A connector that relies on ribbon-like hard metal twisted pressure wiring

A hard metal and connector technology, applied in the direction of clamping/spring connection, base/housing, etc., can solve the problems of inconvenient operation, poor safety, tools cannot be removed, etc., and achieve the effect of convenient operation, avoiding electric shock, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

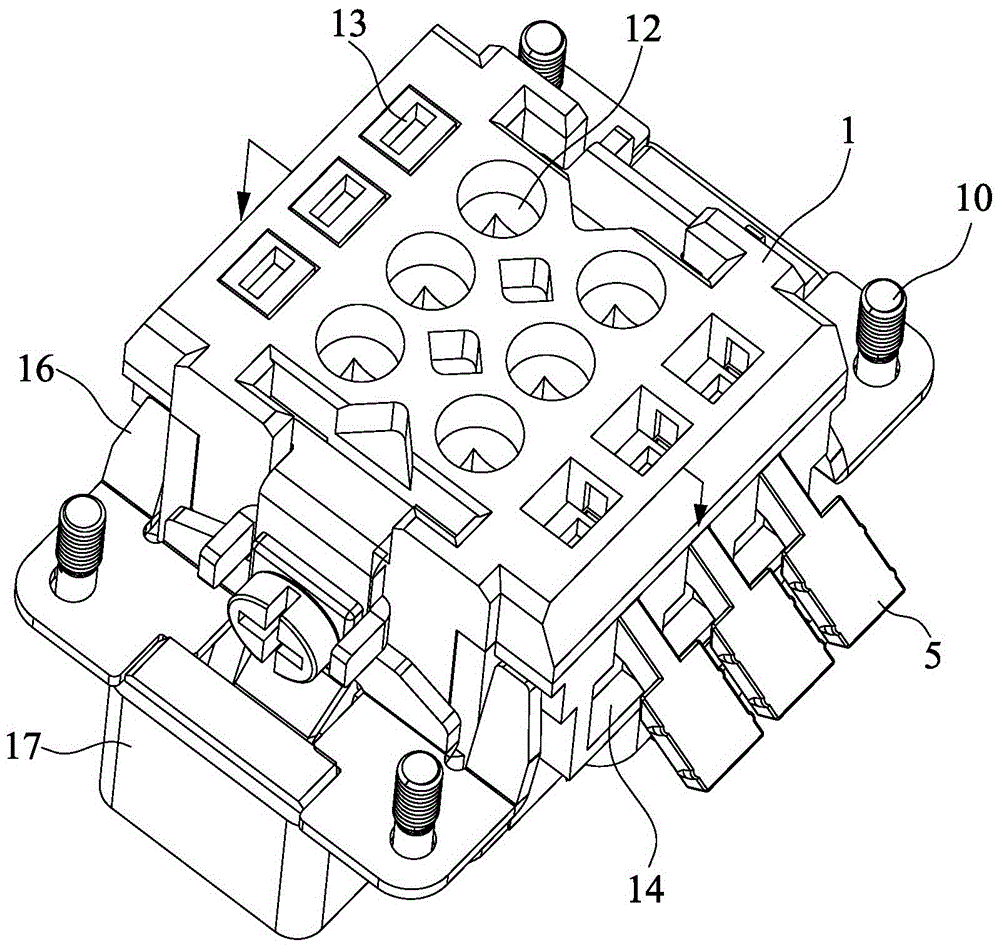

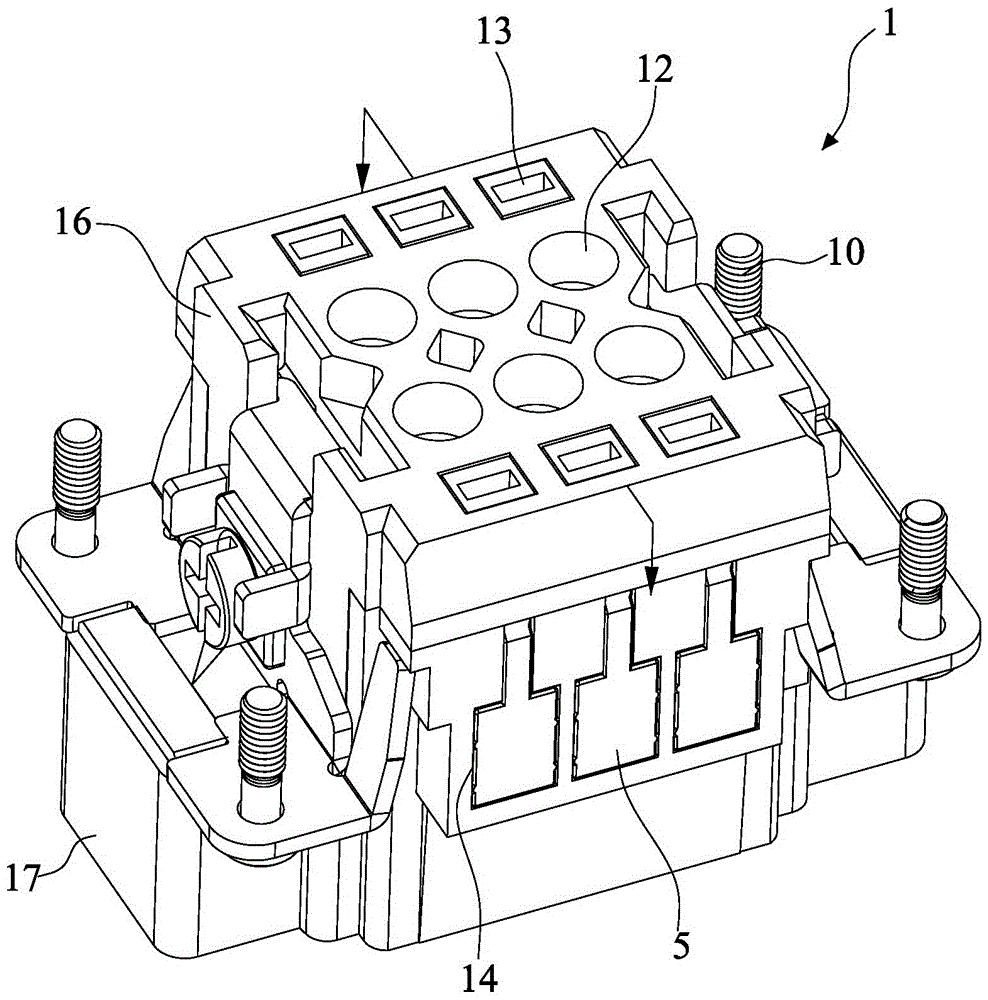

[0050] Such as Figure 1 to Figure 8 Shown is a preferred embodiment of the present invention, which discloses a connector that relies on strip-shaped hard metal torsion and pressure wiring.

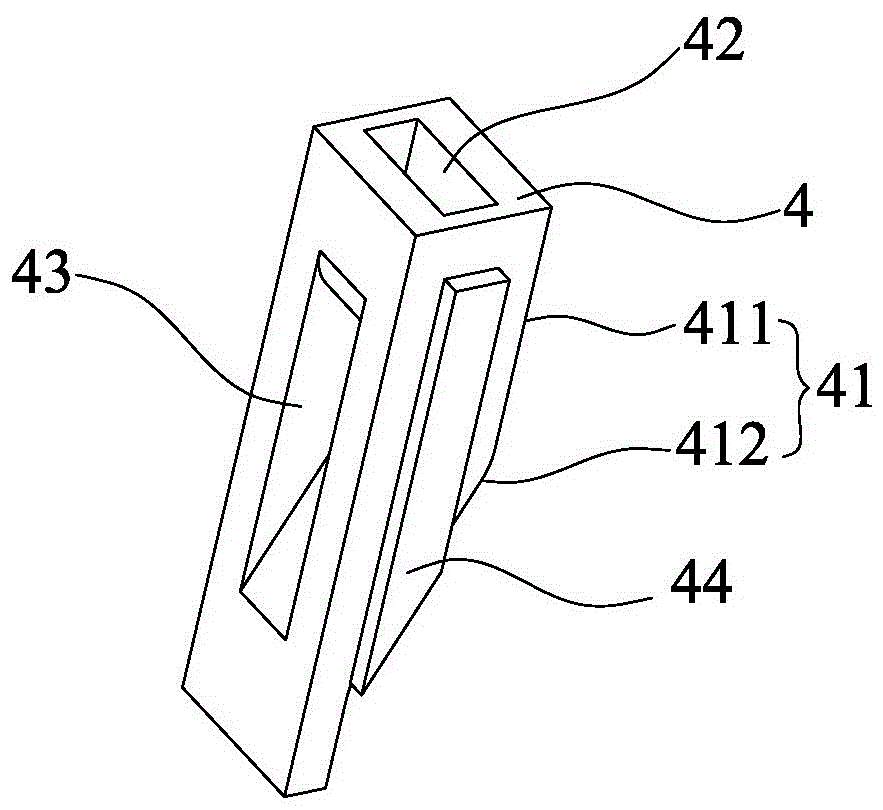

[0051] A lower insertion hole 11 is formed below the middle of the base body 1 for the insertion of the terminal 2, an upper insertion hole 12 is formed corresponding to the lower insertion hole 11 above the middle of the base body 1 for the insertion of the conductor 3, and an upper side insertion hole 13 is formed above the side of the base body 1 For the insertion of the push rod 4, a side groove 14 passing through the upper insertion hole 13 is formed on the side of the base body 1 for the installation of the push rod 5, and the upper insertion hole 12 and the lower insertion hole are formed between the upper insertion hole 12 and the lower insertion hole 11. 11 and the wiring cavity 15 of the jack 13 on the upper side. For the convenience of forming and assembling, the substrate 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com