Material conveying and locating device

A technology for positioning devices and materials, applied to conveyor control devices, transportation and packaging, conveyors, etc., can solve problems such as long time consumption, low work efficiency, and difficulty in ensuring positioning accuracy, so as to improve production efficiency and reduce scrap efficiency, the effect of liberating the labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

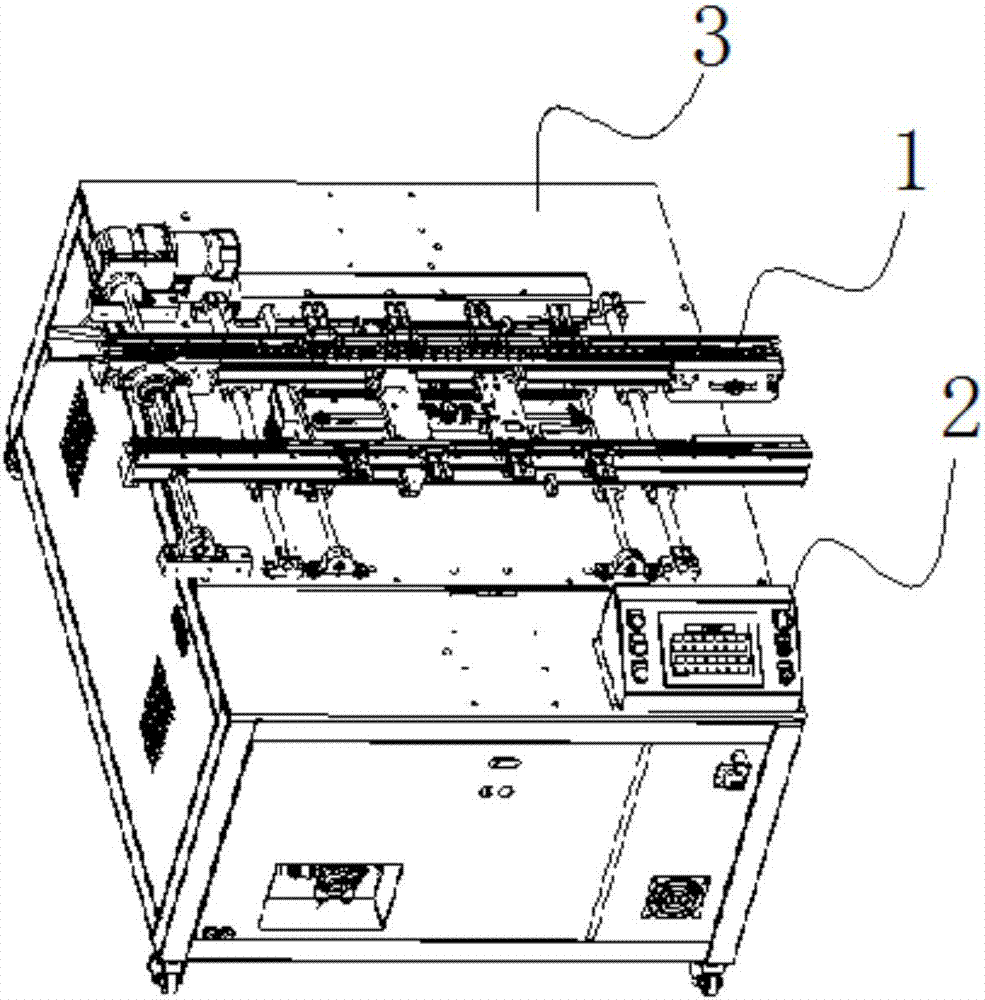

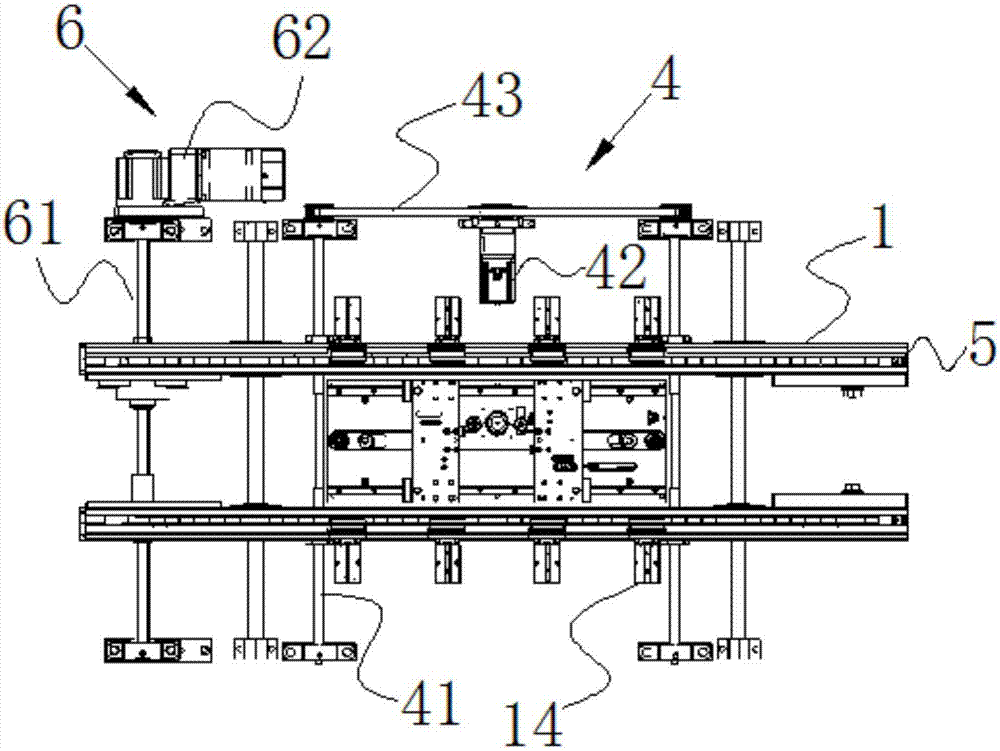

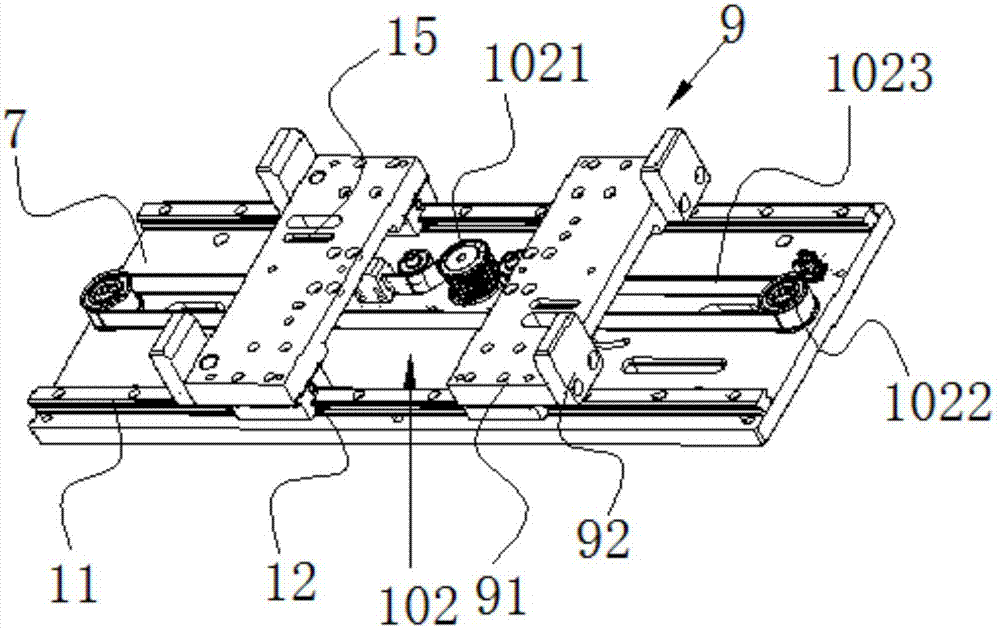

[0030] Embodiment: a kind of conveying and positioning device of material, such as Figure 1-6 As shown, the present invention includes a conveying track 1, a controller 2 and a workbench 3, and the conveying direction of the material is defined as the front. Located on the left and right sides of the workbench respectively, the conveying track is provided with a variable-pitch drive mechanism 4, and the variable-pitch drive mechanism drives the two conveying tracks closer to or farther away to adjust the distance between the two conveying tracks. pitch, the conveying track is provided with a conveying chain 5 and the direction of the conveying chain is consistent with the direction of the conveying track, the conveying chain is connected with a conveying drive mechanism 6, and a lifting plate 7 is arranged above the workbench, The bottom of the lifting plate is provided with a lifting drive mechanism 8 that drives the lifting plate to move up and down, and the lifting plate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com