Full automatic unpacking unloader

A package and unloading machine, fully automatic technology, applied in the field of fully automatic unpacking and unloading machines, to achieve the effects of light weight, less pollution and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

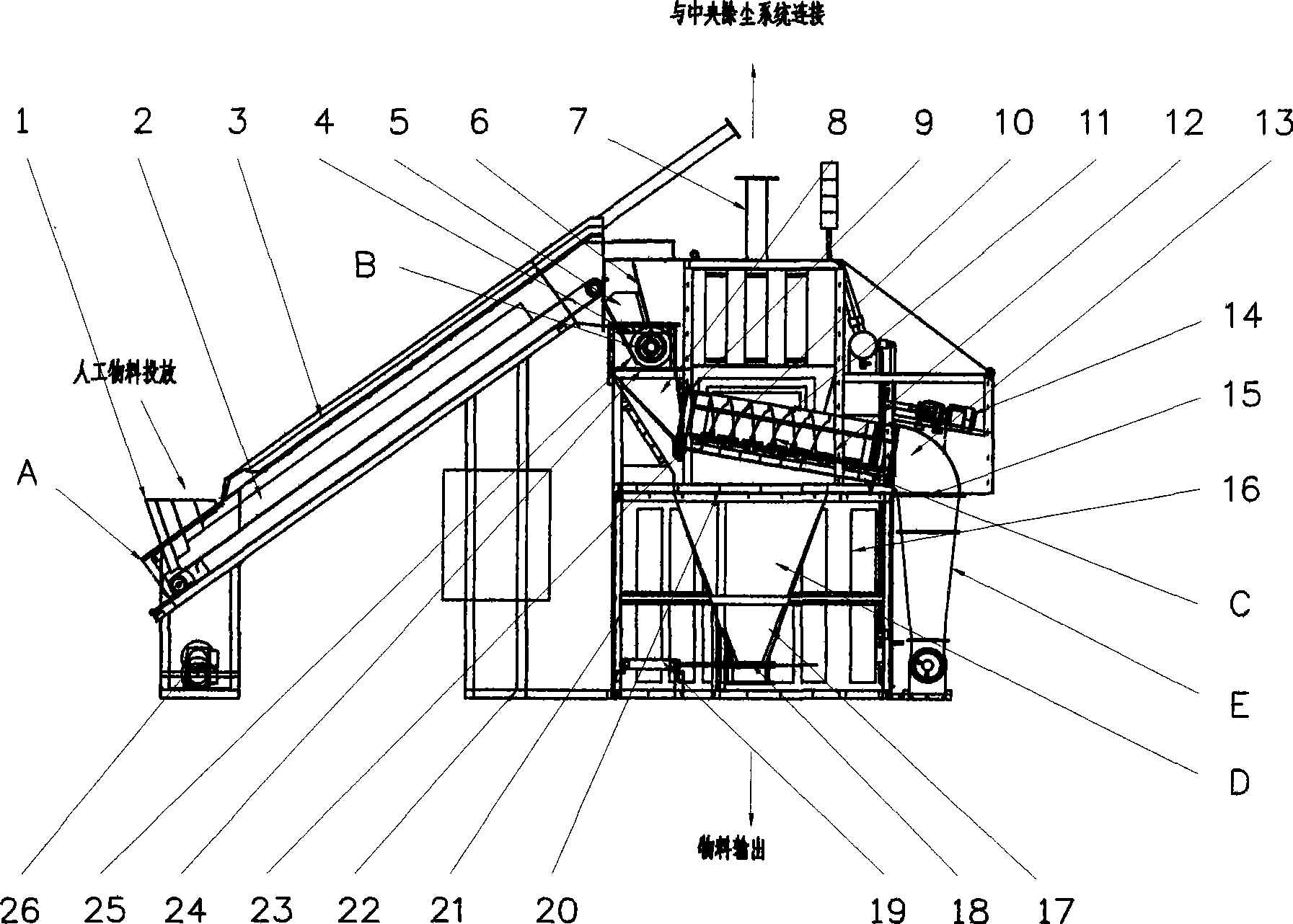

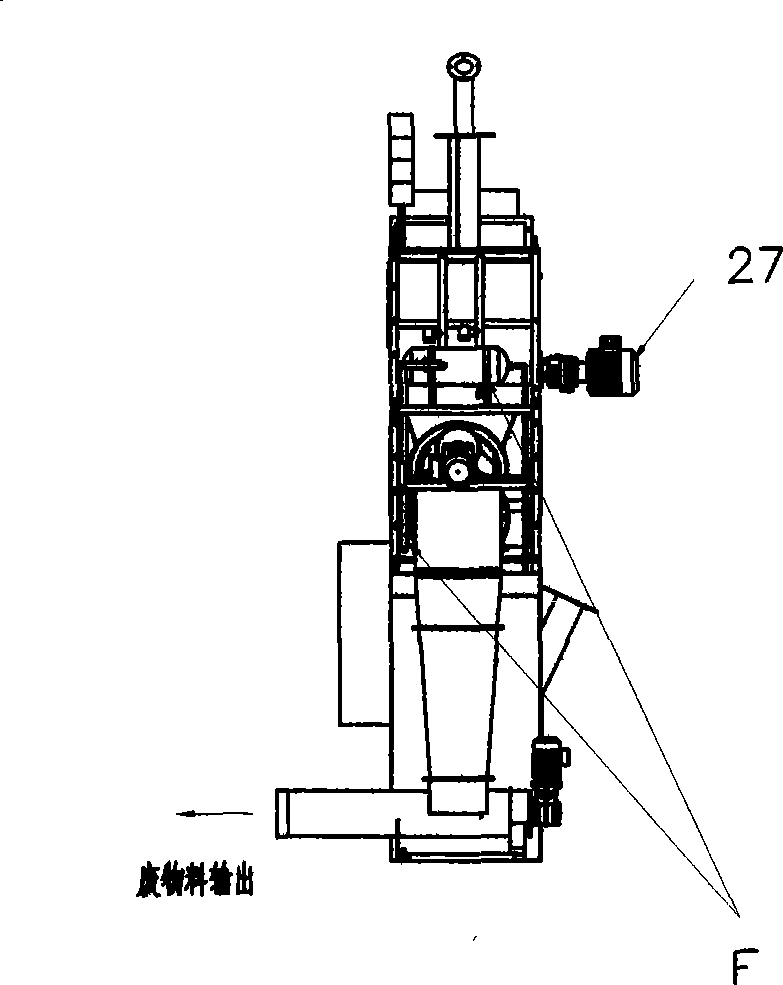

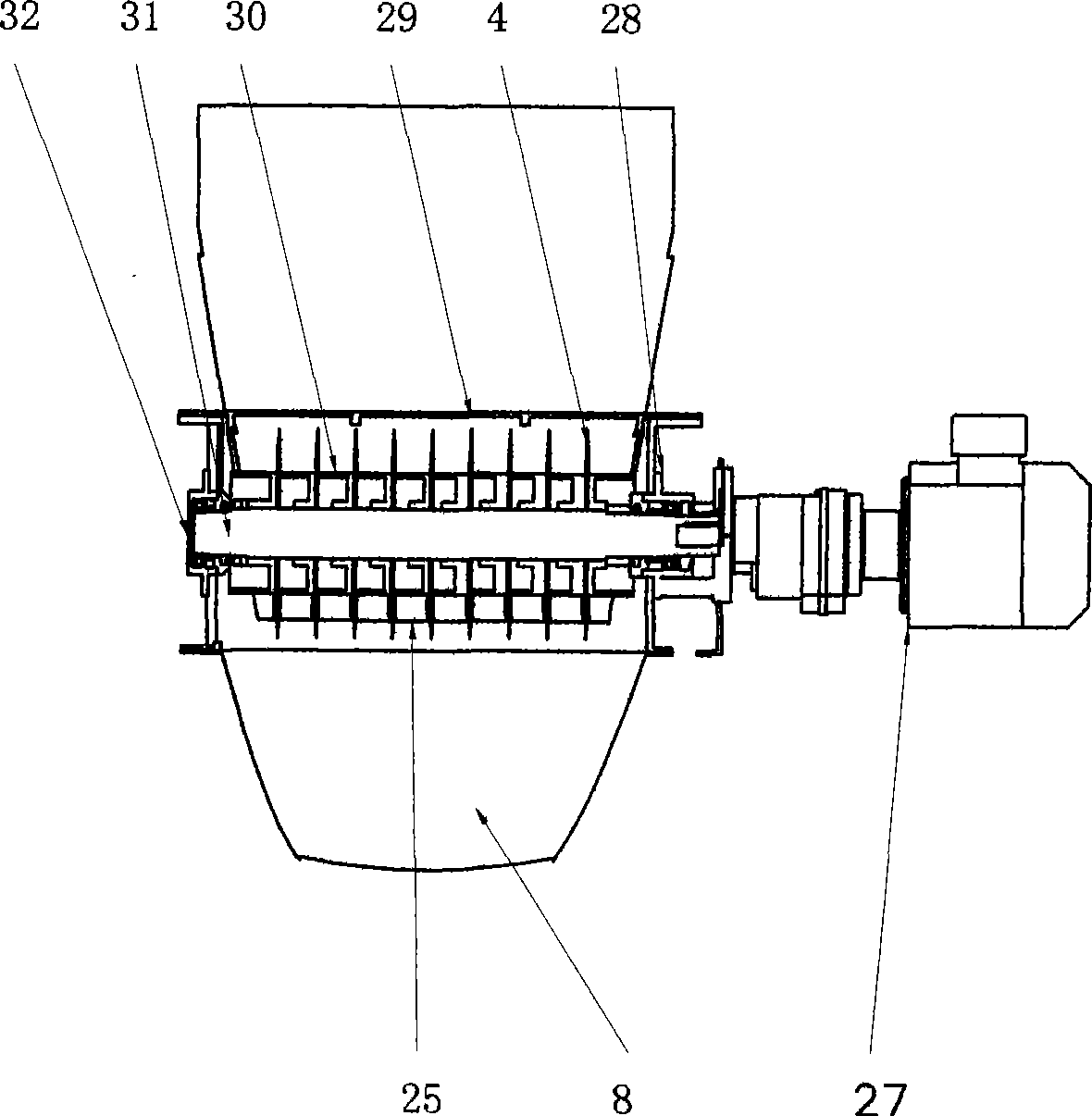

[0027] Such as figure 1 , figure 2 As shown, the present invention realizes the fully automatic unpacking and unloading machine that removes packaging (50 kg, 40 kg, 10 kg, 5 kg and below packaging bags), separation, collection, and delivery functions between packaging and materials. Its main structure includes: multi-feeding feeding mechanism A, multi-knife bag breaking mechanism B, screening mechanism C, material output mechanism D, waste bag output mechanism E, automatic screening and blowing cleaning system F and integrated electrical control The system consists of seven parts, among which, the feeding mechanism with multiple feeding ports is an independent unit of belt conveyor, and the feeding mechanism with multiple feeding ports uses a double-speed variable frequency motor. Through the electrical integration system and the silo material level controller, the different conveying speeds of the feeding mechanism with multiple feeding ports can be realized when the silo ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com