Electromagnetic type fused salt evaporating method

An electromagnetic, molten salt technology, applied in the field of molten salt distillation, can solve problems such as affecting the cooling effect, and achieve the effect of stable cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

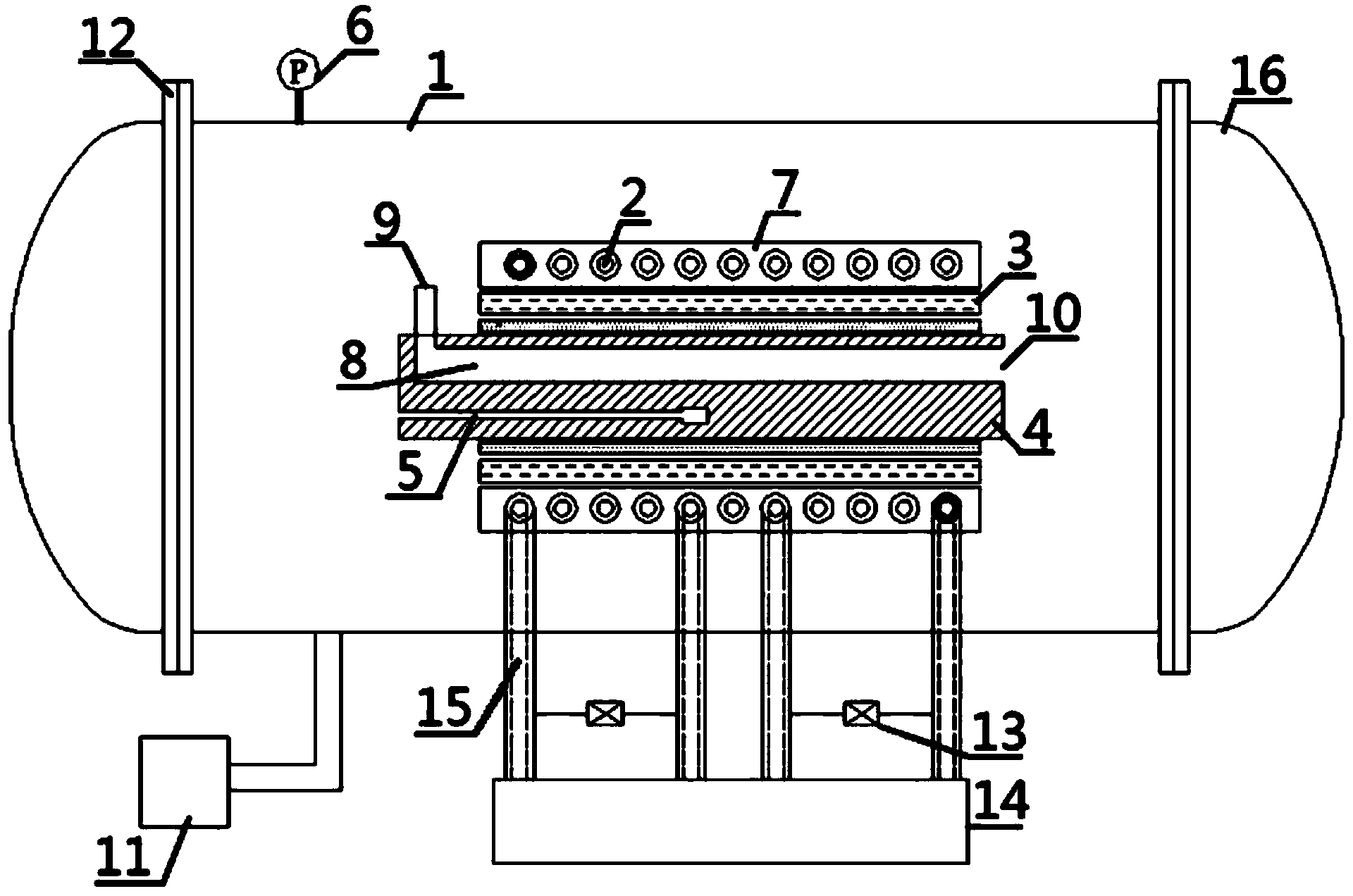

[0032] A preferred embodiment is given below to illustrate the present invention more clearly and completely in conjunction with the accompanying drawings.

