Method for assembling metal pipes with two-component polyurethane adhesive

A two-component polyurethane and metal pipe technology, applied in the direction of adhesives, bonding methods, rod connections, etc., can solve the problems of reducing productivity and achieve the effects of increasing productivity, simplifying the preparation process, and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] Preparation of two-component polyurethane adhesives

[0128] Two-component polyurethane adhesives were synthesized from the components shown in Table 1, and the amounts of each component are also shown in Table 1. The compositions of Part A were first mixed together to form a milky white liquid, and the resulting liquid was then mixed with Part B in a static mixer to obtain an adhesive. The properties of Component A, Component B and the adhesive are shown in Tables 2 and 3 below.

[0129] Table 1

[0130] Component A Amount (wt%) Polyol A 10.55 Polyol B 17 Polyol C 13 calcium carbonate 50 Tripropylene glycol 1 Triethylenediamine 0.2 NingRui 100 / 3A 8.25 Component B Diphenylmethane 4,4'-diisocyanate to NCO index of 103

[0131] Table 2

[0132] Component A Component B Exterior Milky white liquid brown liquid Viscosity (20℃), mPa·s 30,000±5000 250±100 Density(25℃),g...

Embodiment 2

[0136] The two metal tubes were joined and sealed using the adhesive of Example 1 .

[0137] The two metal tubes were first rinsed with ethanol and air-dried for 10 minutes to allow complete evaporation of the solvent. The first tube is made of copper and the second tube is made of aluminum. One end of the first tube is inserted into one end of the second tube to form a tube assembly with an overlapping area between the two ends.

[0138] Once the adhesive of Example 1 was obtained in the static mixer, it was drained from the mixer and then applied to one side of the jig within 5 minutes of its operating time. The collapsible clamp is made of polypropylene and has an axisymmetric shuttle shape. Place the clamp with adhesive applied on one side concentric with the tube assembly. The clamp is then closed so that the adhesive in the clamp fills the gap in the overlapping area of the tube assembly and coats the outer surface area of the tube assembly in the overlapping area...

Embodiment 3

[0154] Performance Evaluation of Two-component Polyurethane Adhesives

[0155] 1. Two-component polyurethane adhesive shows high bond strength between metal sheets.

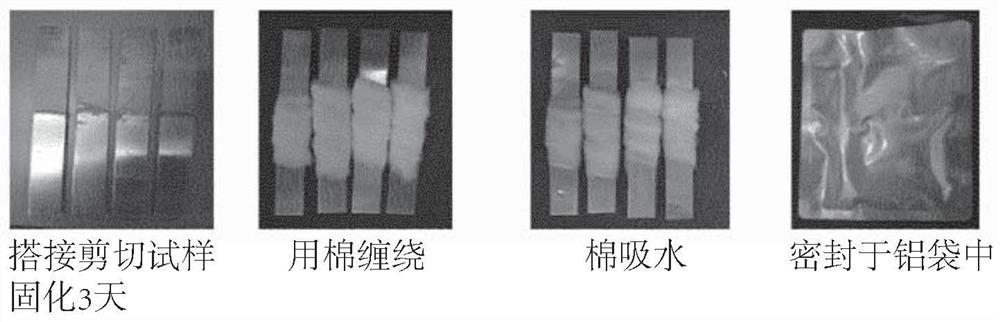

[0156] Two standard aluminum panels were sandblasted and cleaned with ethanol, and air-dried for 10 minutes to allow complete evaporation of the solvent. A two-component polyurethane (PU) adhesive was then applied to the overlapping surfaces between the two aluminum panels. The adhesive was then pressed to a thickness of 2 mm using glass beads as a caliber to control the thickness, and then cured for 3 days. Lap shear strength tests were performed according to Test Method: ISO 4587. The test was repeated 3 times.

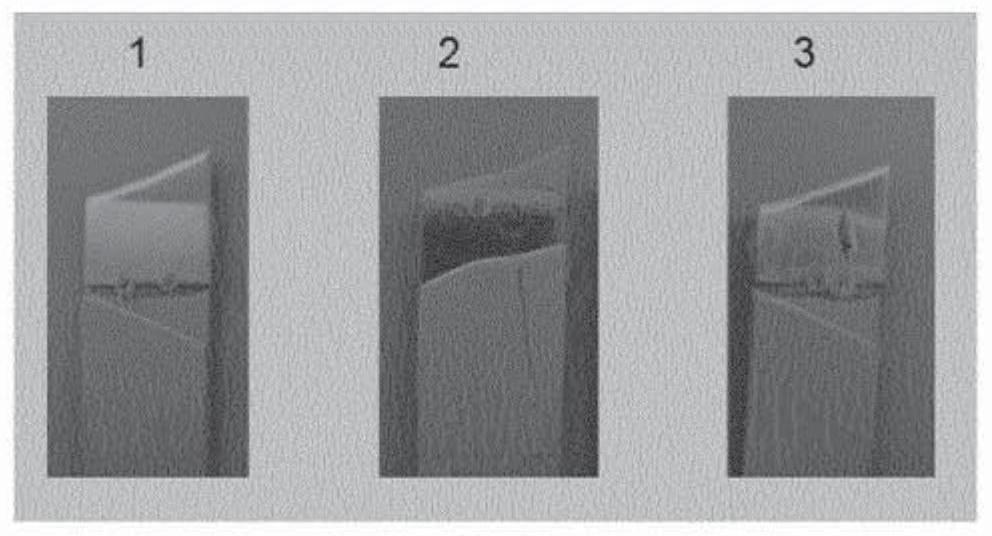

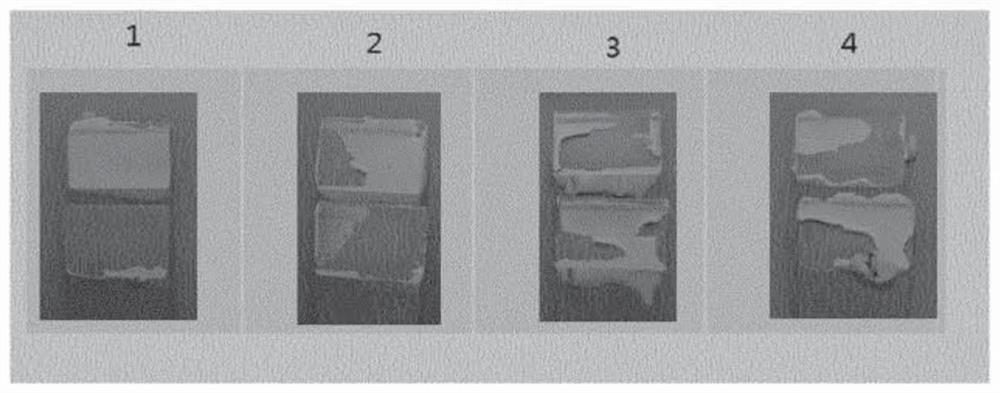

[0157] As shown in Table 4 and figure 1 shown, an average lap shear strength of 14.6 MPa at substrate failure was achieved.

[0158] Table 4

[0159] Experiment number 1 2 3 average Lap shear strength / MPa 13.6 14.6 15.6 14.6 fracture mode Substrate damage Substrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lap shear strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| lap shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com