Double-effect perforating bullet containing active material layer, and active material

An active material layer and active material technology, applied in the fields of production fluids, wellbore/well components, earthwork drilling, etc., can solve the problems of secondary compaction damage of perforation, affecting gas production channels, etc. Good effect and easy to prepare effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

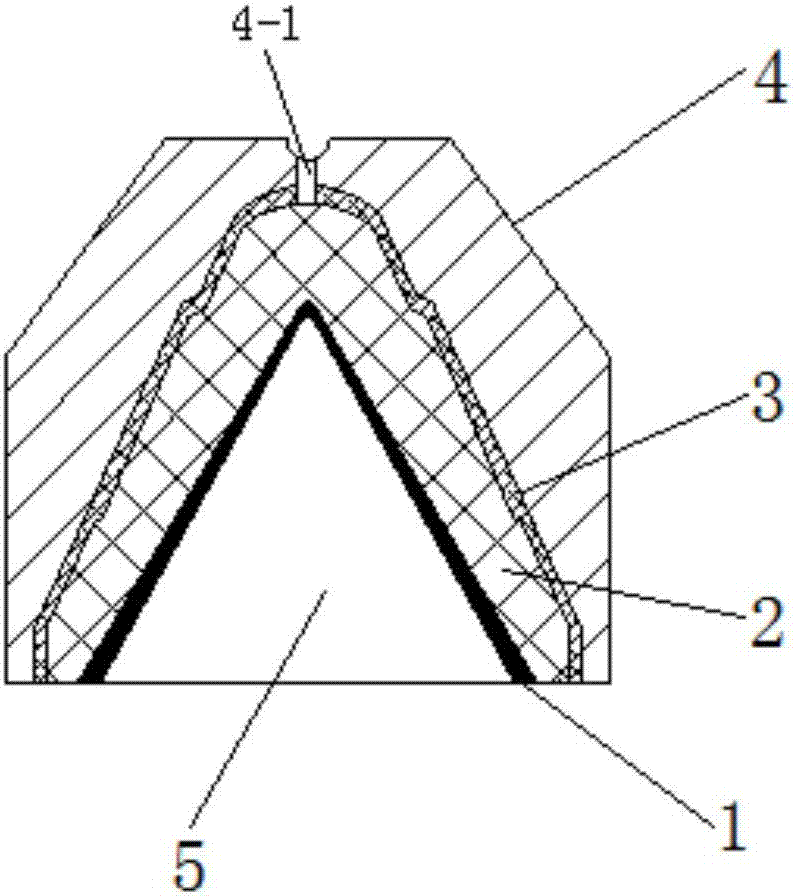

[0042] combine figure 1 , the structure of the double-effect perforating charge containing active materials in this embodiment includes: a liner cover 1, a high explosive layer 2 and a shell case 4 that are sheathed in sequence from the inside to the outside, and are arranged between the high explosive layer 2 and the shell case 4 The active material layer 3 that can completely cover the high-energy explosive layer has a thickness of 0.8 mm; the liner cover 1 is a conical cover body, and the space formed by the liner cover 1 is the hollow area 5 of the perforating charge. The volume of the hole bomb hollow area 5 is 32.6cm 3 Cartridge case 4 is the shell that the inner wall is a conical shape, and the outer wall of the cartridge case 4 is cylindrical near the large opening end of the inner wall class conical shape, and the outer wall of the cartridge case 4 is trapezoidal near the small opening end of the inner wall class conical shape, and the trapezoidal end is an ignition ...

