Medium-and-low-temperature direct diffusion bonding method of oxygen-free copper and chromium-zirconium-copper

A technology of diffusion connection and chrome-zirconium copper, which is applied in the direction of welding/welding/cutting items, welding equipment, non-electric welding equipment, etc., can solve the problems of high manufacturing cost, increase manufacturing cost, and prolong the manufacturing cycle, so as to avoid scratch defects , Avoid secondary quenching, high connection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

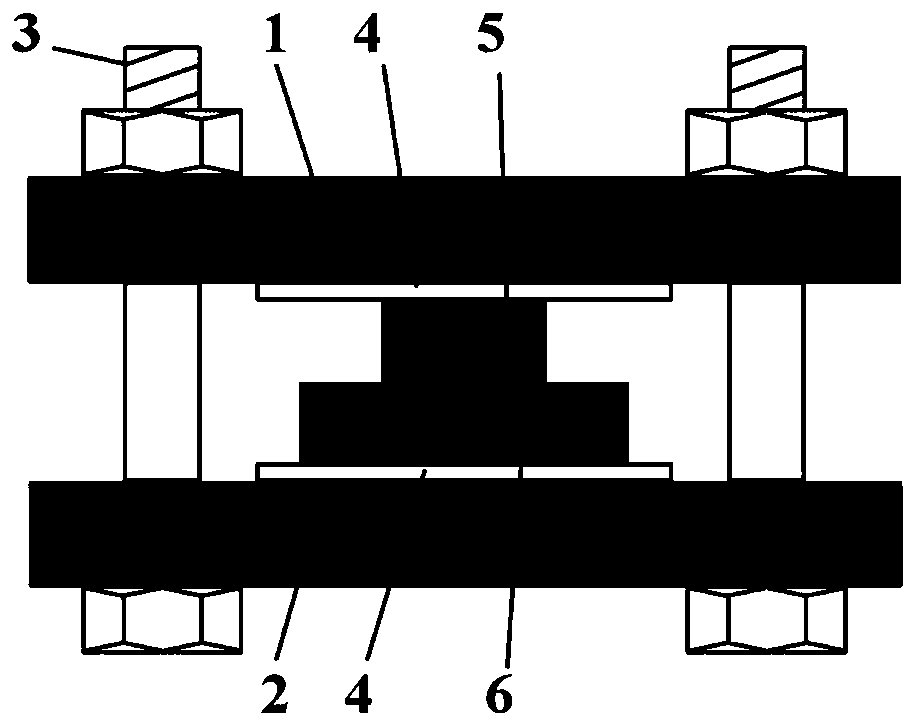

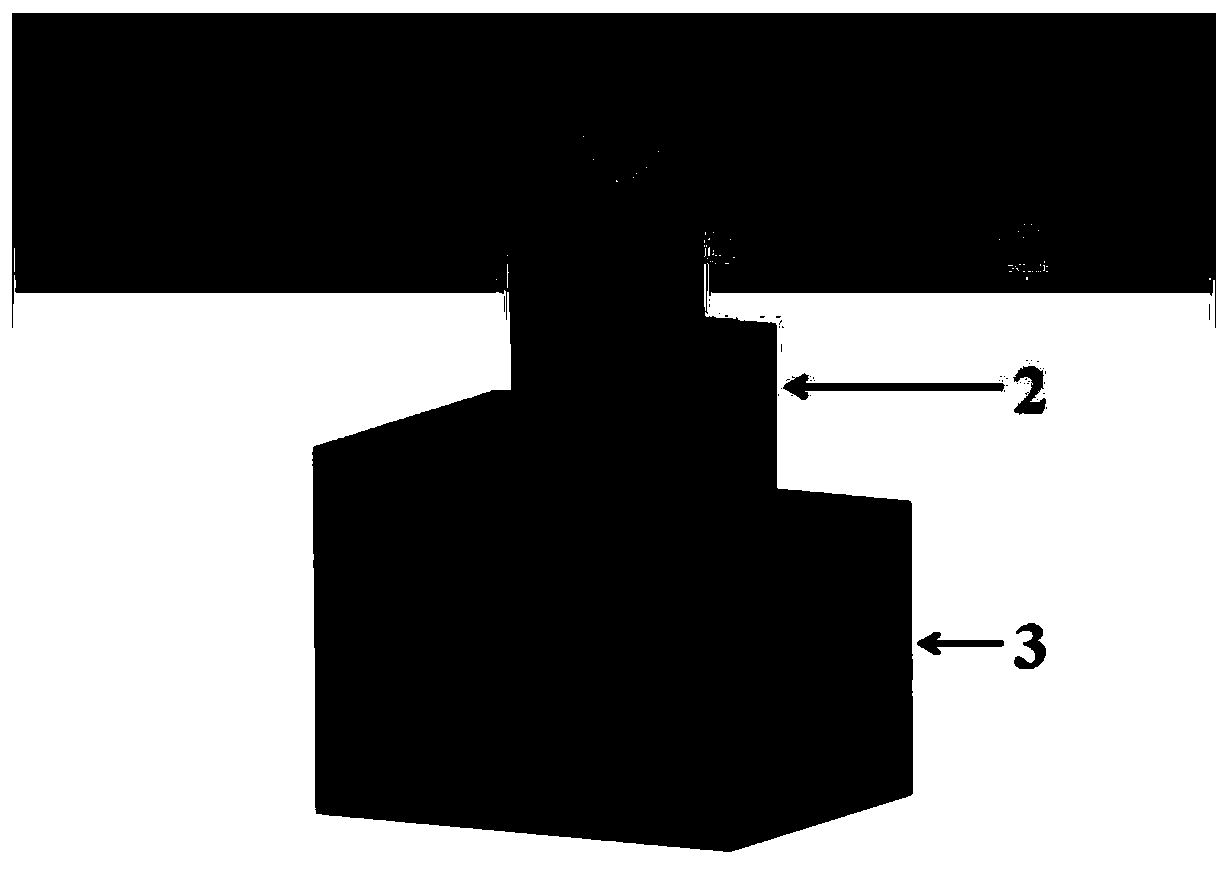

[0028] Embodiment 1. The medium and low temperature direct diffusion bonding process of oxygen-free copper and chromium zirconium copper includes the following steps:

[0029] Step 1) Pretreatment of oxygen-free copper block and chromium zirconium copper block:

[0030] The surface is polished. The surfaces to be connected of the oxygen-free copper block and the chromium-zirconium-copper block with dimensions of 10mm×10mm×5mm and 22mm×12mm×5mm are respectively used 400#, 600#, 800#, 1000#, 1500# metallographic Sand paper smoothly. Among them, every time the sandpaper is changed, the grinding direction is rotated by 90° until the previous grinding marks disappear completely, and finally there are only grinding marks of 1500# sandpaper on the connecting surface;

[0031] polishing. The surface to be connected that has been polished with sandpaper is polished with a 0.5μm diamond polishing agent with high precision, and the surface to be connected is polished to a mirror surface with...

Embodiment 2

[0038] Example 2. Low-temperature direct diffusion bonding process of oxygen-free copper and chromium-zirconium copper. The steps are basically the same as those of Example 1, except that in step 3), the annealing time is changed from 3h to 2.5h.

