Tape cartridge and tape printer

A technology with printing and cassettes, applied in the directions of printing devices, ink ribbon cassettes, and inking devices, etc., can solve the problems of inability to abut the thermal head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

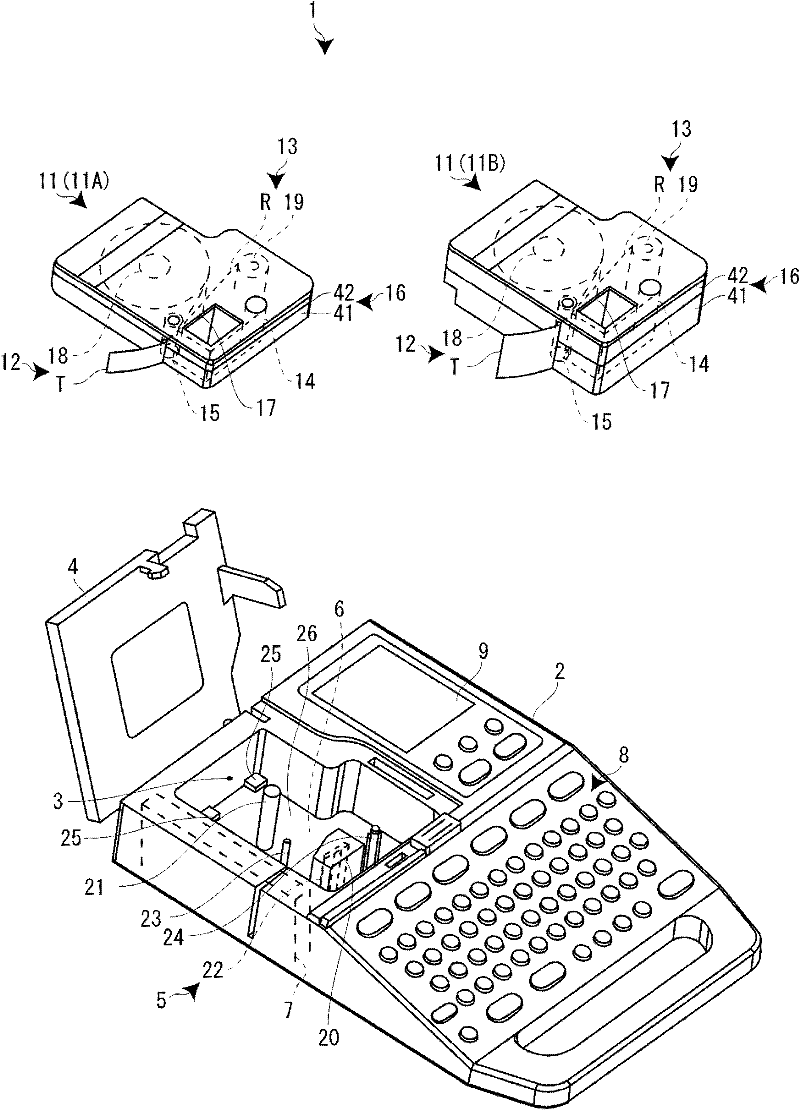

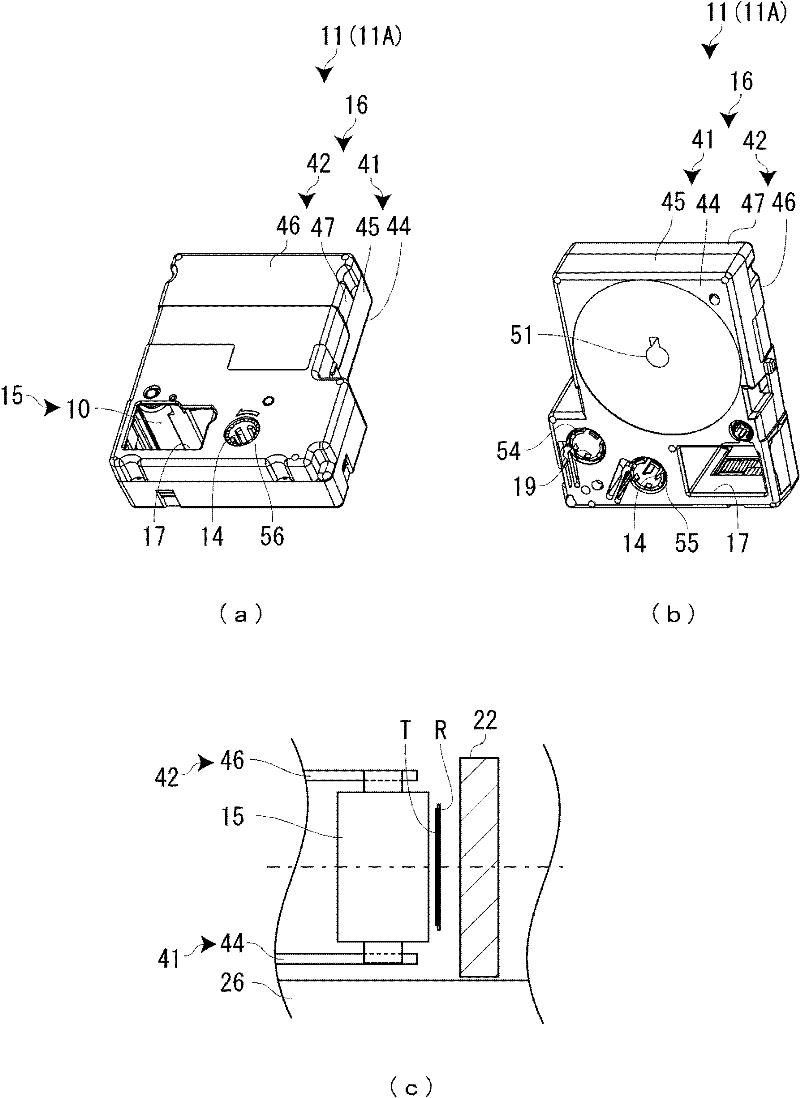

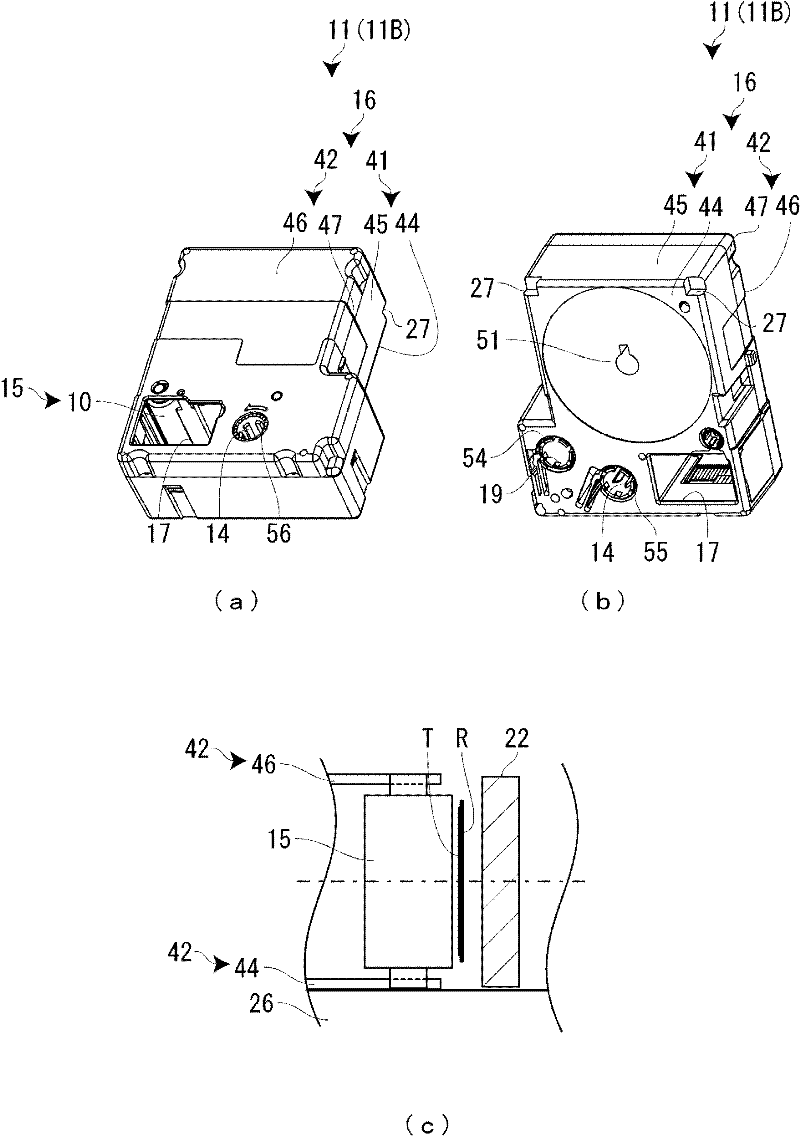

[0027] Hereinafter, a tape cassette according to an embodiment of the present invention and a tape printing apparatus mounted with the tape cassette will be described with reference to the drawings. This tape printing device performs printing while conveying a printing tape and an ink ribbon from an attached tape cassette, and cuts the printed portion of the printing tape to form a label (tape sheet).

[0028] Such as figure 1 As shown, the tape printing device 1 has: a casing 2 forming a casing; a cassette mounting portion 3 (tape mounting portion) is recessed and formed on the upper surface of the casing 2, and a printing tape T etc. is detachably mounted and housed therein. The tape cassette 11; the opening and closing cover 4, which opens and closes the cassette installation part 3; the printing mechanism 5, which has the print head 22 vertically arranged in the cassette installation part 3, and prints the printing tape T; the tape feeding mechanism 6 , which feeds the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com