Flange welding method and welding device

A flange welding and flange technology, which is applied in the field of flange welding methods and welding devices, can solve problems such as inability to process qualified products, vibration of steel pipes, and influence on welding quality, so as to achieve ideal welding effects, ensure welding quality, and operate convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

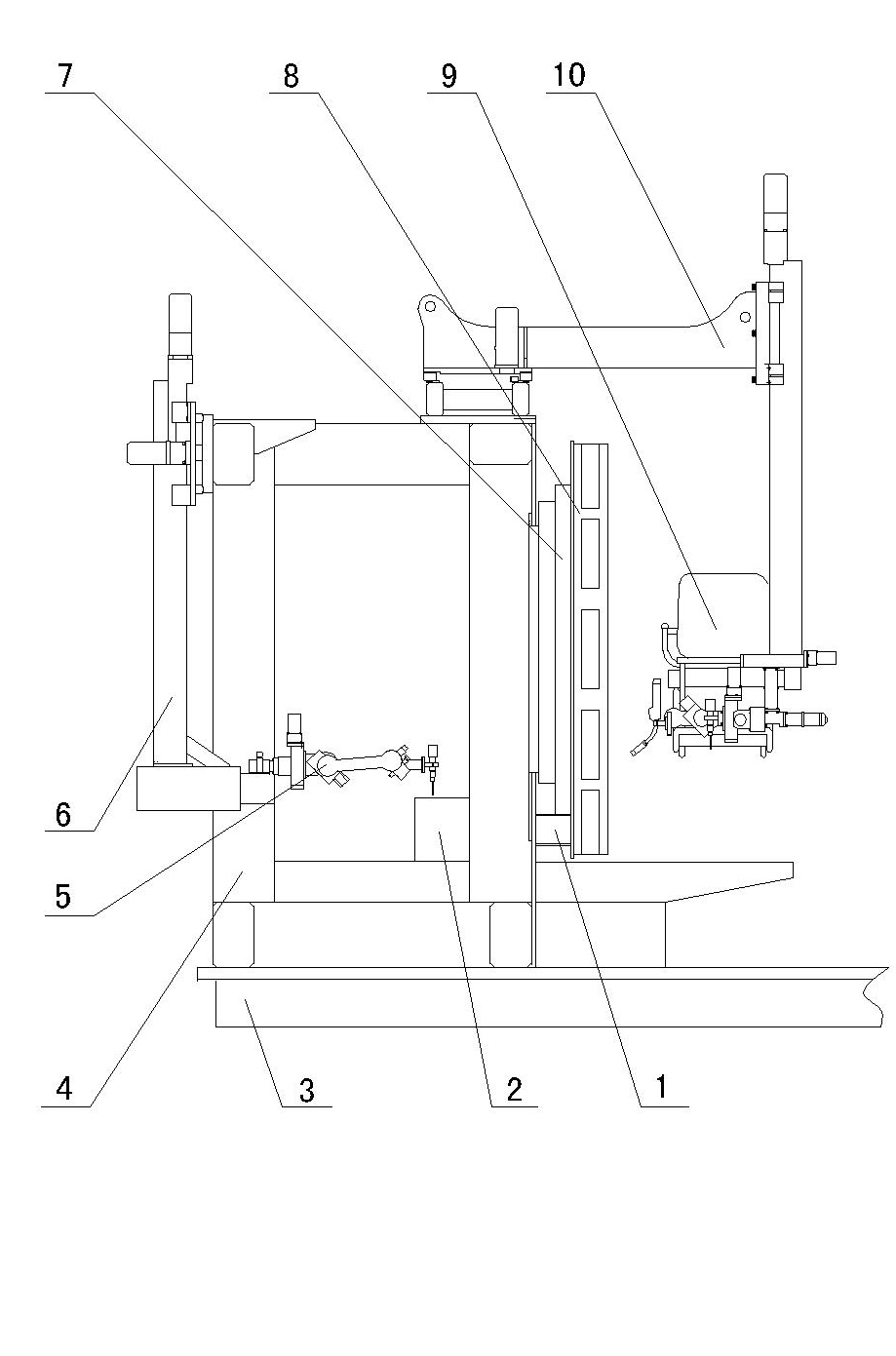

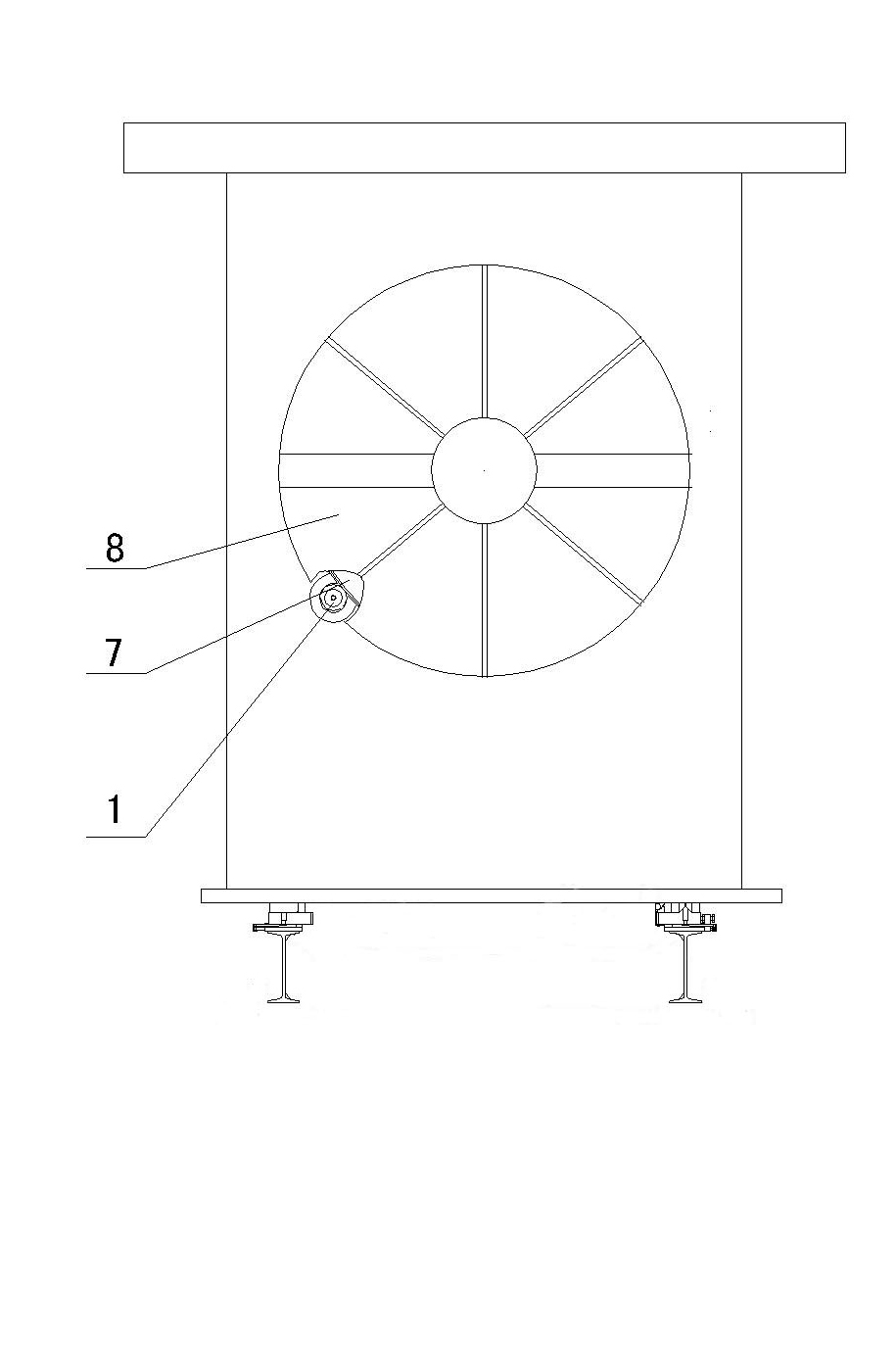

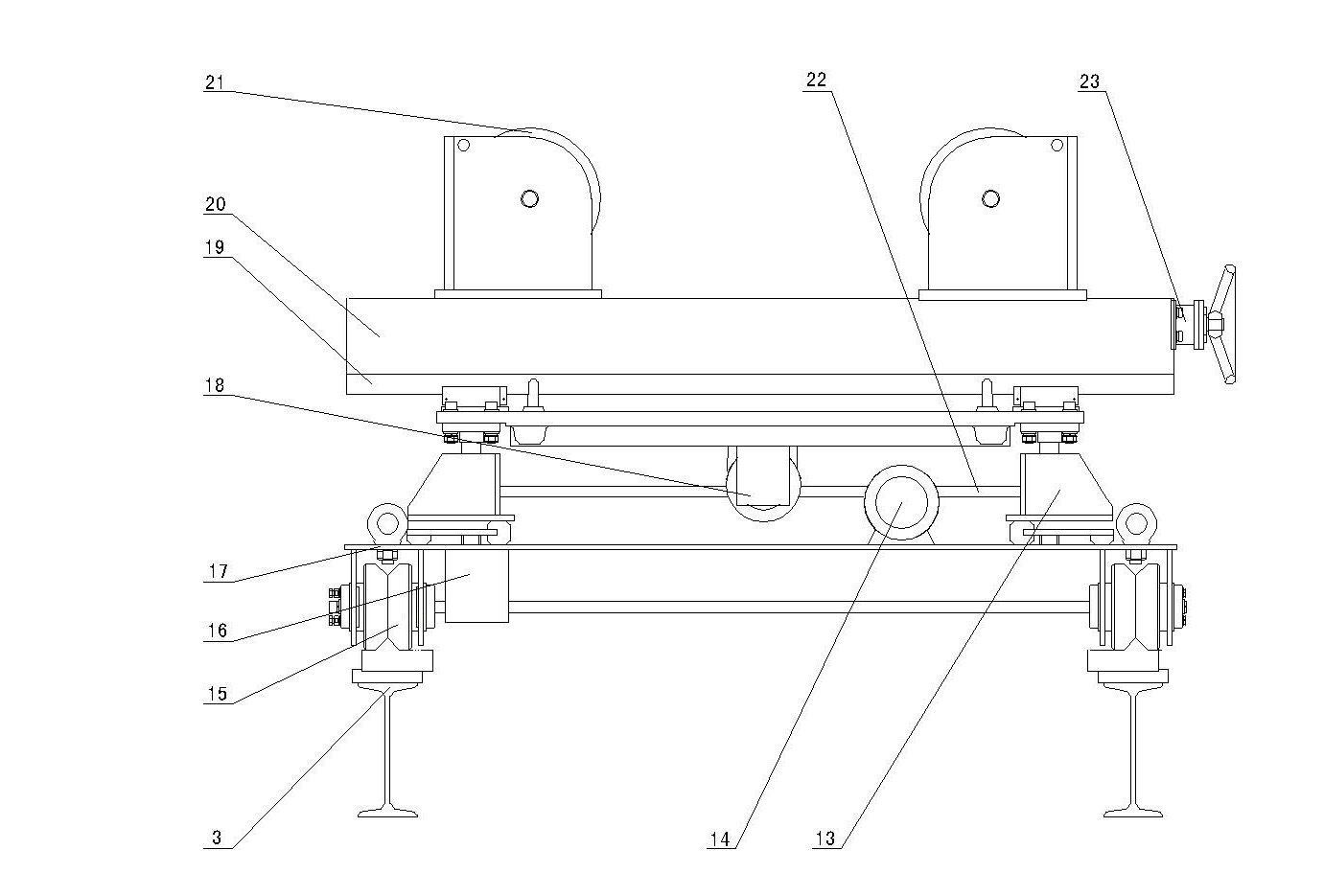

[0021] Such as Figure 1 to Figure 5 Shown, the present invention has two rails 3, is respectively provided with fixed chuck seat 4 and movable chuck seat 12 at the two ends of track 3, is respectively provided with at fixed chuck seat 4 and movable chuck seat 12 horizontal relative positions The chuck 8 is respectively provided with a drive device 2 on the fixed chuck seat 4 and the movable chuck seat 12, the drive device 2 meshes with the rotary support 7 through the gear 1, and the described chuck 8 is fixed on the rotary support 7 On the fixed chuck seat 4 and the inside and outside sides of the movable chuck seat 12, cross brackets 6, 10 are installed respectively, flexible welding equipment 5, 9 are respectively provided on the cross brackets 6, 10, and on the track 3 Two automatic adjustment brackets 11 are arranged, and described automatic adjustment bracket 11 comprises longitudinal translation mechanism 17, and longitudinal translation mechanism 17 can move along tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com