A floating pressing roller and a winding machine comprising the floating pressing roller

A technology of pressing roller and frame, which is applied in the field of textile and chemical fiber machinery, can solve the problems of poor parallelism of two bobbin chuck axes, finishing of winding machine, difficulty of assembly, debugging and maintenance, etc., and achieve good contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

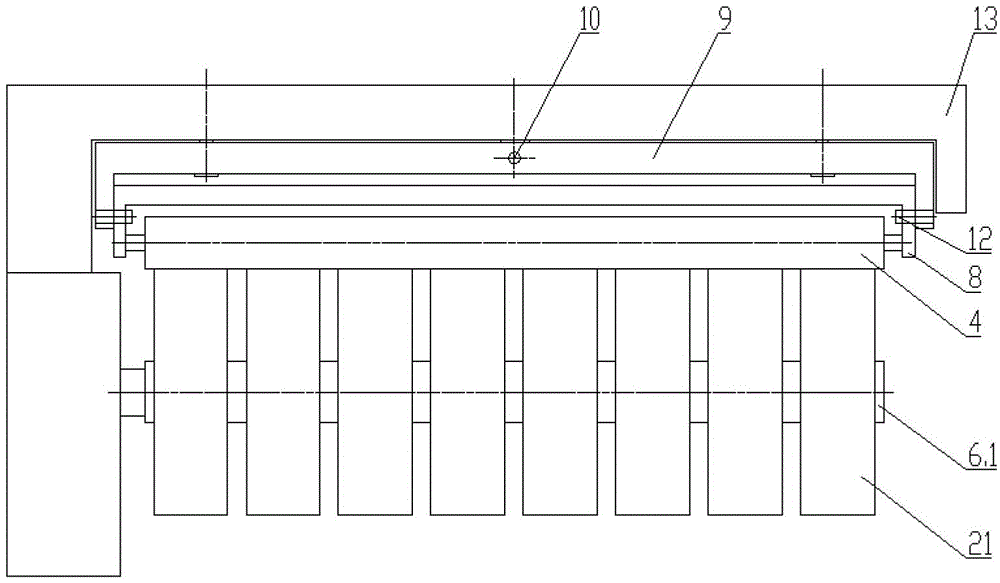

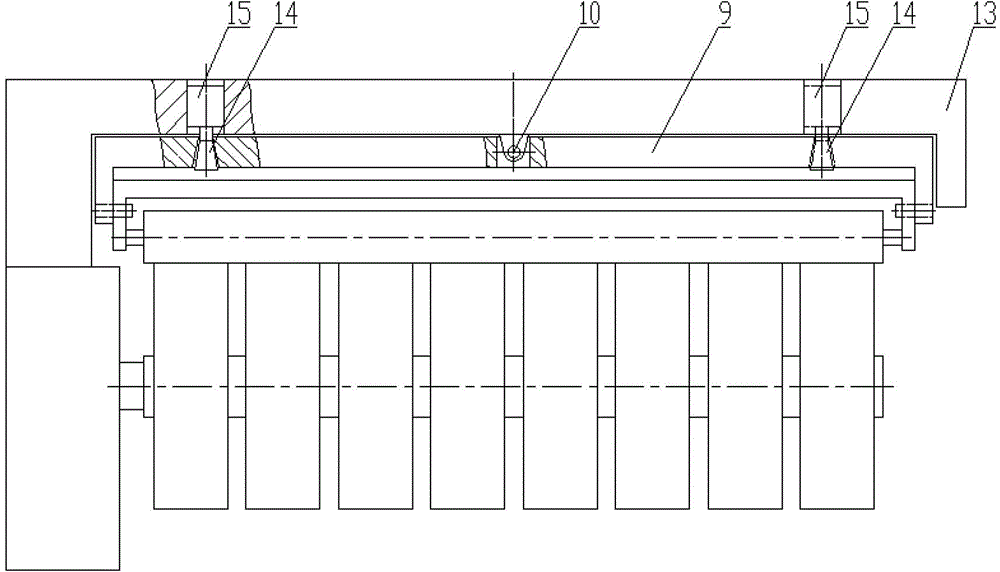

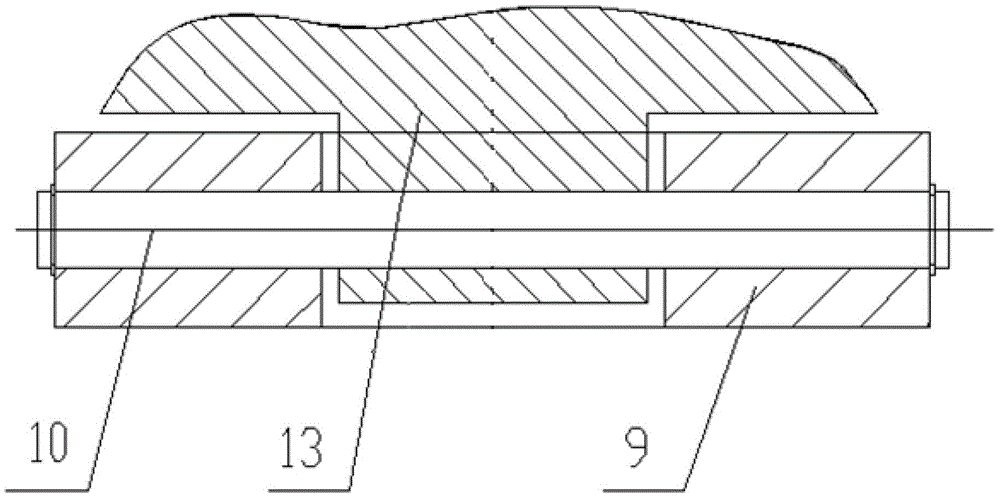

[0029] see figure 1 and figure 2 As shown, the floating pressing roller provided by the embodiment of the present invention includes a second bracket 8 and a first bracket 9, and the left and right ends of the pressing roller 4 are rotatably mounted on the two arms of the second bracket 8 through bearings. Inside, the two arms of the second bracket 8 are formed by bending the left and right ends of the second bracket 8 . The second bracket 8 is installed on the two arms of the first bracket 9 through pin shafts 12 , wherein the two arms of the first bracket 9 are formed by bending the left and right ends of the first bracket 9 . Such as image 3 As shown, the first bracket 9 is connected to the frame 13 through a shaft.

[0030] see figure 2 , at the left and right ends of the first bracket 9, two locking pins 14 are installed. The locking end of the locking pin 14 is movably connected with the first bracket 9 through the hole provided on the first bracket 9, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com