Silicon carbide joint and its metal penetration connection method

A technology of metal infiltration and connection method, which is applied in the field of ceramic material connection, can solve the problems of lower connection strength, use of solder under low temperature conditions, and accelerate the decomposition of the MAX phase of the intermediate layer, so as to achieve lower requirements, lower preparation conditions, and high-strength connection gas. tightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053]Metal Ti foil (thickness 10 μm, purity 99.99%) and Si powder (particle size 1 μm, purity 99.999%) are used as the raw materials of the connecting material; after the metal Ti foil is polished with sandpaper, the Si powder is smeared on both sides of the metal Ti foil. On the other hand, the molar ratio of metal Ti foil and Si powder is 2:3; the above metal Ti foil and Si powder are placed between silicon carbide to form a sandwich structure. In a graphite crucible, the above sandwich structure is placed around the iron, cobalt, and nickel blocks, and then the graphite crucible is placed in a sintering furnace for sintering connection. During sintering, the temperature was raised to 1500° C. at 20° C. / min, and the temperature was maintained for 1 h. The sintering atmosphere was vacuum, and a silicon carbide joint was obtained after sintering.

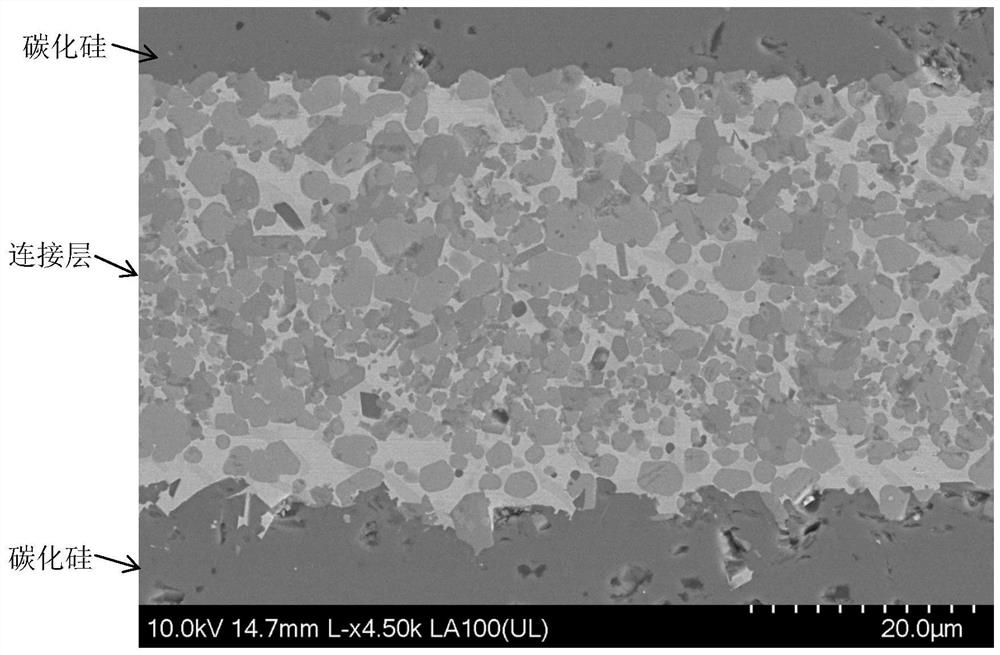

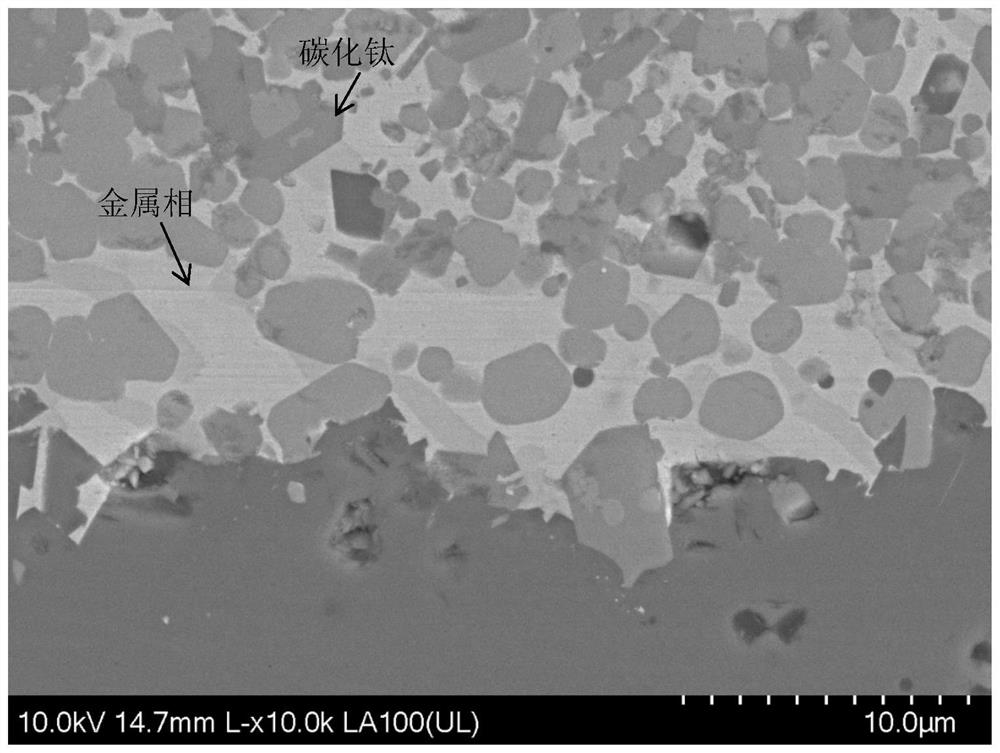

[0054] The SEM image of the silicon carbide joint obtained above is as follows figure 1 shown. from figure 1 It can be seen th...

Embodiment 2

[0057] Metal Mo (thickness 20 μm, purity 99.99%) and Si powder (particle size 5 μm, purity 99.999%) were used as the raw materials of the connecting material; the connection of silicon carbide was realized according to the method of Example 1, wherein during sintering, the sintering temperature was 1600 ℃, holding the temperature for 2h, and the sintering atmosphere is argon, to obtain a silicon carbide joint with a dense connection layer.

[0058] For the silicon carbide joint prepared above, the thickness of the connecting layer is 60 μm. In the shear strength test, the shear strength at room temperature is 120MPa, and the shear strength at a high temperature of 1200°C is 150MPa. Silicon carbide joints have a leak rate of 1×10 -9 Pa·L / s.

Embodiment 3

[0060] Metal Ta (thickness 20 μm, purity 99.99%) and Al powder (particle size 20 μm, purity 99.999%) were used as the raw materials of the connection material; the connection of silicon carbide was realized according to the method of Example 1, wherein during sintering, the sintering temperature was 1700 ℃, holding the temperature for 2h, and the sintering atmosphere is argon, to obtain a silicon carbide joint with a dense connection layer.

[0061] For the silicon carbide joint prepared above, the thickness of the connecting layer is 50 μm. In the shear strength test, the shear strength at room temperature is 150MPa, and the shear strength at a high temperature of 1200°C is 200MPa. Silicon carbide joints have a leak rate of 1×10 -8 Pa·L / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com