Thermally-isolated anchoring systems with split tail veneer tie for cavity walls

a technology of split tail veneer and anchoring system, which is applied in the direction of building components, building reinforcements, construction, etc., can solve the problems of affecting the installation, affecting the integrity of the insulation system, and loosening of the stud, so as to prevent pin-point loading, prevent disengagement, and high tension and compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

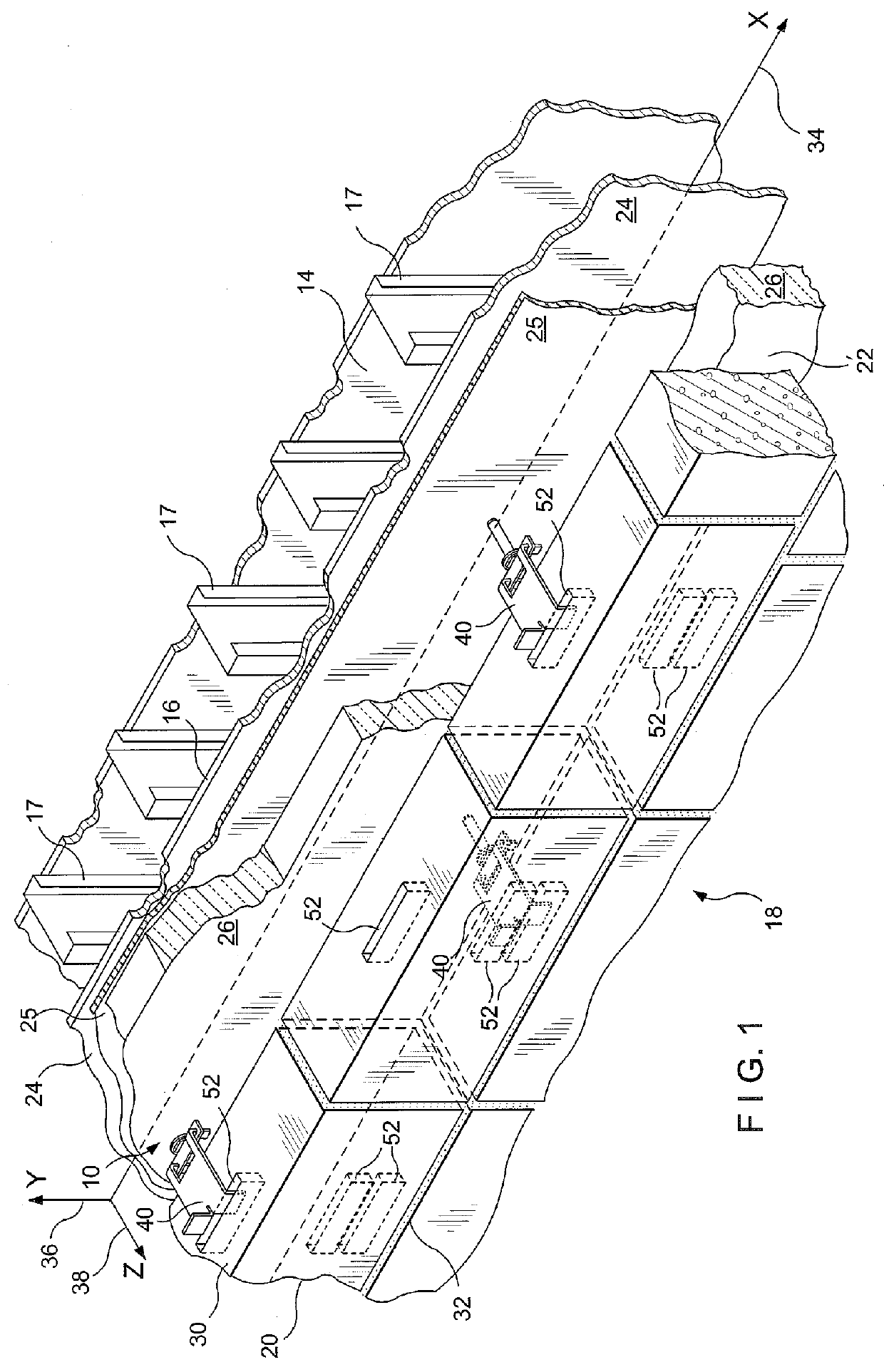

