System and method for feeding and conveying high-concentration solid powder particle suspension

A particle suspension and solid powder technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as malfunction, blocked pipelines, valve delivery pumps, hardening, etc., and achieve the effect of inhibiting the deposition of solid particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0061] The density of the high-concentration solid powder particle corresponding to the high-concentration solid powder particle suspension of the present invention is greater than that of the dispersed phase (liquid item).

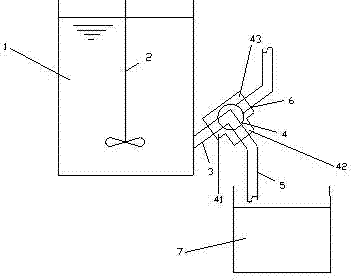

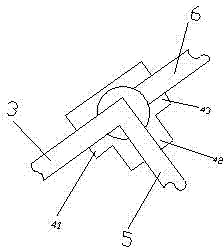

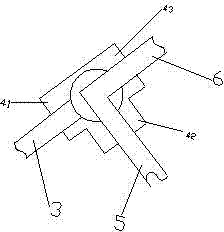

[0062] Such as figure 1 , the first system introduced in the present invention: a high-concentration solid powder particle suspension dosing and delivery system 100, including: a mixing device for forming a high-concentration solid powder particle suspension 1, need to add high-concentration solid Feeding device for powder particle suspension 7, mixing device agitator 2, inclined pipe for deriving high-concentration solid powder particle suspension from the mixing device, three-way valve 4, used for feeding to the required The device 7 introduces a water outlet channel 5 for high-concentration solid powder particle suspension, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com