Lock bolt

A technology of anti-loosening bolts and bolt heads, which is applied in the direction of bolts, screws, nuts, etc., can solve the problems of affecting the working performance and stability of mechanical equipment, affecting the processing accuracy of precision equipment, and deteriorating the fastening effect of bolts, so as to prevent prolapse Threaded hole, improve working performance and stability, not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described below in conjunction with accompanying drawing.

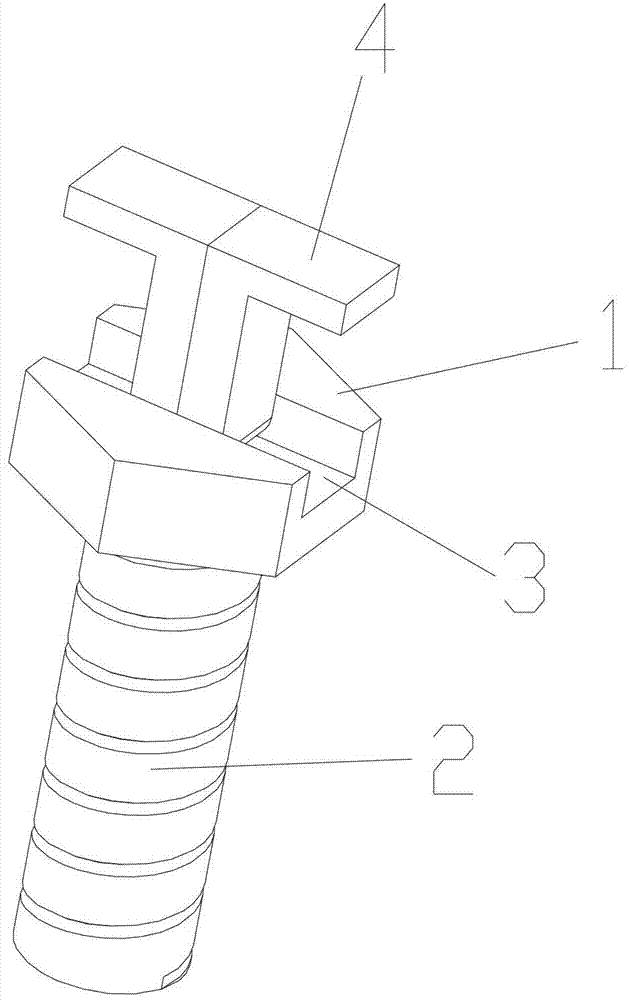

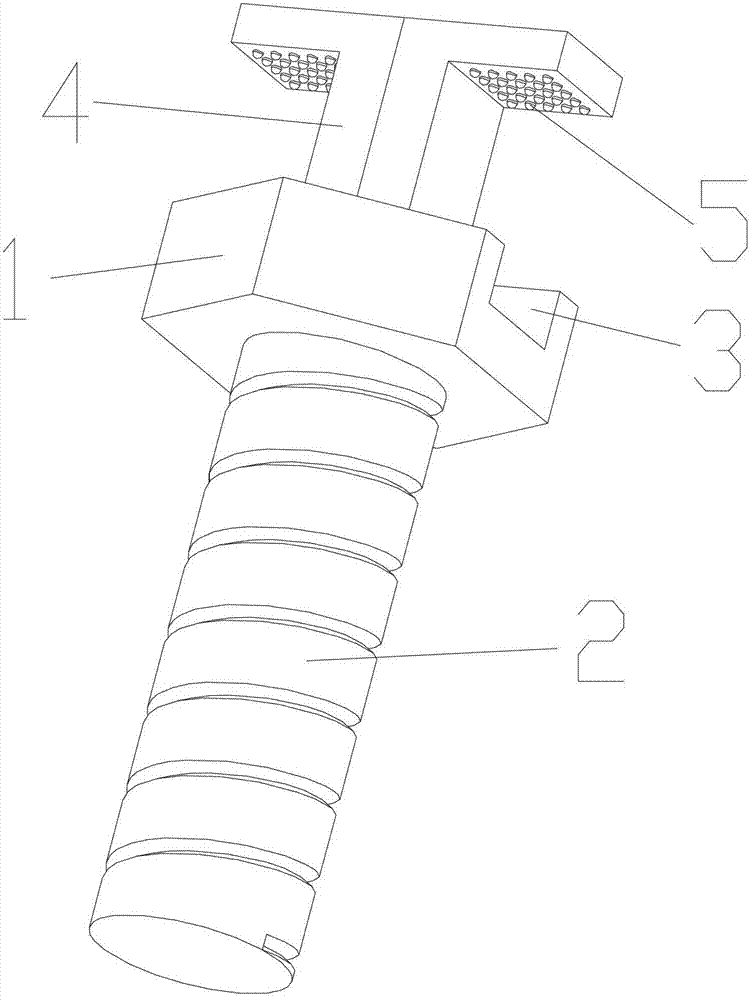

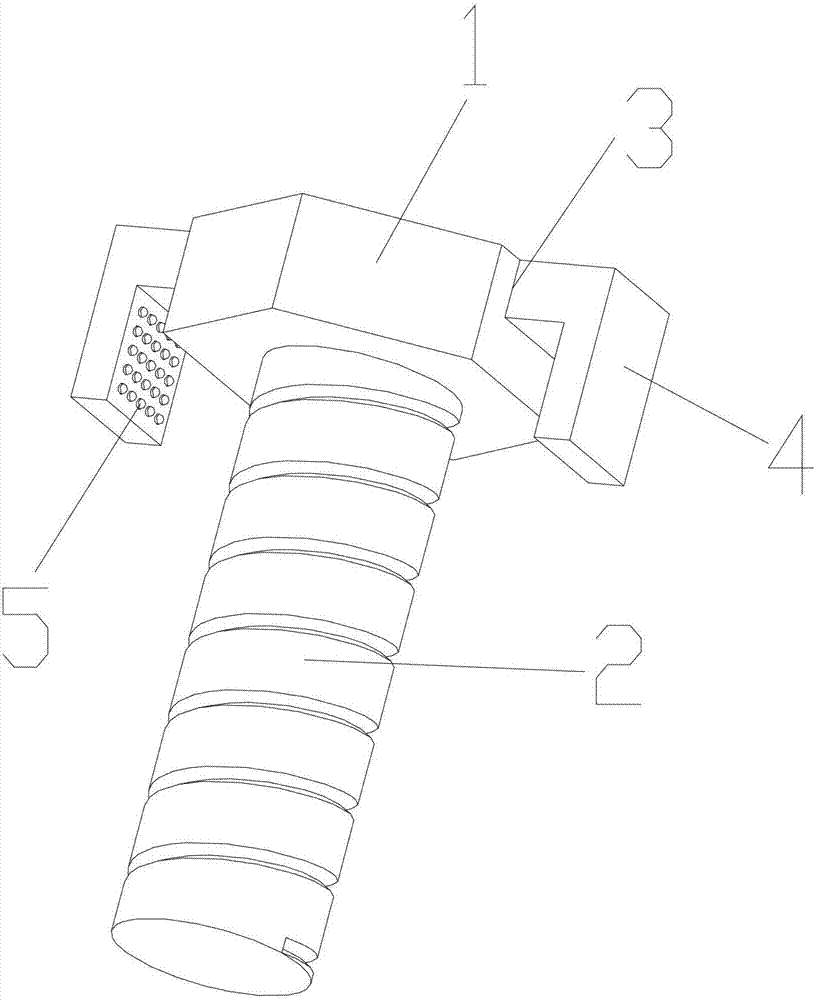

[0015] as attached figure 1 , 2 The illustrated anti-loosening bolt of the present invention includes a bolt head 1 and a screw rod 2, the bolt head 1 and the screw rod 2 are connected as a whole, and the upper surface of the bolt head 1 is provided with a through groove 3; Two "L" shaped turning blocks 4 are symmetrically arranged in the through groove 3; the top of the "I" part of the "L" shaped turning block 4 is rotatably connected to the side plate of the through groove 3; the "L" When the "I" portion of the "L"-shaped rotary block 4 is located in the through groove 3, the "-" portion of the "L"-shaped rotary block faces the direction of the screw, and the "-" portion of the "L"-shaped rotary block 4 The lower surface of the lower surface is located below the lower surface of the bolt head 1; when the "I" parts of the two "L" shaped turning blocks 4 are perpendicular to the throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com