Integrated preparation process of foamed cement sandwich color steel plate

A technology of foam cement and preparation process, which is applied in the direction of manufacturing tools and ceramic molding machines, and can solve problems such as low bonding strength, limited bonding strength, and cumbersome process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] see figure 1 , an integrated preparation process of foamed cement sandwich color steel plate, comprising the following steps:

[0048] S1. Prepare the corresponding foaming mold, and then install two corona-treated color steel plates in the foaming mold to prepare foamed cement;

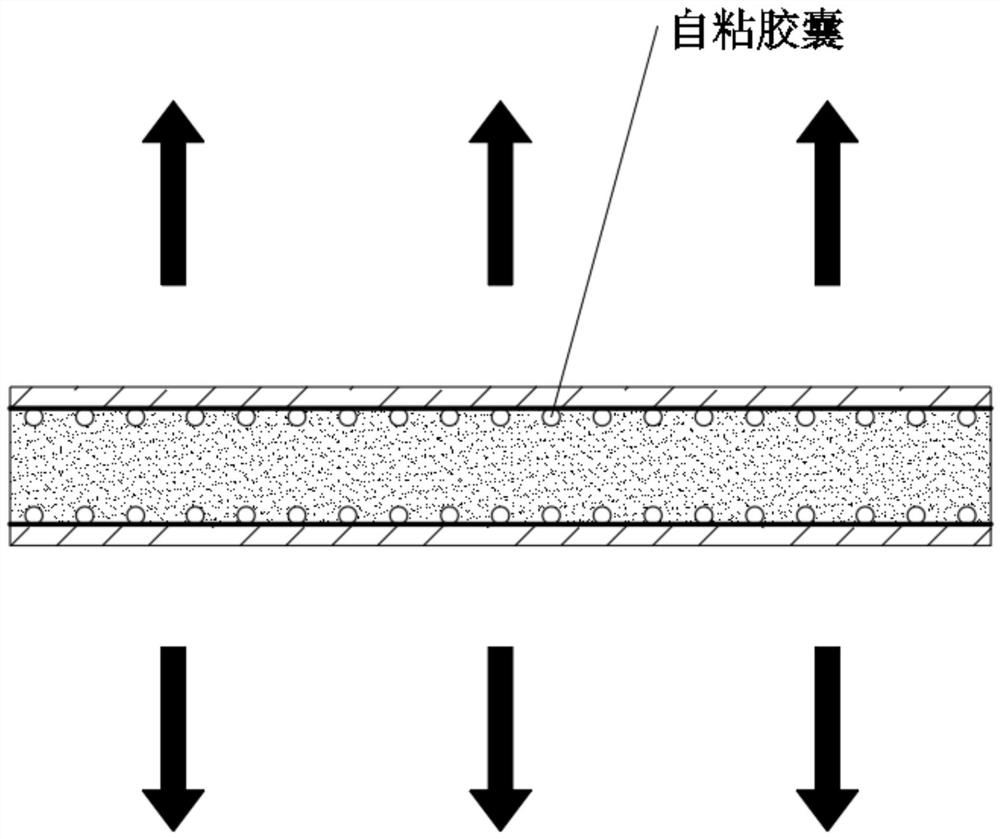

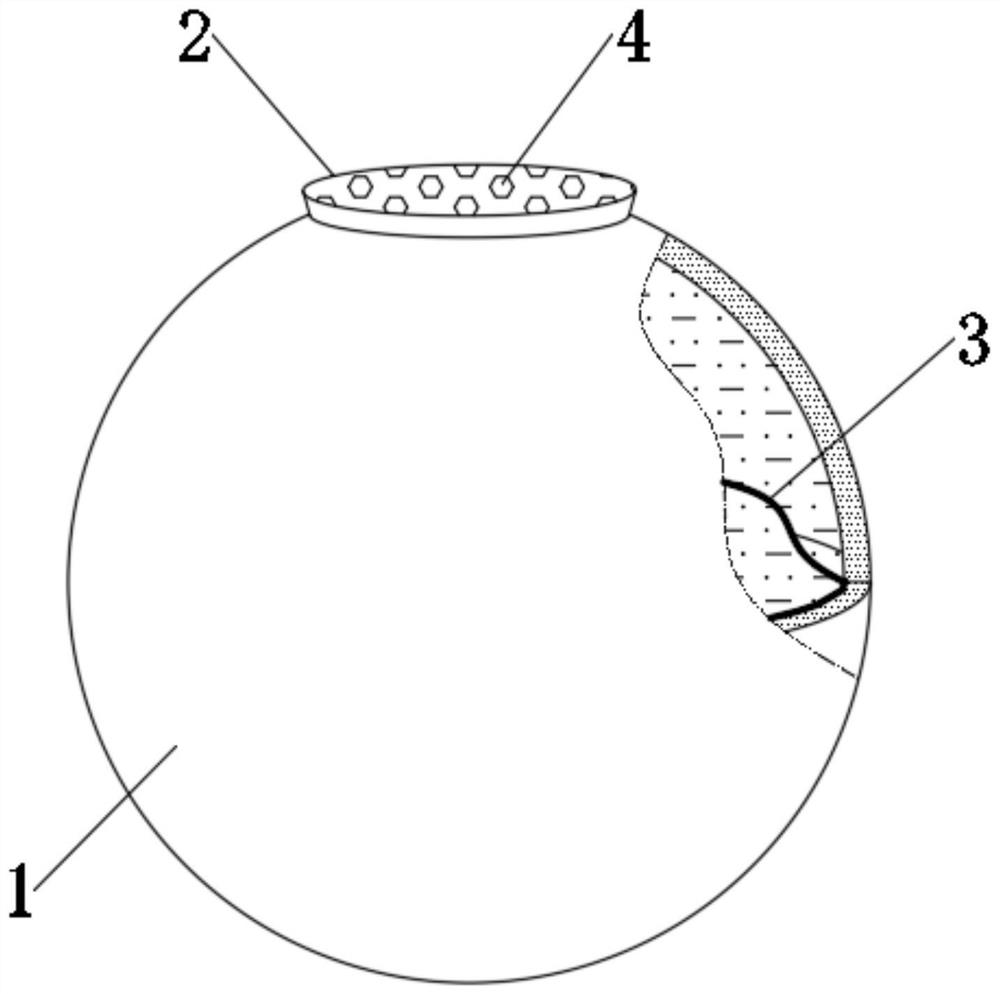

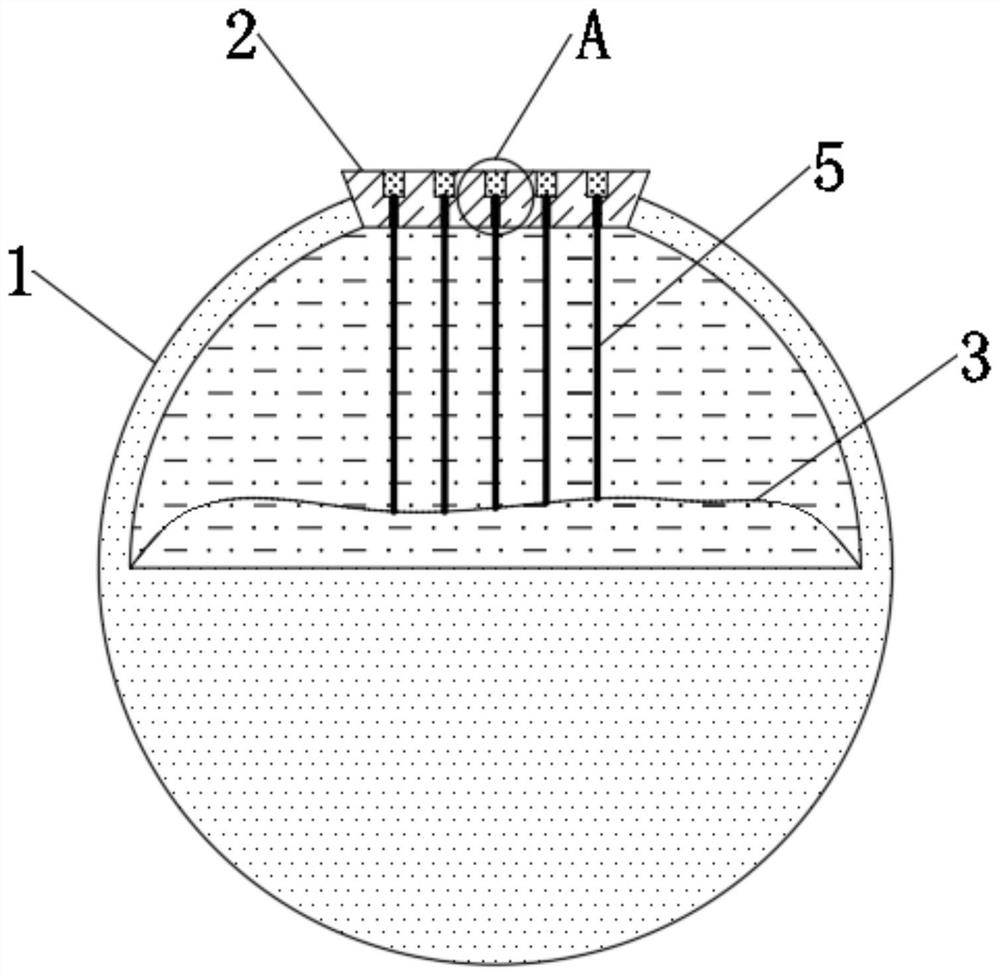

[0049] S2. Apply a magnetic field to the outside of the foaming mold to absorb a plurality of evenly distributed self-adhesive capsules on the surface of the two color steel plates;

[0050] S3. Inject the prepared foamed cement into the foaming mold, foam the cement sandwich, and wrap the cement sandwich with a plastic film to keep it moist for 24 hours;

