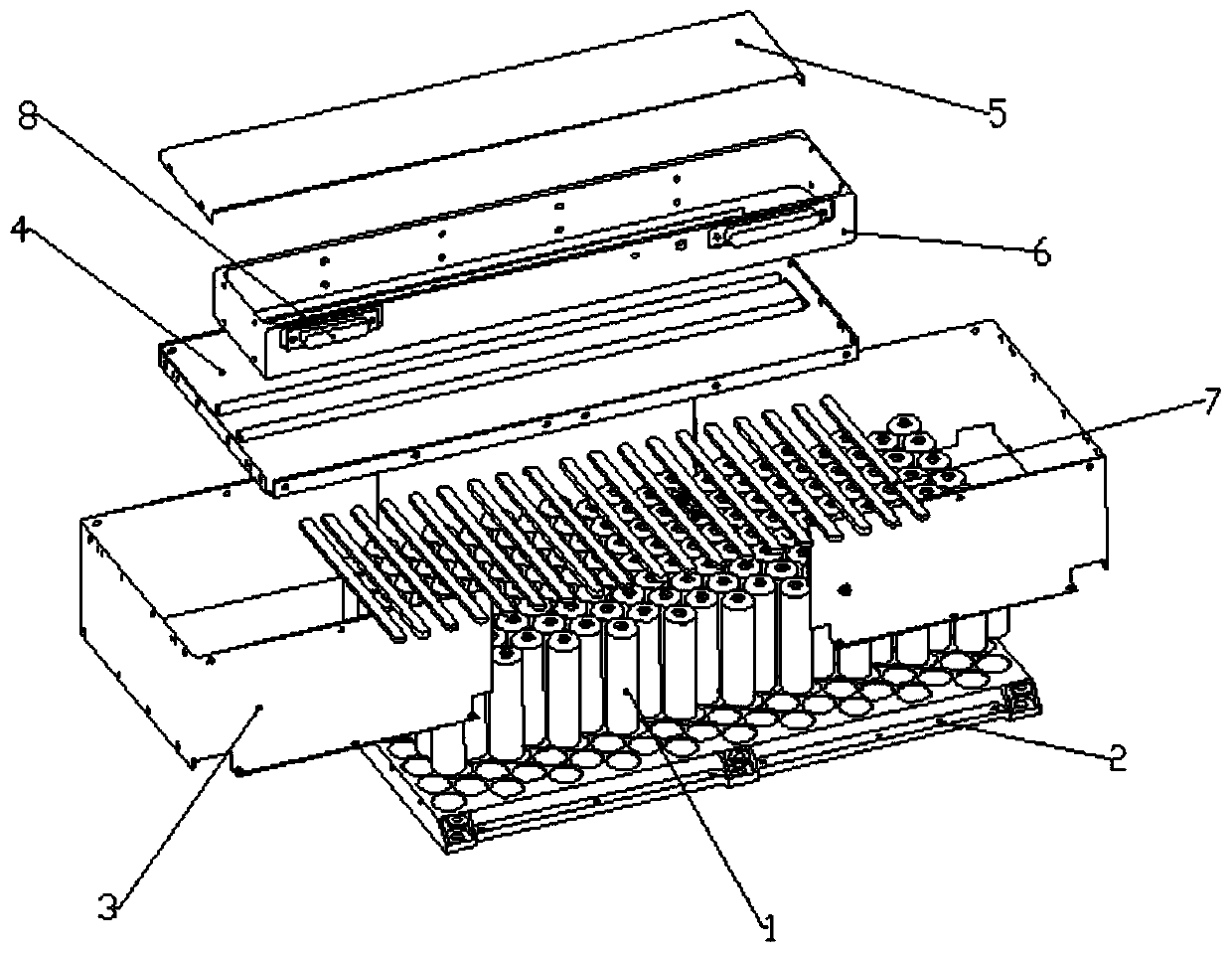

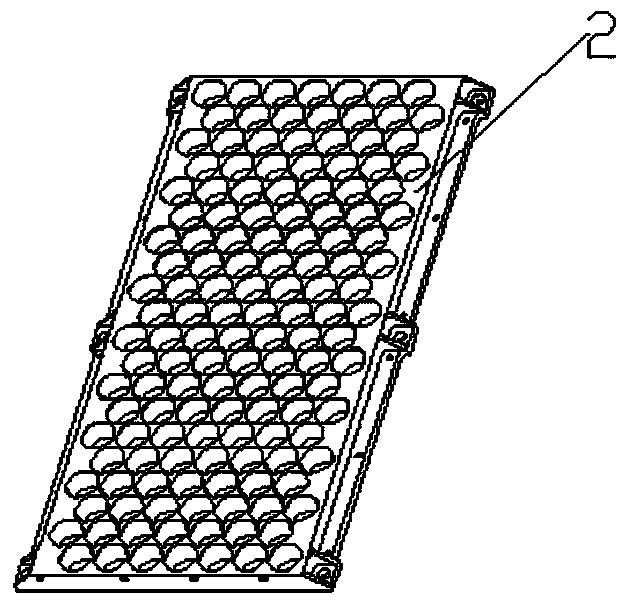

18650 lithium ion battery pack structure

InactiveCN110571372AIncrease specific energyRequires minimizationSecondary cellsCell component detailsHigh resistanceCyclic process

The invention provides a 18650 lithium ion battery pack structure, which includes: lithium ion battery individuals, a bottom plate, a side plate, a pressure plate, a cover plate, an electrical connector fixing plate, an elastic plate, an electrical connector, a guide bar, and a grounding device, and is characterized in that the positive electrodes of all the lithium ion battery individuals have the same orientation so as to contribute to modular expansion; the lithium ion battery individuals are directly bonded in the sleeve-type bottom plate so as to achieve rapid heat transfer; sufficient gaps are arranged between the lithium ion battery individuals to release the stress generated during the cyclic process of the lithium ion battery individuals; the elastic plate is arranged between thelithium ion battery individuals and the pressure plate; by adjusting the amount of deformation of the elastic plate, the lithium ion battery individuals and the bottom plate can be tightly connected;the high-resistance grounding device can release the charges accumulated in the battery pack structure. The structure provided by the invention has high specific energy, good thermal conductivity, high structural strength, and good safety and reliability, and is suitable for the field of small satellites.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

