Blade rest of slicing machine

A slicer and knife holder technology, which is applied in metal processing and other directions, can solve the problems that the knife holder has no protective structure, the blade is prone to accidents, finger scratches, etc., and achieves the effects of less accidents, easy removal, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

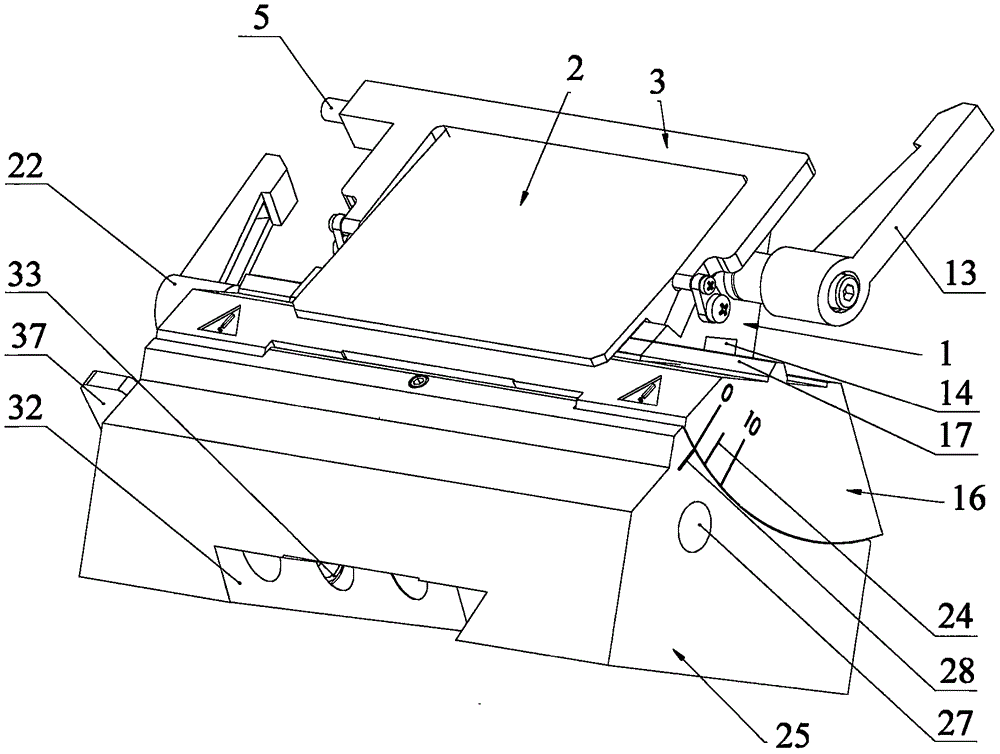

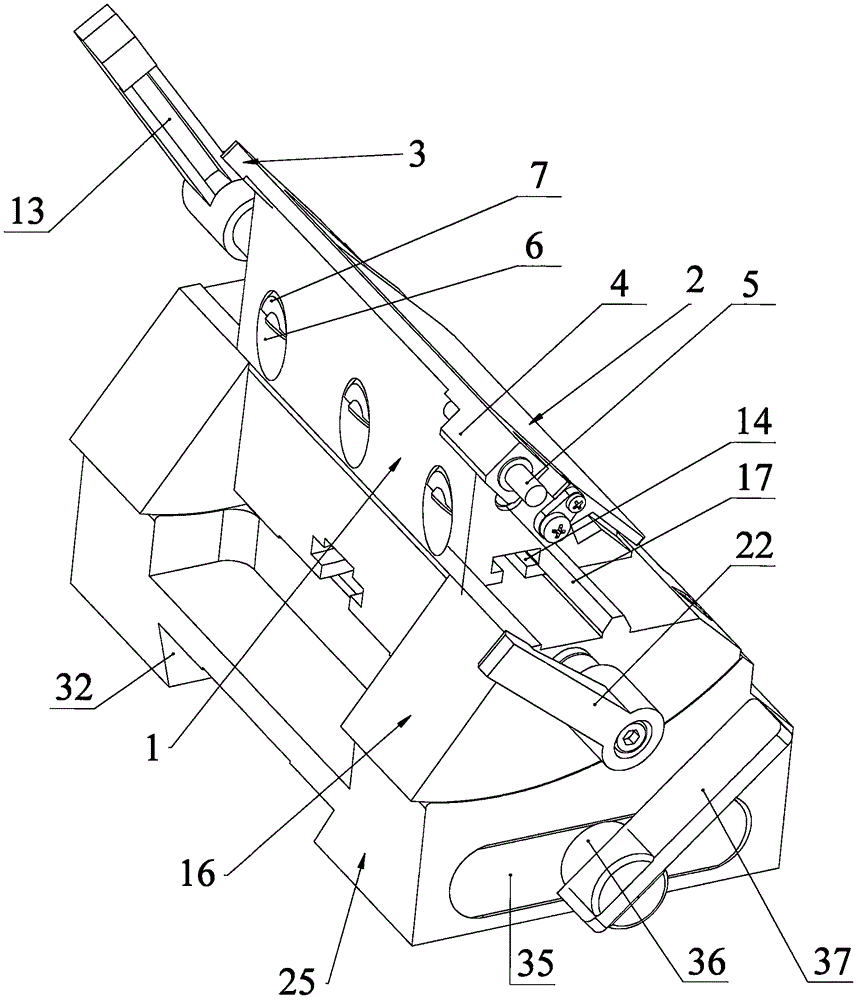

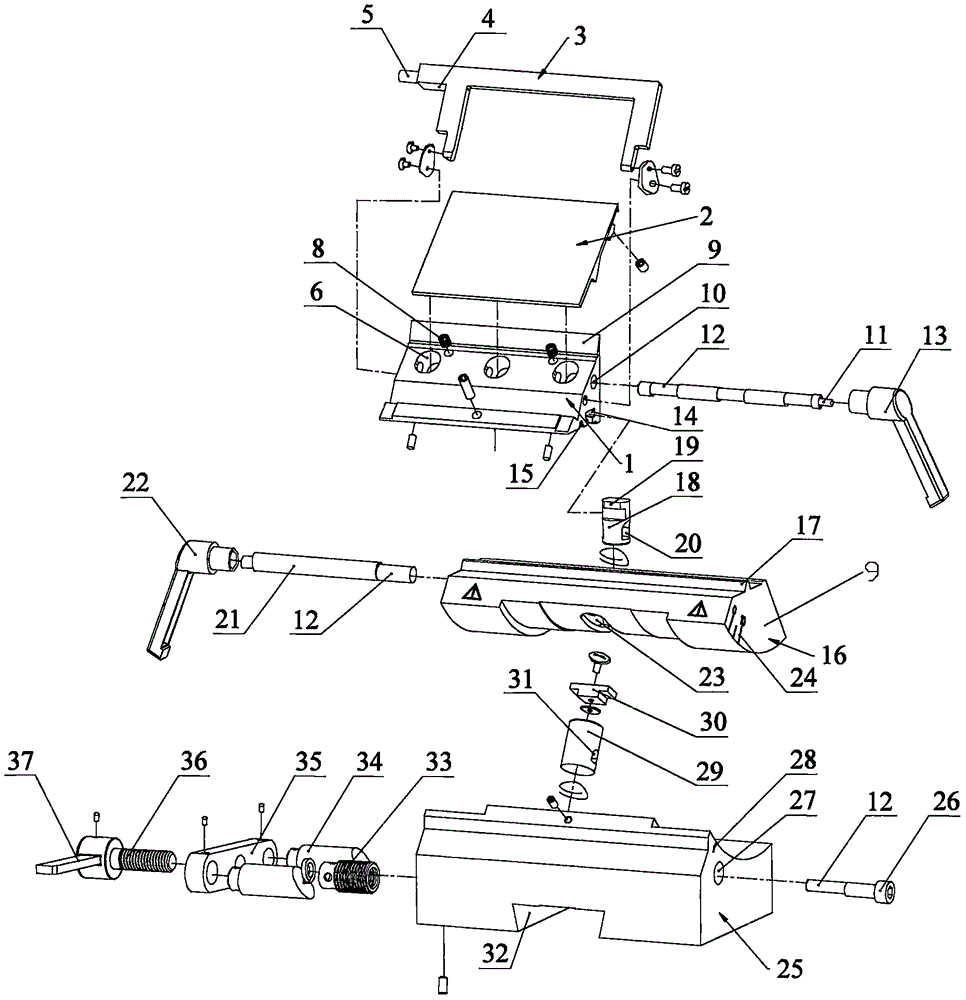

[0056] Below in conjunction with each accompanying drawing, the present invention is described in detail.

[0057] Such as figure 1 , 2 As shown in and 3, a knife holder of a slicer includes a mounting base 1 and a clip 2 that cooperates with the mounting base to clamp the blade, and also includes:

[0058]The turret 3 is rotatably mounted on the mounting base 1. The turret 1 has a first working position that is turned up to cover the blade, and a second working position that is turned down;

[0059] The unloading tool 5 is slidably arranged on the free end of the turret 3, and is used to cooperate with the blade when the turret is in the first working position, and push the blade out of the mounting seat;

[0060] The elastic piece is used to reset the knife unloading piece 5 .

[0061] Such as image 3 As shown, in this embodiment, the mounting seat 1 has a blade mounting surface 9, and the clip 2 cooperates with the blade mounting surface 9 for clamping the blade; and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com