Laundry detergent composition for inhibiting ash deposition

A composition and detergent technology, applied in the directions of detergent compositions, surface active detergent compositions, detergent compounding agents, etc., to achieve the effects of reducing ash deposition and inhibiting the formation of precipitation by hardness ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

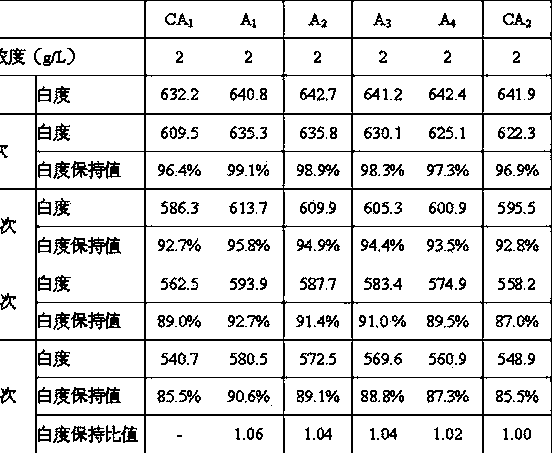

Examples

Embodiment 1

[0053] Detergent Composition A 1 1 kg: 80 grams of linear alkyl benzene sulfonate sodium, 20 grams of fatty alcohol sodium sulfate, 100 grams of fatty alcohol polyoxyethylene ether, 350 grams of sodium carbonate, 100 grams of sodium bicarbonate, 210 grams of sodium peroxycarbonate, hydroxyethyl alcohol 40 grams of disodium fork diphosphonate, 60 grams of sodium carboxymethyl cellulose, 20 grams of polyvinyl alcohol, 5 grams of alkaline protease, 5 grams of amylase, 5 grams of stilbene biphenyl whitening agent, 5 grams. [Microsoft user 3]

Embodiment 2

[0055] Detergent Composition A 2 1kg: 20g sodium α-alkenyl sulfonate, 20g sodium fatty alcohol polyoxyethylene ether sulfate, 100g fatty acid methyl ester ethoxylate, 500g potassium carbonate, 100g sodium bicarbonate, 210g sodium peroxycarbonate gram, 10 grams of tetrasodium amino trimethylene phosphonate, 5 grams of amylase, 30 grams of sodium polyacrylate, and 5 grams of bistriazine aminostilbene whitening agent.

Embodiment 3

[0057] Detergent Composition A 3 1kg: 20g sodium secondary alkyl sulfonate, 20g sodium fatty acid methyl ester sulfonate, 50g fatty alcohol polyoxyethylene ether, 60g alkyl polyglycoside, 350g sodium carbonate, 250g potassium bicarbonate, peroxygen Sodium carbonate 210 grams. Polyvinylpyrrolidone 10g, Polyethylene Glycol 10g, Pentasodium Diethylenetriamine Penta(Methylene Phosphonate) 10g, Tetrasodium 2-Phosphonate Butane-1,2,4-Tricarboxylate [Microsoft User 4] 10gram.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com