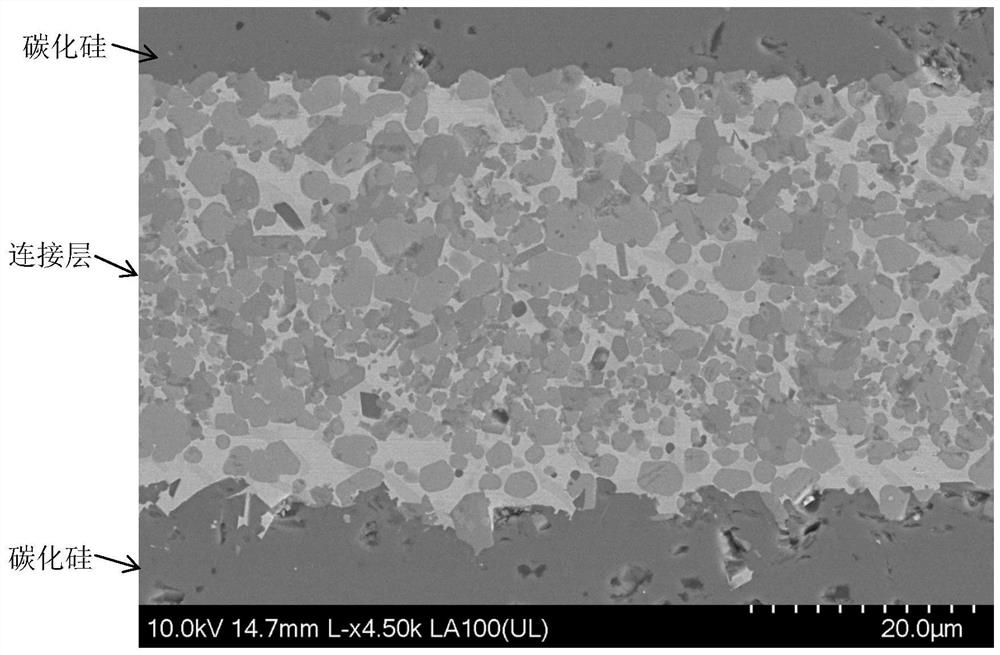

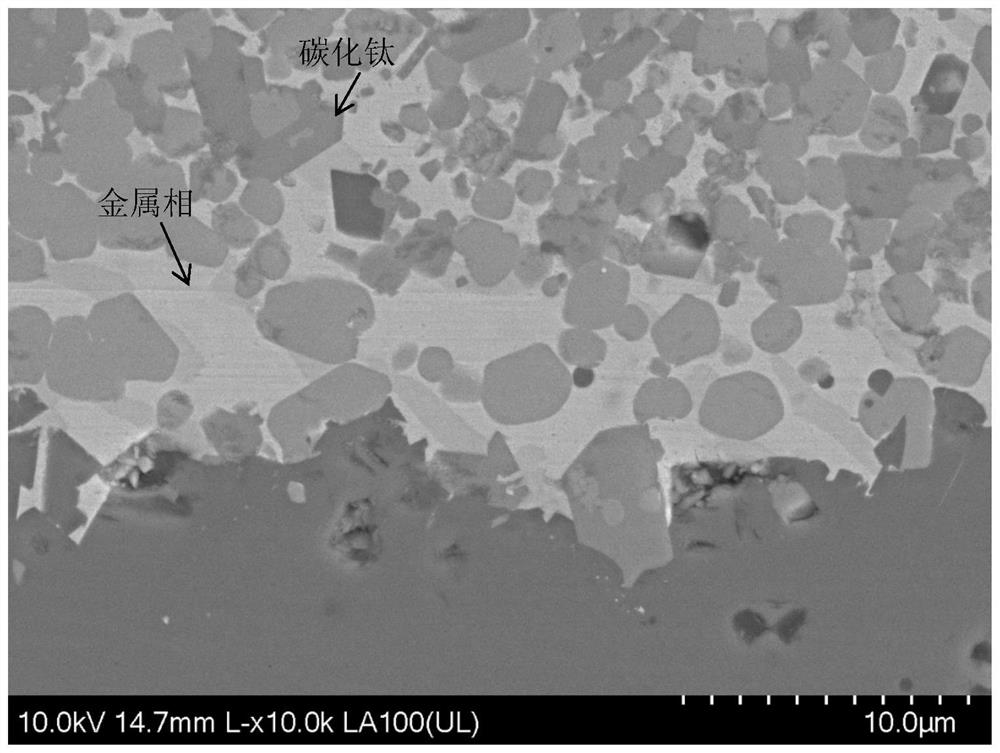

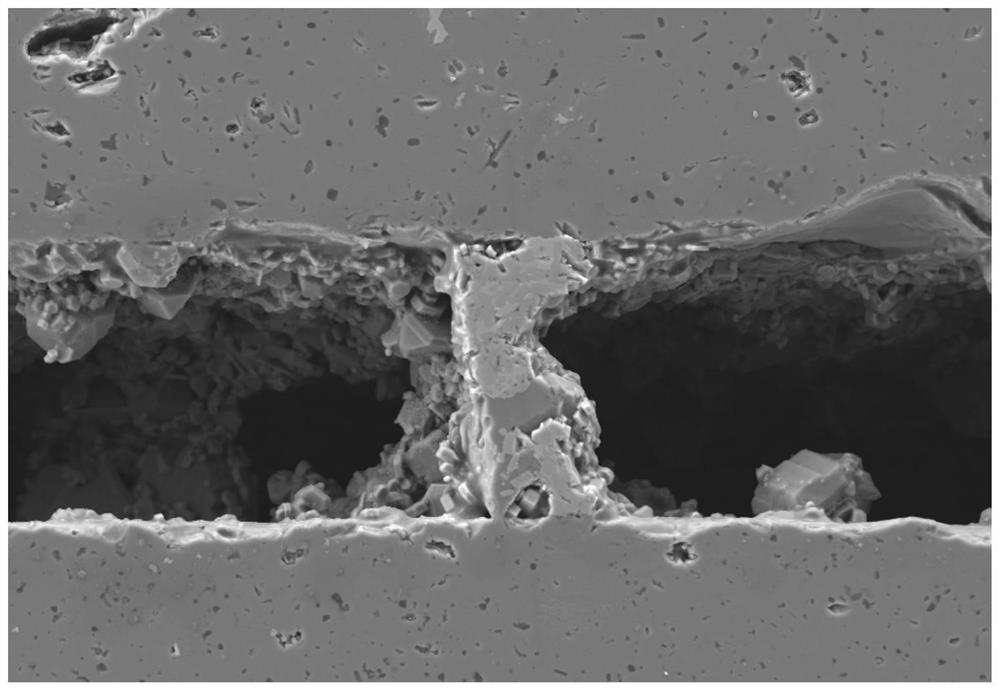

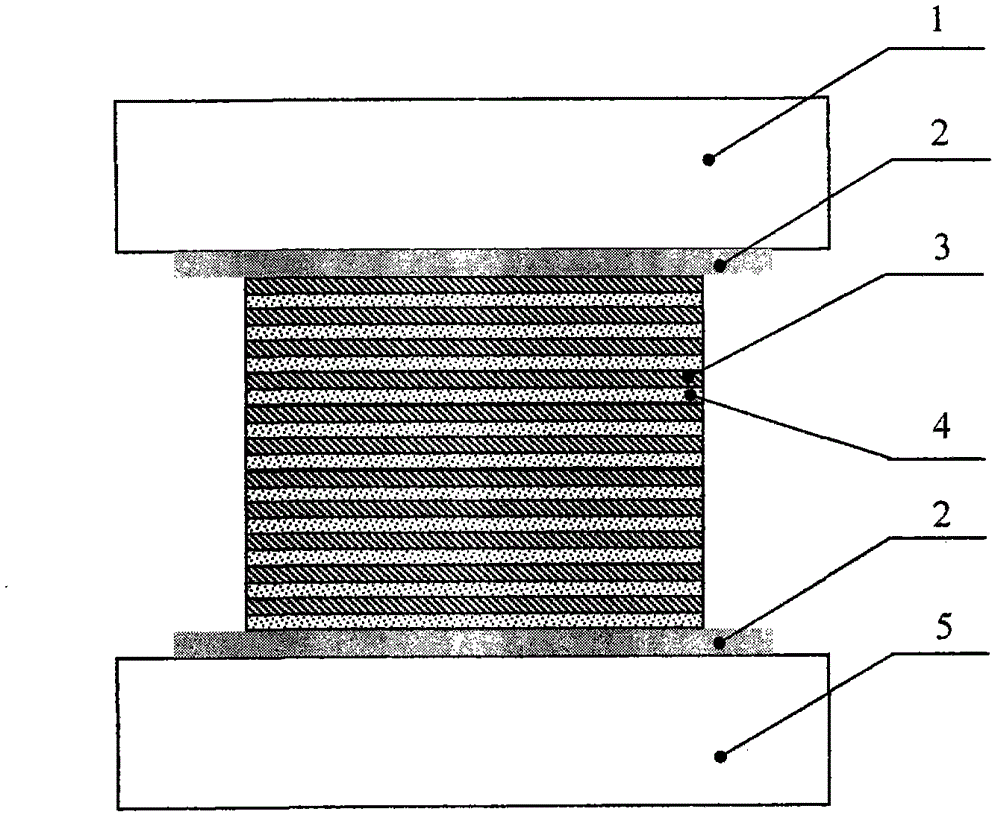

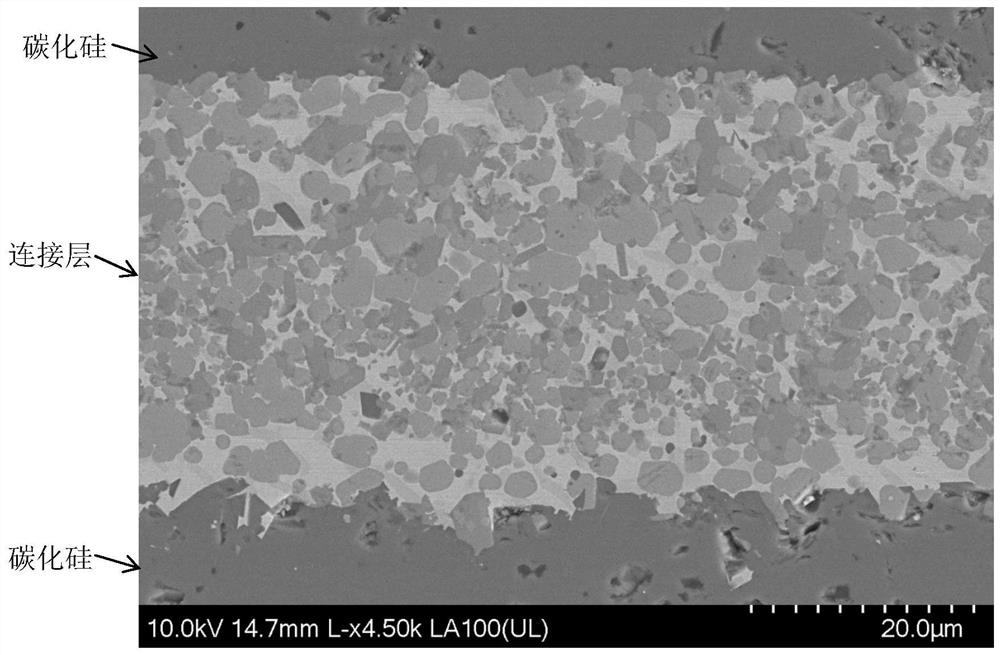

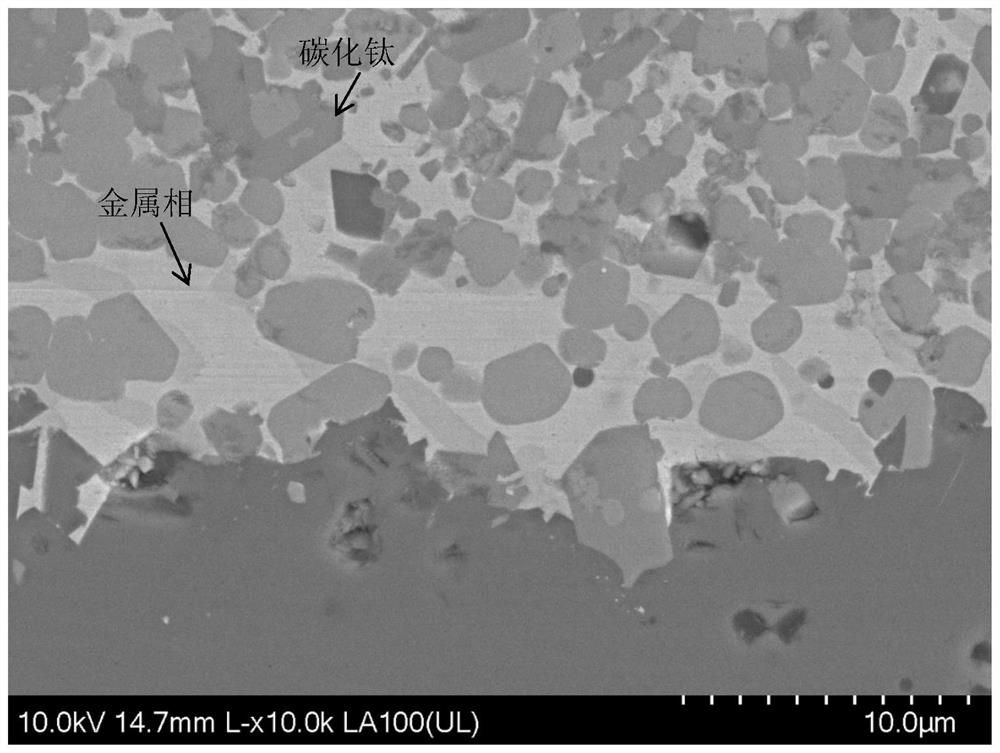

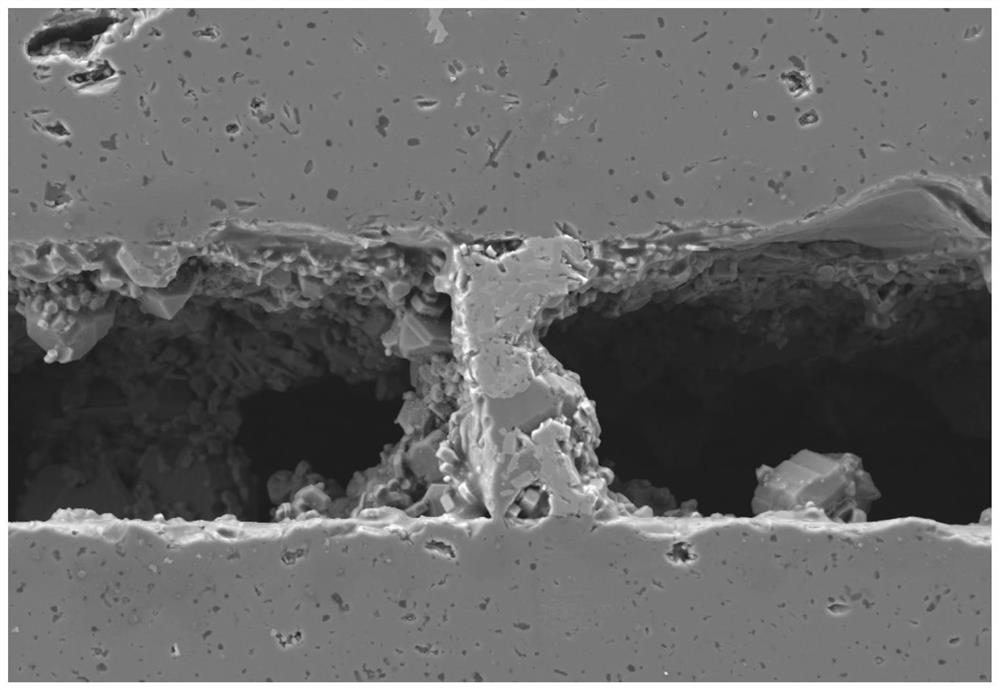

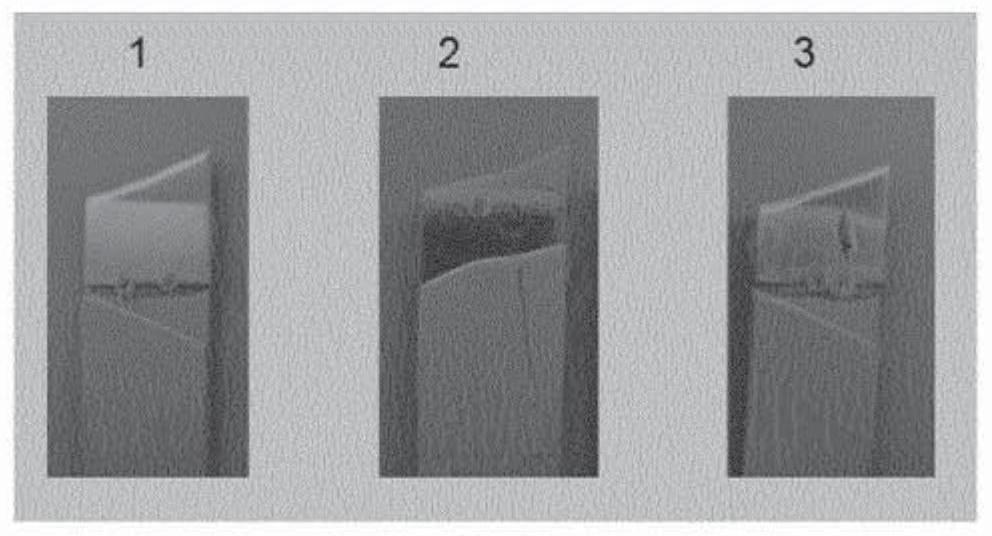

Silicon carbide joint and its metal penetration connection method

ActiveCN114031415BReduction of requirements for shape structure, etc.High-strength connectionCarbide siliconAir tightness

The invention discloses a silicon carbide joint and a metal penetration connection method thereof. The metal penetration connection method includes the following steps: S1, preparing a first metal raw material and a second metal raw material to form a connecting material; S2, disposing the connecting material in a Between the connection surfaces of the two silicon carbide pieces, a sandwich structure is formed with the two silicon carbide pieces; S3, the sandwich structure is placed in a sintering environment with a metal phase and sintered; during the sintering process, the metal phase infiltrates into the connecting material and fill in the pores generated in the connecting material; S4, after sintering, the connecting material is densified to form a connecting layer, and two silicon carbide parts are connected to form a silicon carbide joint. The metal infiltration connection method of the silicon carbide joint of the present invention penetrates into the connecting material with the metal phase, realizes the densification of the connecting material, obtains a high-strength connection and a silicon carbide joint with good air tightness, and reduces the requirements on the shape and structure of silicon carbide. .

