Automobile tire grinding and grooving integrated device

An all-in-one technology for automobile tires, used in grinding/polishing safety devices, grinding machines, grinding workpiece supports, etc., which can solve the problems of uneven grinding of the upper and lower curved end faces of tires, time-consuming and laborious manual grinding, and poor grinding quality. , to achieve the effect of not easy to shake, improve efficiency and good grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

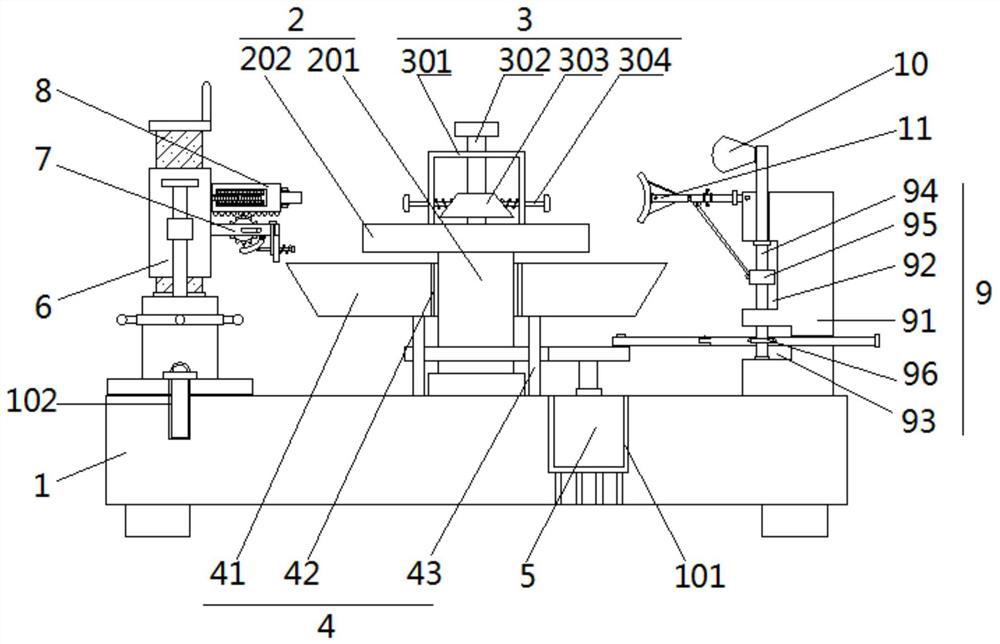

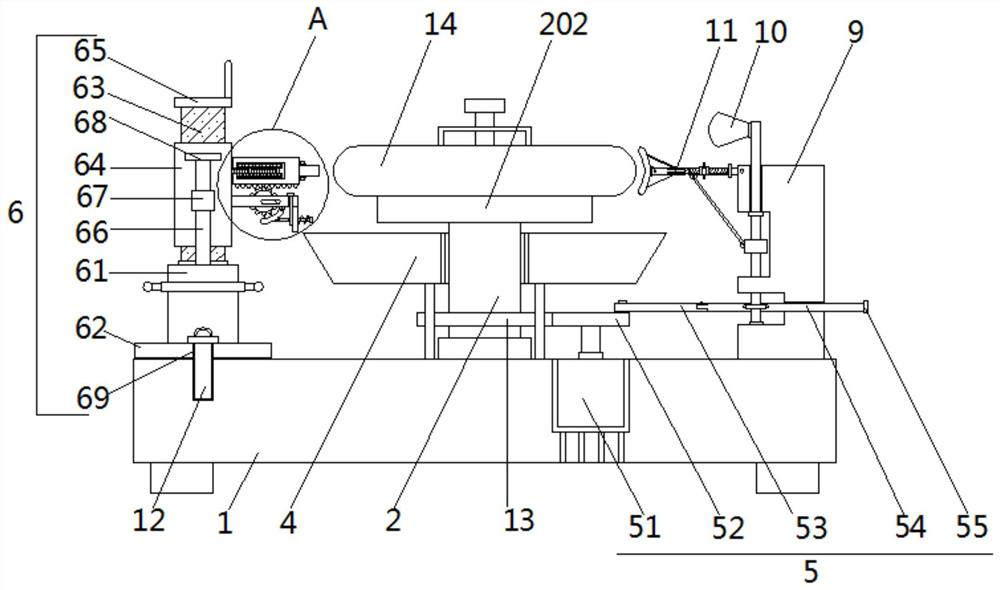

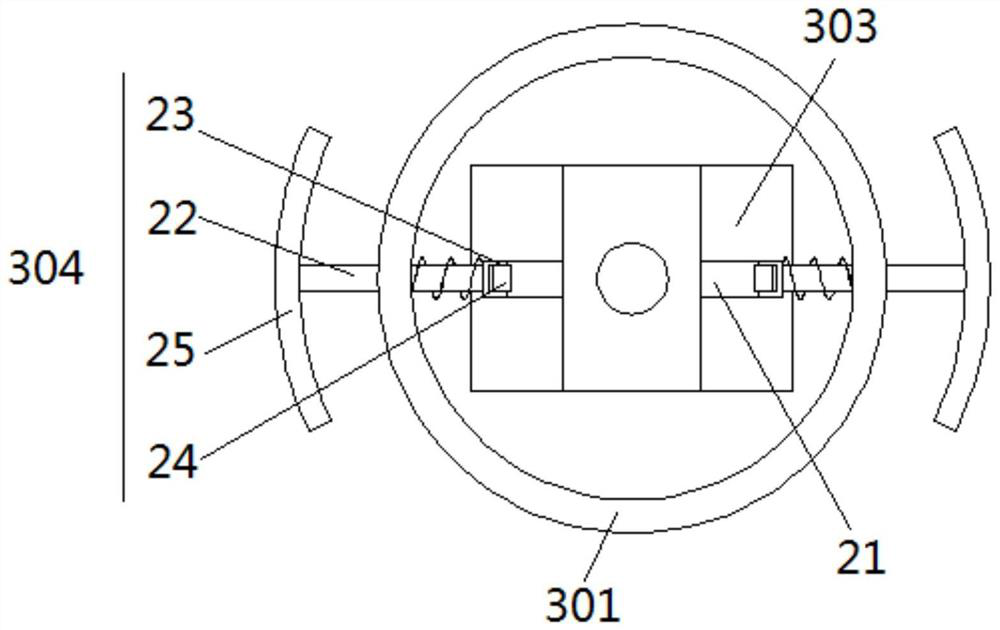

[0031] as attached figure 1 to attach Figure 8 Shown: an integrated device for grinding and grooving automobile tires, including a base 1, a rotating support assembly 2, a rotating shaft 201, and a support plate 202. The top center of the base 1 is rotatably connected to a rotating supporting assembly 2. The support plate 202 is fixedly connected with the support plate 202 on the top of the rotating shaft 201. The support plate 202 is in a circular shape. The rotating shaft 201 is rotatably connected to the center of the base 1. The lower end of the rotating shaft 201 is sleeved and fixedly connected to a No. 1 gear 13. There is a fixing device 3, the top center of the base 1 is located at the lower end of the support plate 202 and is fixedly connected with a collecting device 4, and one side of the top center of the base 1 is rotatably connected with a rotating device 6, and the upper and lower ends of the rotating device 6 near the rotating support assembly 2 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com