Downhole Tool having Slips Set by Stacked Rings

a technology of stacked rings and tools, applied in the field of downhole tools, can solve the problems of limited contact area between slips and cones, failure to achieve successful attempts, and collapse of cones of element systems, etc., and achieve the effect of decreasing spacing and decreasing spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

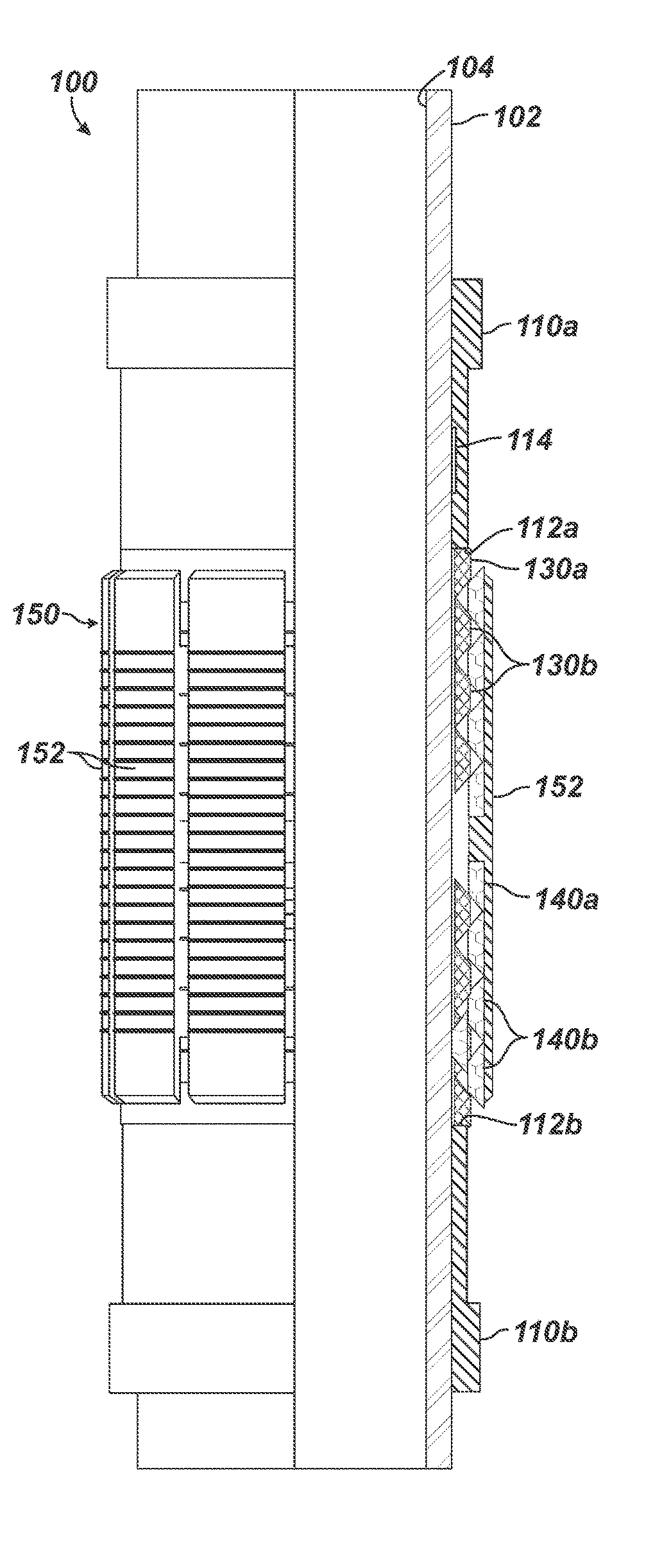

[0059]FIGS. 3A-3B illustrate a downhole tool 100 according to the present disclosure in partial cross-section in a run-in condition. The downhole tool 100 can be configured as a bridge plug, a frac plug, a packer, or any other desired downhole packer tool. In a particular example, the downhole tool 100 can be a permanent sump packer used as a base for a cased-hole gravel pack completion.

[0060]The downhole tool 100 has a mandrel 102, first and second opposing shoulders 112a-b, a plurality of stacked rings 130a-b and 140a-b, and a slip 150. The first and second opposing shoulders 112a-b are disposed on the mandrel 110, and at least one of the opposing shoulders (e.g., the first shoulder 112a) is movable toward the second opposing shoulder 112b. These opposing shoulders 112a-b can be part of sleeves 110a-b disposed on the mandrel 102. In this context, the first sleeve 110a can be a drive sleeve movable along the mandrel 102 toward the second, fixed sleeve 110b. (FIG. 6 shows an isolate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com