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

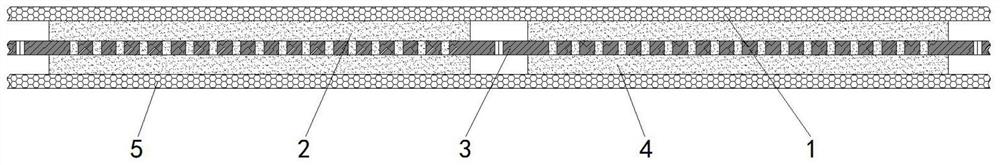

Diffusion welding method of titanium or titanium alloy and stainless steel

InactiveCN102218592BHigh-strength connectionHigh strengthNon-electric welding apparatusSS - Stainless steelTitanium

The invention discloses a diffusion welding method of titanium or titanium alloy and stainless steel. A plate pack having the same material quality with welded workpieces is welded into a block structure in advance. The plate pack is lengthways cut into slices along the block structure to form a structural middle layer 7. The middle layer is processed and then vertically arranged between the welded workpieces for diffusion welding. Because the middle layer having the same material quality with the workpiece is adopted, a joint heterogeneous interface combination mode is changed into a combination mode that half heterogeneous workpieces are directly combined and half heterogeneous workpieces are combined, and the titanium or titanium alloy and stainless steel workpieces are in high-intensity connection. In the diffusion welding method, the tensile strength of the joint is improved to above 80% from 50-70%(week side workpiece intensity) obtained by the direct diffusion welding technology, and various types of titanium or titanium alloy and stainless steel can be in high-intensity connection.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Ultra-fragile double-sided adhesive tape for gift box packaging and preparation method thereof

PendingCN112724869ASimple preparation stepsImprove processing efficiencyFilm/foil adhesivesAmide/imide polymer adhesivesRelease linerComposite material

The invention relates to the technical field of double-sided adhesive tapes, and discloses an ultra-fragile double-sided adhesive tape for gift box packaging. The ultra-fragile double-sided adhesive tape sequentially comprises a first release film layer, a first adhesive layer, a base layer, a second adhesive layer and a second release film layer from top to bottom. According to the ultra-fragile double-sided adhesive tape for gift box packaging and the preparation method thereof, the double-sided adhesive tape can be conveniently broken at equal intervals through the easy-to-tear gaps in the base layer so that the situations that the double-sided adhesive tape is not easy to tear off and broken openings are not aligned in the pasting process are avoided, and the first adhesive layer and the second adhesive layer are adhered more tightly; the situation that the first adhesive layer or the second adhesive layer is separated from the base layer and is not firmly adhered is avoided, the effects of simplicity, convenience in use and high-strength connection are achieved, meanwhile, the ultra-fragile double-sided adhesive tape is simple in preparation step and high in processing efficiency so that the processing period is greatly shortened, the production efficiency is improved, and the ultra-fragile double-sided adhesive tape is convenient to popularize.

