Industrial part conveying device

A conveying device and industrial technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as poor track rigidity, affecting work efficiency, and occurrence of safety accidents, so as to achieve good overall structural rigidity and reduce Labor intensity, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

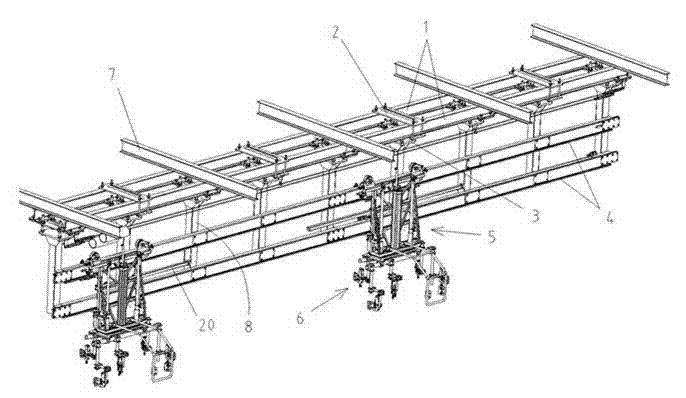

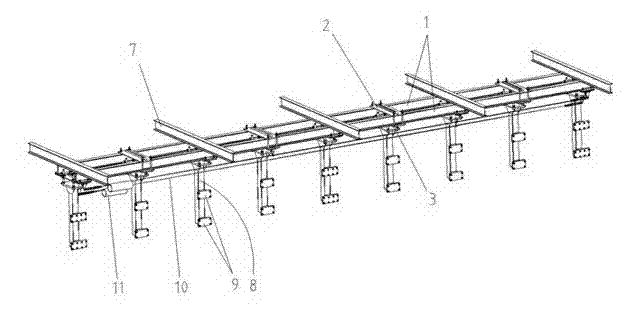

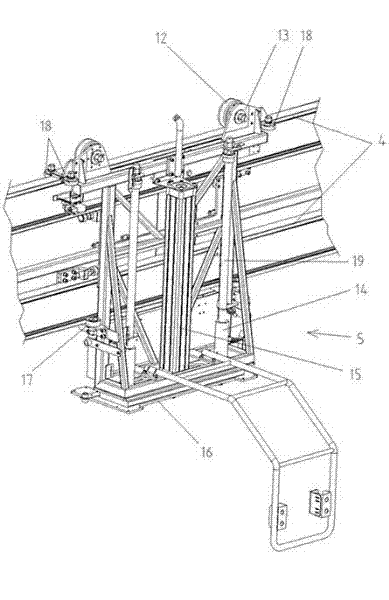

[0011] Such as figure 1 , 2 , Shown in 3: 6 is a part gripper, used for grasping parts, which belongs to the prior art part.

[0012] 1 is the main beam arranged vertically, 2 is the cross beam arranged horizontally, the cross beam 2 and the main beam 1 are fixedly connected or welded by bolts, and the main beam 1 and the cross beam 2 form the frame body of the device. Vertical beams 8 arranged at intervals are connected below the frame body, and the vertical beams 8 and the frame body are fixedly connected by bolts and connecting plates 3 .

[0013] Welding or bolting on each vertical beam 8 are connected with two track connecting plates 9 up and down, and on the track connecting plate 9, are fixed with a track 4 parallel to the main beam by bolts, and the track 4 is divided into two up and down. The tackle 5 with frame structure is suspended on the track 4, and the vertically arranged cylinder 15 connected with the pneumatic control device is housed on the tackle 5. 16 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com