Device and packaging method for end sealing of deformable metal foil structure

A technology of end sealing and metal foil, which is applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problem of unreliable connection between deformable metal foil structure and flange, and solve the problem of low welding strength, Meet the application requirements, no air leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

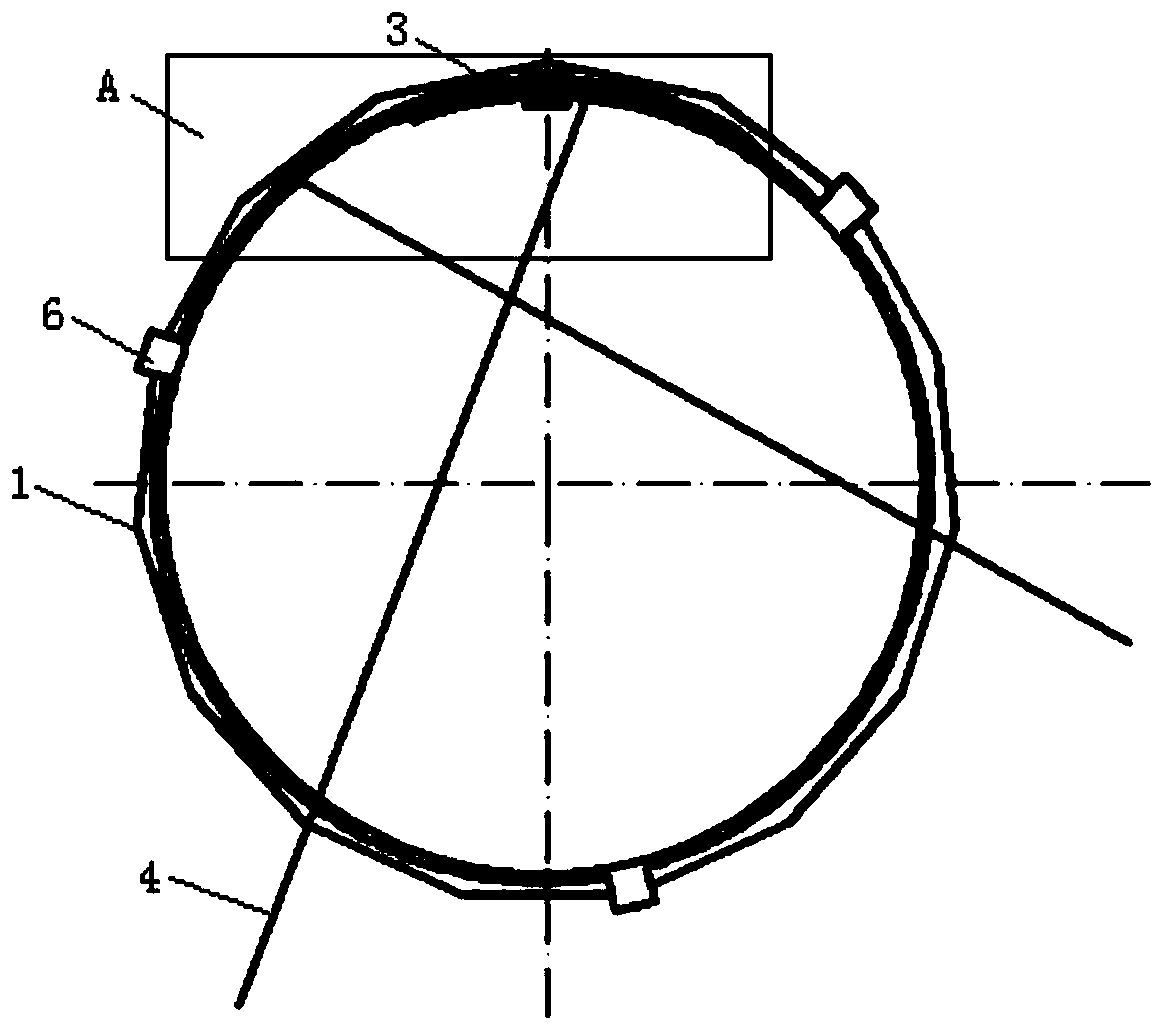

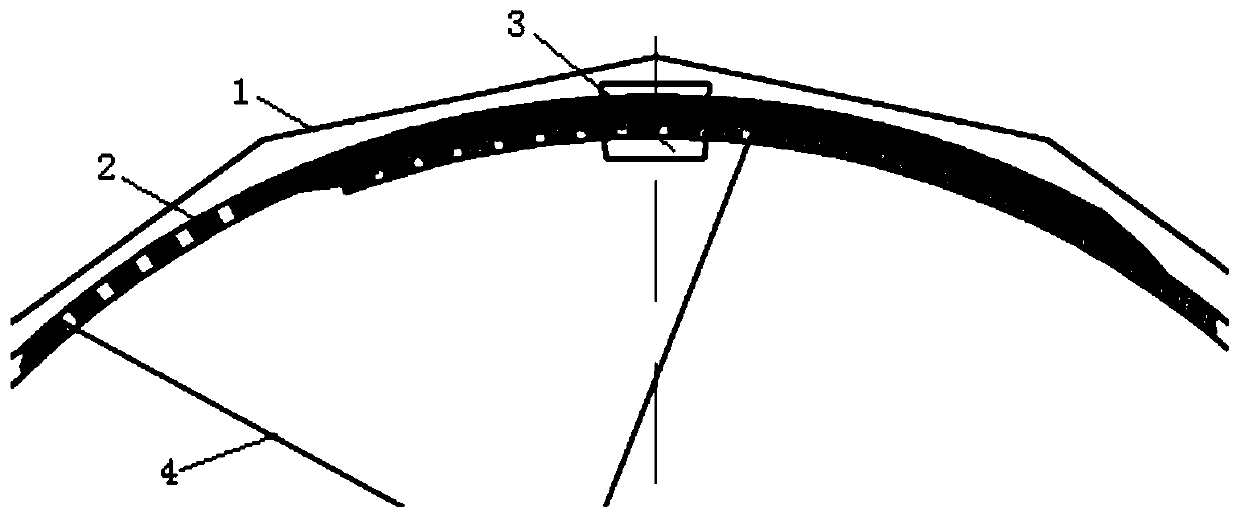

[0019] Embodiment 1: This embodiment is a device for sealing the end of a deformable metal foil structure, which includes a highly elastic metal foil 2, a lock 3, a flange 5 and several positioning pieces 6;

[0020] One end of the high elastic metal foil material 2 is set as an inner zigzag end, and several holes are arranged on the high elastic metal foil material 2 connected to the inner zigzag end, and the axial direction of the hole is in line with the high elastic metal The thickness direction of the foil material 2 is parallel; the other end of the highly elastic metal foil material 2 is set as an outer zigzag end, and several holes are arranged on the outer zigzag end, and the axis direction of the hole is the same as that of the