Owner:SHENZHEN LICHANGSHI ADHESIVE PROD

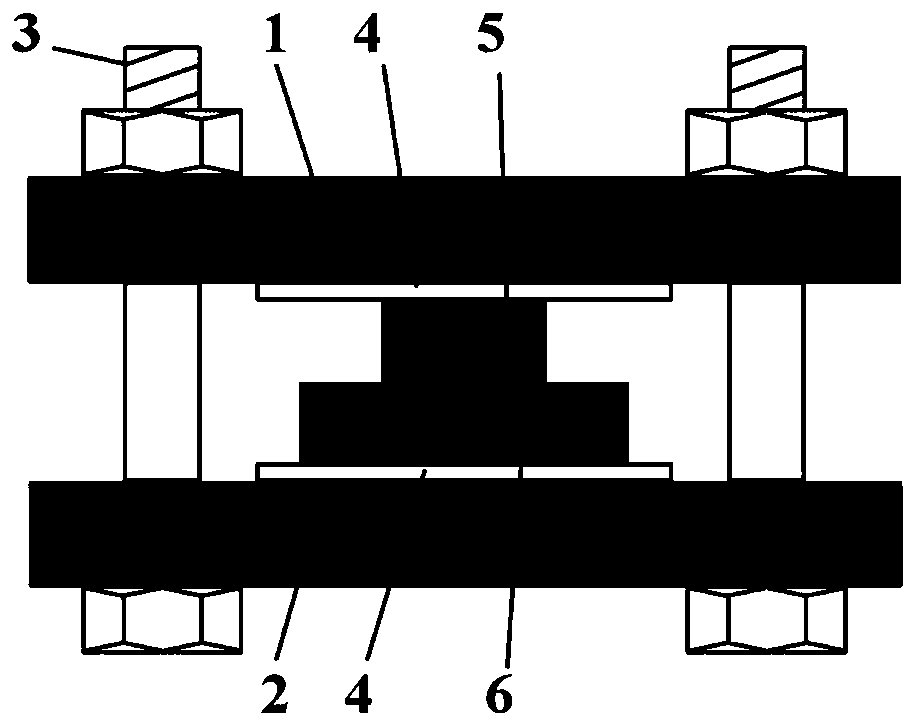

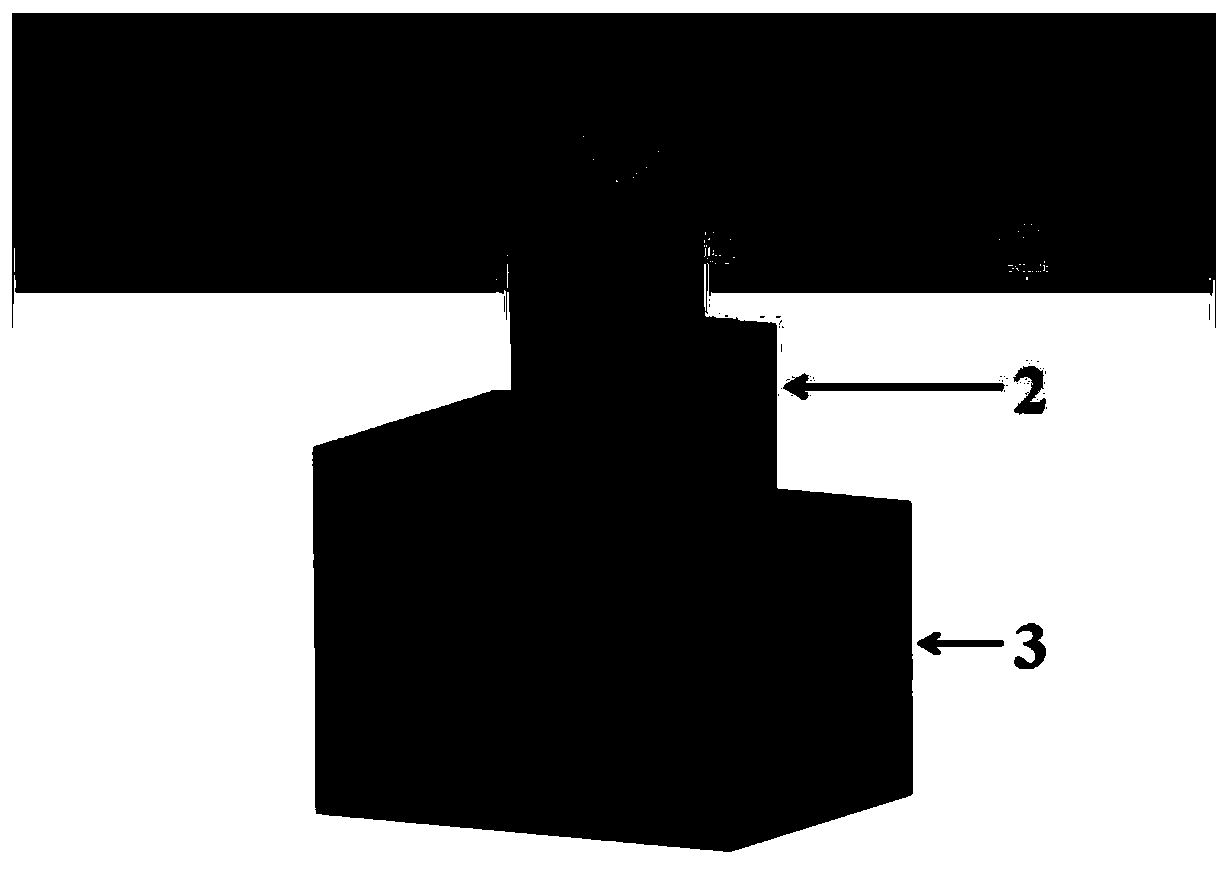

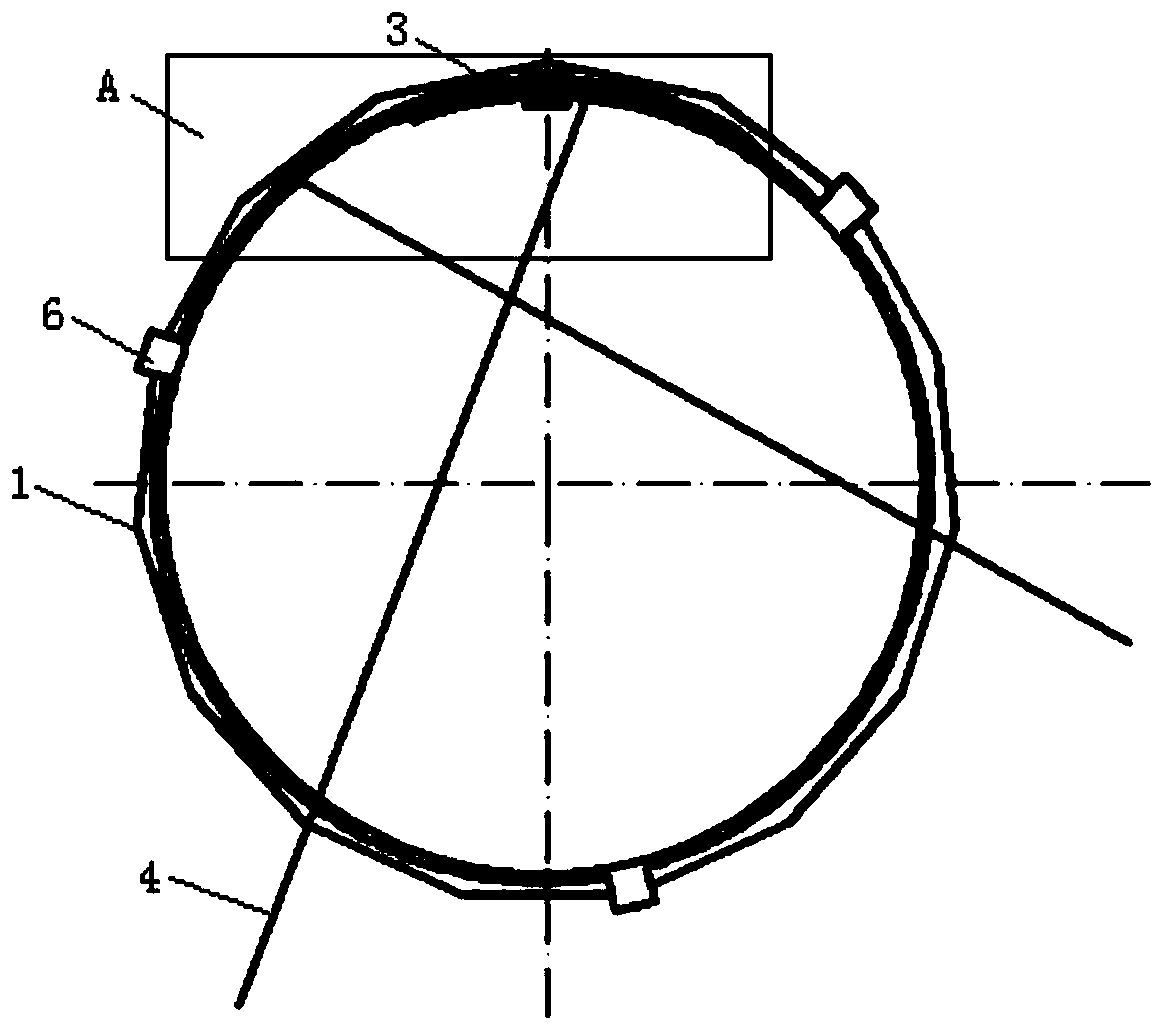

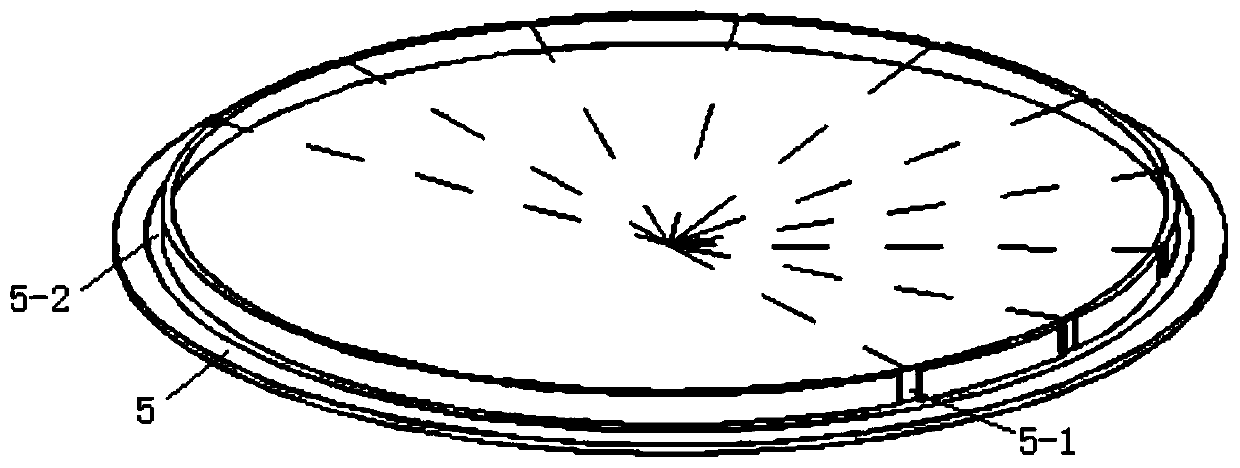

Device and packaging method for end sealing of deformable metal foil structure

InactiveCN108655526BSolving Sealed Connection ProblemsImprove sealingSoldering apparatusThin metalMetal foil

The invention provides a device and method for sealing the end part of a deformable metal foil material structure, and belongs to the field of precise connection of deformable ultra-thin metal structures, and particularly relates to a sealing device and a sealing method for the end part of a deformable metal foil material structure. The invention aims to solve the problem that the deformable metalfoil material structure and a flange cannot be reliably connected. The device for sealing the end part of the deformable metal foil material structure comprises a high-elasticity metal foil material,a lock catch, a flange plate and a plurality of positioning pieces. The sealing method comprises the following steps: 1, a high-elasticity thin-wall metal ring is formed; 2, the high-elasticity thin-wall metal ring is horizontally placed; 3, the end part of the deformable ultra-thin metal foil material structure is supported into a circle; and 4, the deformable metal foil material structure is arranged on a flange plate, and keeps warm in a nitrogen atmosphere in a heat treatment furnace and is cooled to the room temperature along with the furnace, so that the deformable ultra-thin metal foil material structure with the sealed end is obtained. The device is mainly used for sealing the end part of the deformable metal foil material structure.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

