A kind of transition metal hypervalent oxide electrode and its preparation method and application

A technology of high-valent oxides and transition metals, applied in the field of electrochemistry, can solve problems such as electrode structure damage, achieve the effect of improving the overall energy density and avoiding the release of toxic gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

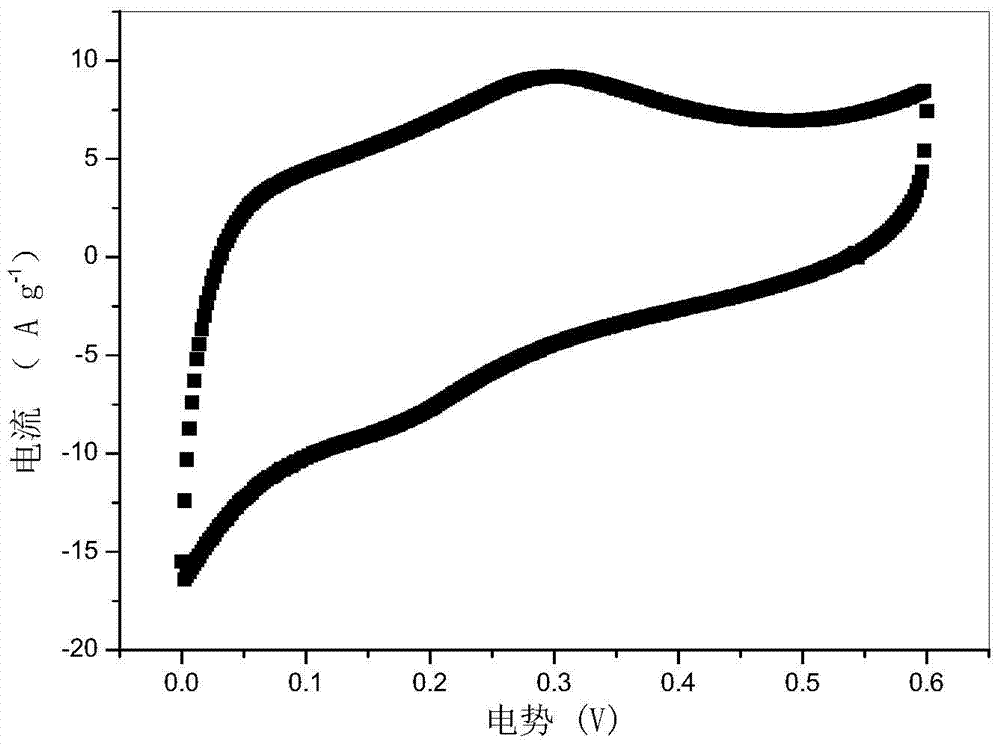

Embodiment 1

[0042] NiSO 4 ·6H 2 O and C 6 h 5 COONa is dissolved in water to prepare Ni 2+ 0.05mol / L, C 6 h 5 COO - 0.4mol / L mixed solution, adjust the pH value of the solution to 8 with sodium hydroxide and sulfuric acid; obtain the electrodeposition solution.

[0043] Cut the 304 stainless steel foil into an area of 4×1cm 2The stainless steel belt is used as a current collector, which is ultrasonically washed with acetone, rinsed with water and dried. A titanium mesh electrode coated with ruthenium oxide on the surface of 4 × 4 cm is used as the cathode, the above mixed solution is the electrodeposition solution, and the carbon cloth current collector after surface cleaning is used as the anode (the working area is 1 × 1 cm 2 ) for constant current electrodeposition with a current density of 1mA / cm 2 , and the electrodeposition time was 20 minutes to obtain an oxidized high-nickel deposition layer (with a thickness of 5 microns).

Embodiment 2

[0046] Operation process and other conditions are all consistent with embodiment 1; Different condition parameters are as follows:

[0047] Ni in electrodeposition solution 2+ The concentration is 1mol / L, the concentration of acetate is 0.6mol / L, the concentration of sodium benzoate is 0.4mol / L, and the pH value of the electrodeposition solution is 6;

[0048] The area is 4×1cm 2 Carbon paper is used as a current collector, and the current density of constant current electrodeposition is 10mA / cm 2 , the electrodeposition time was 8 minutes, and the measured specific capacitance of the electrode active material was 518.9 F / g.

Embodiment 3

[0050] Operation process and other conditions are all consistent with embodiment 1; Different condition parameters are as follows:

[0051] Just use cobalt sulfate instead of nickel sulfate, the concentration of divalent cobalt ions in the electrodeposition solution is 0.4mol / L, the concentration of acetate is 0.6mol / L, and the anode is within the potential range of 0.6V to 1.3V relative to the saturated calomel electrode The kinetic potential deposition was performed with a potential scanning speed of 10 mV / s. The measured specific capacitance of the electrode active material was 421.2 F / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com