W-Ta-Mo-Nb-Zr high-temperature high-entropy alloy and preparation method thereof

A w-ta-mo-nb-zr, high-entropy alloy technology, applied in the field of W-Ta-Mo-Nb-Zr high-temperature high-entropy alloy and its preparation, can solve the shortage of high-temperature high-entropy alloy system, and the strength needs to be further improved Improvement, room temperature plasticity is not high, etc., to achieve the effect of improved impact resistance, improved compressive strength, and simple preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

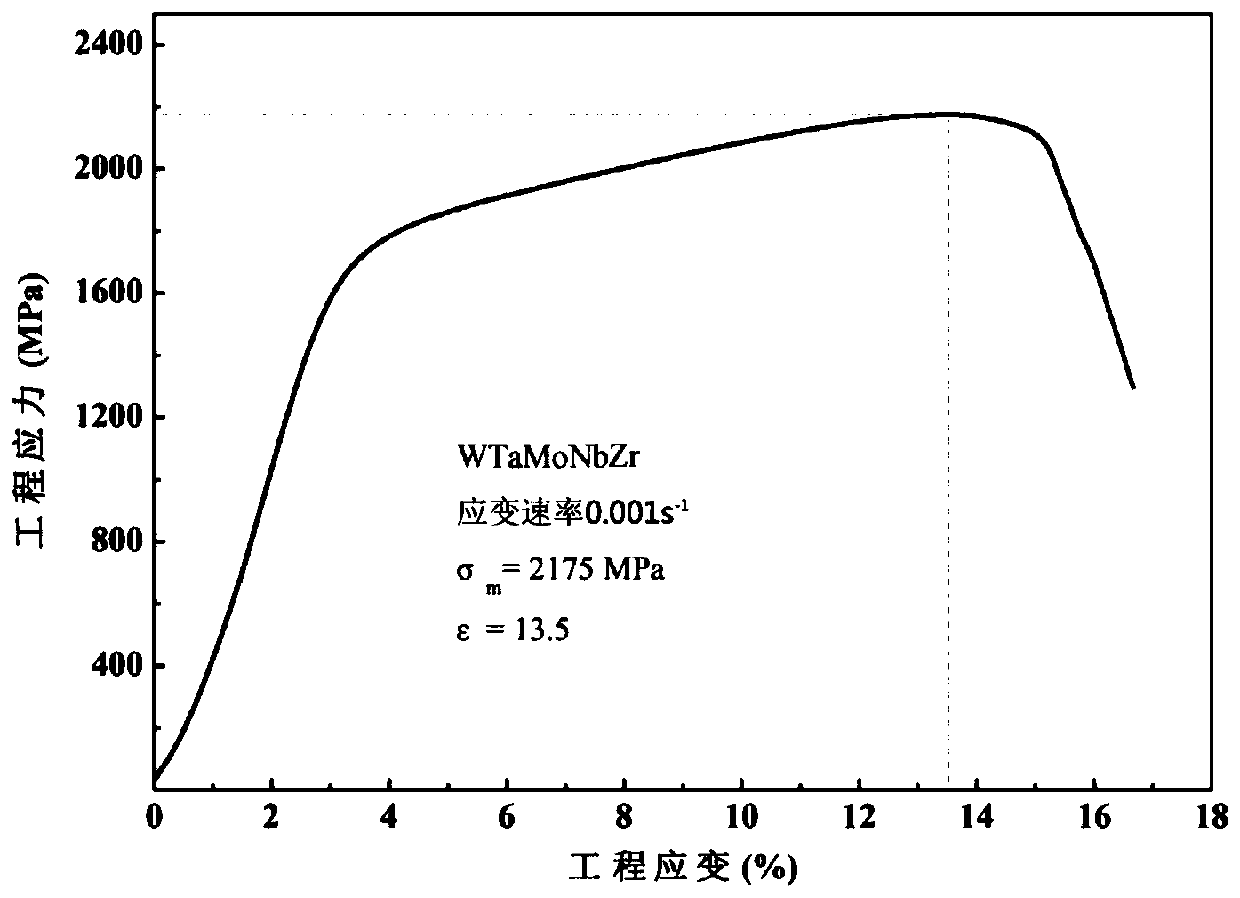

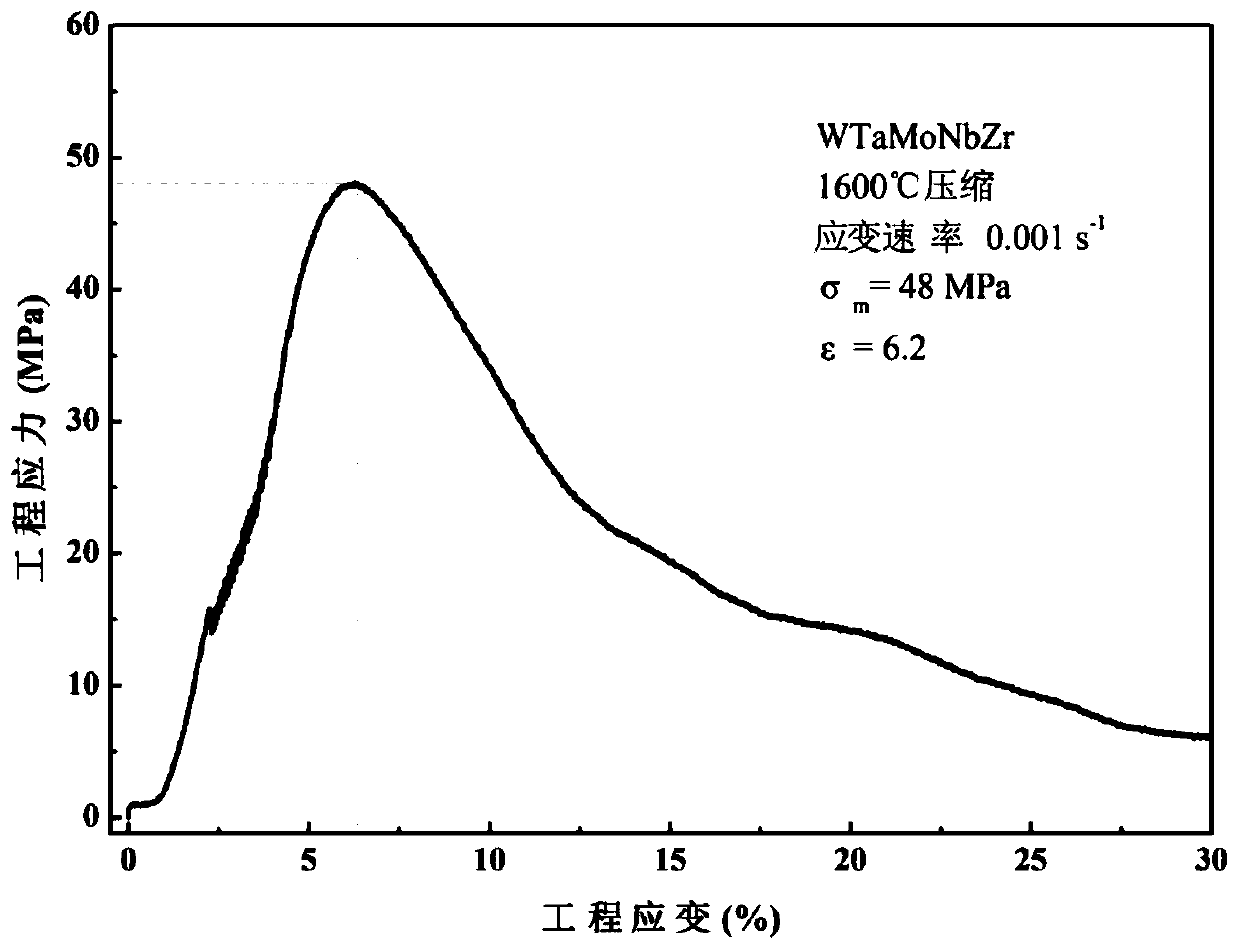

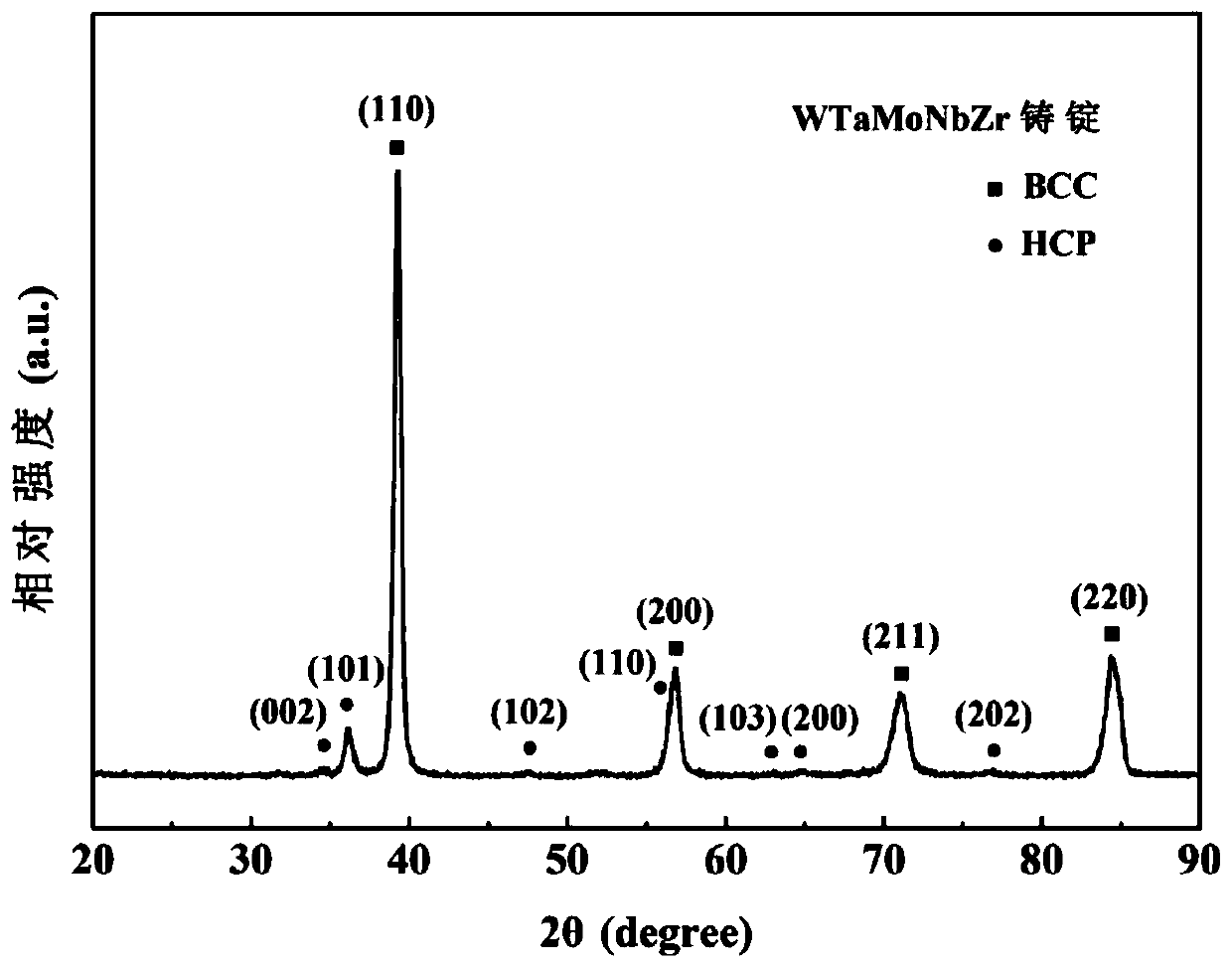

[0041] The preparation of embodiment 1WTaMoNbZr high-temperature high-entropy alloy

[0042] The raw materials used are W elemental powder, Ta elemental powder, Mo elemental particles, Nb elemental particles, and Zr elemental particles, and are prepared in an equiatomic ratio. Put the above raw materials into the water-cooled copper crucible of the non-consumable vacuum arc melting furnace, and then carry out vacuum arc melting: vacuumize the vacuum chamber to 5×10 -3 Pa, refill high-purity argon with a purity of 99.999% until the pressure of the vacuum