Embodiment 2

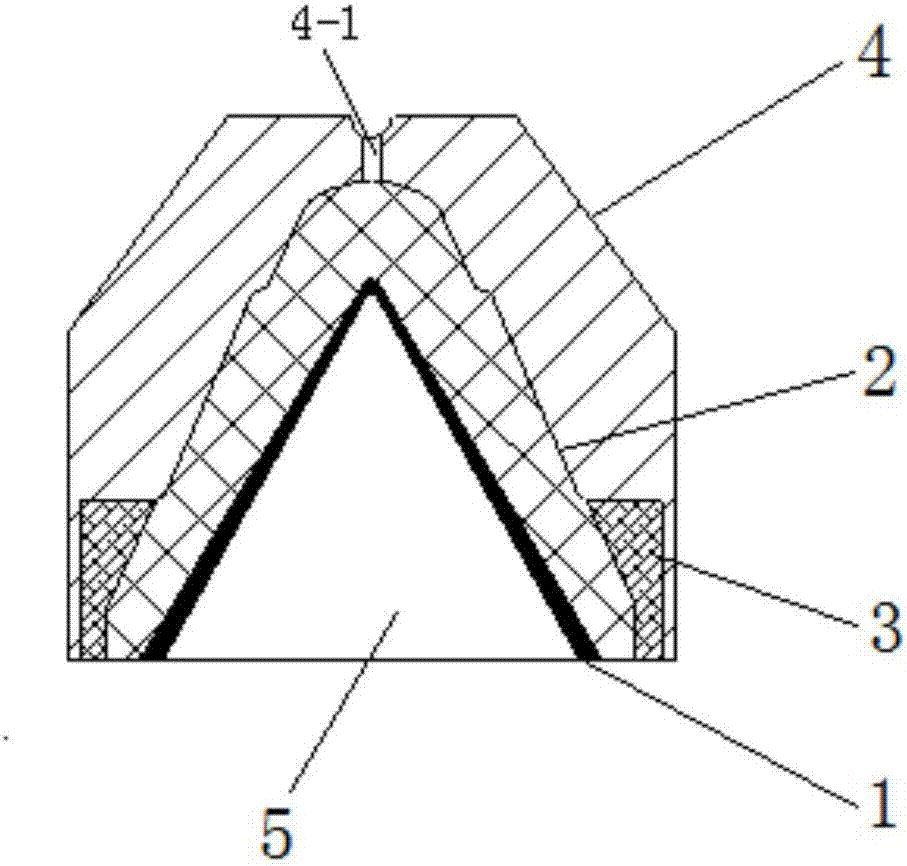

[0050] The difference between this embodiment and embodiment 1 is that the active material layer 3 is according to figure 2 The front type double-effect perforating charge shown is pressed, and the active material layer 3 partially covers the end of the high-energy explosive layer 2 away from the ignition end. The thickness of the active material layer 3 is 7.3 mm, and the height of the active material layer 3 is 8 mm. .

[0051] Others are the same as embodiment 1.

[0052] The perforation depth can be increased by 4.5%, the hole diameter can be increased by 3.7%, and the fracture-making and plugging-removing force can be enhanced by using the double-effect perforating bullet containing the active material described in Example 2.

Embodiment 3

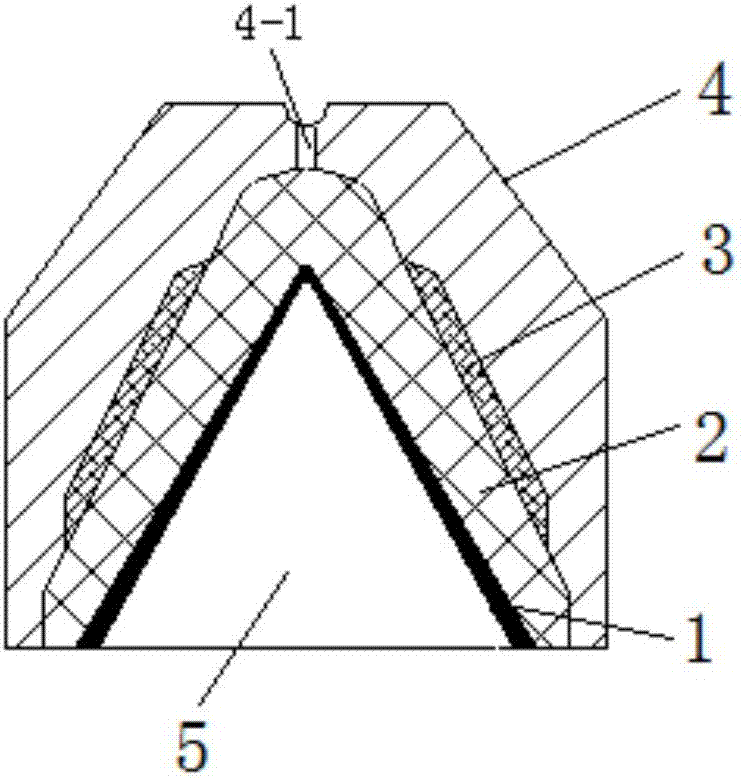

[0054] The difference between this embodiment and embodiment 1 is that the active material layer 3 is according to image 3 The slotted double-effect perforating charge shown is pressed. The active material layer 3 partly covers between the ignition end and the jet end of the high-energy explosive layer 2. The thickness of the active material layer 3 is 3.6mm, and the height of the active material layer 3 is is 25mm.

[0055] Others are the same as embodiment 1.

[0056] The perforation depth can be increased by 4.2%, the hole diameter can be increased by 4.0% after the double-effect perforating bullet containing the active material described in Example 3 is used, and the fracture-making and plugging-removing capabilities are enhanced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com