Positioning clamping system of testing machine for automatic transmission valve body assembly of automobile

An automatic gearbox, positioning and clamping technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of oil leakage and pressure relief, labor-consuming and laborious operation, and many ineffective work, etc., to achieve accurate and fast positioning and clamping, avoiding Time-consuming and labor-intensive, the effect of avoiding repeated damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

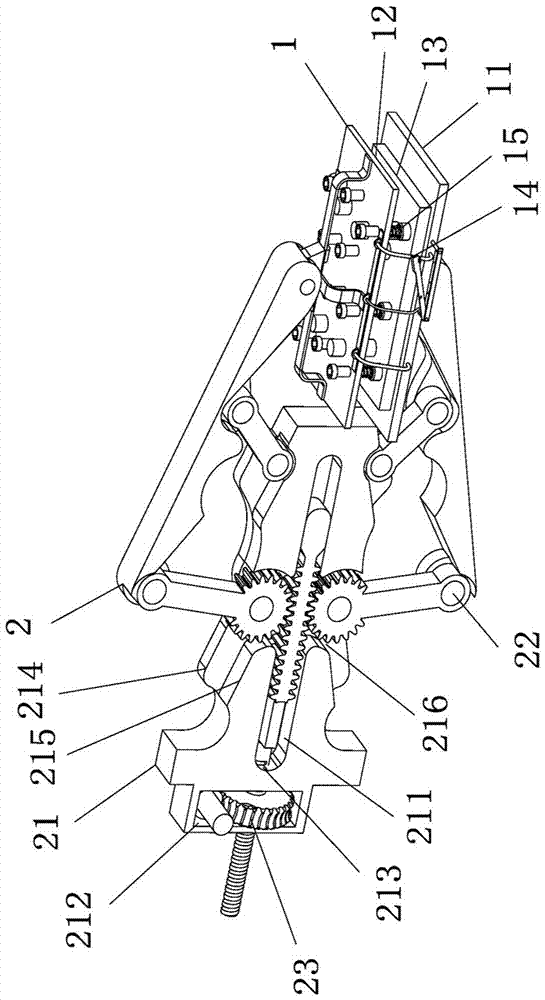

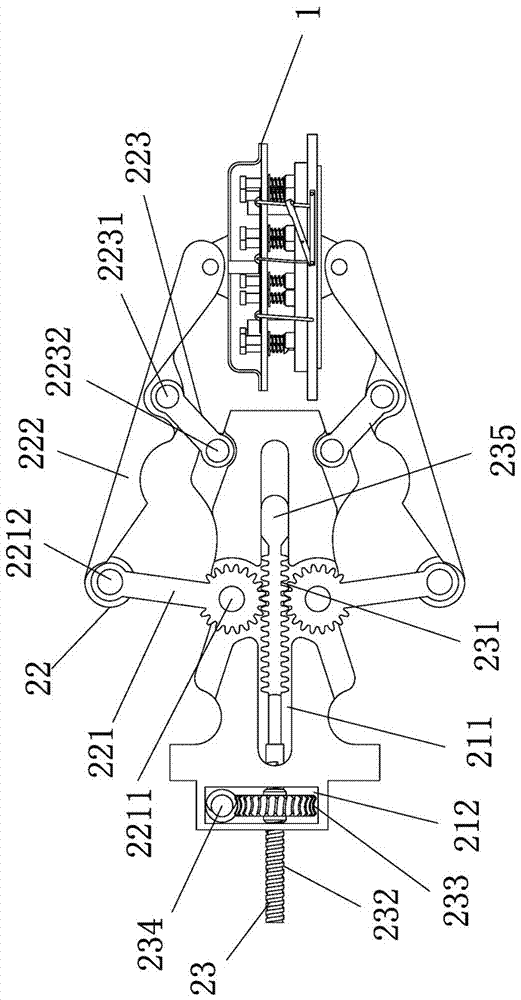

Method used

Image

Examples

Embodiment approach

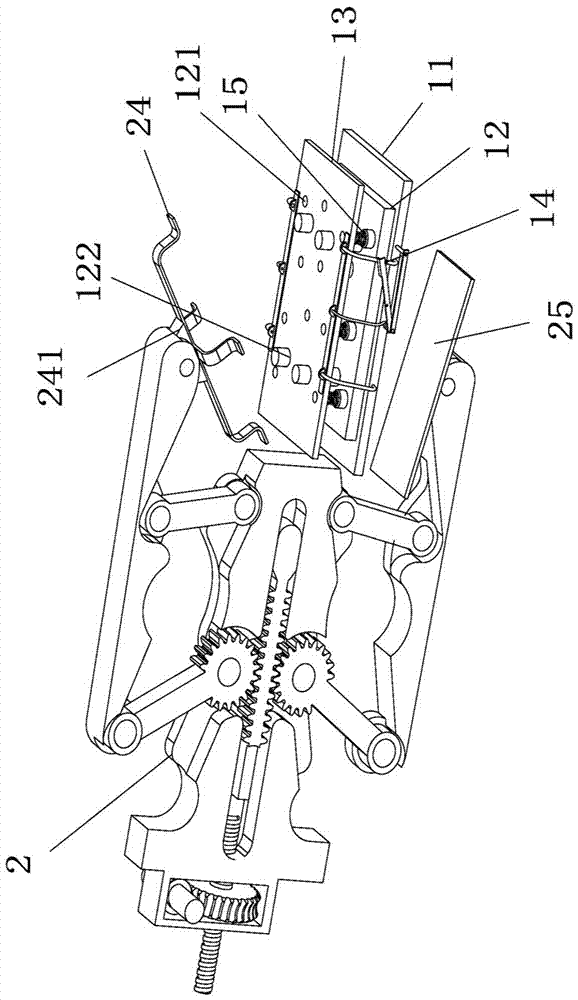

[0037] Such as Figure 9 As shown, the present invention provides an embodiment of the bolt pressure regulating mechanism 15. The bolt pressure regulating mechanism 15 includes a bolt 151, a guide post 152 and a spring 153. The valve body tooling plate 12 is provided with a bolt hole 121 and a guide post hole 122. The valve body plate 13 is provided with a bolt sleeve 131 corresponding to the bolt hole 121. The bolt 151 includes an integrally formed bolt head 156 and a bolt post 157. The bolt post 157 passes through the stud hole 121 and is covered with a bolt washer 154 and an arc-shaped washer. The sheet 155 is connected in the bolt sleeve 131, the spring 153 is sleeved on the bolt post 157 and is located between the bolt washer 154 and the arc washer 155; the guide post 152 is connected to the valve body plate 13 through the guide post hole 121; The bottom of the bolt column 157 is provided with a pin shaft 158 , and the pin shaft 158 is inserted into the bolt sleeve 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com