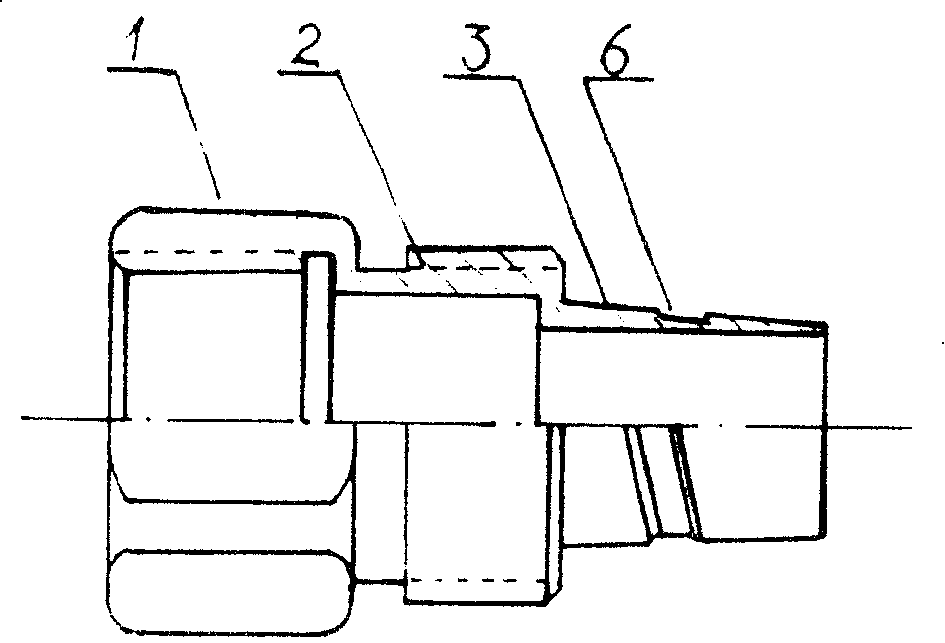

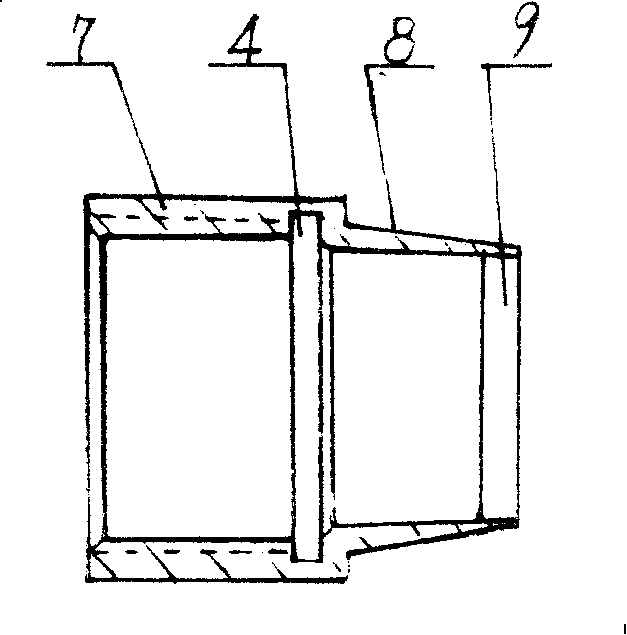

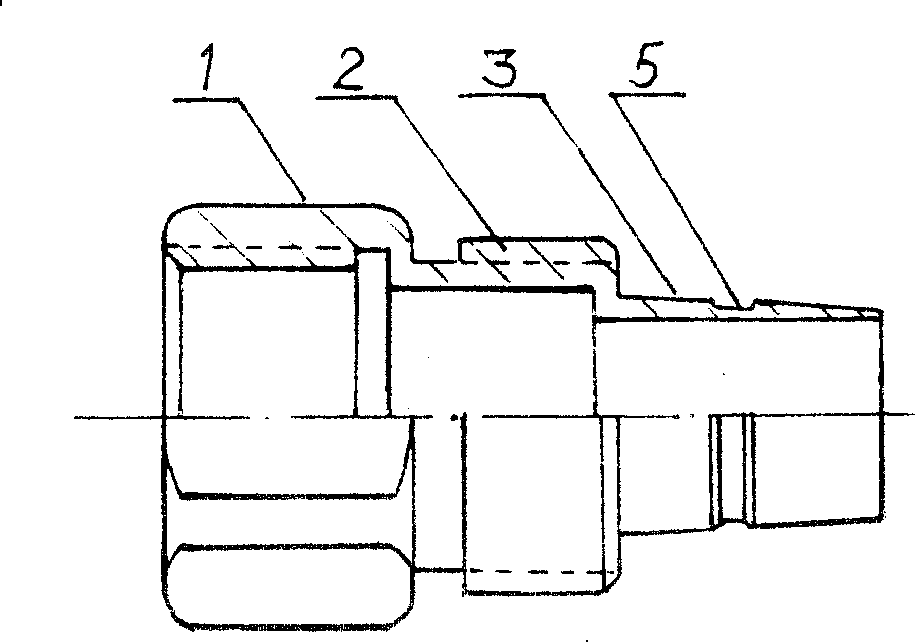

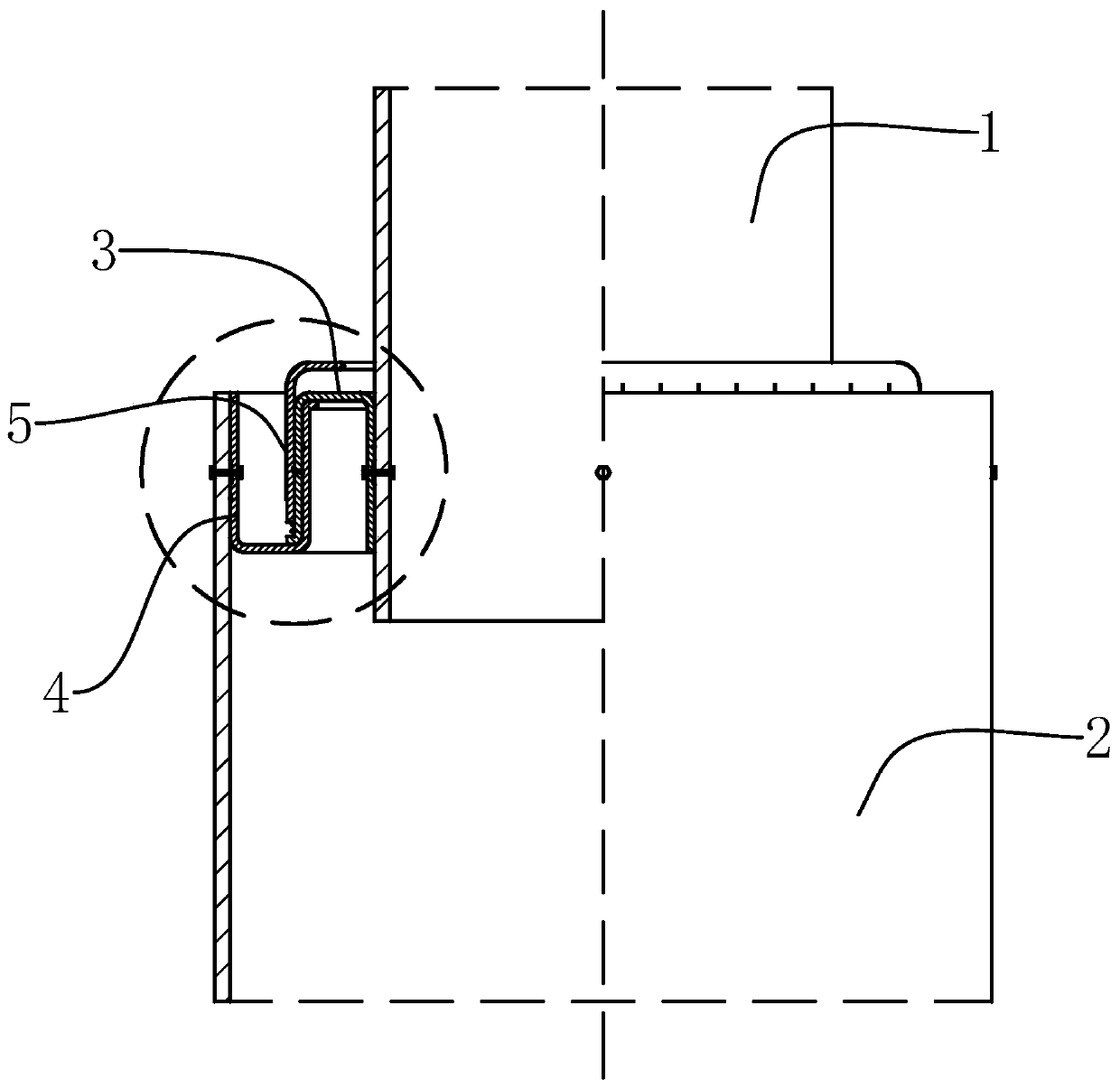

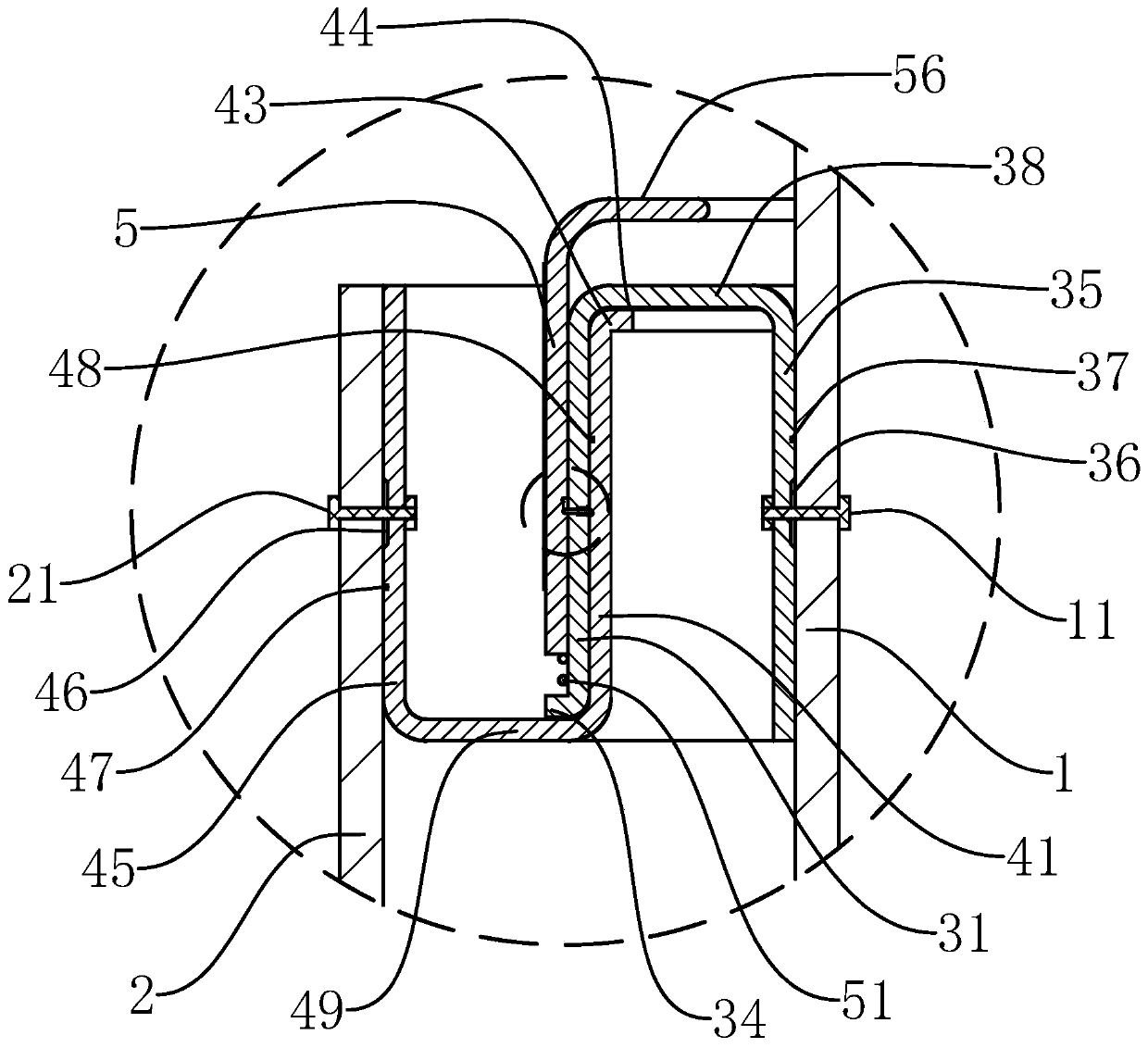

A kind of pipeline quick connection structure and its assembly and disassembly method

ActiveCN110043728BHigh strength connectionImprove seal strengthPipe-jointsIndustrial engineeringFastener

The invention provides a quick pipeline connecting structure and a mounting and dismounting method, and belongs to the field of pipelines. The problem that existing pipeline connecting is low in strength and poor in sealing performance is solved. The quick pipeline connecting structure comprises an upper pipeline, a lower pipeline and a connecting device. The connecting device comprises an upper connecting component connected with the upper pipeline, and a lower connecting component connected with the lower pipeline. The upper connecting component comprises an upper quick connecting pipe, an upper connecting pipe and an upper connecting plate. The upper connecting component further comprises an upper fastener penetrating through the upper connecting pipe and the upper pipeline to be fixed.The lower connecting component comprises a lower quick connecting pipe, a lower connecting pipe and a lower connecting plate, and further comprises a lower fastener penetrating through the lower connecting pipe and the lower pipeline to be fixed. A circular-ring-shaped upper baffle ring is fixed to the outer wall of the bottom end of the upper quick connecting pipe coaxially. A circular-ring-shaped lower baffle ring is fixed to the inner wall of the top end of the lower quick connecting pipe coaxially. The quick pipeline connecting structure further comprises an adjusting pipe sleeving the outer side of the upper quick connecting pipe, the inner diameter of the upper quick connecting pipe is the same as the outer diameter of the lower quick connecting pipe, and a circular-ring-shaped sealing pad is fixed to the top end of the lower baffle ring. The connecting structure can be used for connecting pipelines in a high strength and high sealing performance manner.

Owner:ZHEJIANG BANNINGER PIPING SYST LTD

Quick pipeline connecting structure and mounting and dismounting method

The invention provides a quick pipeline connecting structure and a mounting and dismounting method, and belongs to the field of pipelines. The problem that existing pipeline connecting is low in strength and poor in sealing performance is solved. The quick pipeline connecting structure comprises an upper pipeline, a lower pipeline and a connecting device. The connecting device comprises an upper connecting component connected with the upper pipeline, and a lower connecting component connected with the lower pipeline. The upper connecting component comprises an upper quick connecting pipe, an upper connecting pipe and an upper connecting plate. The upper