Automatic locking safety pin

An automatic locking and safety pin technology, applied to quick-action fasteners, bolts, etc., can solve the problems of being difficult to replace, easily causing accidents, time-consuming and labor-intensive, etc., and achieve the effect of easy replacement, less accidents, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] The description in the following text takes the pin in the vertical position as an example, and the position in actual use can be deduced by analogy.

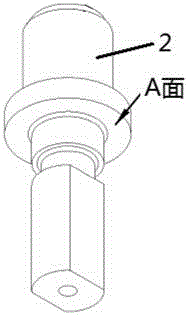

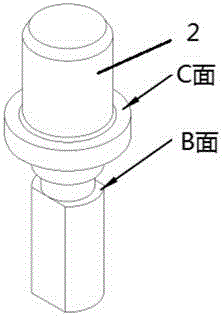

[0018] refer to figure 1 , figure 2 , the structure of the safety pin main body 2 of the present invention is that the main body of the safety pin main body 2 is a multi-layer stepped pin, which is successively a cylinder, a convex cylinder, a thin cylinder, a thin neck, and a beveled cylinder from top to bottom, wherein the convex cylinder The lower end surface (A surface) of the body is the spring matching surface, the upper end surface (C surface) of the convex cylinder is the locking position positioning surface, and the upper end surface (B surface) of the beveled cylinder is the loosening position positioning surface.

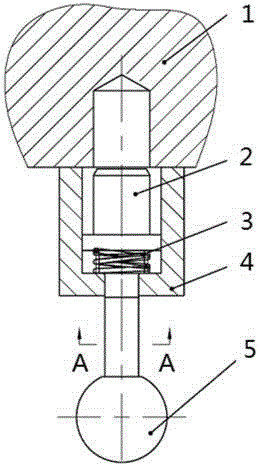

[0019] refer to image 3 The overall structure of the aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com