Design method for vertical constant force system

A vertical direction and system design technology, applied in space navigation equipment, simulation devices of space navigation conditions, transportation and packaging, etc., can solve problems such as failure, small range of motion, and high accuracy requirements of spring coefficients, and achieve cost and maintenance costs The effect of low, increased degree of freedom, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

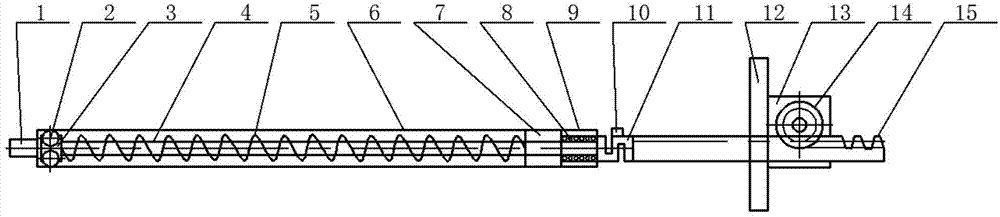

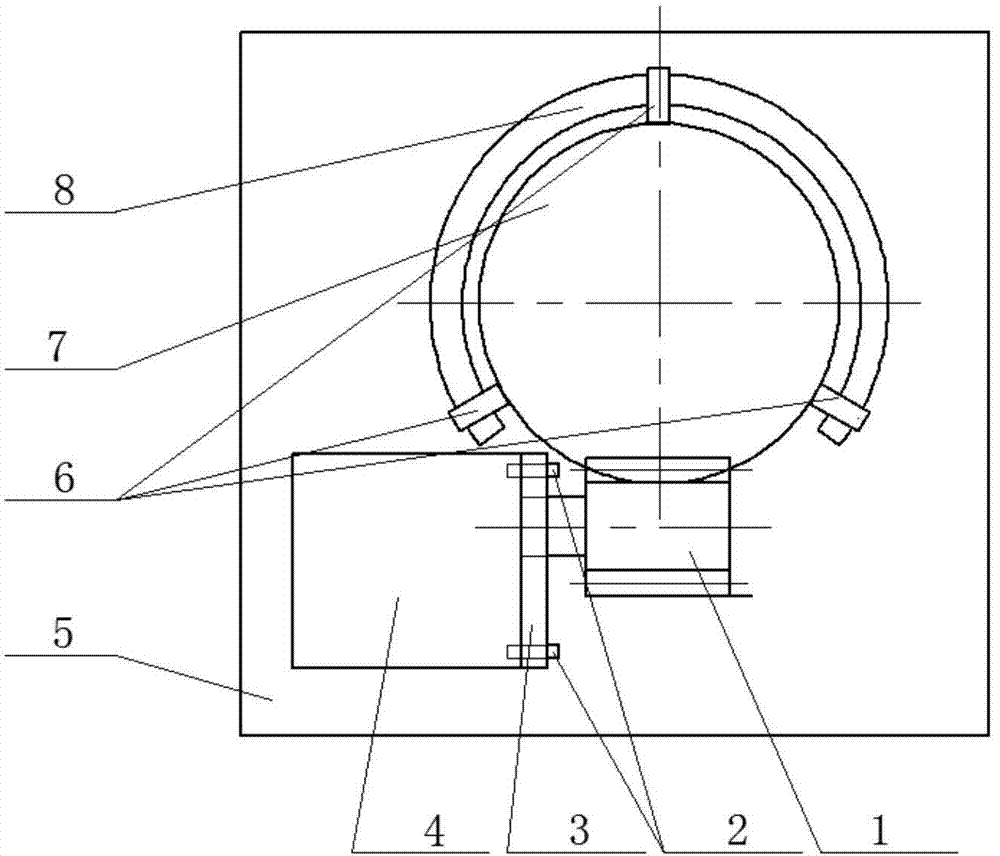

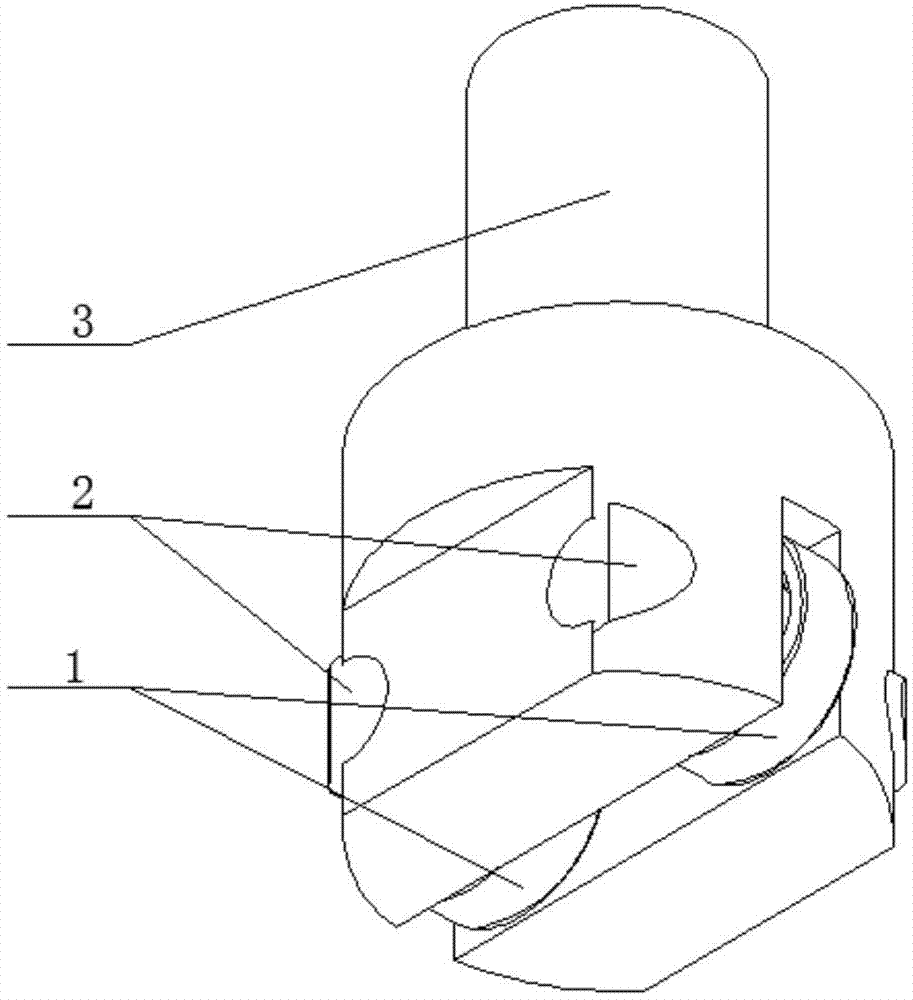

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

[0032] combine figure 1 and Figure 5, the basic idea of the present invention is to use the feedforward information of the spacecraft to realize the system constant force output near the balance point through the balance point constant force spring module. When there is a force in the vertical direction to make it deviate from the balance point, the tension sensor and The change measured by the displacement sensor is transmitted to the PC. After the PC processes the signal, it issues a control command to control the movement of the rack and pinion compensation module to compensate for the change of the force on the spring caused by the external force and ensure the constant force output of the system.

[0033] The left end of the connecting end 1 of the spring jacket can be connected with the spacecraft or the device for suspending the spacecraft, and the other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com