Parallel separating and cooling recovery device for processing drug and food powder

A technology for separating cooling and recovery devices, which is applied in combination devices, water supply devices, separation methods, etc., and can solve problems such as inability to apply instant high-temperature sterilization of traditional Chinese medicine powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

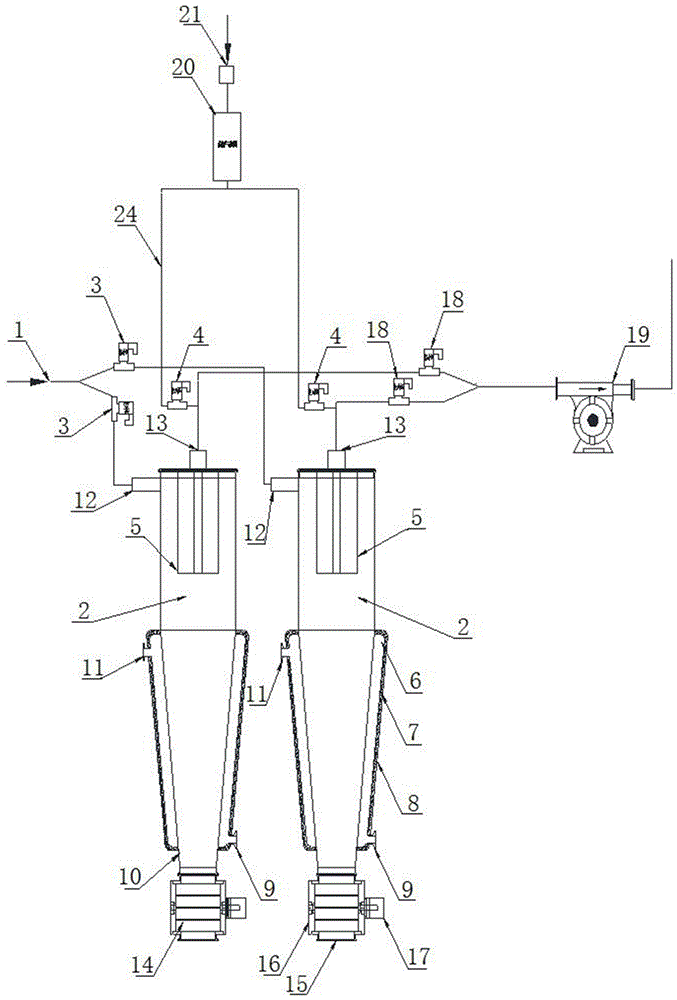

[0016] The accompanying drawings disclose the specific structures of the embodiments of the present invention without limitation, and the present invention will be further described below in conjunction with the accompanying drawings.

[0017] Depend on figure 1 It can be seen that the present invention includes two vertical powder separation and recovery towers 2 with the same structure, extending from the middle of the tower body to the lower part as a closed interlayer structure 6, the interlayer is a refrigerant passage, the refrigerant inlet 9 is located at the lower part of the interlayer, and the refrigerant outlet is located at the bottom of the interlayer. The upper part of the interlayer is provided with an insulating layer 7 outside the interlayer; the top of the tower body is provided with a feed port 12, and the center of the top is provided with an exhaust port 13, and the tower body corresponding to the exhaust port 13 is provided with a fine powder filter 5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com