[0033] The structure of the electromagnetic molten salt evaporator of this embodiment is as follows:

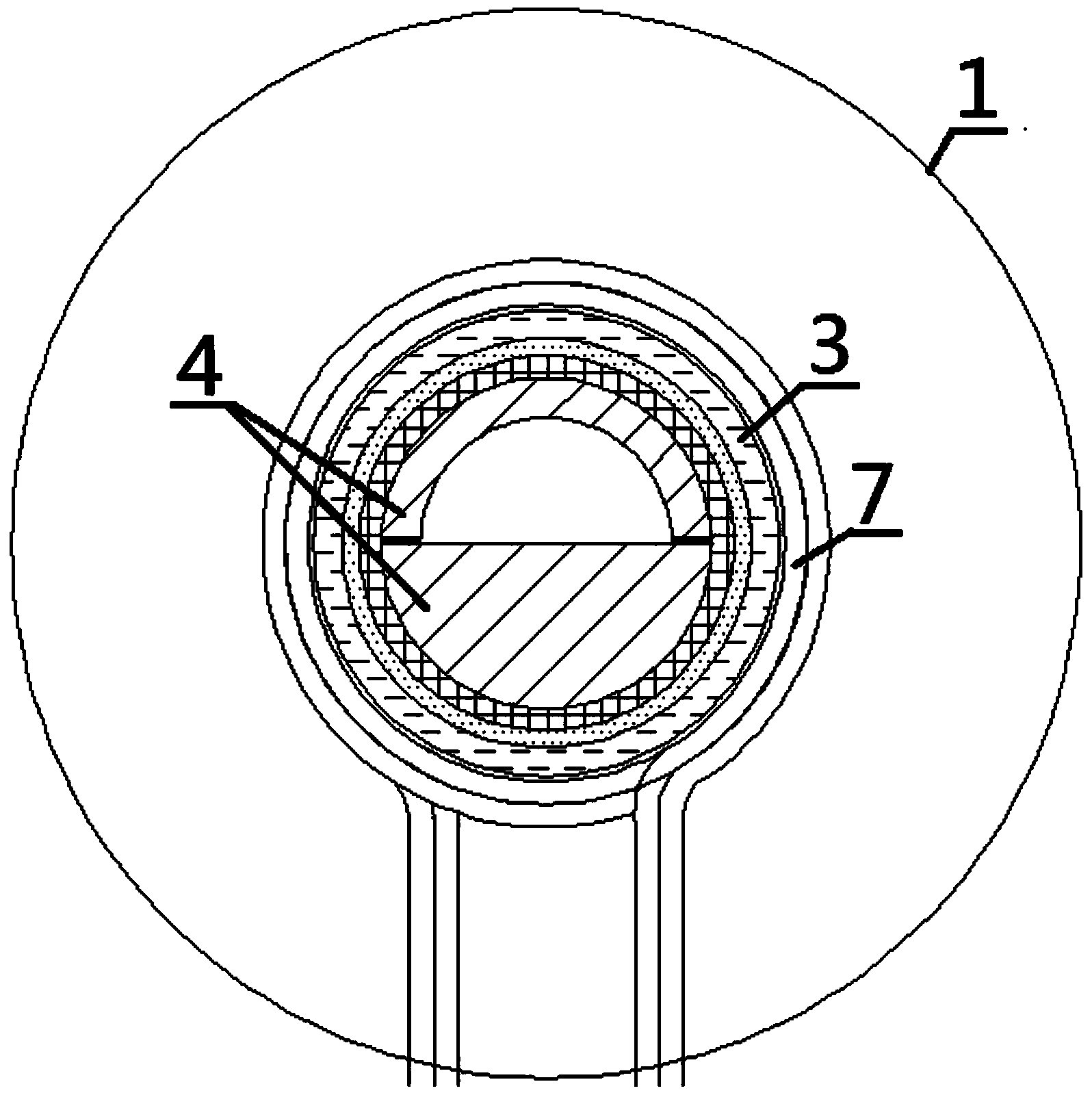

[0034] Please combine Figure 1-2 It should be understood that this embodiment provides an electromagnetic molten salt evaporator, which includes an evaporation cavity 1, two electromagnetic induction coils 2, a molten salt evaporator 4, and at least one protective bracket 7 made of ceramic material. The protective brackets 7 are sleeved outside the molten salt evaporating body 4. The molten salt evaporating body 4 has a molten salt evaporating tube 8 inside, and the electromagnetic induction coil 2 surrounds and is fixed on the protective brackets 7. The electromagnetic induction coil 2 is a metal hollow tube, and a gas flow channel 15 is formed inside the metal hollow tube. The electromagnetic molten salt evaporator also i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com