Embedded ultrasonic flowmeter

An ultrasonic and flowmeter technology, which is applied in the field of embedded ultrasonic flowmeters, can solve problems such as measurement failure, measurement influence of ultrasonic flowmeters, corrosion, etc., and achieve the effects of improving accuracy and service life, facilitating cleaning or replacement, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

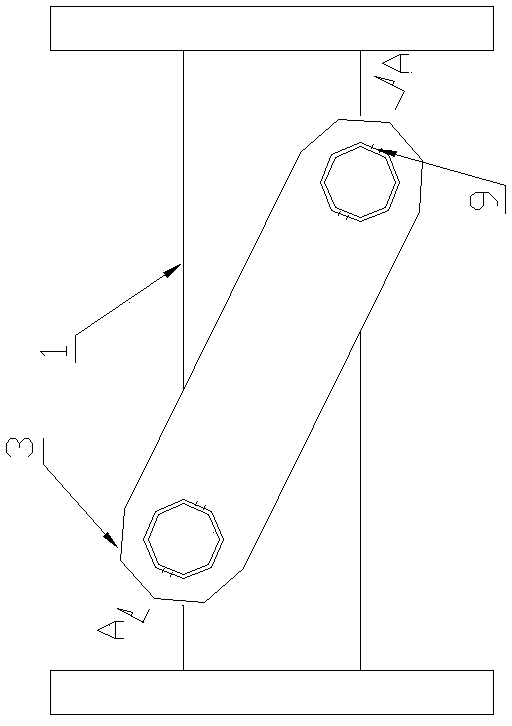

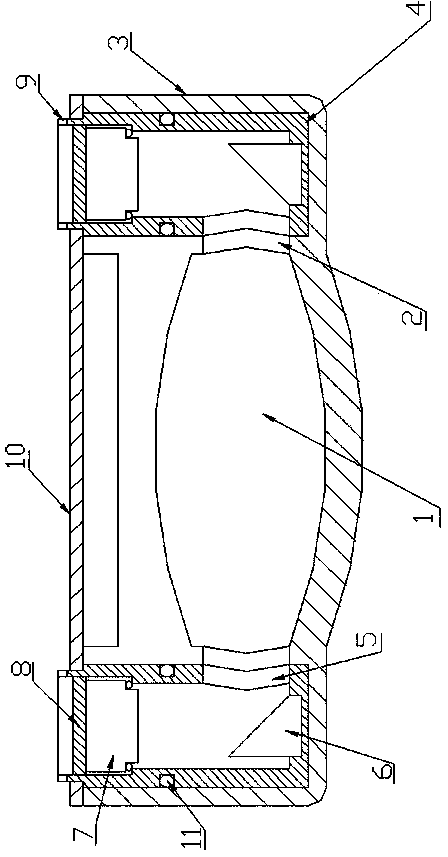

[0013] refer to figure 1 with figure 2 , an embedded ultrasonic flowmeter, including a measuring tube 1, measuring holes 2 are opened on both sides of the measuring tube 1, and the two measuring holes 2 are staggered forward and backward along the axis of the tube body, and each measuring hole 2 is outside All are provided with a transduction measurement assembly, the transduction measurement assembly includes a fixed seat 3 connected to the measuring tube 1, a rotating tube 4 is installed in the fixed seat 3, and the outer wall of the rotating tube 4 is slidably fitted with the inner wall of the fixed seat 3, The side wall of the rotating tube 4 is provided with a reflecting hole 5 corresponding to the measuring hole 2 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com