connecting component further comprises an upper fastener penetrating through the upper connecting pipe and the upper pipeline to be fixed.The lower connecting component comprises a lower quick connecting pipe, a lower connecting pipe and a lower connecting plate, and further comprises a lower fastener penetrating through the lower connecting pipe and the lower pipeline to be fixed. A circular-ring-shaped upper baffle ring is fixed to the outer wall of the bottom end of the upper quick connecting pipe coaxially. A circular-ring-shaped lower baffle ring is fixed to the inner wall of the top end of the lower quick connecting pipe coaxially. The quick pipeline connecting structure further comprises an adjusting pipe sleeving the outer side of the upper quick connecting pipe, the inner diameter of the upper quick connecting pipe is the same as the outer diameter of the lower quick connecting pipe, and a circular-ring-shaped sealing pad is fixed to the top end of the lower baffle ring. The connecting structure can be used for connecting pipelines in a high strength and high sealing performance manner.

Owner:ZHEJIANG BANNINGER PIPING SYST LTD

Silicon carbide joint and metal penetration connection method thereof

ActiveCN114031415AReduction of requirements for shape structure, etc.High-strength connectionCarbide siliconAir tightness

The invention discloses a silicon carbide joint and a metal penetration connection method thereof. The metal penetration connection method comprises the following steps that: S1, preparing a first metal raw material and a second metal raw material are prepared to form a connection material; S2, the connecting material is arranged between the connecting faces of two silicon carbide parts, and the connecting material and the two silicon carbide parts form a sandwich structure; S3, the sandwich structure is placed in a sintering environment with a metal phase and sintered; and in the sintering process, the metal phase permeates into the connecting material and fills air holes generated in the connecting material; and S4, after sintering, the connecting material is densified to form a connecting layer, and the two silicon carbide parts are connected to form the silicon carbide joint. According to the metal permeation connection method of the silicon carbide joint, the metal phase permeates into the connection material, densification of the connection material is achieved, the silicon carbide joint with high-strength connection and good air tightness is obtained, and the requirements for the shape structure and the like of silicon carbide are lowered.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

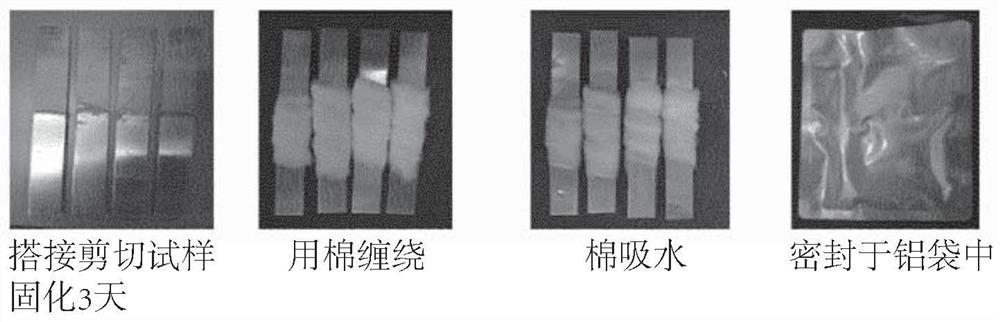

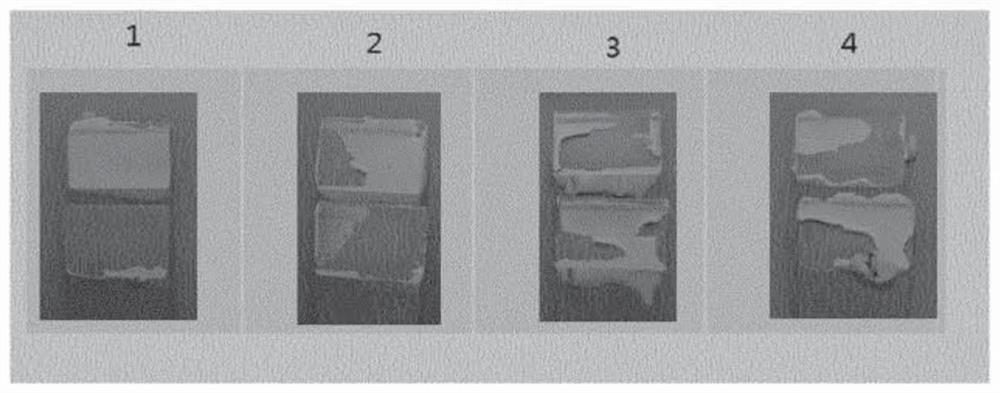

Method for assembling metal pipes with two-component polyurethane adhesive

PendingCN114787306AHigh bonding strengthImprove toughnessAdhesive processesPipe laying and repairAdhesive cementPolymer science