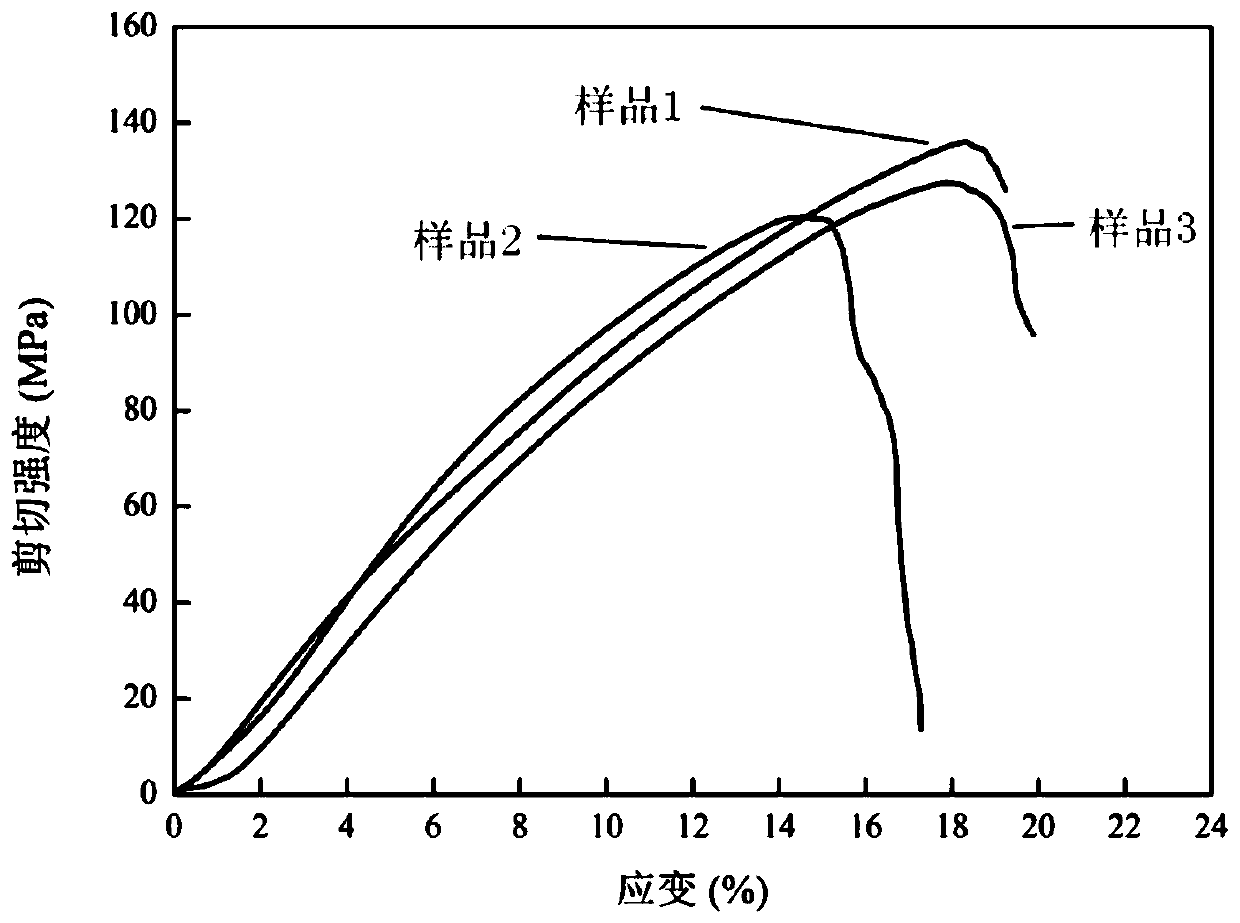

[0039] Figure 3(b) is a graph of the interlayer shear strength test curve of the oxygen-free copper / chromium-zirconium-copper bonded link of Example 2, and its average shear strength is 95MPa. Fig. 6(b) is a high-magnification scanning electron microscope (SEM) photograph of the morphology of the chromium-zirconium-copper side of the oxygen-free copper / chromium-zirconium-copper connector of Example 2. It can be seen from Figure 6(b) that the shear fracture of the oxygen-free copper / chromium-zirconium-copper connector shows ductile fracture, but compared to Example 1, the dimples become larger and shallower, and the number of dimples is also reduced.

Embodiment 3

[0040] Embodiment 3, the low-temperature direct diffusion bonding process of oxygen-free copper and chromium-zirconium copper, the steps are basically the same as those of embodiment 1, except that in step 3), the annealing time is changed from 3h to 3.5h.

[0041] Figure 4 (c) is a test graph of the interlayer shear strength of the oxygen-free copper / chromium-zirconium-copper connector of Example 2, and its average shear strength is 104 MPa. Fig. 6(c) is a high-magnification scanning electron microscope (SEM) photograph of the morphology of the chromium-zirconium-copper side of the oxygen-free copper / chromium-zirconium-copper connection shear fracture of Example 2. It can be seen from Fig. 6(c) that the shear fracture of the oxygen-free copper / chromium-zirconium-copper connector is ductile fracture, and the dimple size is relatively small, but compared to Example 1, the dimple becomes shallow.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Average shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com