outer zigzag end. The thickness direction is parallel; the highly elastic metal foil material 2 is interlocked with the inner serrated end and the outer serrated end through the lock 3 to form a highly elastic thin-walled metal ring, and the hi...

specific Embodiment approach 2

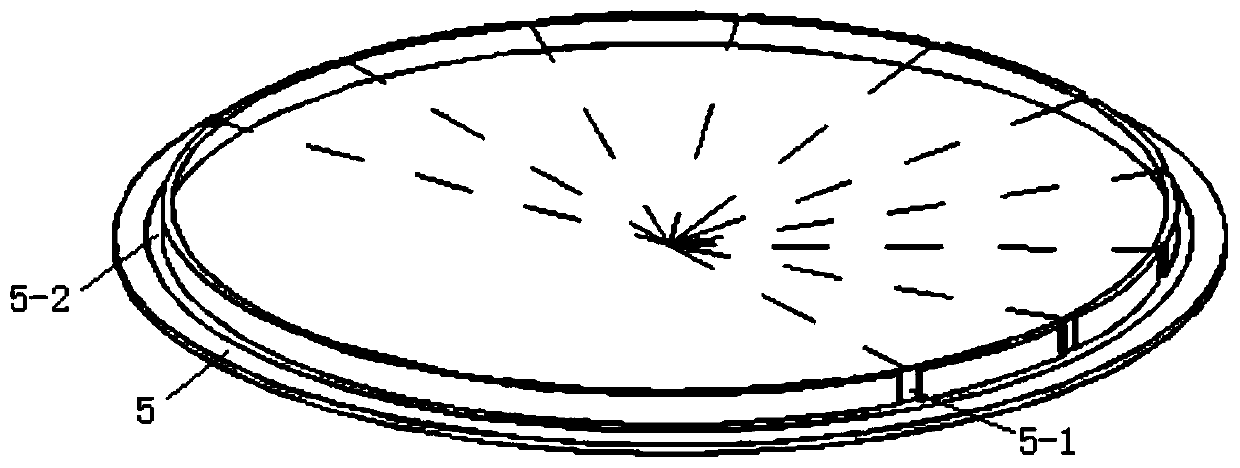

[0021] Embodiment 2: The difference between this embodiment and Embodiment 1 is: 10 micro-grooves 5-1 are arranged on the outer side of the tubular wall of the flange plate 5, except for the two adjacent micro-grooves 5-1 on the outermost side. , and the distances between the other two adjacent micro-grooves 5-1 along the circumferential direction are equal. Others are the same as the first embodiment.

specific Embodiment approach 3

[0022] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: the diameter of the outer surface of the flange plate 5 tubular wall is 396mm, and the length of the miniature groove 5-1 is 5mm, and the width is 3mm. The distance between the outermost two adjacent micro-grooves 5-1 along the circumferential direction is 907 mm, and the distance between the other two adjacent micro-grooves 5-1 along the circumferential direction is 350 mm. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com