Antibiotic bone cement chain bead manufacturing device and method

A technology for manufacturing device and manufacturing method, which is applied in the field of antibiotic bone cement chain bead manufacturing device, and achieves the effects of low cost, pain relief and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

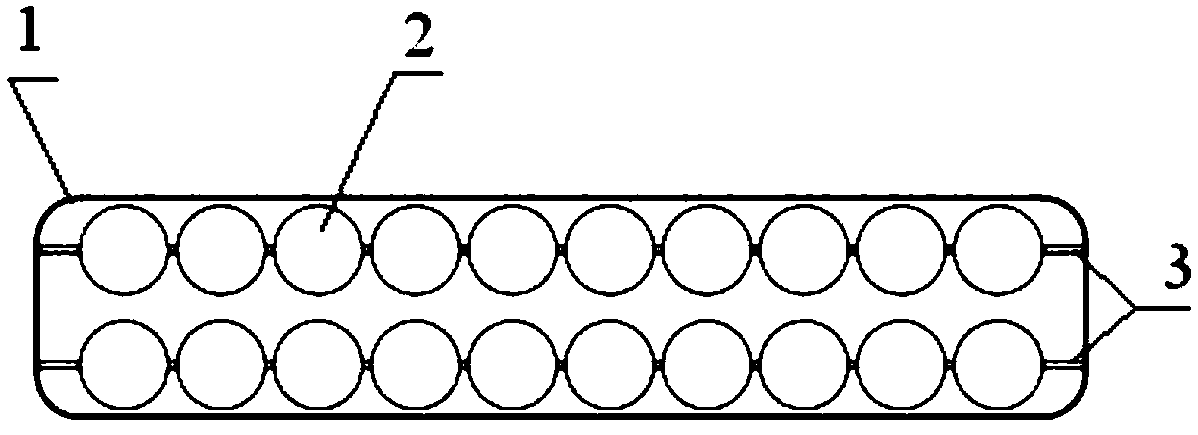

[0024] The main body 1 of the antibiotic bone cement chain bead manufacturing device provided by the present invention has a rectangular structure, and two rows of grooves 2 are provided in the longitudinal direction of the main body 1, and the number of grooves 2 in each row is ten, and the diameter of the grooves 2 is 20mm. A wire groove 3 is opened on the body 1 at a position corresponding to the opening of the groove 2 .

[0025] The body 1 is made of steel plate.

Embodiment 2

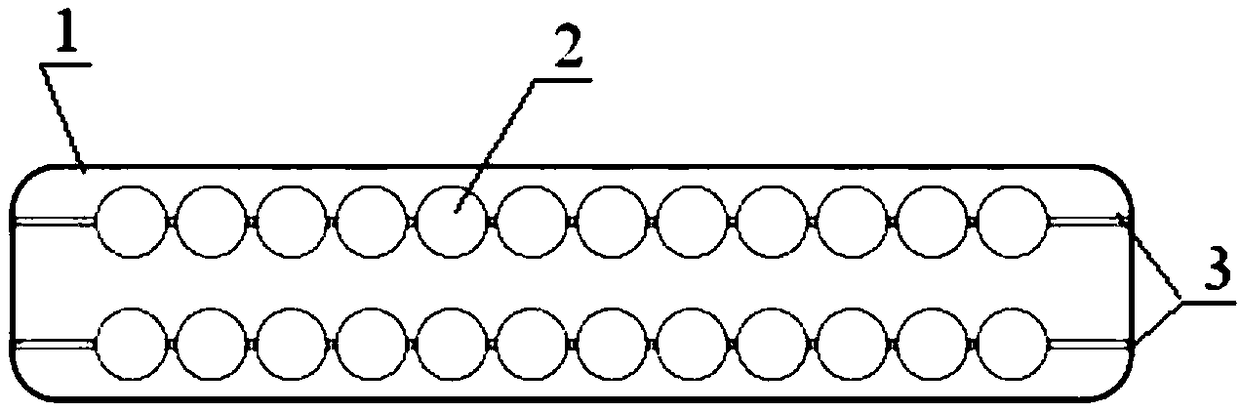

[0027] The body 1 of the antibiotic bone cement chain bead manufacturing device provided by the present invention is a rectangular structure, and the body 1 is provided with two rows of grooves 2 in the longitudinal direction, and the number of grooves 2 in each row is twelve, and the diameter of the grooves 2 is 15 mm. , the main body 1 is provided with a wire groove 3 at a position corresponding to the groove 2 .

[0028] The body 1 is made of steel plate.

Embodiment 3

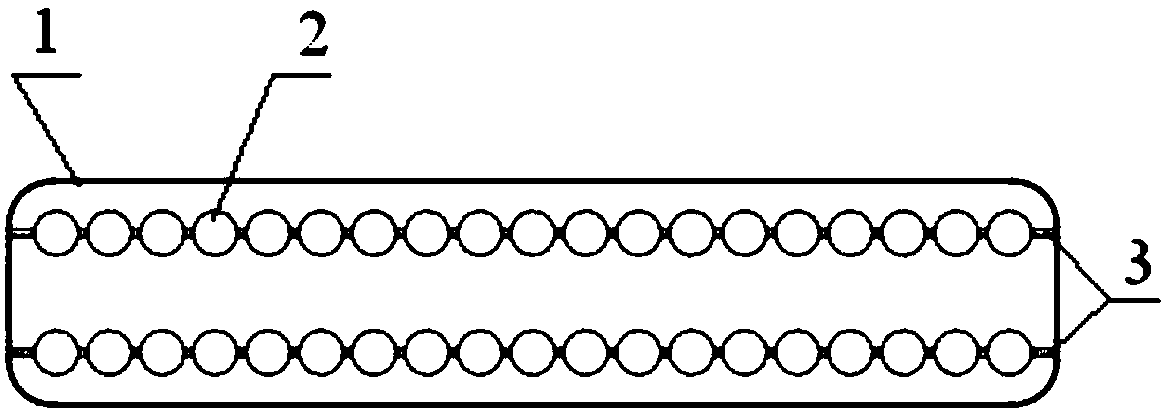

[0030] The body 1 of the antibiotic bone cement chain bead manufacturing device provided by the present invention is a rectangular structure, and the body 1 is provided with two rows of grooves 2 in the longitudinal direction, and the number of grooves 2 in each row is nineteen, and the diameter of the grooves 2 is 10 mm. , the main body 1 is provided with a wire groove 3 at a position corresponding to the groove 2 .

[0031] The body 1 is made of steel plate.

[0032] The method for producing antibiotic bone cement chain beads provided by the invention is as follows:

[0033] Step 1. Select an antibiotic bone cement bead manufacturing device with matching specifications according to the size of the bone cement bead actually required by the operation, soak it with saline and dry it, and then place it on a piece of flat gauze;

[0034] Step 2: Mix antibiotics and bone cement at a ratio of 1:20 by weight and add purified water to form a mixture;

[0035] Step 3, filling the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com