Door and window glass wire pressing mechanism with height increase material and with function of enhancing wind pressure effect

A door and window glass and anti-wind pressure technology, which is applied in the installation of window glass, sealing devices, etc., can solve problems such as ventilation, limited bearing capacity, and gaps in glass contact positions, so as to ensure airtightness and watertightness, and increase support , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

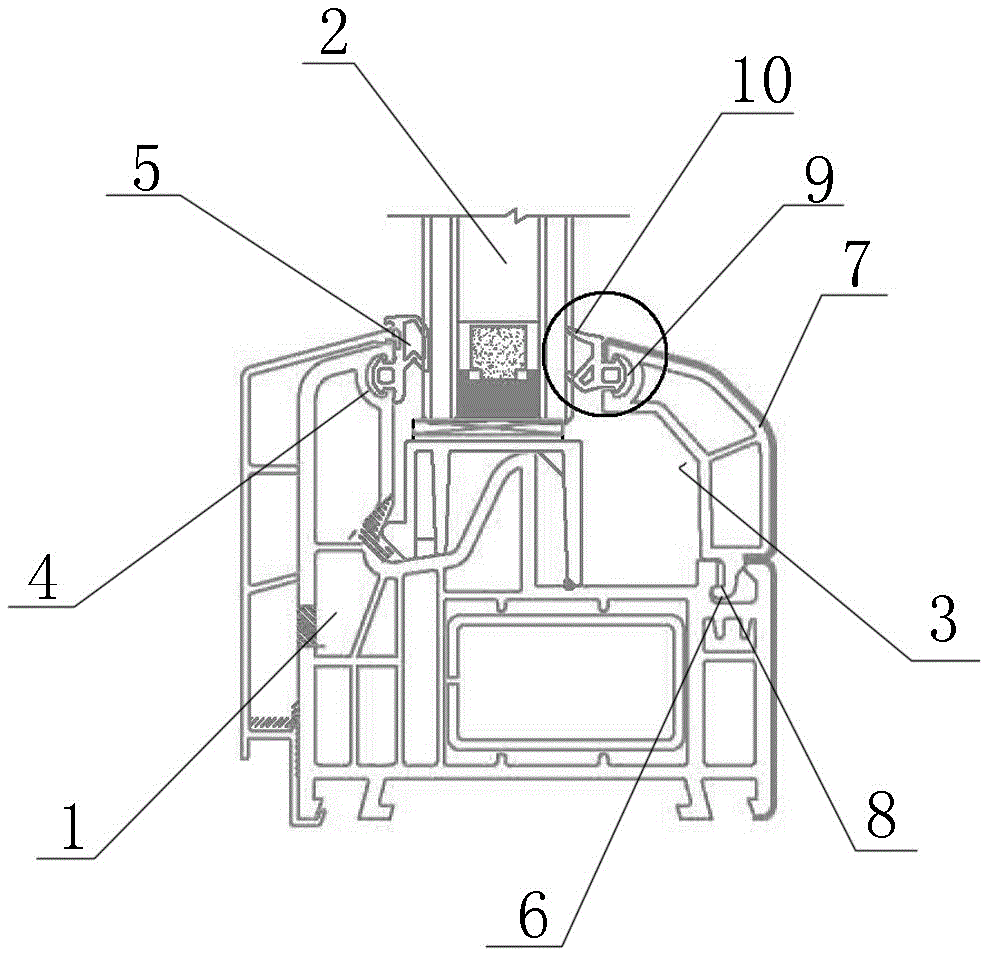

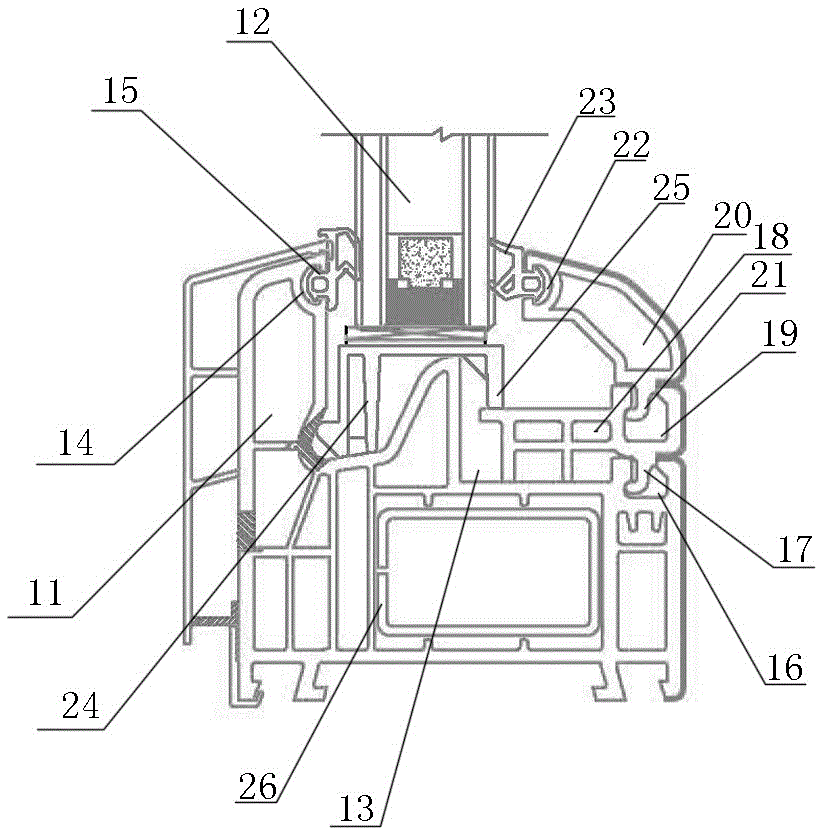

[0010] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the door and window glass includes an outer frame 1 or fan of the door and window, and an L-shaped glass installation groove 3 for embedding and installing glass 2 is provided on the inner end surface of the profile frame of the outer frame 1 or fan toward the interior side, An outer glass rubber gasket 5 is installed on the inner side of the L-shaped glass installation groove 3 through the snap-in groove 4, and an indoor side snap-in groove 6 is arranged on the bottom edge of the L-shaped glass installation groove 3 near the indoor side. The crimping line 7 of the shape is clamped in the indoor side clamping groove 6 through the clamping strip 8 of the lower bottom, and the upper end is clamped with another inner glass glue pressed on the surface of the glass 2 through the clamping groove 9 provided. pad 10; from figure 1 As shown, the distance between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com