Gear component

A technology of gears and components, applied to components with teeth, belts/chains/gears, engine components, etc., can solve the problems of inconvenient gear installation, complex structure and large volume of induction parts, and achieve convenient disassembly and simple structure , Guarantee the effect of sensing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

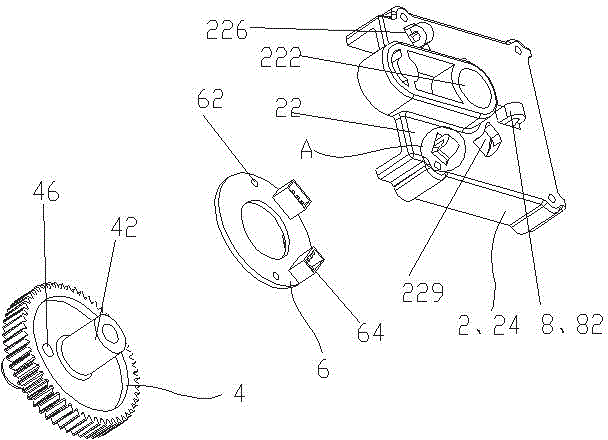

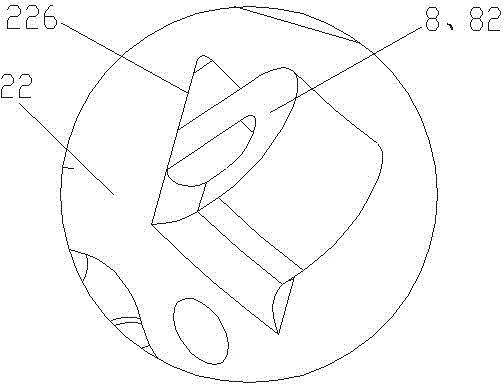

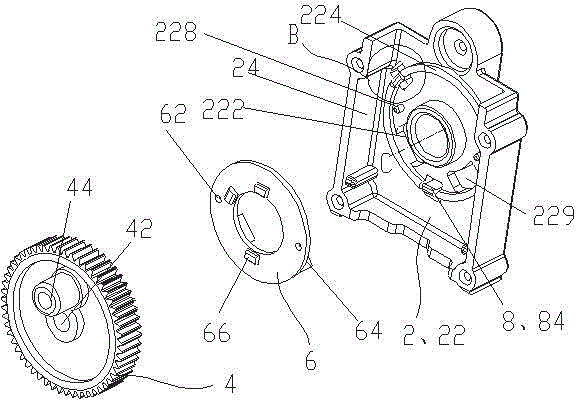

[0023] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0024] Such as Figure 1-4 As shown, the gear assembly includes a gear seat 2 and a rotatable gear 4 arranged on the gear seat 2. There is also an annular circuit board fixed on the gear seat 2 and sensing the rotation angle of the gear 4 between the gear 4 and the gear seat 2. 6. The gear 4 is provided with a magnet 46 , and the annular circuit board 6 is provided with a plurality of Hall elements 66 for sensing the magnet 46 .

[0025] The gear seat 2 includes a plate-shaped base 22 and a side wall 24 vertically arranged on the edge of the base 22 . Wherein the middle part of base 22 is provided with the shaft hole 222 that gear 4 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com