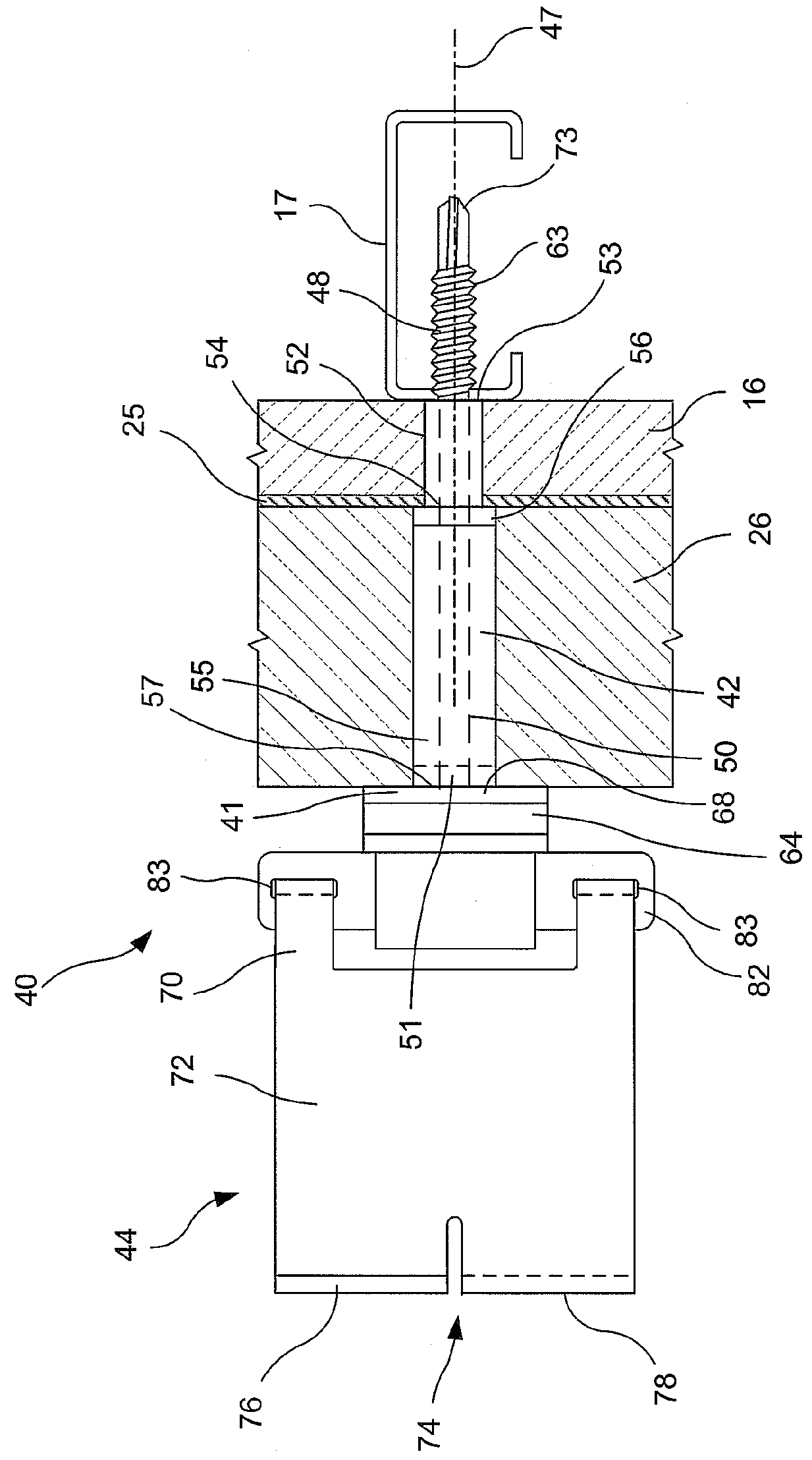

[0054]Referring now to FIGS. 1, 3, 4 and 5 illustrating the first embodiment and showing a surface-mounted, thermally-isolating anchor assembly for a cavity wall with a split veneer tie. This anchor is suitable for recently promulgated standards. The system, discussed in detail herein below, is a high-strength wall anchor for connection with an inter-engaging veneer tie. The wall anchor is either surface mounted onto an externally insulated dry wall inner wythe or installed onto an externally insulated masonry inner wythe (not shown).

