A kind of mn-cu based welding wire and its preparation method and application

A technology of mn-cu and welding wire, applied in welding equipment, manufacturing tools, welding media, etc., can solve problems such as welding difficulties between Mn-Cu alloy and steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

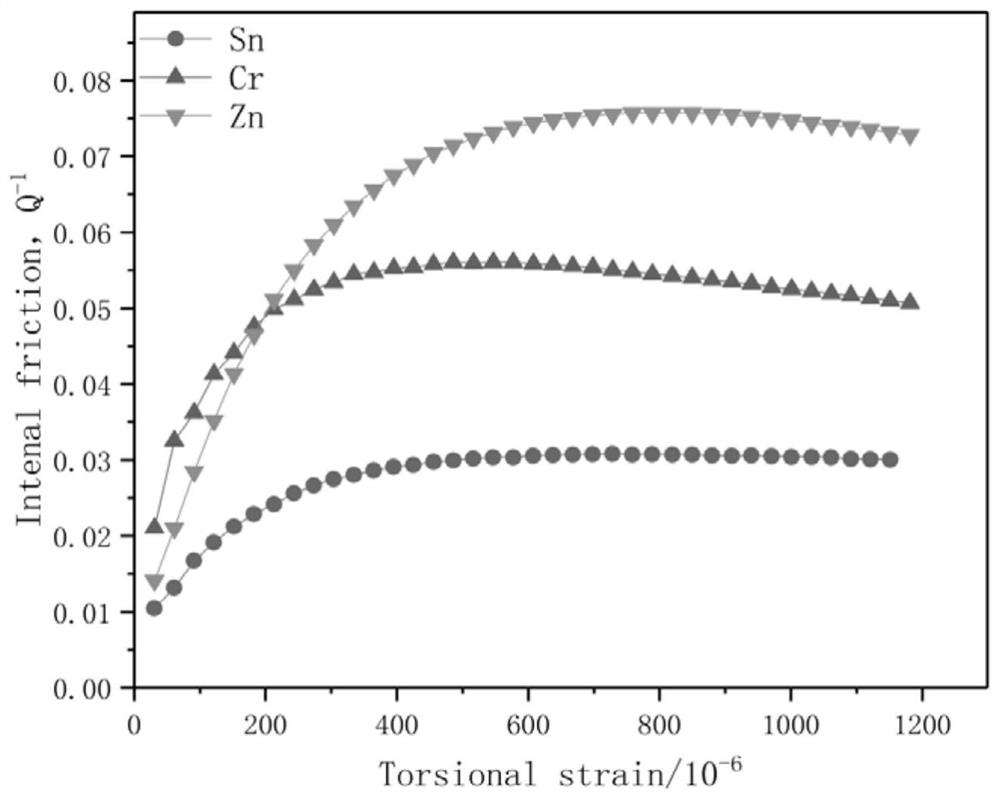

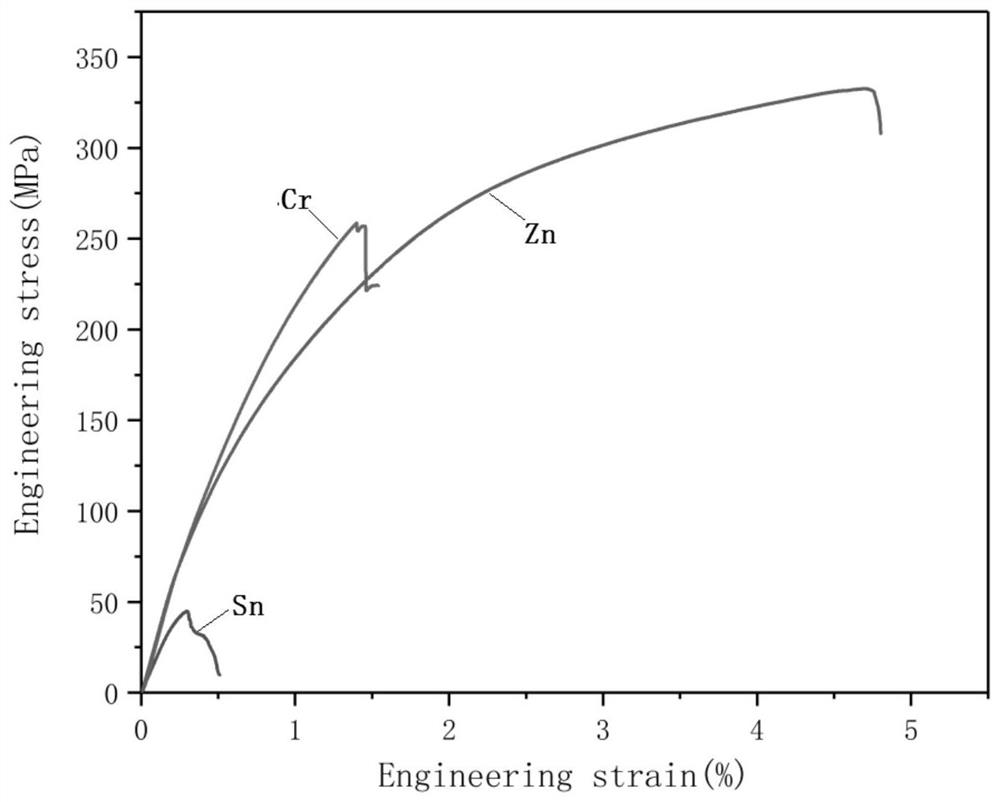

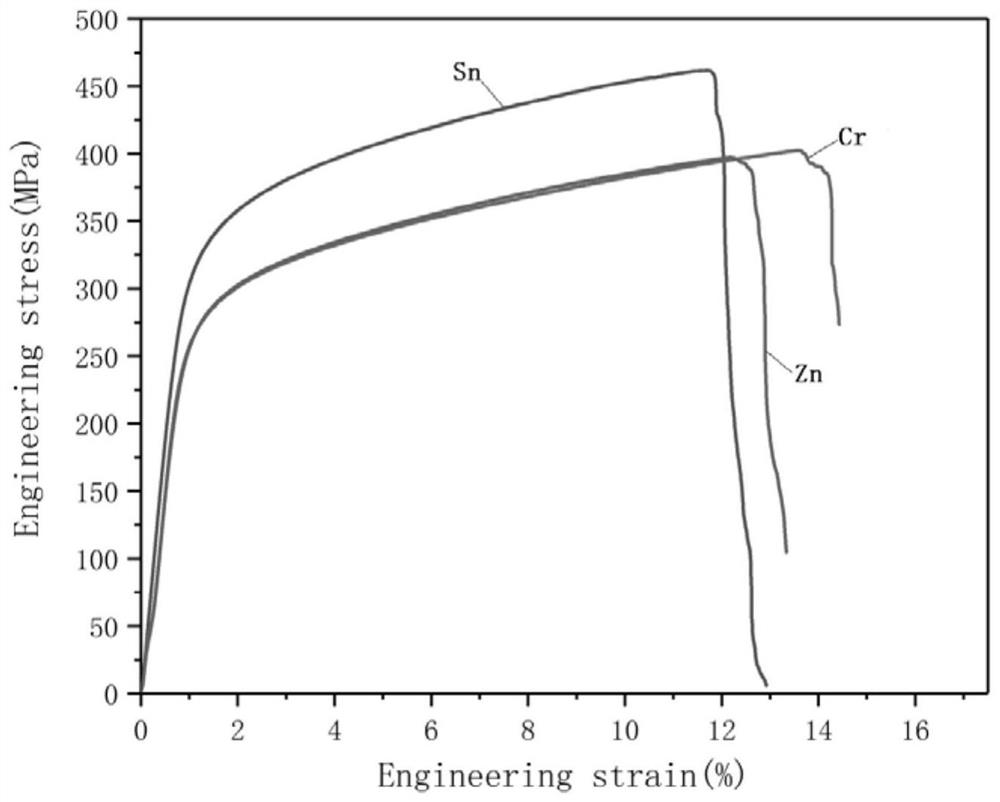

[0031] A Mn-Cu based welding wire, comprising the following components in mass percentage:

[0032] Copper 43%, Manganese 54.5%, Aluminum 1.5%, Tin 1%.

[0033] The welding wire in the present embodiment is made through the following steps:

[0034] S1: Put the welding wire raw materials (volatility: copper<manganese<aluminum<tin) into the smelting furnace in the order of decreasing volatility of the raw materials, and add the slag remover while discharging the material. The mass ratio of welding wire raw materials is 1:30, the slag remover used includes calcium fluoride, sodium chloride, boric acid and borax, and the mass ratio of calcium fluoride, sodium chloride, boric acid and borax is 1:1:1:1 ; After discharging, raise the temperature of the smelting furnace to about 1350°C, and carry out preliminary smelting of the raw materials in the furnace until the raw materials are completely melted; then lower the temperature to about 1000°C, and carry out refining. Good to prom...

Embodiment 2

[0038] A Mn-Cu based welding wire, comprising the following components in mass percentage:

[0039] Copper 41%, Manganese 54.5%, Aluminum 1.5%, Tin 1%, Zinc 2%.

[0040] The welding wire in the present embodiment is made through the following steps:

[0041] S1: Put the welding wire raw materials (volatility: copper<manganese<aluminum<zinc<tin) into the smelting furnace in the order of decreasing volatility of the raw materials, and add the slag remover at the same time as the material is discharged. The mass ratio of flux to welding wire raw material is 1:25, the slag removal agent used includes calcium fluoride, sodium chloride, boric acid and borax, and the mass ratio of calcium fluoride, sodium chloride, boric acid and borax is 1:3:1 : 3; after discharging, raise the temperature of the smelting furnace to about 1400°C, and carry out initial smelting of the raw materials in the furnace until the raw materials are completely melted; then cool down to about 1000°C, and carry...

Embodiment 3

[0045] A Mn-Cu based welding wire, comprising the following components in mass percentage:

[0046] 42.5% copper, 54.5% manganese, 1.5% aluminum, 1% tin, 0.5% chromium.

[0047] The welding wire in the present embodiment is made through the following steps:

[0048]S1: Put the welding wire raw materials (volatility: copper < chromium < manganese < aluminum < tin) into the smelting furnace in the order of decreasing volatility of the raw materials, and add the slag remover while discharging the material, and the slag removed The mass ratio of flux to welding wire raw material is 1:28, the slag removal agent used includes calcium fluoride, sodium chloride, boric acid and borax, and the mass ratio of calcium fluoride, sodium chloride, boric acid and borax is 3:1:3 : 1; After discharging, raise the temperature of the smelting furnace to about 1300°C, and carry out initial smelting of the raw materials in the furnace until the raw materials are completely melted; then lower the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com