The invention relates to a method for joining a first metal pipe to a second metal pipe, said pipes being joined together in an overlap region by using a two-component polyurethane adhesive covering the overlap region, the method comprising the following steps: (1) applying the two-component polyurethane adhesive on an inner surface of a clamp; (2) one end of the first metal tube is inserted into one end of the second metal tube to form a tube assembly with an overlapping area between the two ends, and the overlapping area of the tube assembly is placed into a clamp; (3) closing the clamp such that the overlapping region of the tube assembly is secured in the clamp and wherein the adhesive covers the overlapping region of the tube assembly; (4) curing the adhesive; and (5) optionally, removing the clamp from the pipe assembly.

Owner:BASF AG

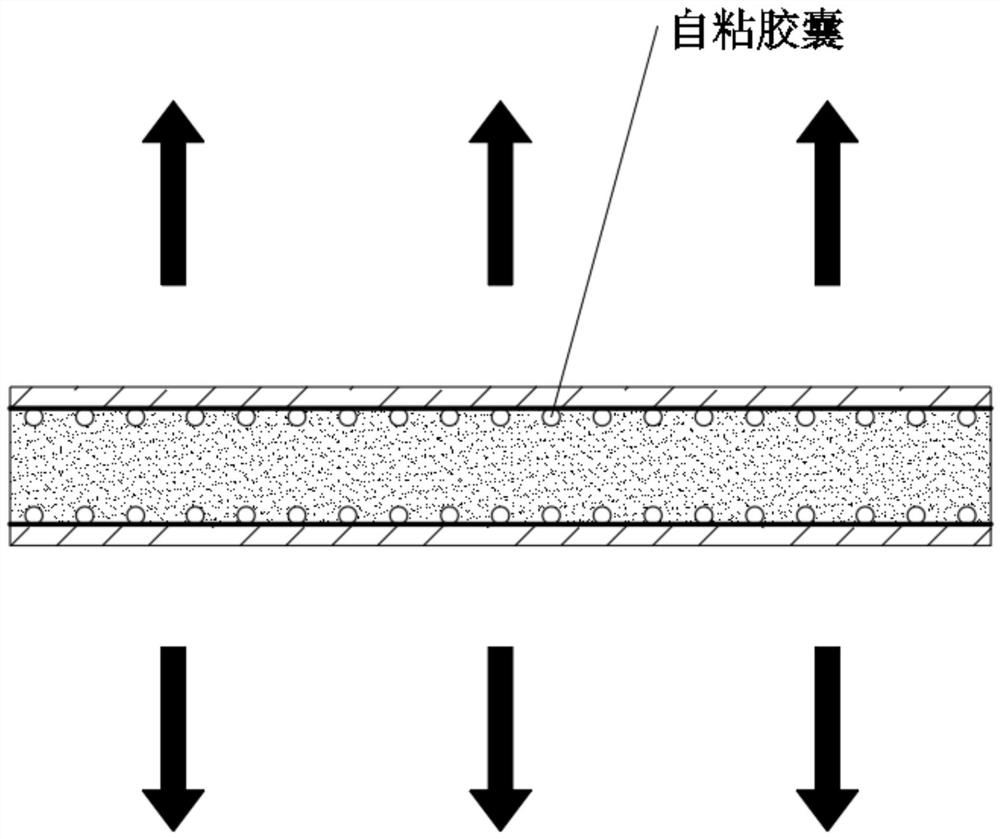

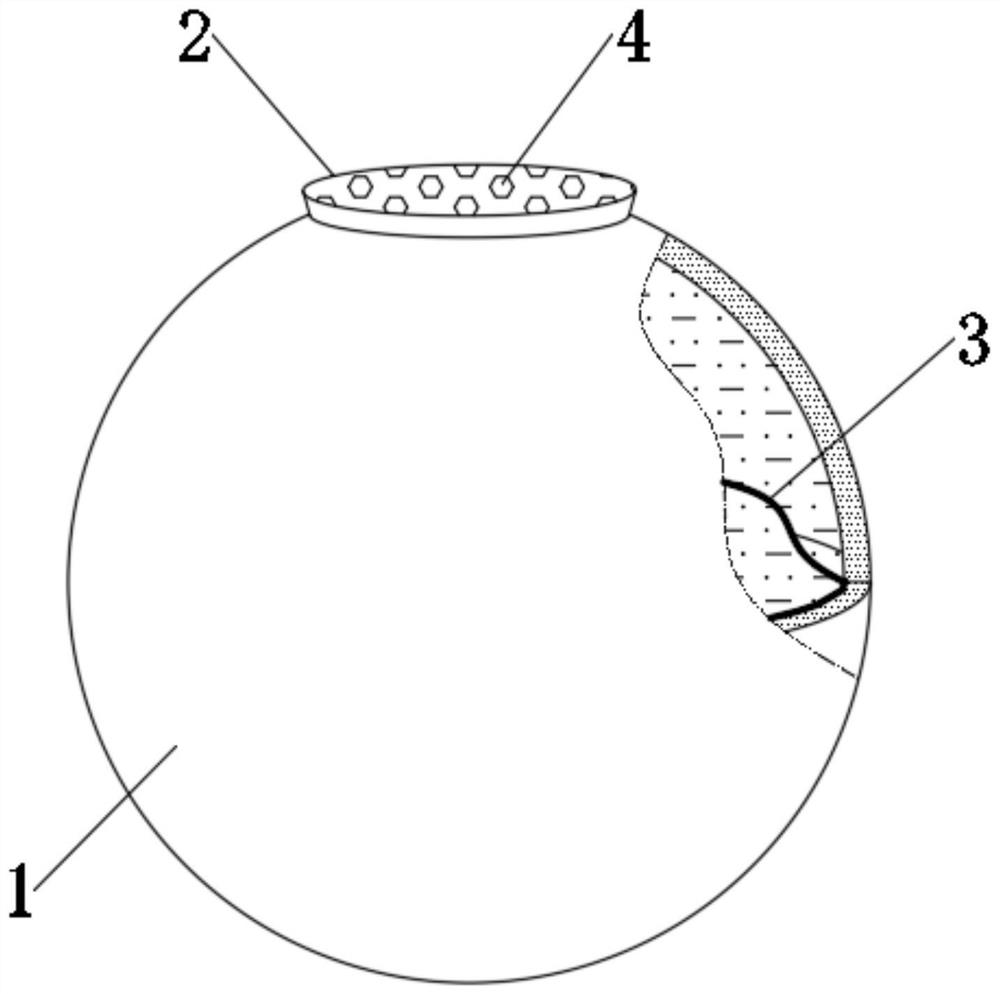

Integrated preparation process of foamed cement sandwich color steel plate

ActiveCN113427601AHigh strength connectionHigh bonding strengthCeramic shaping apparatusBonding strengthCement Material

The invention discloses an integrated preparation process of a foamed cement sandwich color steel plate, and belongs to the technical field of color steel plate preparation. The color steel plate is used as a template, a plurality of self-adhesive capsules are adsorbed on the surface of the color steel plate by utilizing a magnetic field, then a mold is matched for foaming to obtain a cement sandwich, and the self-adhesive capsules are reserved on the surface of the cement sandwich; in the later steam curing process, the self-adhesive capsules are heated and opened, meanwhile, air between the cement sandwich and the color steel plate is heated and expanded to jack up the color steel plate to form a gap, tentacles extend out under the action of the magnetic field to be close to the color steel plate subjected to corona treatment, and the tentacles are combined with pits in the surface of the color steel plate; and meanwhile, the extrusion releases a binder to fill the gap, then the high strength connection between the color steel plate and the cement sandwich is realized under heavy pressure after cooling, compared with the prior art, the foamed cement sandwich and the color steel plate can be integrally prepared, and the foamed cement sandwich and the color steel plate are high in bonding strength and not easy to separate.

Owner:佛山市勇旺达建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com