[0051] S4. After moisturizing, remove the mold and take out the cement sandwich, perform steam curing, and trigger the release action of the self-adhesive capsule, and apply a magnetic field at the same time;

[0052] S5. After curing, the plastic film is uncovered, and the color steel plate is pressed with a pressure of 200kg / m2 to obtai...

Embodiment 2

[0063] An integrated preparation process of foamed cement sandwich color steel plate, comprising the following steps:

[0064] S1. Prepare the corresponding foaming mold, and then install two corona-treated color steel plates in the foaming mold to prepare foamed cement;

[0065] S2. Apply a magnetic field to the outside of the foaming mold to absorb a plurality of evenly distributed self-adhesive capsules on the surface of the two color steel plates;

[0066] S3. Inject the prepared foamed cement into the foaming mold, foam to form a cement sandwich, and wrap the cement sandwich with a plastic film to keep it moist for 36 hours;

[0067] S4. After moisturizing, remove the mold and take out the cement sandwich, perform steam curing, and trigger the release action of the self-adhesive capsule, and apply a magnetic field at the same time;

[0068] S5. After curing, the plastic film is uncovered, and the color steel plate is pressed with a pressure of 250kg / m2 to obtain a foamed...

Embodiment 3

[0073] An integrated preparation process of foamed cement sandwich color steel plate, comprising the following steps:

[0074] S1. Prepare the corresponding foaming mold, and then install two corona-treated color steel plates in the foaming mold to prepare foamed cement;

[0075] S2. Apply a magnetic field to the outside of the foaming mold to absorb a plurality of evenly distributed self-adhesive capsules on the surface of the two color steel plates;

[0076] S3. Inject the prepared foamed cement into the foaming mold, foam the cement sandwich, and wrap the cement sandwich with a plastic film to keep it moist for 48 hours;

[0077] S4. After moisturizing, remove the mold and take out the cement sandwich, perform steam curing, and trigger the release action of the self-adhesive capsule, and apply a magnetic field at the same time;

[0078]S5. After curing, the plastic film is uncovered, and the color steel plate is pressed with a pressure of 300kg / m2 to obtain a foamed cement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com