[0055]As to the first embodiment, an exemplary cavity wall having an insulative layer of 3½ inches (approx.) and a total span of 6 inches (approx.) has been chosen for a discussion. This structure meets the R-factor requirements of the public sector building specification. On the other hand, use of the invention with other wall structures is contemplated. The anchoring system is referred to as high-span and generally identified by the numeral 10. For pu...

second embodiment

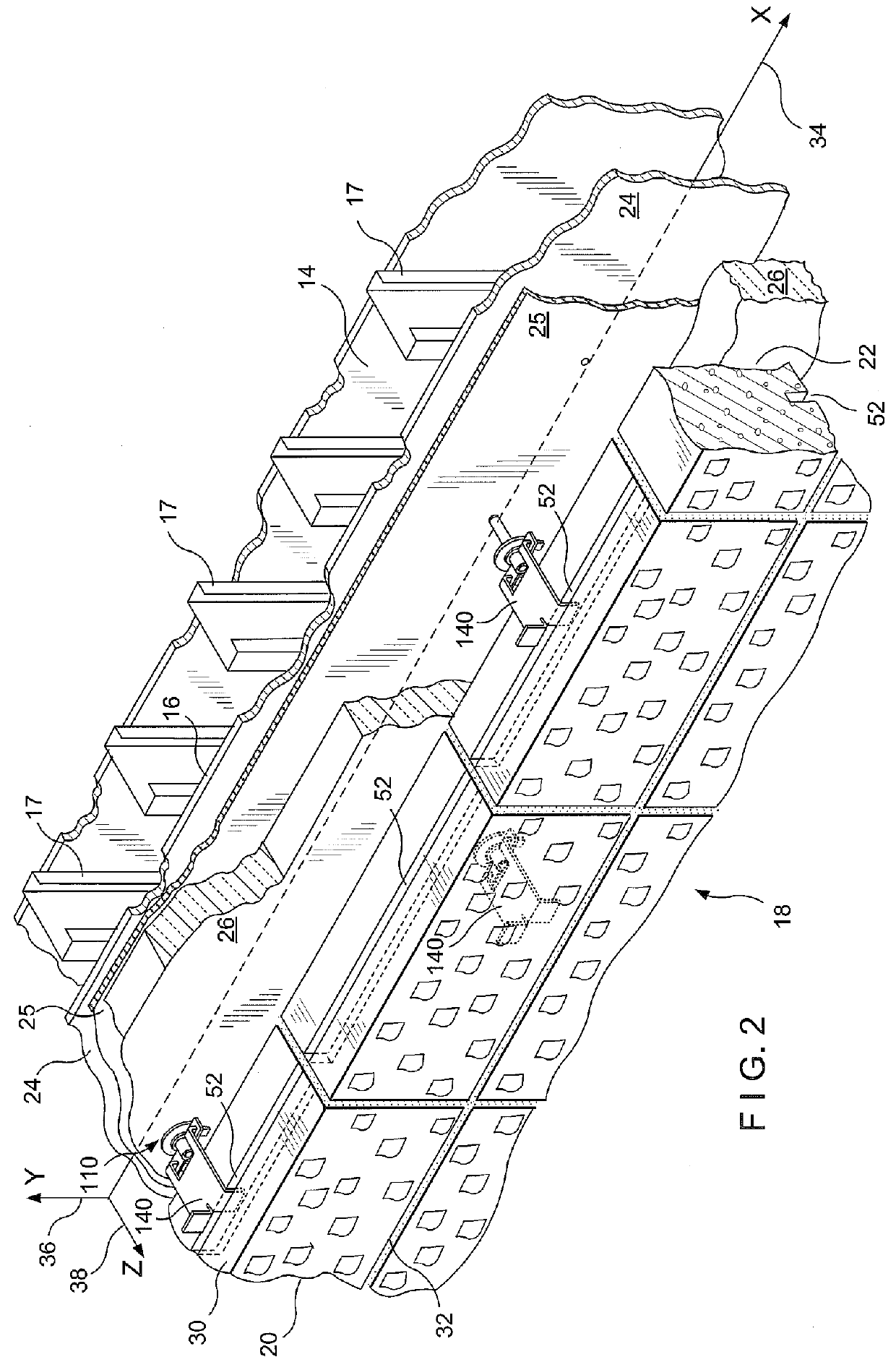

[0065]Illustrated in FIGS. 2, 6 and 7, the anchor is suitable for recently promulgated standards with more rigorous characteristics. The system of the second embodiment discussed in detail hereinbelow, is a high-strength wall anchor for connection with an interengaging veneer tie. The wall anchor is either surface mounted onto an externally insulated dry wall inner wythe (as shown in FIGS. 2 and 7) or installed onto an externally insulated masonry inner wythe.

[0066]Similar to the above-discussed first embodiment, FIG. 2 illustrates a cavity wall having a respective insulative layer with a respective total span. This structure meets the R-factor requirements of the public sector building specification. The anchoring system is referred to as high-span and generally referred to by the numeral 110. A cavity wall structure having an inner wythe or dry wall backup 14 with sheetrock or wallboard 16 and insulation 26 mounted on metal studs or columns 17 and an outer wythe of facing concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com