chamber is -0.7MPa, high-purity argon is used as the protective gas and arcing medium, the melting current is 450A, and cooling water is passed during melting to prevent the water-cooled copper plate from overheating and melting , the front and back sides were repeatedly smelted 5 times, each smelting time was 4 minutes, and the alloy was in liquid state for 20 minutes. After cooling, a WTaMoNbZr high-temperature high-entropy a...

Embodiment 2

[0043] Performance test and structural characterization of embodiment 2 WTaMoNbZr high-temperature high-entropy alloy ingot

[0044] 1. Density determination:

[0045] The Archimedes drainage method is used for measurement, and the specific operation steps are as follows: the WTaMoNbZr high-temperature high-entropy alloy prepared in Example 1 is prepared into three cylindrical samples of Φ4mm×4mm, and put into a beaker filled with absolute alcohol before measurement , ultrasonically oscillate and clean for 10 minutes, take it out and blow dry, and then use a DT-100 precision balance (accuracy 0.1mg) to weigh the dry weight of each sample M 1 , weigh each sample 3 times to reduce the measurement error; then, weigh the mass M of each sample in water 2 , each sample was weighed 3 times; finally, the density was calculated according to the following formula,

[0046]

[0047] In the formula, ρ 0 is the density of water, 0.9982g / cm 3 (20°C); ρ l is air density, 0.0012g / cm ...

Embodiment 3

[0061] Example 3W 20 Ta 20 Mo 21 Nb 19 Zr 20 Preparation, performance testing and structural characterization of high-temperature high-entropy alloys

[0062] The raw materials used are W elemental powder, Ta elemental powder, Mo elemental particles, Nb elemental particles, and Zr elemental particles according to W:Ta:Mo:Nb:Zr=20:20:21:19:20. Put the above raw materials into the water-cooled copper crucible of the non-consumable vacuum arc melting furnace, and then carry out vacuum arc melting: vacuumize the vacuum chamber to 5×10 -3 Pa, refill high-purity argon with a purity of 99.999% until the pressure of the vacuum chamber is -0.7MPa, high-purity argon is used as a shielding gas and arcing medium, the melting current is 380A, and cooling water is passed during melting to prevent the water-cooled copper plate from overheating and melting , the front and back sides are repeatedly smelted 4 times, each smelting is 4 minutes, the alloy is in the liquid state for 16 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com